Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

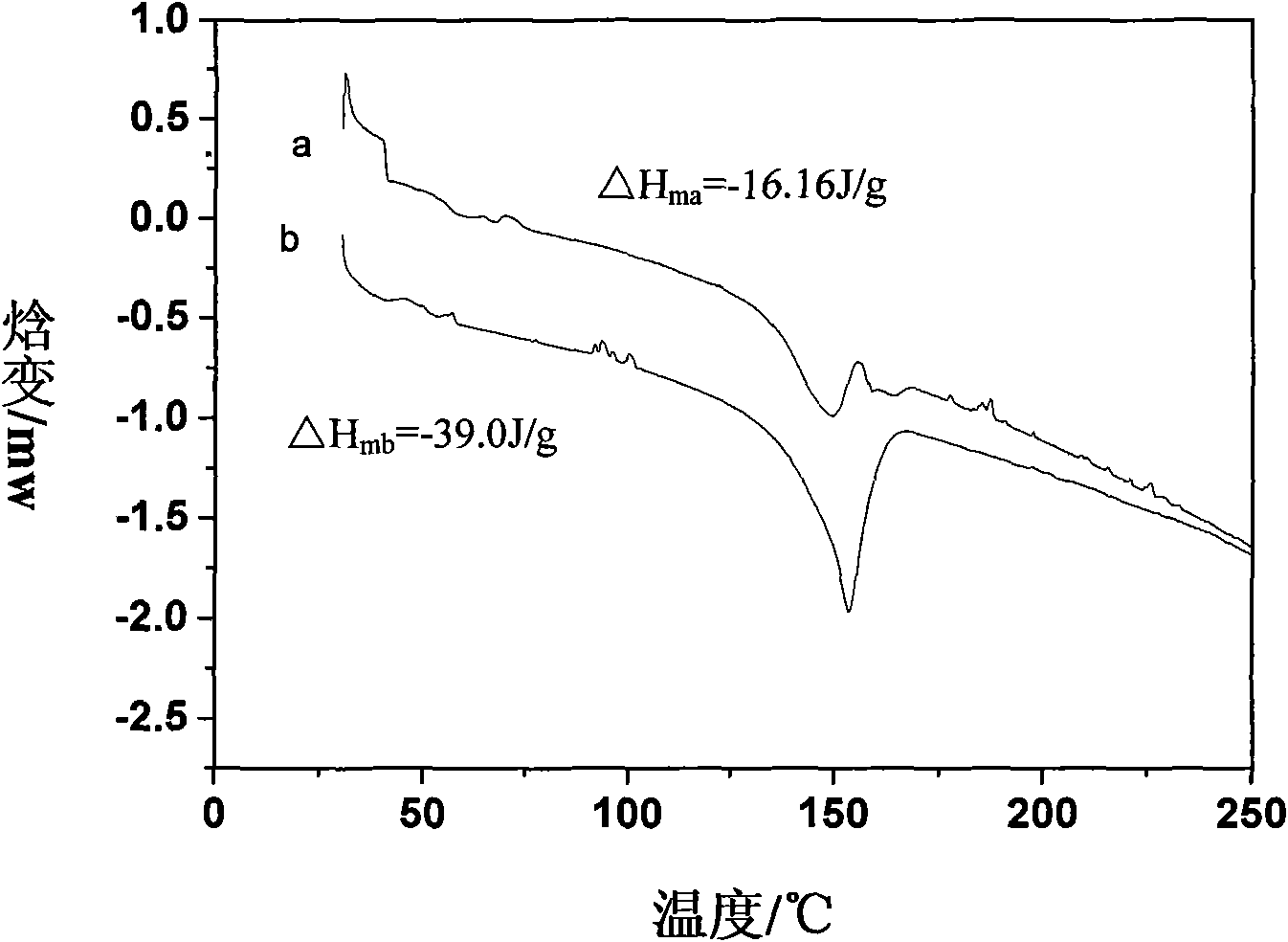

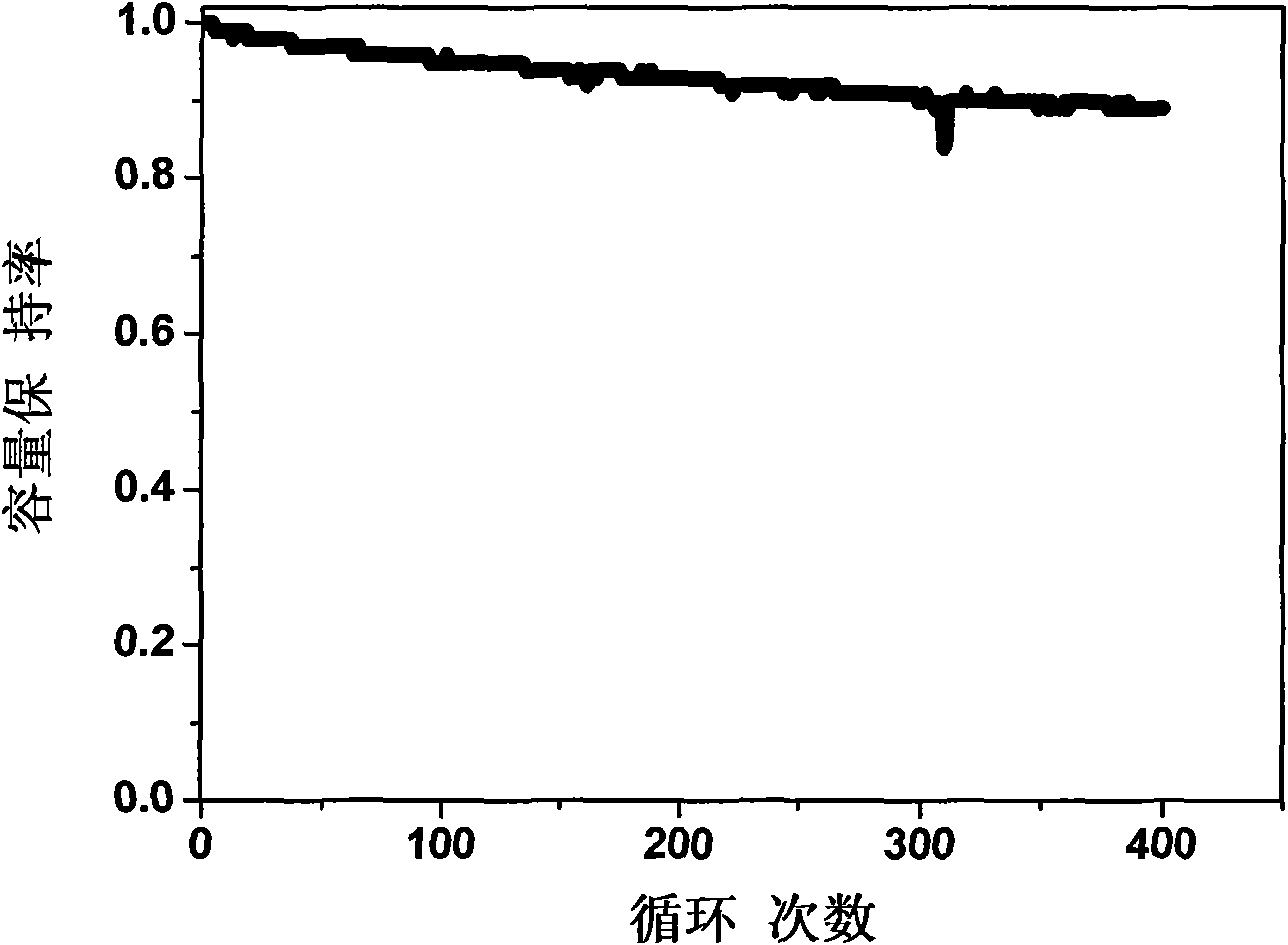

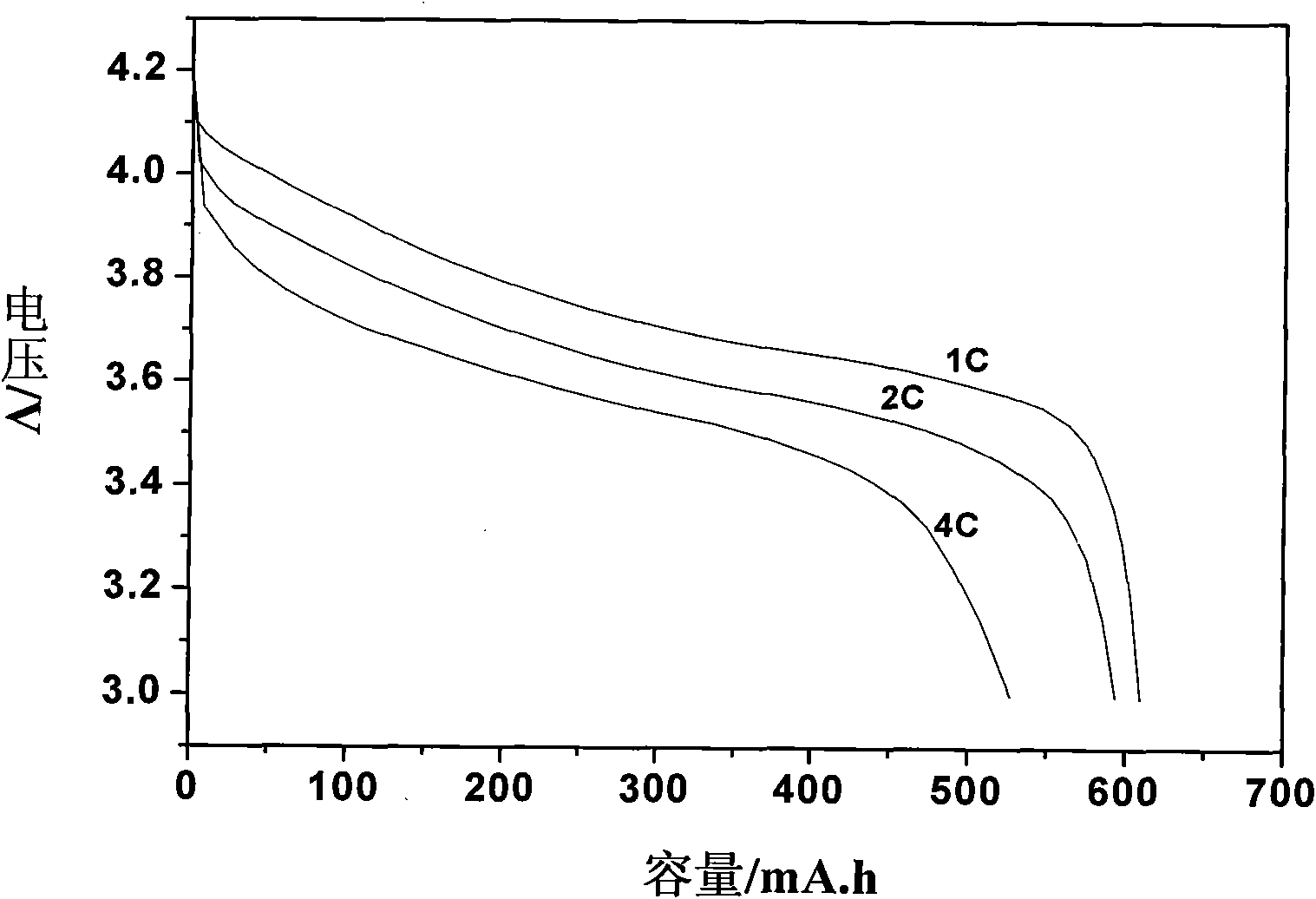

A polymer and porous membrane technology, applied in the field of polymer porous membrane, polymer electrolyte, polymer battery and battery preparation, can solve the problem of poor liquid absorption capacity and electrolyte retention capacity, poor ion conductivity of polymer electrolyte, Unsatisfactory interfacial compatibility and other problems, to achieve the effect of simple method, improved ion conductivity, good rate discharge performance and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028]The present invention also provides a preparation method for the above-mentioned porous diaphragm, which includes adding carbon materials, polymers and pore-forming agents into a solvent for mixing, forming a film, and volatilizing the pore-forming agents and solvents to obtain a polymer porous film. Among them, the carbon material in the present invention is preferably one or more of acetylene black, activated carbon, graphite, carbon fiber and carbon nanotubes, etc.; the polymer in the present invention is not particularly limited, and is selected according to the requirements of the prepared polymer porous membrane; The pore-forming agent and solvent are not particularly limited in the present invention, and can be various substances commonly used by those skilled in the art that can decompose or volatilize and finally form pores on the membrane. For example, the pore-forming agent can be selected from conventional water, toluene, ethanol, butanol , glycerol, isopropan...

Embodiment 1

[0042] Polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) with a content of 6wt% is dissolved in a mixture of 88wt% acetone, 5wt% water and 1wt% acetylene black (the average particle size of the crystal particles is 0.02 μm) solution, after stirring for one hour. It is coated on a polyethylene film (PE) with a thickness of 16 μm and a porosity of 40%, cast into a film, the thickness of the film is 10 μm, and dried to obtain a porous polymer film with a porosity of 45% and an average pore diameter of 90nm.

[0043] The positive electrode sheet coated with lithium cobaltate, the polymer porous membrane prepared above, and the negative electrode sheet coated with graphite are wound to form a pole core, which is inserted into the aluminum-plastic composite film. Prepare a lithium hexafluorophosphate electrolyte solution containing 20 wt% of methyl methacrylate monomer, 0.1 wt% of dibenzoyl peroxide and 1M lithium hexafluorophosphate, wherein EC / DMC=1:1 (volume ratio). The abo...

Embodiment 2

[0045] Polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) with a content of 5wt% is dissolved in a mixture of 83wt% acetone, 10wt% ethanol and 2wt% acetylene black (the average particle size of the crystal particles is 0.02 μm) After stirring for one hour, it is coated on a polyethylene film (PE) with a thickness of 16 μm and a porosity of 40%, and cast into a film. The thickness of the film is 12 μm, and the porosity is 38% after drying. The first porous polymer film was 86 nm. Polyvinylidene fluoride-hexafluoropropylene (PVDF-HFP) with a content of 6wt% was dissolved in 81wt% methyl ethyl ketone, 12wt% toluene and 1wt% acetylene black (the average particle size of the crystal particles was 0.01 μm) In the mixed solution, after stirring for one hour, coat the surface of the first porous polymer membrane prepared above, cast it into a membrane, the thickness of the membrane is 8 μm, and dry to obtain the first porous polymer membrane with a porosity of 50% and an average p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com