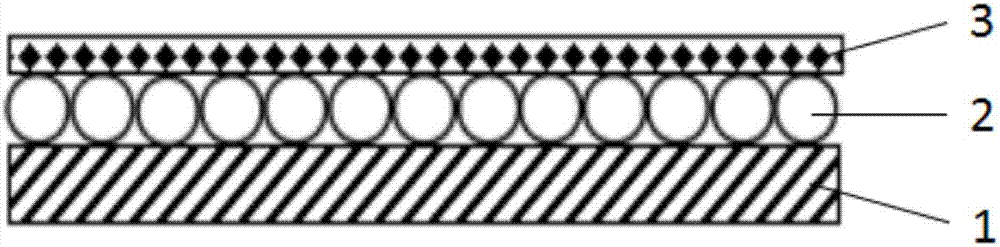

Diaphragm of lithium battery and preparation method thereof

A lithium battery separator and base film technology, which is applied in battery pack components, separators/films/diaphragms/spacers, circuits, etc. Short circuit, the effect of preventing heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

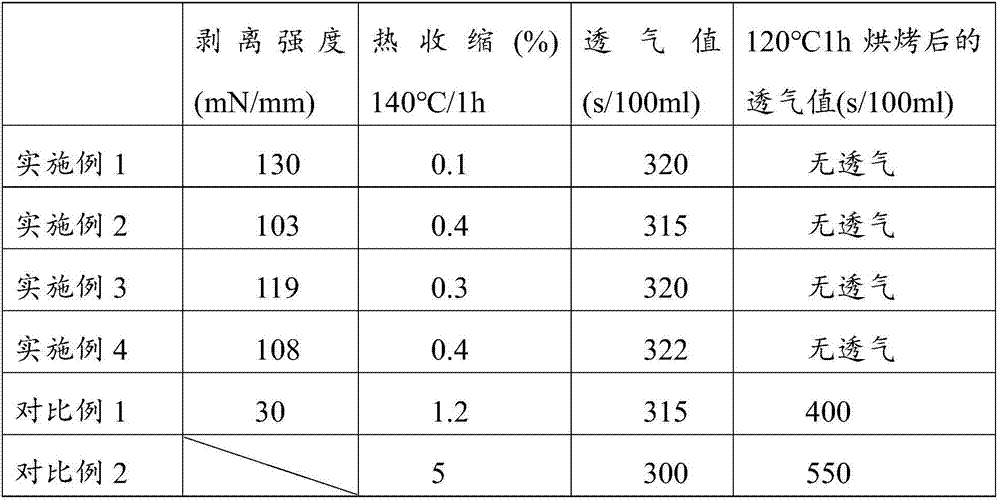

Examples

preparation example Construction

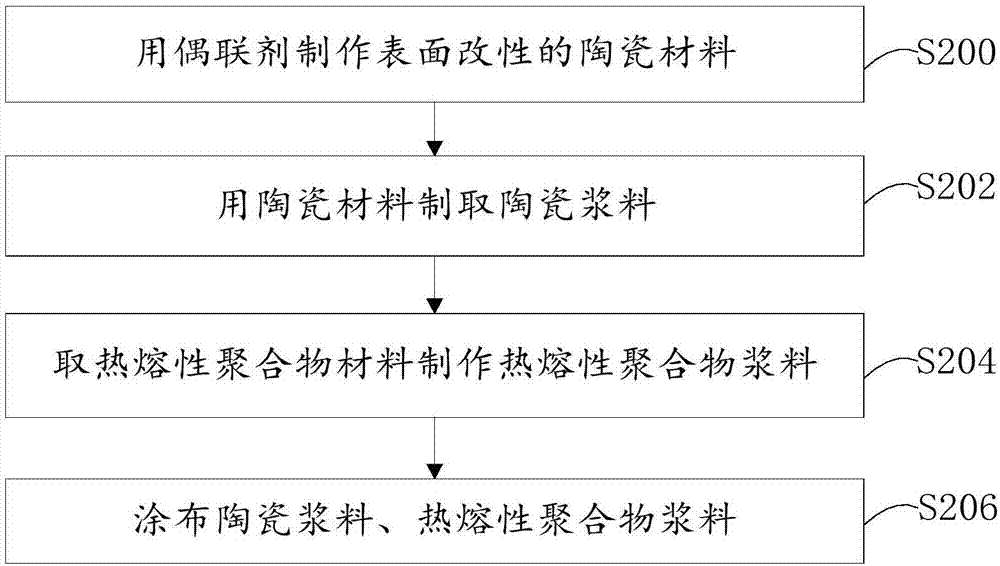

[0038] Such as figure 2 In the illustrated embodiment, the present invention also provides a method for preparing a lithium battery separator, which includes the following steps: S202 Take 90-93 parts by weight of ceramic material and add it to deionized water, stir and disperse evenly, and then add 7-10 parts by weight of the first Binder, stir and mix evenly to obtain ceramic slurry; S204 takes 92-95 parts by weight of hot-melt polymer material, 5-8 parts by weight of the second binder, add deionized water and mix and stir to obtain hot-melt polymer Material slurry, S206 coating the prepared ceramic slurry and hot-melt polymer slurry on the same side of the base film by gravure roll coating;

[0039] The first binder and the second binder include polyvinyl alcohol, epoxy resin or polyvinylpyrrolidone.

[0040] Further, it specifically includes the steps of coating the prepared ceramic slurry on one side of the base film by gravure roll coating, and obtaining a ceramic coat...

Embodiment 1

[0052] Dissolve the coupling agent in water for hydrolysis, add acetic acid as a hydrolysis catalyst, adjust the pH to 3.5-5.5, and react at a constant temperature of 30°C for 1 hour, add the pre-dispersed porous ceramic material into the solution, stir and react for 1.5 hours, pass After suction filtration and drying, a surface-modified ceramic material is obtained. Take 90 parts of the modified ceramic material and add it to the solvent, stir and disperse evenly, then add 10 parts of the first binder, stir and mix evenly to obtain a ceramic slurry. Apply the prepared ceramic slurry on one side of the base film by gravure roller coating, and obtain a ceramic coating after drying; take 92 parts of hot-melt polymer materials and 8 parts of the second binder, and add them to the solvent Mix and stir for 2 hours to obtain a hot-melt polymer slurry, and apply the hot-melt polymer slurry on the ceramic coating side. The porous ceramic material is alumina, the hot-melt polymer is p...

Embodiment 2

[0054] The main features of this embodiment are: 93 parts of porous ceramic material, 7 parts of the first binder, 95 parts of hot-melt polymer material, and 5 parts of the second binder. All the other are with specific embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Melting temperature | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com