Lithium ion battery composite diaphragm and preparation method and application thereof

A lithium-ion battery and composite diaphragm technology, which is applied to secondary batteries, battery pack components, circuits, etc., can solve the problems of potential safety hazards such as thermal runaway of batteries, poor liquid-holding capacity of diaphragms, and poor electrolyte affinity. Large-scale short-circuit or overheating, improving liquid retention capacity, and not easy to short-circuit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

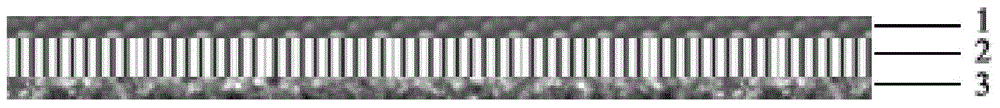

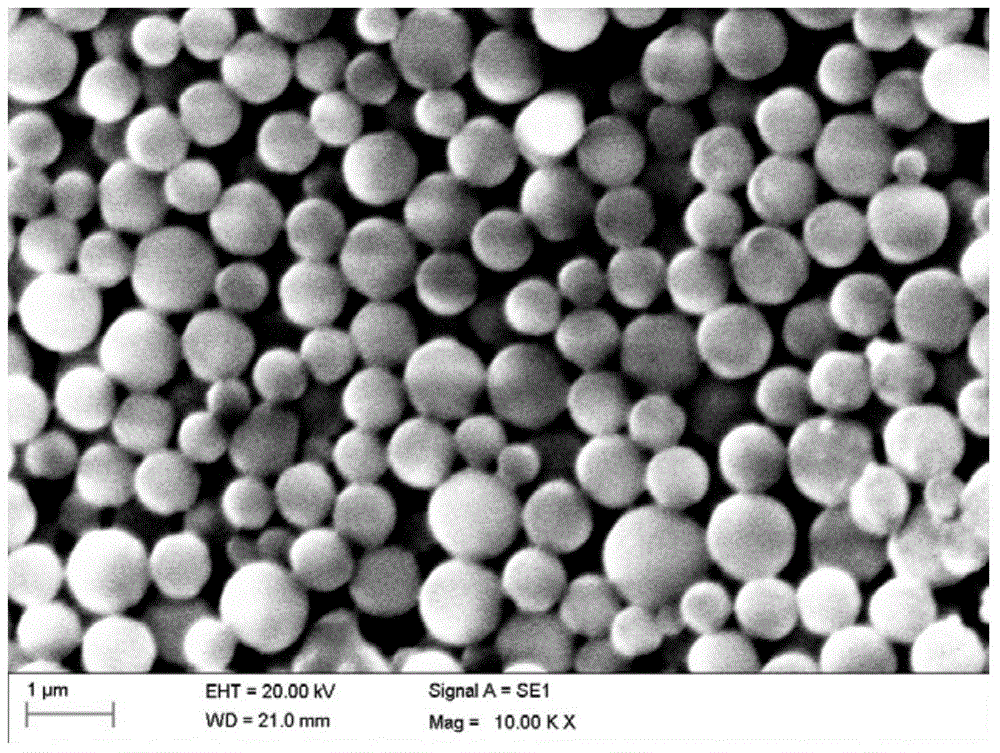

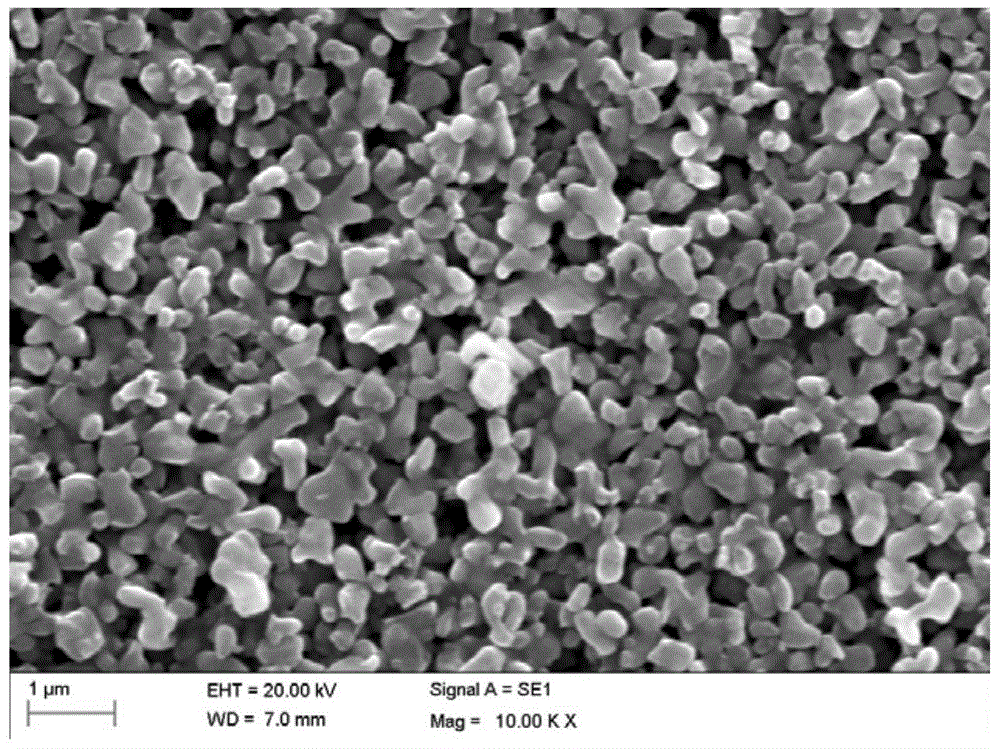

[0039] The lithium ion battery composite separator in this embodiment includes a polyolefin microporous membrane, a polymer microsphere-based coating coated on one side of the polyolefin microporous membrane, and a coating on the other side of the polyolefin microporous membrane Inorganic ceramic-based coating. The thickness of the composite diaphragm is 27 μm, wherein the thickness of the polyolefin microporous membrane is 20 μm, the porosity is 40%, the thickness of the polymer microsphere-based coating is 4 μm, and the thickness of the inorganic ceramic-based coating is 3 μm. The structure diagram of the composite diaphragm is shown in figure 1 , See the SEM image of each coating figure 2 , image 3 , See the SEM picture of ordinary PP film Figure 4 . figure 1 Middle 1 and 3 are polymer microsphere-based coating and inorganic ceramic-based coating respectively, and 2 is polyolefin microporous membrane (polypropylene microporous membrane).

[0040] The preparation method of t...

Embodiment 2

[0050] The lithium ion battery composite separator in this embodiment includes a polyolefin microporous membrane (polypropylene microporous membrane), a polymer microsphere-based coating coated on one side of the polyolefin microporous membrane, and a polyolefin Inorganic ceramic-based coating on the other side of the microporous membrane. The thickness of the composite diaphragm is 27 μm, wherein the thickness of the polyolefin microporous membrane is 20 μm, the porosity is 40%, the thickness of the polymer microsphere-based coating is 4 μm, and the thickness of the inorganic ceramic-based coating is 3 μm.

[0051] The preparation method of the lithium ion battery composite diaphragm in this embodiment includes the following steps:

[0052] (1) Add SiO with a particle size of 0.9μm to deionized water 2 The particles were stirred with a high-speed disperser for 1 hour, then the binder PVDF was added, and the stirring was continued for 1 hour to obtain inorganic ceramic slurry, in w...

Embodiment 3

[0057] The lithium ion battery composite separator in this embodiment includes a polyolefin microporous membrane (polypropylene microporous membrane), a polymer microsphere-based coating coated on one side of the polyolefin microporous membrane, and a polyolefin Inorganic ceramic-based coating on the other side of the microporous membrane. The thickness of the composite diaphragm is 27 μm, wherein the thickness of the polyolefin microporous membrane is 20 μm, the porosity is 40%, the thickness of the polymer microsphere-based coating is 3 μm, and the thickness of the inorganic ceramic-based coating is 4 μm.

[0058] The preparation method of the lithium ion battery composite diaphragm in this embodiment includes the following steps:

[0059] (1) Add TiO with a particle size of 1.0μm to deionized water 2 The particles are stirred for 1 hour with a high-speed disperser, then the binder PVDF is added, and the stirring is continued for 1 hour to obtain inorganic ceramic slurry, in whic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com