Porous membrane and preparation method thereof

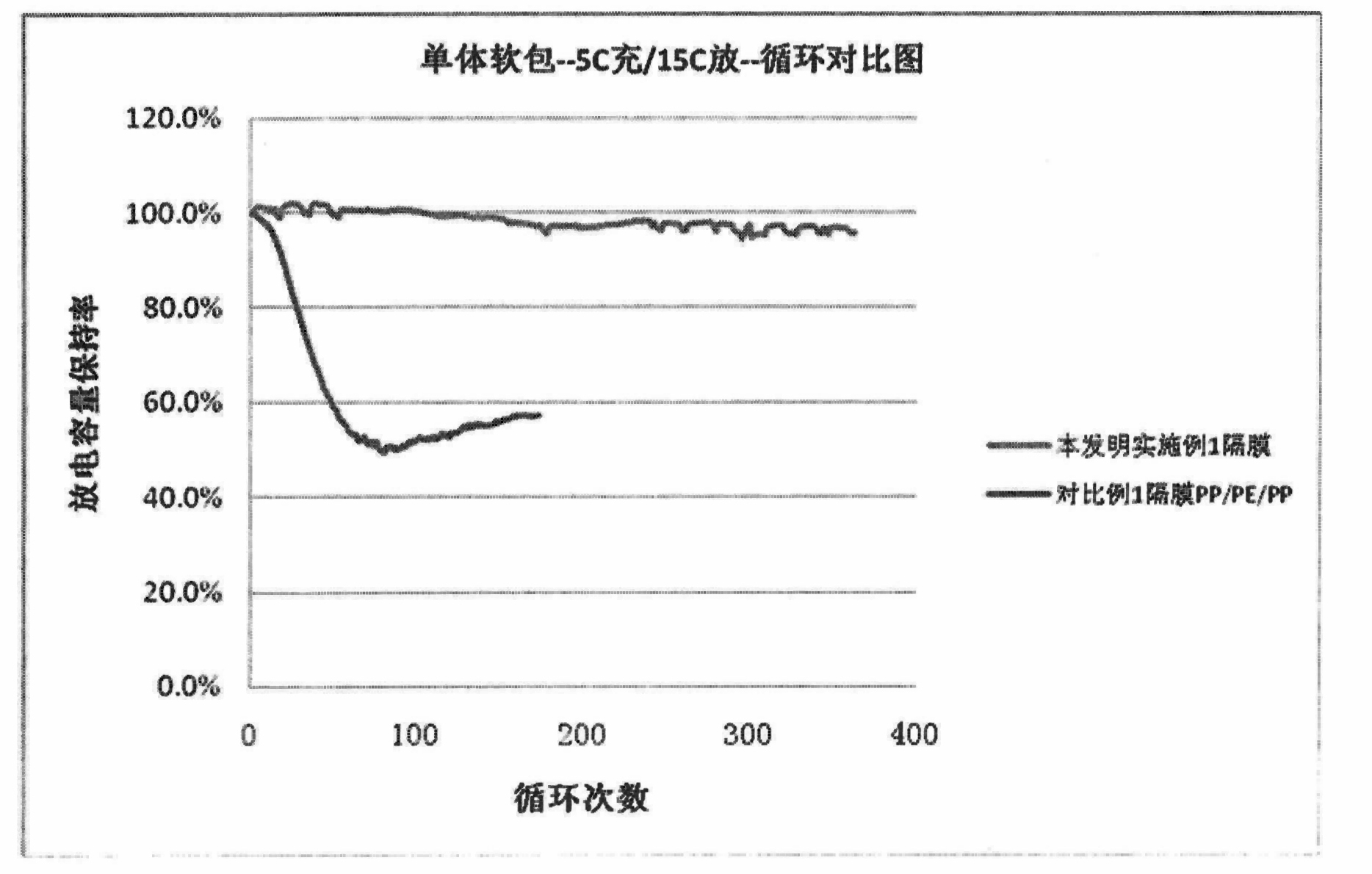

A technology of porous membrane and porous thin film, applied in the field of porous membrane and its manufacturing, can solve the problems of high cost, unfavorable mass production, complex process, etc., achieve low cost, improve safety performance, high current and high rate charge and discharge performance, The effect of simplifying the separation and recovery process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

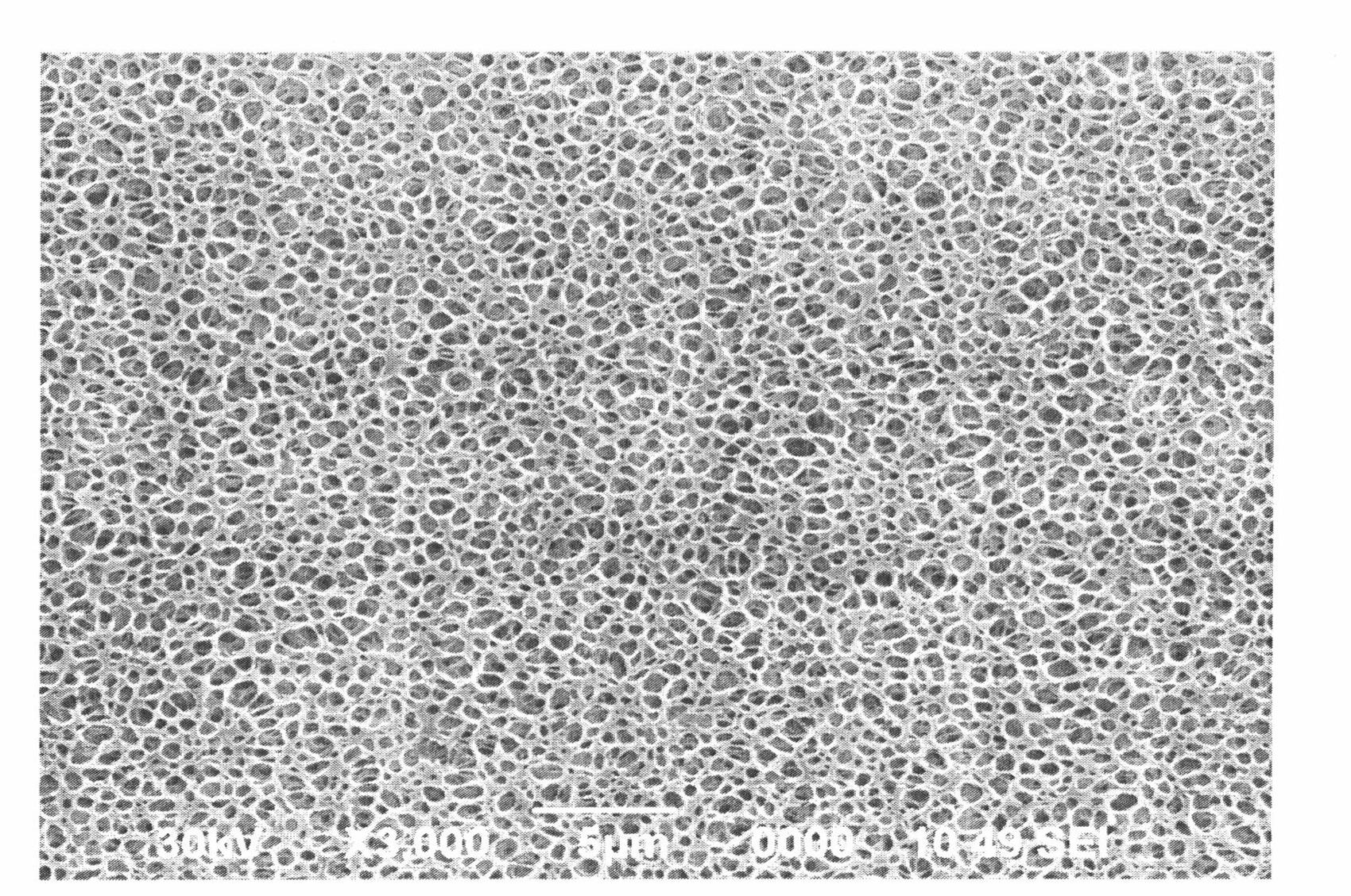

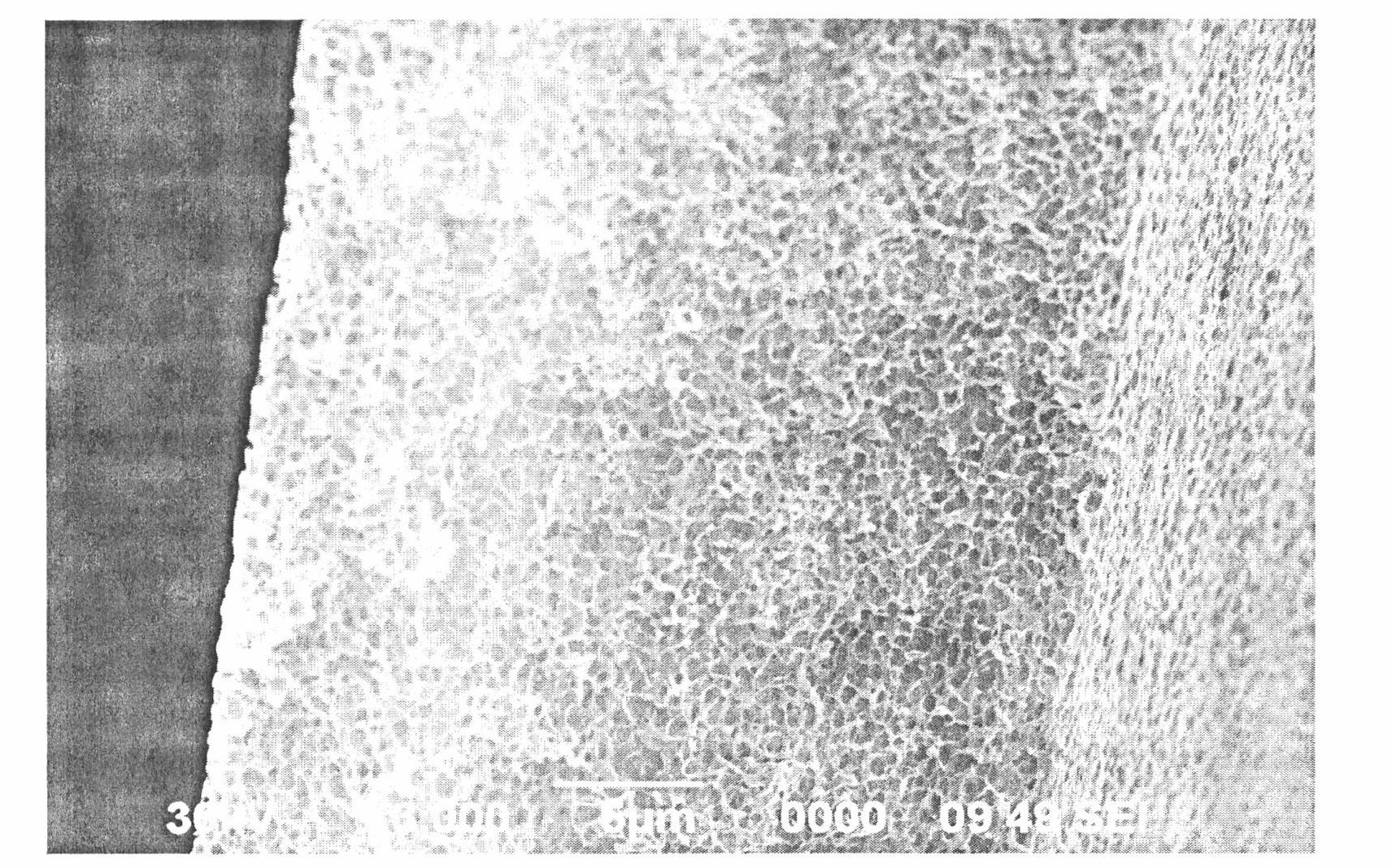

[0049] Mix 10kg of polyvinylidene fluoride (PVDF) material and 20kg of N-methylpyrrolidone (NMP) solvent, disperse in a twin-screw machine at a controlled temperature of 90°C, extrude through a die head through a melt pump, and condense in water. Glue forms a thin film. Next, the above-mentioned film is drawn into an extraction tank, and the solvent is extracted with water, thereby forming a film with a porous structure. Finally, the above-mentioned porous film was dried with hot air, and then cut into widths of 125 mm and thicknesses of 22 μm, and the winding was completed after static electricity was removed. The measured air permeability is 150 seconds / 100CC.

Embodiment 2

[0051] Mix 10kg of polysulfone (PS) material, 25kg of N-methylpyrrolidone (NMP) solvent, and 0.3kg of lithium chloride (LiCl), disperse it in a twin-screw machine at a controlled temperature of 100°C, and pass it through a melt pump. Head extruded, into the water gel to form a film. Next, the above-mentioned film is pulled into an extraction tank, and the solvent and inorganic salt are extracted with water, thereby forming a film with a porous structure. Finally, the above-mentioned porous film was dried with hot air, and then cut into widths of 125 mm and thicknesses of 30 μm, and the winding was completed after static electricity was removed. The measured air permeability is 120 seconds / 100CC.

Embodiment 3

[0053] Mix 10kg of polyvinylidene fluoride (PVDF) material and 30kg of triethyl phosphate (TEP) solvent, disperse in a twin-screw machine at a controlled temperature of 90°C, extrude through a die head through a melt pump, and gel in water Form a thin film. Next, the above-mentioned film is drawn into an extraction tank, and the solvent is extracted with water, thereby forming a film with a porous structure. Finally, the above-mentioned porous film was dried with hot air, and then cut into widths of 125 mm and thicknesses of 22 μm, and the winding was completed after static electricity was removed. The measured air permeability is 150 seconds / 100CC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com