Health nursing pad absorber processing method and equipment thereof

A technology for sanitary products and processing methods, applied in absorbent pads, clothing, underwear, etc., can solve problems such as uneven liquid absorption, and achieve the effect of maintaining a soft and comfortable surface, super absorbent capacity, and strong absorbent capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

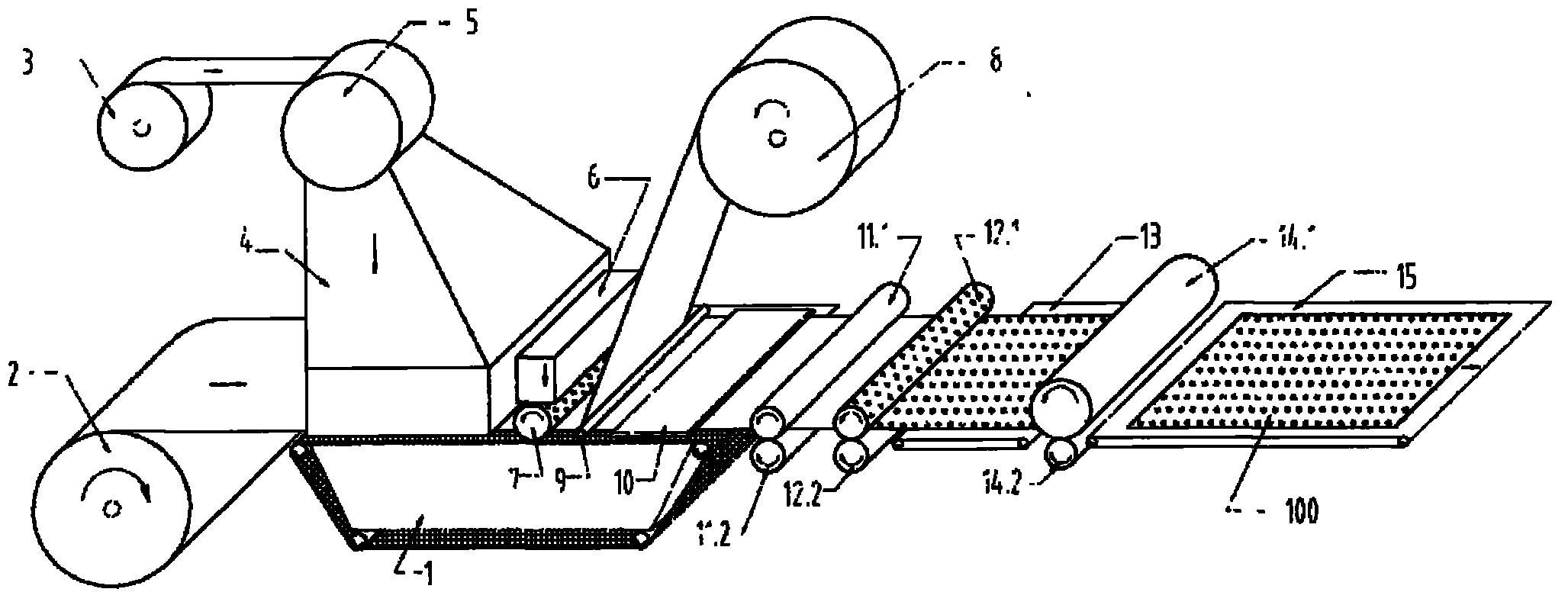

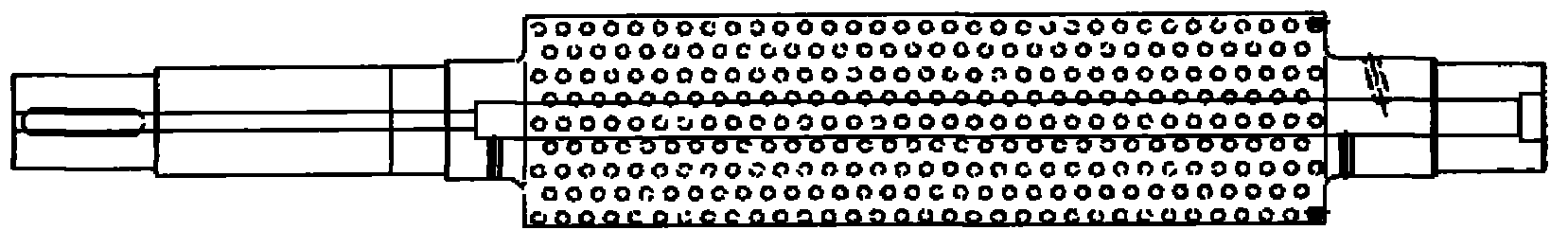

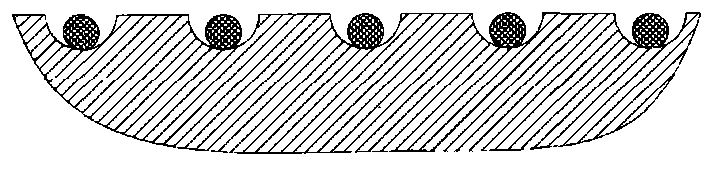

[0032] Such as figure 1 As shown, a kind of equipment of the present invention nursing pad absorber processing method, comprises, the adsorption bed 1 that has negative pressure on the surface, is arranged on the adsorption bed 1 and is used for lowering toilet paper 2 to support the movement mesh belt of floating wood pulp fiber, comprises It is characterized in that: the adsorption bed 1 is provided with a wood pulp pulverizer 5 for pulverizing the wood pulp roll 3 into wood pulp fibers, the wood pulp pulverizer 5 is connected to the wood pulp fiber forming chamber 4, and the wood pulp fibers are pulverized by wood pulp Driven by the airflow generated when the machine rotates, and dragged by the adsorption airflow on the surface of the adsorption bed, it descends in the wood pulp fiber forming chamber 4, and is firmly adsorbed on the lower toilet paper 2 by the negative pressure on the surface of the adsorption bed 1, forming a staggered web shape structure;

[0033] The ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com