Secondary lithium ion battery and preparation method thereof

A technology of lithium-ion batteries and cations, applied in the direction of secondary batteries, secondary battery repair/maintenance, electrolyte storage battery manufacturing, etc., can solve problems such as inability to fully realize battery functions, affect battery life, and reduce battery capacity, and achieve suitable It is suitable for large-scale industrial production, suppresses adverse side effects, and eliminates metal impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The positive active material of the battery in this embodiment is the ternary material nickel-cobalt lithium manganese oxide (LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 ), the negative electrode active material is graphitized carbon, and the electrolyte is LiP containing 1.05M 6 f 4 Solute in ethylene carbonate and ethyl methyl carbonate (3:7, w / w) solution.

[0028] The surface of the negative pole of the battery in this embodiment is coated with lithium ions (Li + ) of aluminosilicates and Al 2 o 3 mixtures, mixtures of aluminosilicates and Al 2 o 3 The weight ratio is 1:1; the coating thickness is controlled at 3±2um.

[0029]Preparation of the negative electrode of the battery in this example: First, the mixture of the anode exchange material and the inorganic material, and polyvinylidene fluoride (3 wt% of the mixture) are evenly dispersed in the organic solvent NMP to make a fluid slurry. The solid content of the material was set at 20wt%, and then coated on the surface...

Embodiment 2

[0032] The only difference between this embodiment and embodiment 1 is that the sodium ion (Na + ) aluminosilicates instead of containing lithium ions (Li + ) of aluminosilicates.

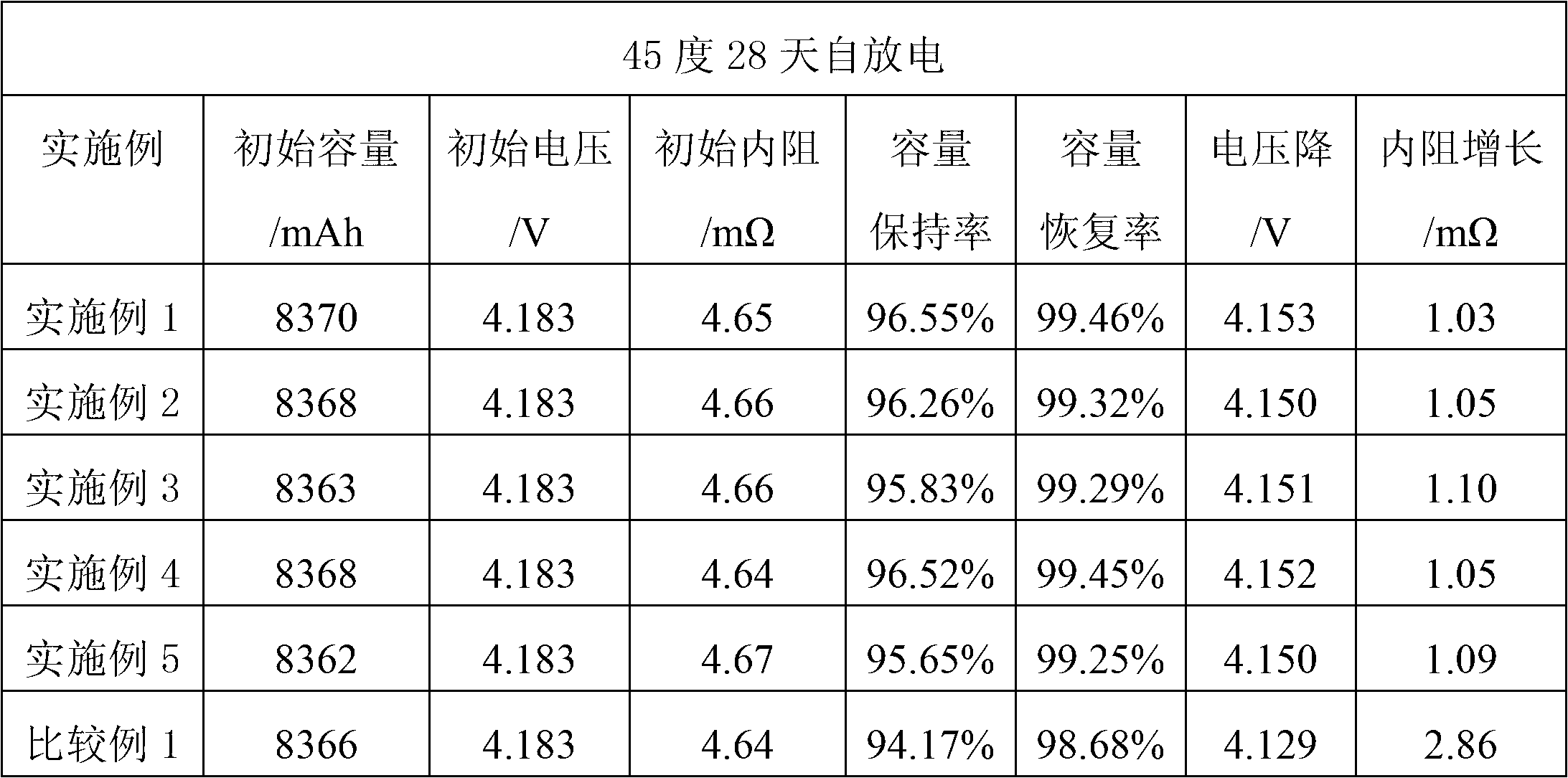

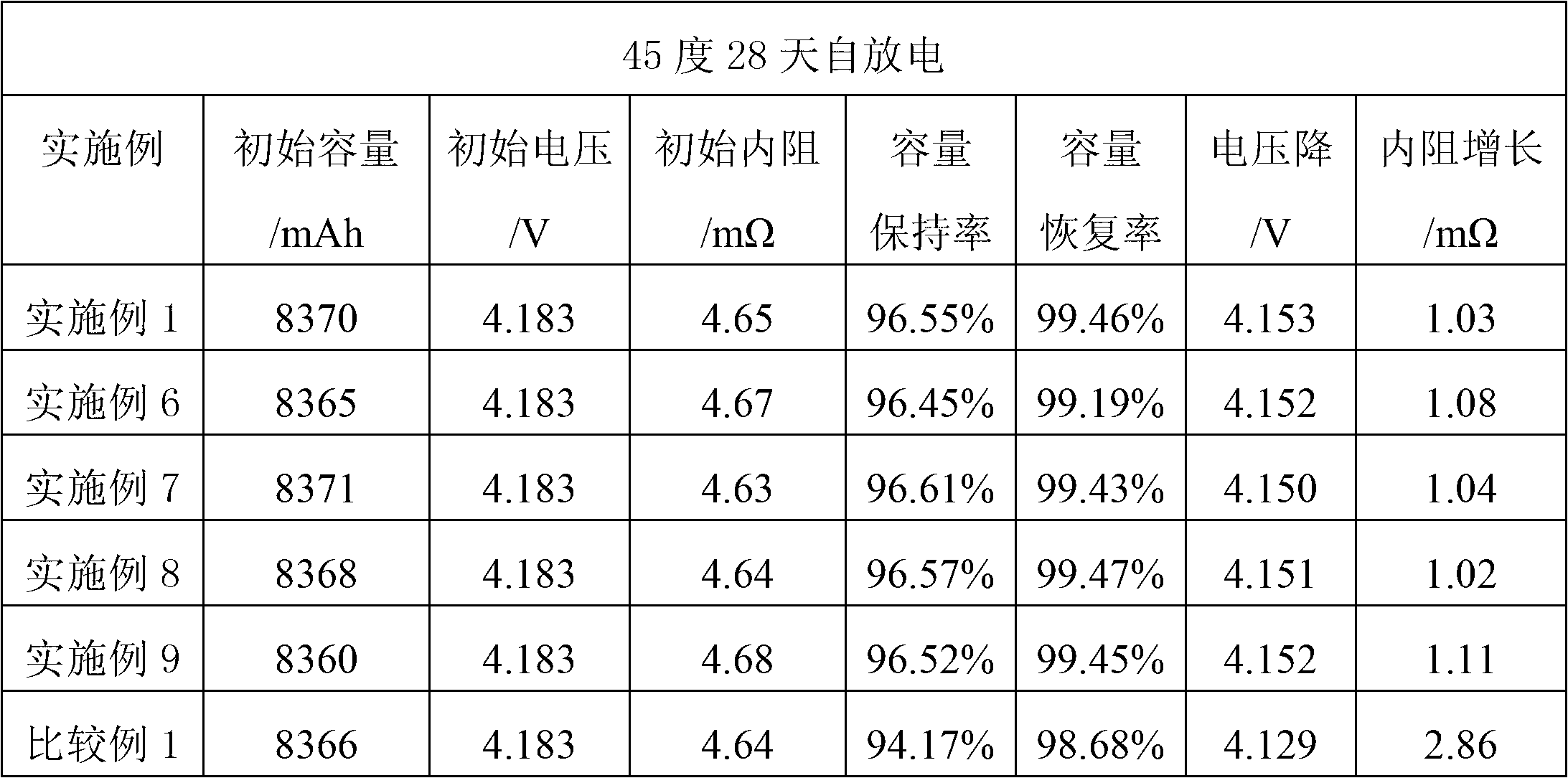

[0033] The lithium-ion secondary battery of this embodiment was tested for cycle, self-discharge at 45°C for 28 days, hot box at 150°C for 30 minutes, short circuit, extrusion, and acupuncture. The test results are shown in Table 1 and Table 2.

Embodiment 3

[0035] The only difference between this embodiment and embodiment 1 is that the ammonium ion (NH 4+ ) aluminosilicates instead of containing lithium ions (Li + ) of aluminosilicates.

[0036] The lithium-ion secondary battery of this embodiment was tested for cycle, self-discharge at 45°C for 28 days, hot box at 150°C for 30 minutes, short circuit, extrusion, and acupuncture. The test results are also shown in Table 1 and Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com