Non-mercury pulp layered paper of zinc-manganese battery containing high-polymer solid electrolyte

A solid electrolyte, zinc-manganese battery technology, applied to battery components, coatings, circuits, etc., can solve the problem that "high-capacity" C-type batteries cannot be fully utilized, reduce battery current and battery capacity, and fail to produce high-quality batteries Pulp layer paper and other problems, to achieve the effects of tight bonding, increased battery capacity, and poor ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1 ammonium chloride type pulp layer paper

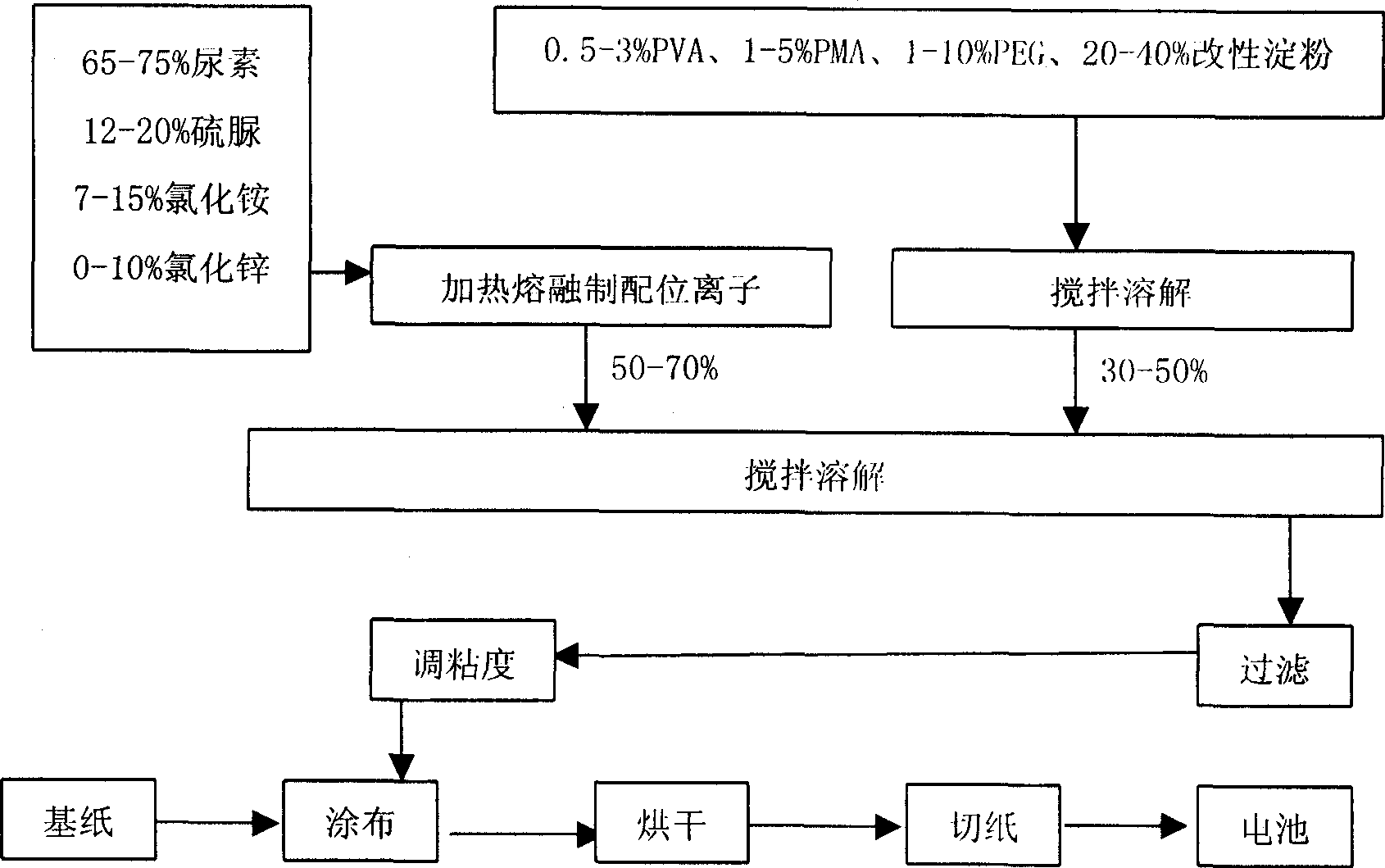

[0023] A mercury-free zinc-manganese battery pulp layer paper, which is composed of base paper and slurry, is characterized in that the slurry layer paper is composed of a polymer solid electrolyte and an organic mercury substitute corrosion inhibitor, and the polymer solid electrolyte is It is made of coordination ionic liquid and PVA, PAM, PEG, and starch. The coordination ionic liquid is made by heating and melting urea, thiourea, zinc chloride, and ammonium chloride according to a certain proportion. Its composition and specific preparation The process is:

[0024] (1) Preparation of coordination ionic liquid:

[0025] The composition of the coordination ionic liquid is:

[0026] Urea: 90.0g

[0027] Thiourea: 18.33g

[0028] Zinc chloride: 5.2g

[0029] Ammonium chloride 12.48g

[0030] Mix the above four substances evenly, put them in a beaker and heat them to a molten state, and cool to obtain a coordin...

Embodiment 2

[0043] Example 2 Zinc chloride type pulp paper

[0044] A mercury-free zinc-manganese dry battery pulp layer paper, which is composed of base paper and slurry, is characterized in that the slurry layer paper is composed of a polymer solid electrolyte and an organic mercury substitute corrosion inhibitor, and the polymer solid electrolyte is Made of coordination ionic liquid and PVA, PAM, PEG, starch, said coordination ionic liquid is made by heating and melting urea, thiourea, zinc chloride and ammonium chloride according to a certain proportion; slurry composition and preparation The process is:

[0045] Coordination ionic liquid 126.0g

[0046] PVA 3.0g

[0047] PAM 7.5g

[0048] PEG 6.0g

[0049] Etherified starch 9.0g

[0050] Cross-linked starch 25.0g

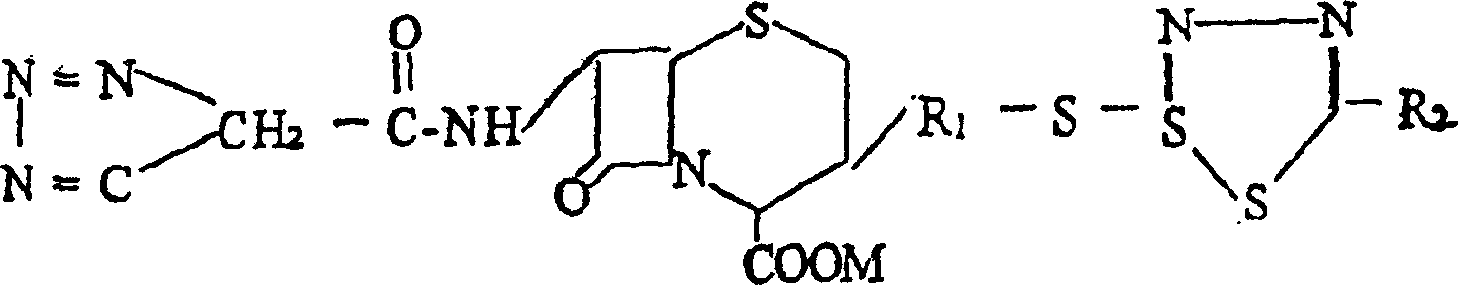

[0051] Cephalosporin salt 0.17g

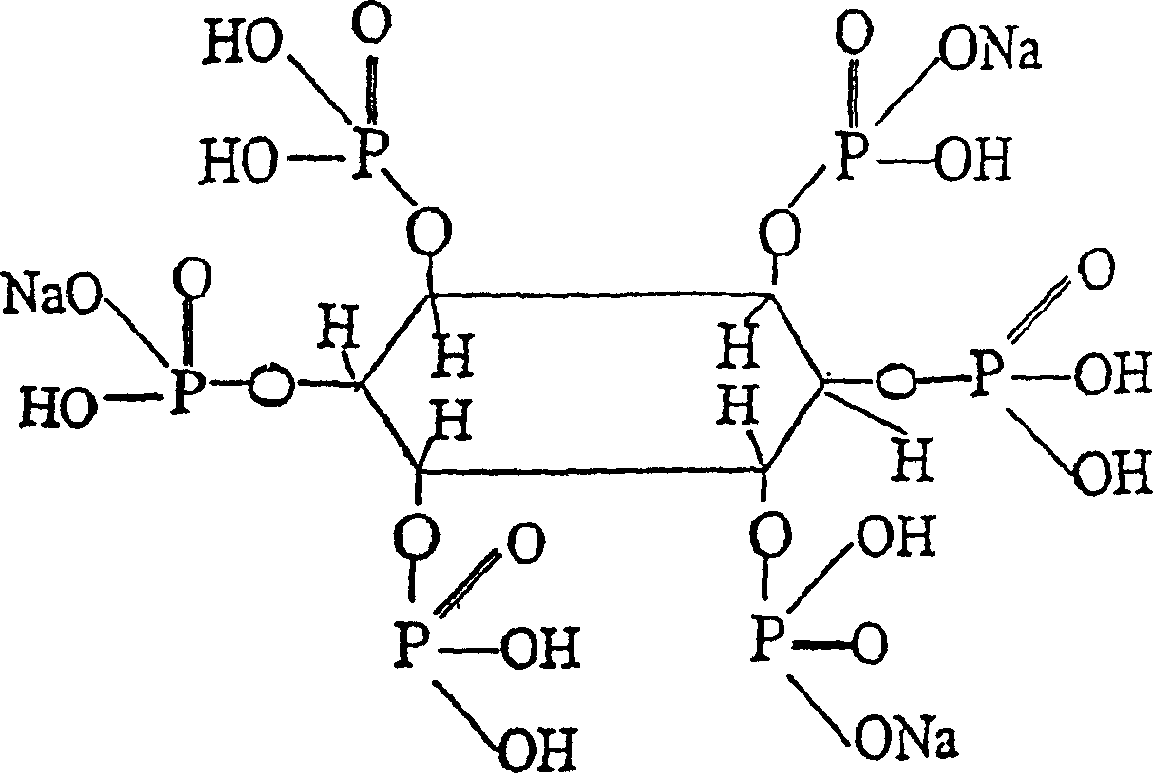

[0052] Sodium Phytate 0.08g

[0053] Water 370.0g

[0054] The composition of the coordination ionic liquid in the slurry is:

[0055] Urea: 92.88g

[0056] Thiourea: 22.11g

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com