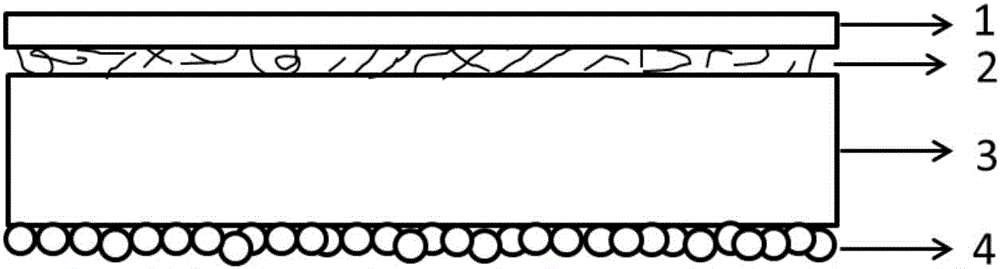

Lithium-ion battery separator subjected to composite coating treatment and preparation method thereof

A lithium-ion battery and coating technology, which is applied to battery components, circuits, coatings, etc., can solve the problem of affecting battery charge and discharge performance and cycle life, inorganic particles and polymer coatings are easy to fall off, and unfavorable battery unit quality Energy density and other issues, achieve good electrolyte wettability and liquid retention, increase volume energy density, and bond tightly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

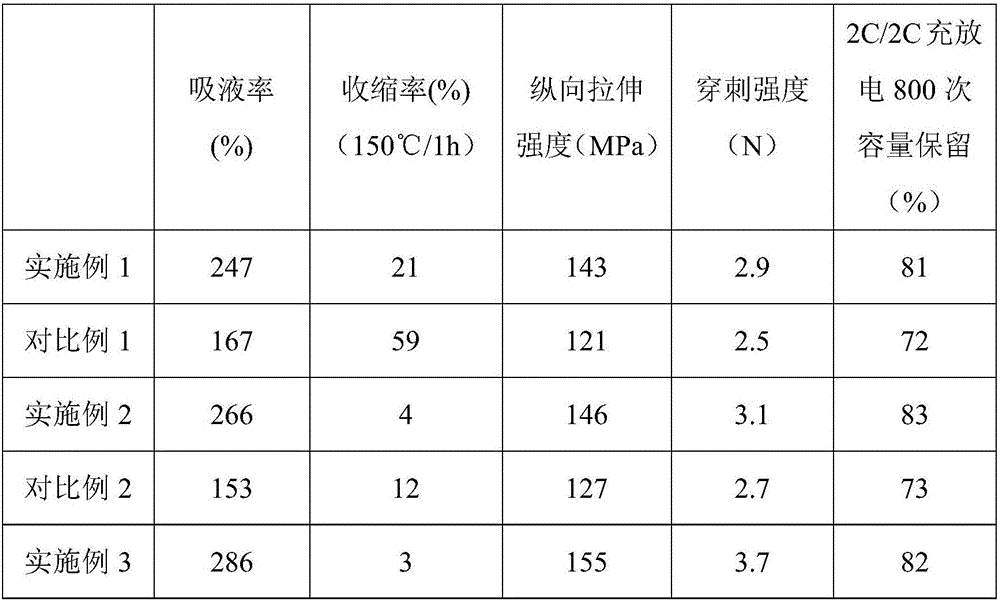

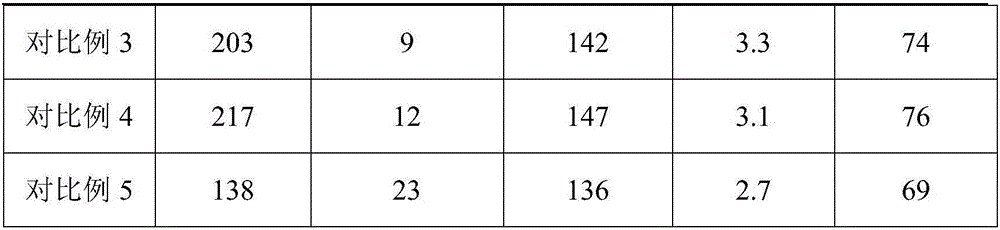

Embodiment 1

[0036] Polymer of the present invention and the lithium-ion battery separator of inorganic particle composite coating process, its preparation method is as follows:

[0037] a. Preparation of aramid coating solution: weigh 0.5 kg of meta-aramid fibers with a molecular weight of 50,000 to 70,000, 8.5 kg of solvent N,N-dimethylformamide, 0.3 kg of cosolvent calcium chloride, and dispersant Polyethylene oxide 0.1kg, emulsifier octadecyltrimethylammonium chloride 0.1kg, binder polyvinylpyrrolidone 0.2kg. Add the co-solvent calcium chloride into the solvent and stir until it is completely dissolved. While stirring, add the dispersant polyethylene oxide, stir at a low speed until the polyethylene oxide is completely dissolved, add meta-aramid fiber, and mix evenly to obtain meta-aramid Coating fluid.

[0038] b. Preparation of polyvinylidene fluoride coating liquid: polyvinylidene fluoride 1kg, solvent is acetone, porogen is ethanol, wherein acetone is 9.5kg, ethanol is 0.5kg. The...

Embodiment 2

[0044] Polymer of the present invention and the lithium-ion battery separator of inorganic particle composite coating process, its preparation method is as follows:

[0045] a. Preparation of aramid coating solution: weigh 0.3kg of para-aramid fiber with a molecular weight of 10,000-20,000, 7kg of solvent dimethyl sulfoxide, 0.35kg of co-solvent sodium hydroxide, and dispersant of ethylene-acrylic acid copolymer 0.1kg, emulsifier lauryltrimethylammonium chloride 0.1kg, binder vinylpyrrolidone and ethylene acetate copolymer 0.15kg. Add the co-solvent calcium chloride into the solvent and stir until it is completely dissolved. While stirring, add the dispersant polyethylene oxide, stir at a low speed until the polyethylene oxide is completely dissolved, add para-aramid fibers, and mix evenly to obtain meta-aramid Coating fluid.

[0046] b. Preparation of polyvinylidene fluoride coating solution: 1kg of vinylidene fluoride and hexafluoropropylene copolymer, solvent is N,N-dimeth...

Embodiment 3

[0052] Polymer of the present invention and the lithium-ion battery separator of inorganic particle composite coating process, its preparation method is as follows:

[0053] a. Preparation of aramid coating solution: weigh 0.32 kg of para-aramid pulp with a molecular weight of 30,000 to 40,000, 7.8 kg of solvent dimethyl sulfoxide, 0.27 kg of cosolvent sodium hydroxide, dispersant ethylene-acrylic acid Copolymer 0.14kg, emulsifier lauryltrimethylammonium chloride 0.18kg, binder vinylpyrrolidone and ethylene acetate copolymer 0.18kg. Add the co-solvent lithium chloride into the solvent and stir until completely dissolved, add the dispersant ethylene-acrylic acid copolymer while stirring, stir at a low speed until the ethylene-acrylic acid copolymer is completely dissolved, add para-aramid pulp, mix well, A para-aramid coating liquid is obtained.

[0054] b. Preparation of polyvinylidene fluoride coating liquid: polyvinylidene fluoride 1.2kg, solvent is N,N-dimethylacetamide, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com