Small-size graphene positive electrode material for lithium-sulfur battery, lithium-sulfur battery prepared by small-size graphene positive electrode material and preparation method

A lithium-sulfur battery and cathode material technology, which is applied in the manufacture of battery electrodes, lithium batteries, and electrolyte batteries, can solve the problems of capacity attenuation and active material reduction, and achieve the effects of small flow barrier, less wrinkles, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A preparation method for a lithium-sulfur battery, comprising the following steps:

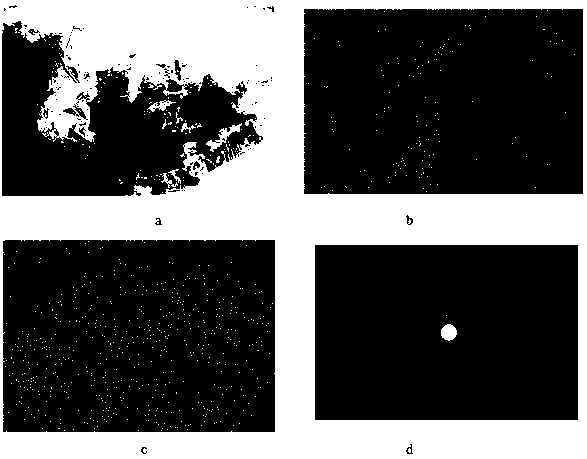

[0072] 1) Using sulfuric acid with a mass fraction of 24.5% as the electrolyte, place microcrystalline graphite powder in a PP bag, use graphite plates as positive and negative electrode plates, and use positive and negative arrays to intercalate sulfate ions. Apply a DC voltage of +5V to -5V between the anode and the anode, electrolyze for 72h, and exchange the electrodes every 2h. The obtained graphene sulfuric acid solution is ball milled and washed to obtain small-sized graphene.

[0073] 2) Place the small-size graphene that has been washed to neutrality in a petri dish, place it in a refrigerator, and freeze for 12 hours, then put it into a freeze dryer for 24 hours.

[0074] 3) the freeze-dried small-size graphene powder is collected, and 2g of small-size graphene powder, 2g sublimated sulfur and 50g of agate balls with a diameter of 1-1.3cm are sealed in an agate ball mill jar ...

Embodiment 2

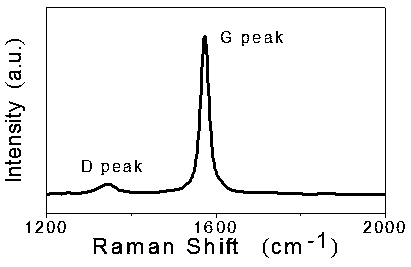

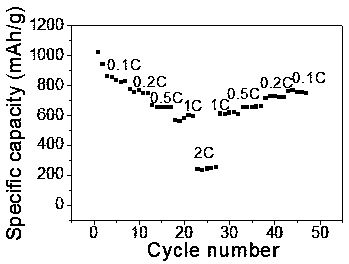

[0085] Lithium-sulfur battery cathode material, composed of small-scale graphene and sulfur compound. The area of the small-sized graphene is 0.1-0.8μm 2 , less than 6 atomic layer thickness, few defects and high purity.

[0086] A preparation method for a lithium-sulfur battery, comprising the following steps:

[0087] 1) Using sulfuric acid with a mass fraction of 10% as the electrolyte, place the microcrystalline graphite powder in a PP bag, use the graphite plate as the positive and negative electrode plates, adopt the form of positive and negative arrays, intercalate sulfate ions, and Apply a DC voltage of +8V to -8V between the anode and the anode, electrolyze for 72h, and exchange the electrodes every 2h. The obtained graphene sulfuric acid solution is ball milled and washed to obtain small-sized graphene.

[0088] 2) Place the small-size graphene that has been washed to neutrality in a petri dish, place it in a refrigerator, and freeze for 12 hours, then put it in...

Embodiment 3

[0097] Lithium-sulfur battery cathode material, composed of small-sized graphene modified by sodium carboxymethyl cellulose and sulfur composite. The area of the small-sized graphene is 0.1-0.8μm 2 , less than 6 atomic layer thickness, few defects and high purity.

[0098] A preparation method for a lithium-sulfur battery, comprising the following steps:

[0099] 1) Using sulfuric acid with a mass fraction of 24.5% as the electrolyte, place microcrystalline graphite powder in a PP bag, use graphite plates as positive and negative electrode plates, and use positive and negative arrays to intercalate sulfate ions. Apply a DC voltage of +5V to -5V between the anode and the anode, electrolyze for 72h, and exchange the electrodes every 2h. The obtained graphene sulfuric acid solution is ball milled and washed to obtain small-sized graphene.

[0100] 2) Place the small-size graphene that has been washed to neutrality in a petri dish, place it in a refrigerator, and freeze for 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com