Method for preparing nitride ceramic coating applied to lithium ion battery

A technology of nitride ceramics and lithium-ion batteries, applied in coatings, battery electrodes, battery components, etc., to achieve good thermal barrier, improve liquid absorption and liquid retention capabilities, improve hydrofluoric acid resistance and thermal shock resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 (take oil-based slurry as an example)

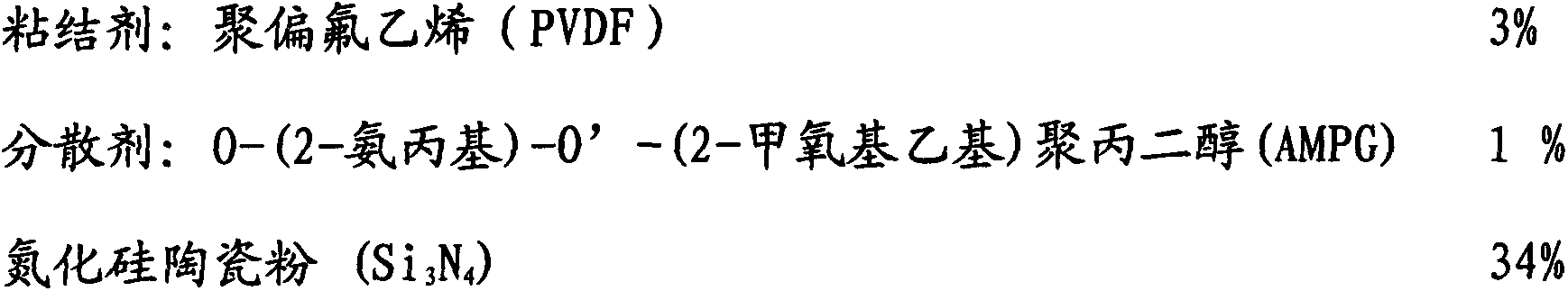

[0031] A nitride ceramic coating applied to lithium-ion batteries, consisting of the following components by weight percentage:

[0032]

[0033]

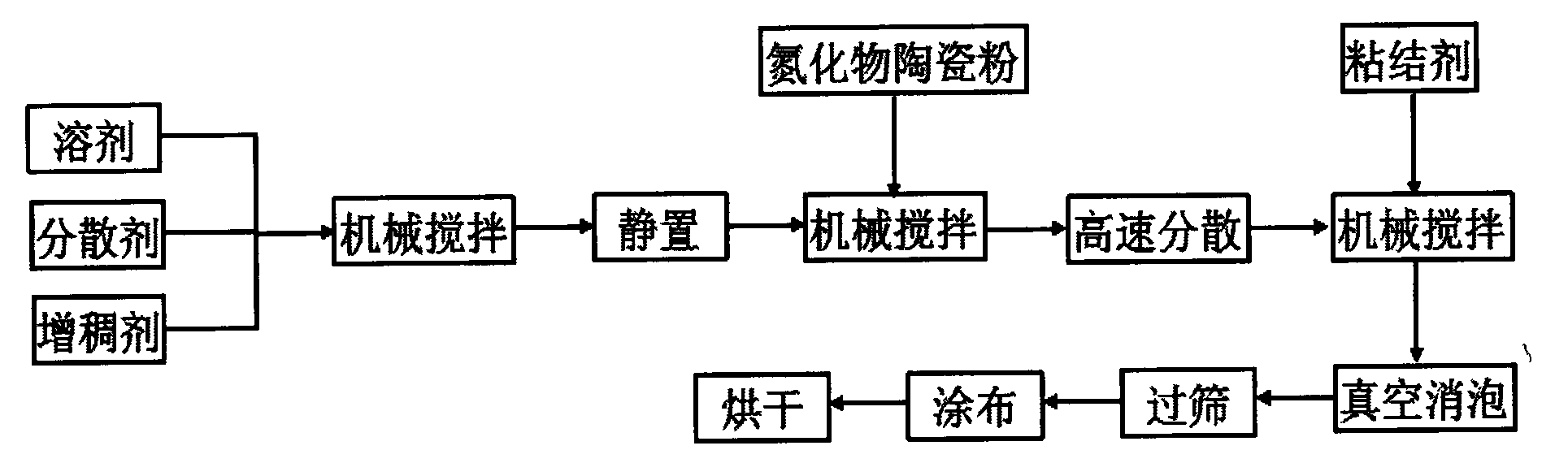

[0034] And prepared by the following steps:

[0035] (1) Combine N-methylpyrrolidone (NMP), O-(2-aminopropyl)-O'-(2-methoxyethyl) polypropylene glycol (AMPG) and butyl phthalate (BBP) ) Mix and stir evenly according to the proportion, let stand for defoaming under vacuum conditions, and then add silicon nitride ceramic particles (Si 3 N 4 ), stir well and set aside;

[0036] (2) Transfer the above-prepared slurry to a vertical shear type micro-dispersing machine for high-speed dispersion. The speed is greater than 6000 rpm, and the current is controlled within 10A. The slurry is passed through the disperser at high speed 4 times to make The agglomerates in the slurry are completely dispersed, and then the binder polyvinylidene fluoride (PVDF) is added in proportion, and it is evenly...

Embodiment 2

[0038] Example 2 (take water-based slurry as an example)

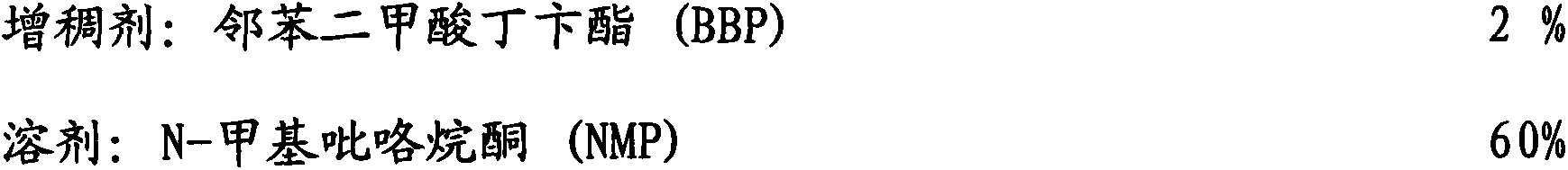

[0039] A nitride ceramic coating applied to lithium-ion batteries, consisting of the following components by weight percentage:

[0040]

[0041] And prepared by the following steps:

[0042] (1) Combine deionized water, sodium carboxymethyl cellulose (CMC) and sodium silicate (NaSiO 3 ) Mix and stir evenly according to the proportion, let stand for defoaming under vacuum conditions, and then add silicon nitride ceramic particles (Si 3 N 4 ), stir well and set aside;

[0043] (2) Transfer the above-prepared slurry to a vertical shear type micro-dispersing machine for high-speed dispersion. The speed is greater than 6000 rpm, and the current is controlled within 10A. The slurry is passed through the disperser at high speed 4 times to make The agglomerates in the slurry are completely dispersed, and then the binder styrene-butadiene rubber (SBR) is added in proportion, and it is evenly dispersed by mechanical stirring, such as f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com