Reconstituted tobacco paper base and method for improving quality of reconstituted tobacco paper base by adding wood pulp fiber

A technology for reconstituted tobacco leaves and wood pulp fibers, applied in the fields of tobacco, tobacco preparation, application, etc., to achieve the effects of improving air permeability, reducing the content of total particulate matter, and improving liquid absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Analysis of wood pulp fiber quality

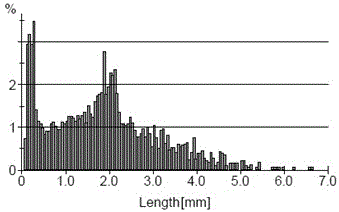

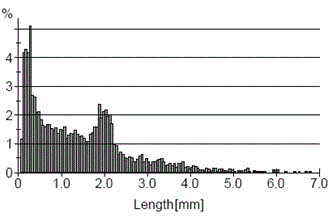

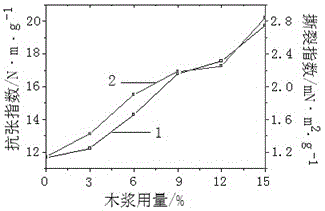

[0044] The quality of the wood pulp fibers obtained after beating the commercially available wood pulp board fibers was analyzed, and two groups of tobacco stem fibers were set as a control, and the results are shown in Table 1. The length distribution of wood pulp board fibers and pulp fibers after beating is shown in the attached figure 1 And attached figure 2 shown.

[0045] Table 1 Kajaani FS300 fiber analysis results

[0046] raw material wood pulp fiber Wood pulp fiber after beating Tobacco Stem Fiber Tobacco Stem Fiber beating degree / o SR 13 33 16 23 Number average length Ln / mm 0.53 0.38 0.33 0.30 Weight average length Lw / mm 2.67 2.35 0.88 0.77 Double weight average length Lww / mm 1.82 1.37 1.79 1.41 Fines(n) content / % 58.03 60.21 45.65 47.30 Fines(l) content / % 9.78 13.78 11.37 12.53 Coarseness / mg·m -1 0.324 0.112 0.137 0.136 Fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com