Patents

Literature

30results about How to "Guaranteed high temperature resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant insulation coating and preparation method and application thereof

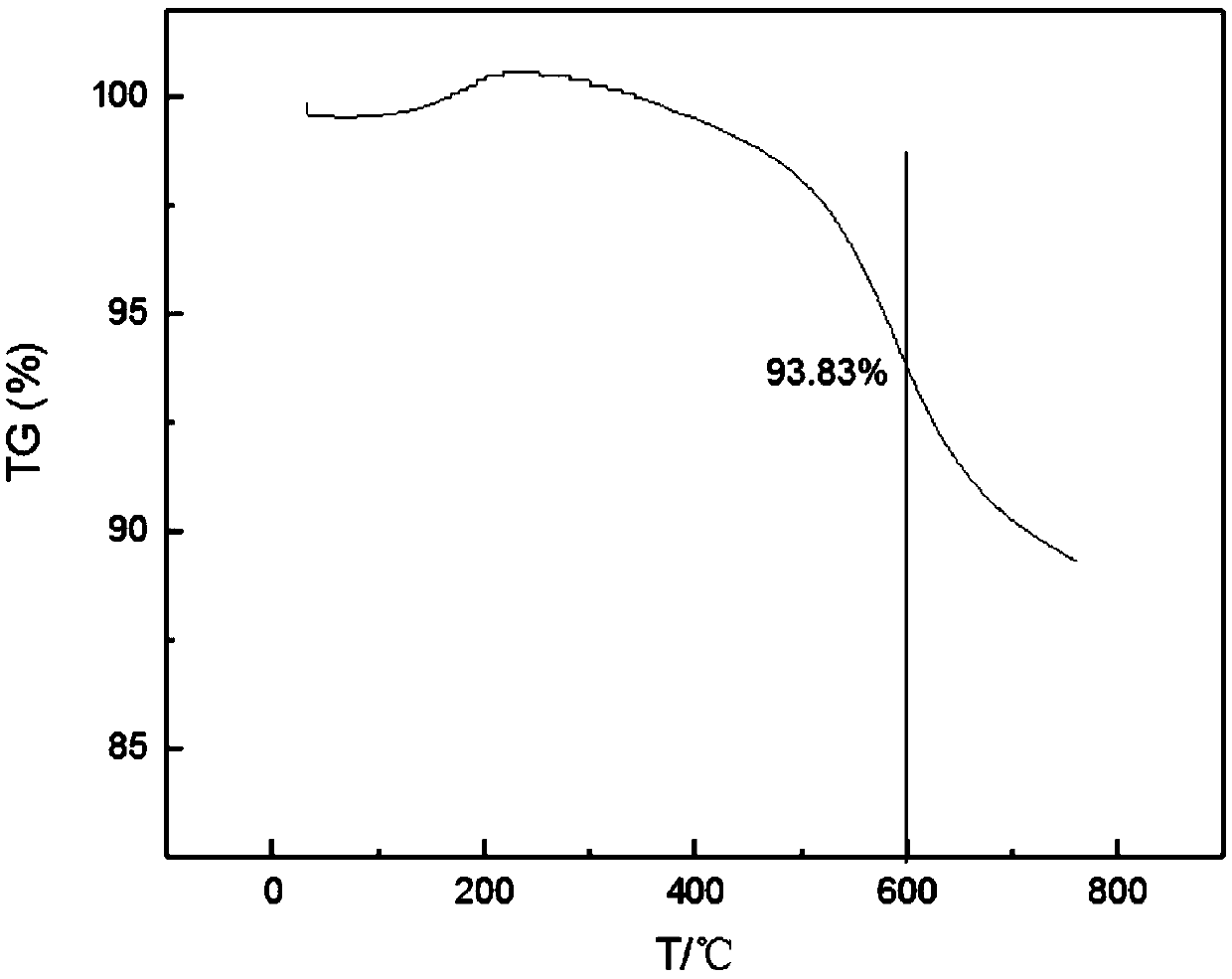

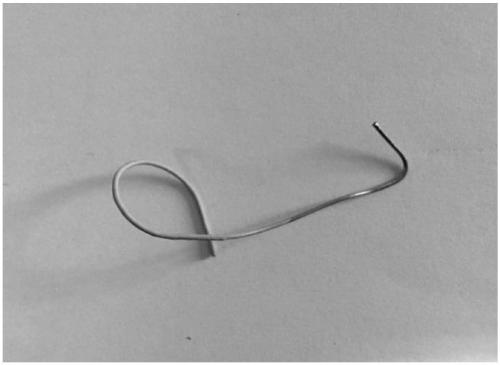

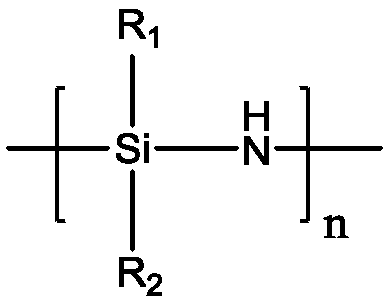

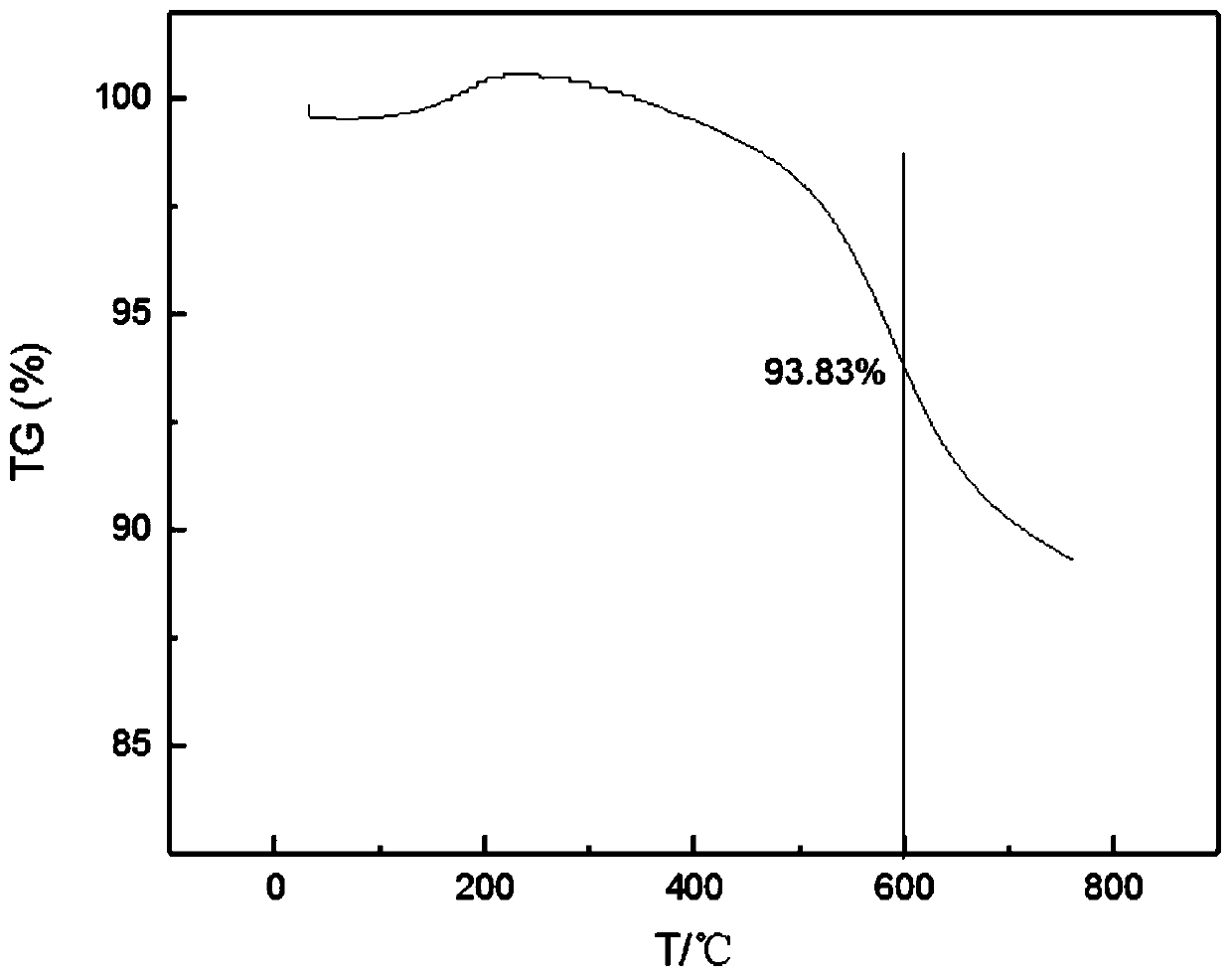

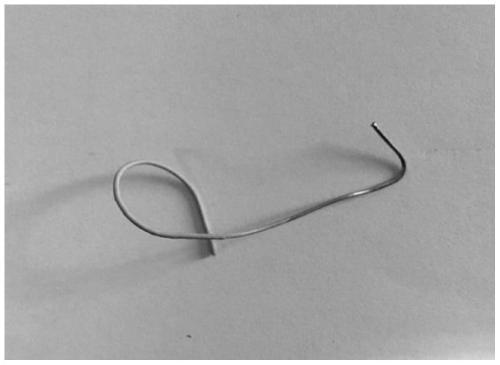

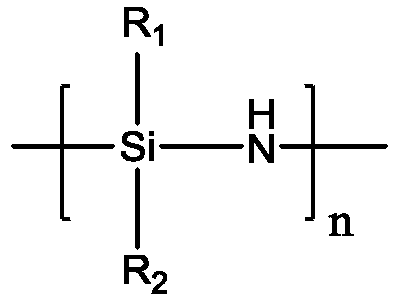

The invention discloses a high-temperature-resistant insulation coating and a preparation method and application thereof. Slurry for preparing the high-temperature-resistant insulation coating is at least prepared from the following components in parts by mass: (a) 100 parts of polysilazane resin, (b) 1-100 parts of polysiloxane resin containing active functional groups, (c) 5-100 parts of a filler, and (d) 0-10 parts of an assistant. By adopting the polysilazane resin as a primary film forming substance and adopting the polysiloxane resin containing the active functional groups as a secondaryfilm forming substance, the high-temperature-resistant property is ensured, and the coating also has good tenacity; the preparation method is simple and does not rely on special equipment; the temperature-resistant property of the high-temperature-resistant insulation coating prepared through the method can be appropriately adjusted according to actual needs so as to adapt to different application fields; and the preparation method is wide in application range and can be suitable for various insulation objects, strips, pipes, wires and the like.

Owner:北京和尔泰新材料科技有限公司

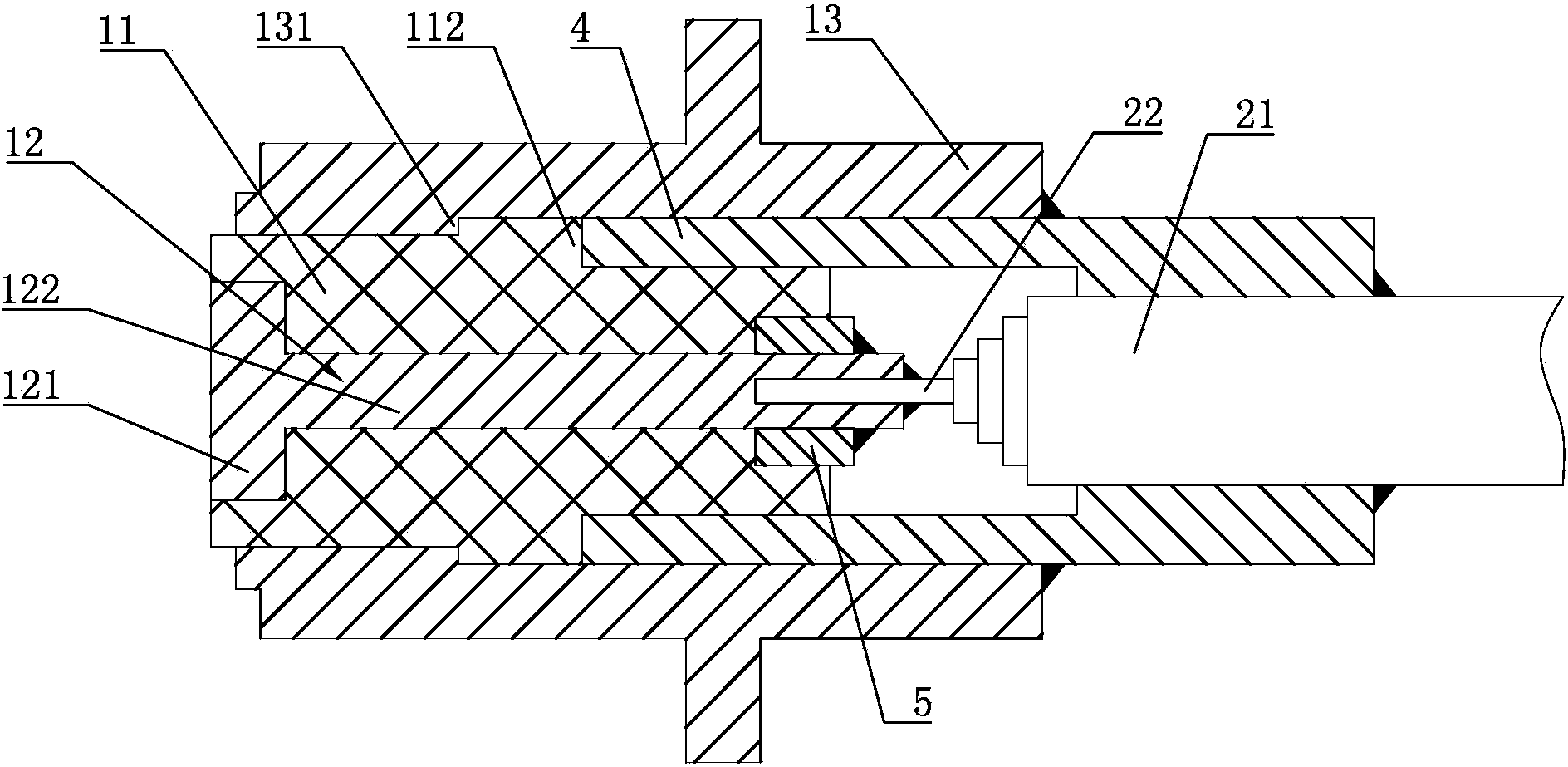

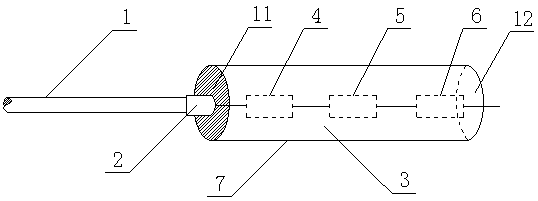

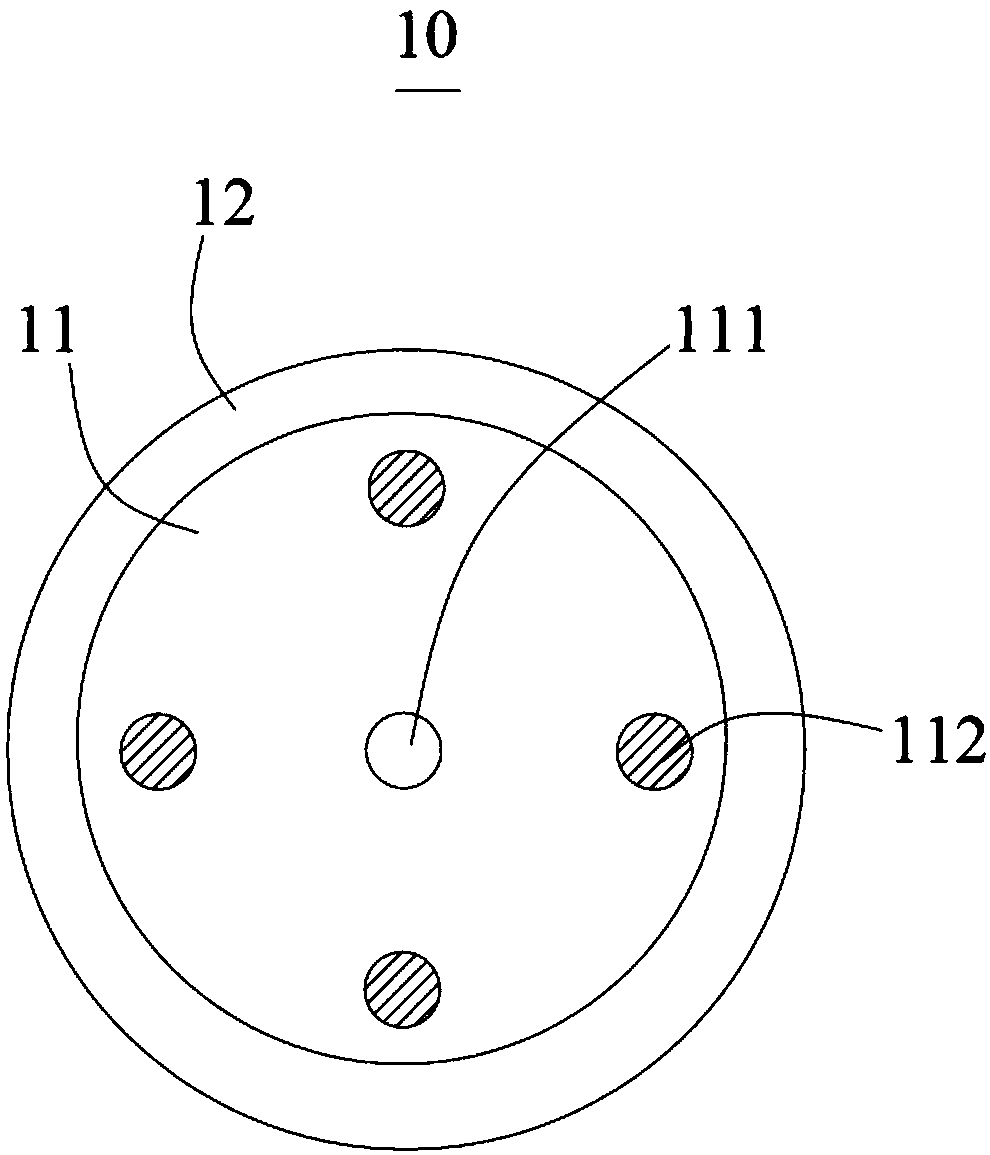

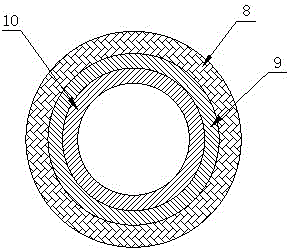

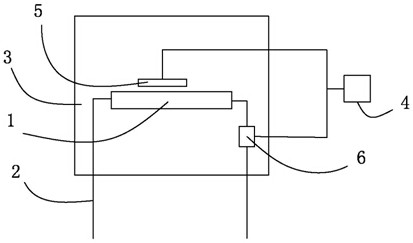

Capacitive sensor

InactiveCN103673863AInhibit sheddingReduce manufacturing costUsing electrical meansTemperature resistanceCapacitance transducer

The invention discloses a capacitive sensor which is characterized in that a positioning convex ring is arranged on a ceramic insulation ring, the inner wall of a metal jacket is provided with a limiting convex ring, a high-temperature hard cable is connected with the ceramic insulation ring, a core electrode comprises a clamping ring and a connecting rod, one end of the ceramic insulation ring is provided with a clamping cavity, a high-temperature core wire in the high-temperature hard cable is fixedly connected with the connecting rod, a metal pressing sleeve is welded and fixed to a metal outer shielding layer of the high-temperature hard cable, the metal pressing sleeve is connected to the positioning convex ring in a butting mode, and the outer surface of the metal pressing sleeve is fixedly connected with the metal jacket. The capacitive sensor has the advantages that the ceramic insulation ring is fixedly clamped into the metal jacket, surface metallization is needless, a high-temperature probe is firmly connected with the hard-temperature hard cable, the situation that parts fall and a to-be-tested system is damaged can be prevented, welding is carried out between metal, and laser welding can be carried out; due to the fact that the high-temperature hard cable is matched with a low-temperature soft cable, the high-temperature-resistance characteristic can be guaranteed, cost is reduced, and on-line monitoring of the equipment is facilitated.

Owner:ZHEJIANG ZHONGXIN POWER MEASUREMENT & CONTROL TECH

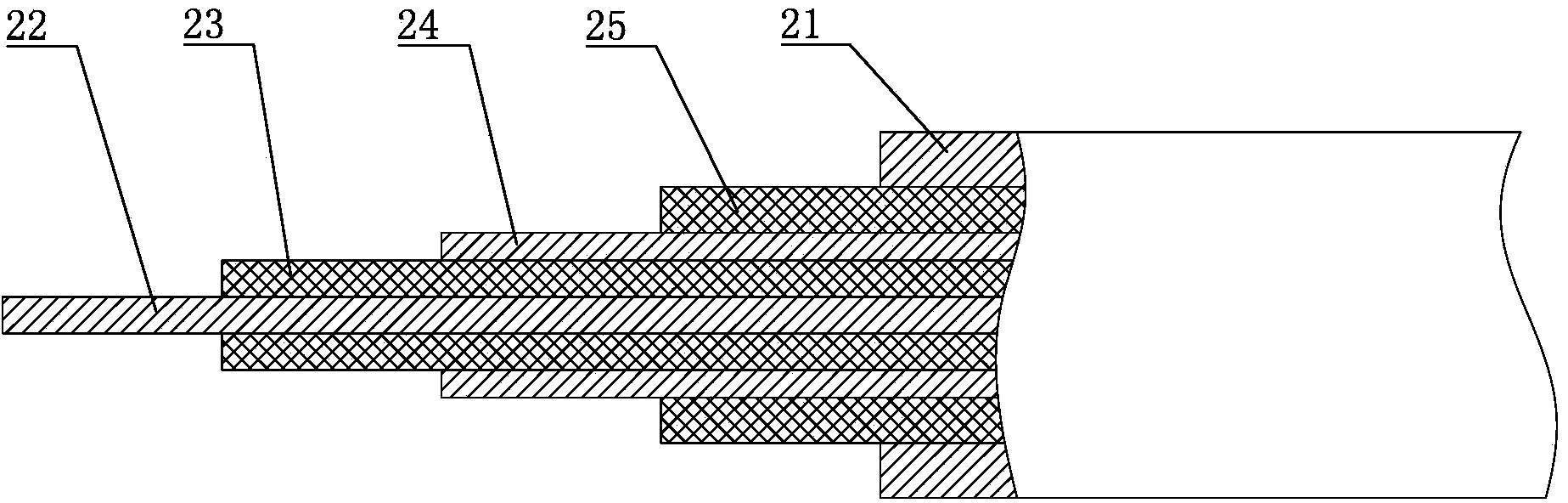

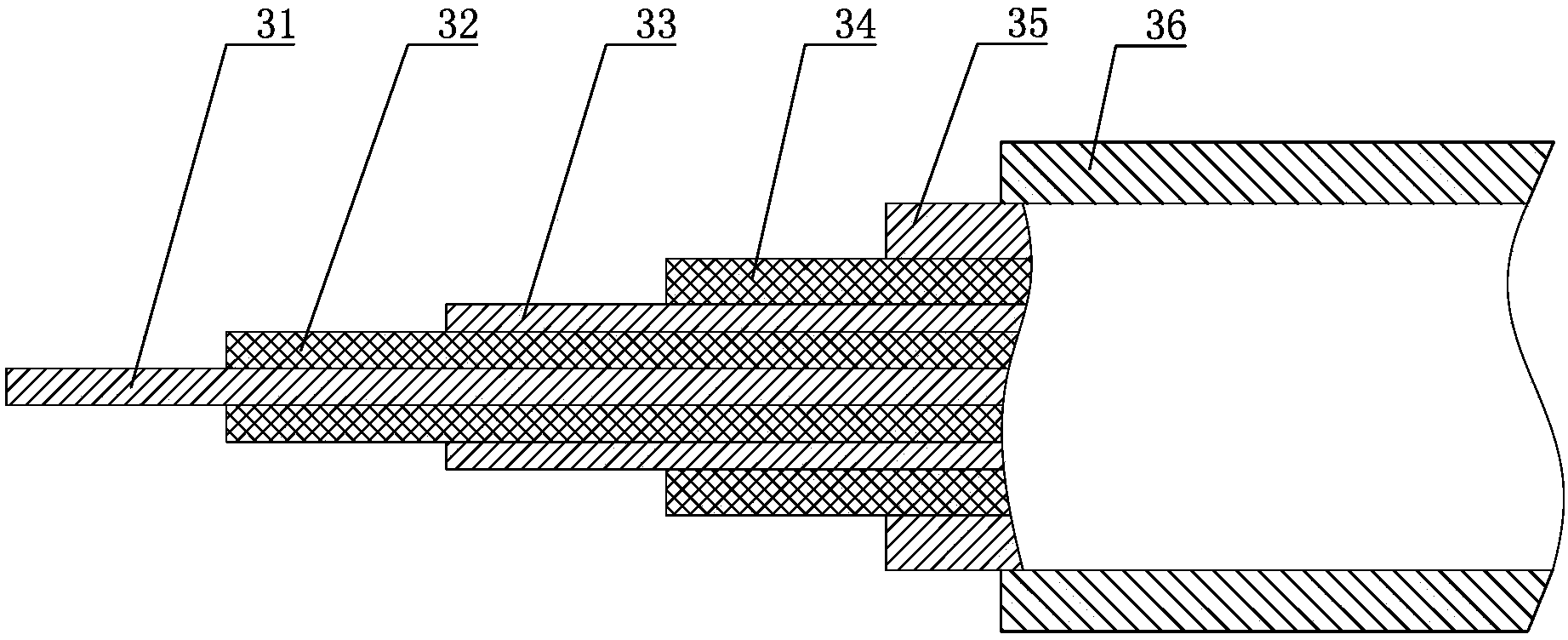

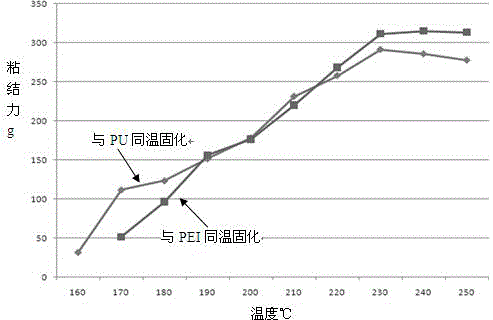

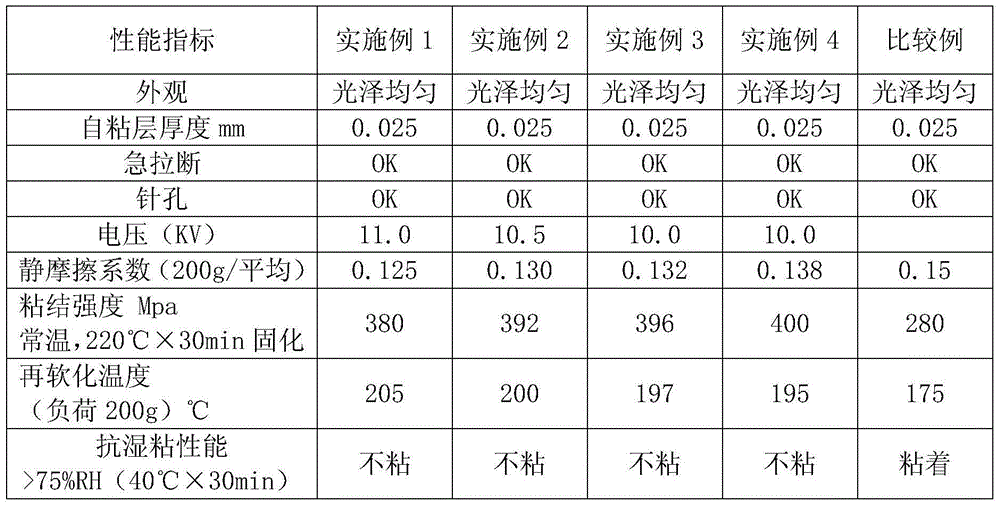

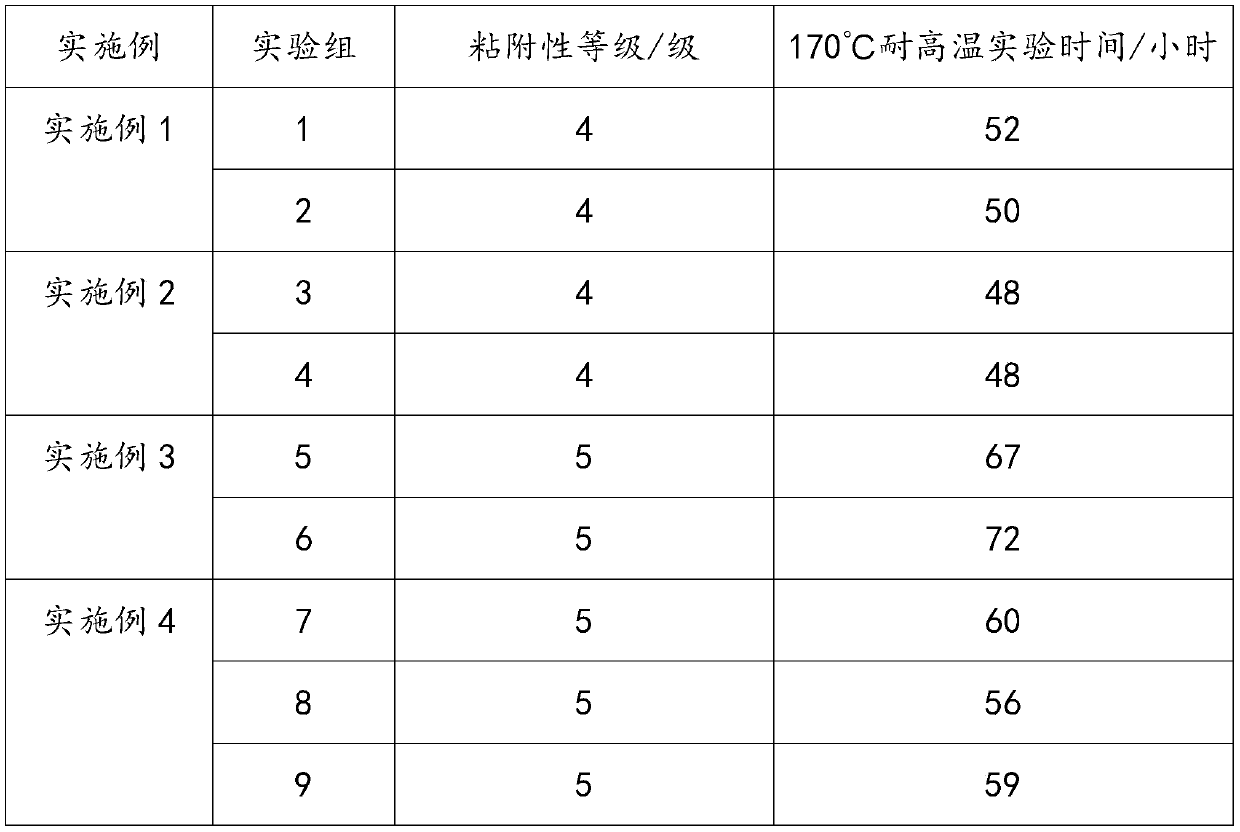

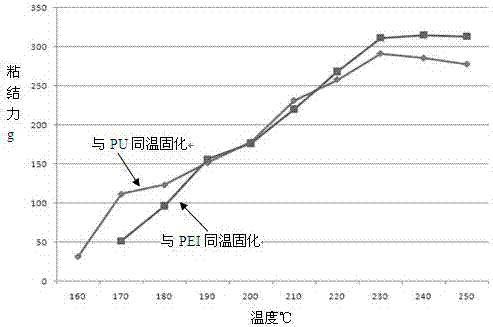

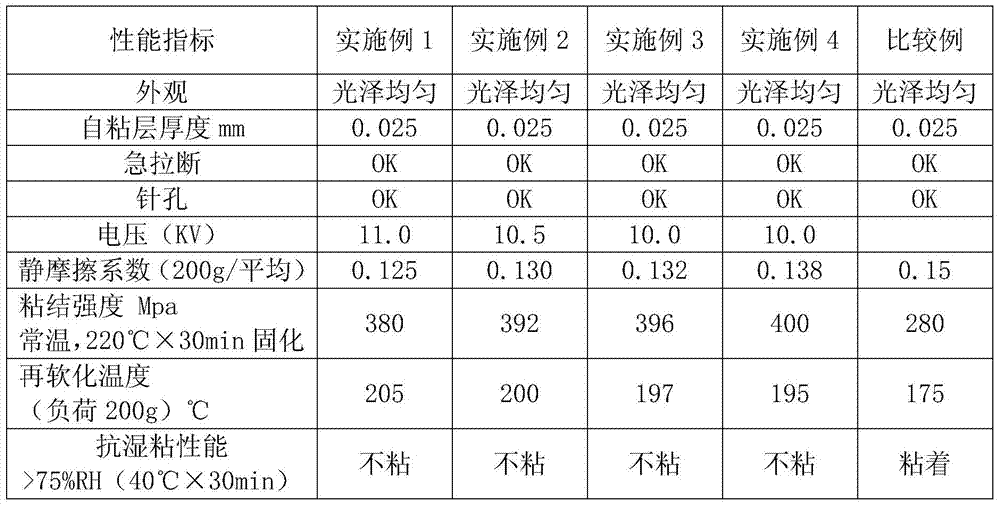

Heat-resistant self-adhesive enamelled wire paint and preparation method thereof

ActiveCN104559752AHigh bonding strengthGood deformation resistanceEpoxy resin coatingsEpoxyPolyetherimide

The invention relates to heat-resistant self-adhesive enamelled wire paint. The heat-resistant self-adhesive enamelled wire paint disclosed by the invention comprises the following raw materials in parts by weight: 160-350 parts of dimethylbenzene, 430-620 parts of N-methylpyrrolidone, 169-191 parts of polyetherimide resin, 10-18.3 parts of boron phenolic resin, 19-33.8 parts of phenol formaldehyde epoxy resin, and 0.2-0.3 part of a slipping agent. The heat-resistant self-adhesive enamelled wire paint disclosed by the invention has good heat resistance and wet-sticky-resistant property, and can meet production requirements under high-temperature and high-humidity weather conditions.

Owner:江苏佳禾电子材料有限公司

Aryl-1,3,5-triazine polyarylester and preparation method thereof

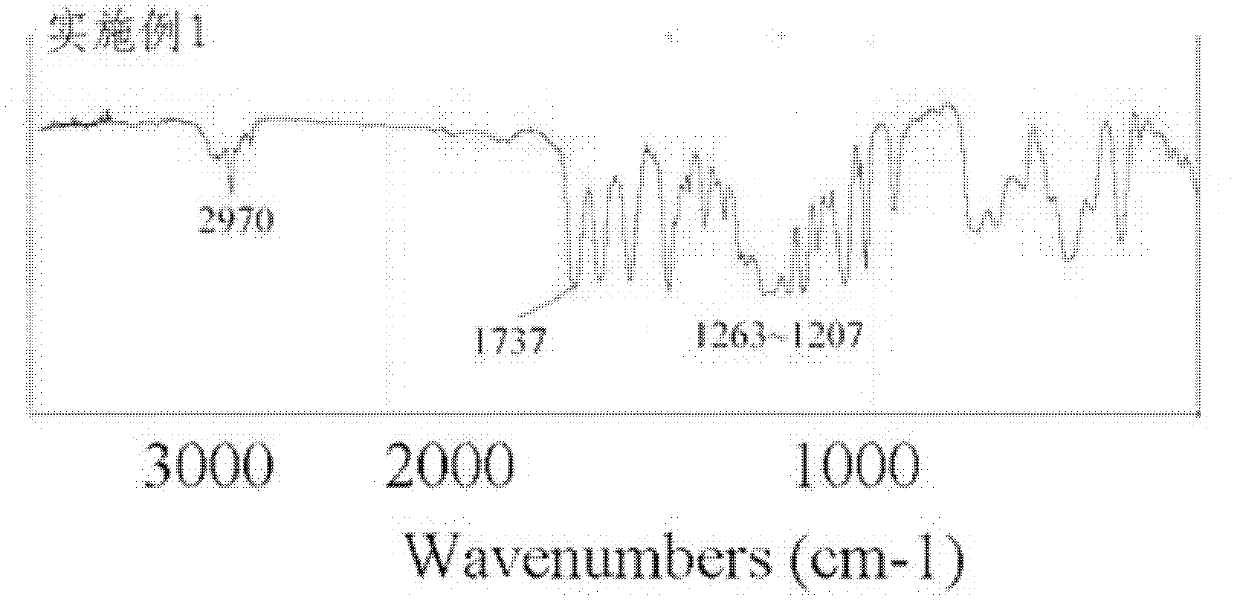

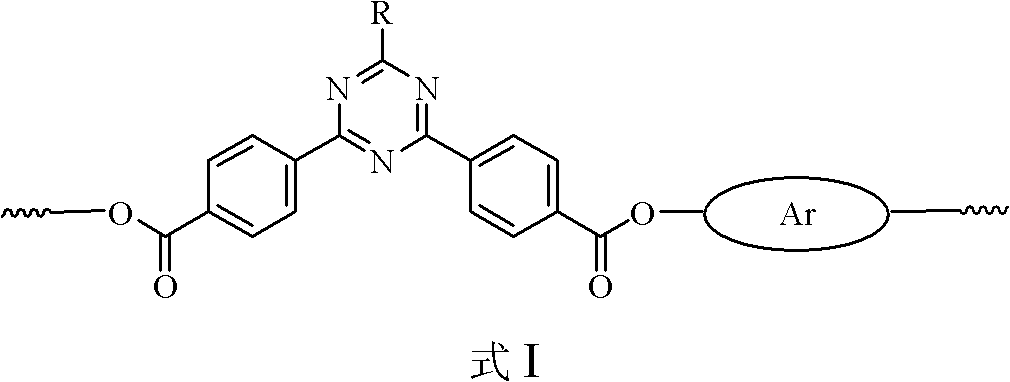

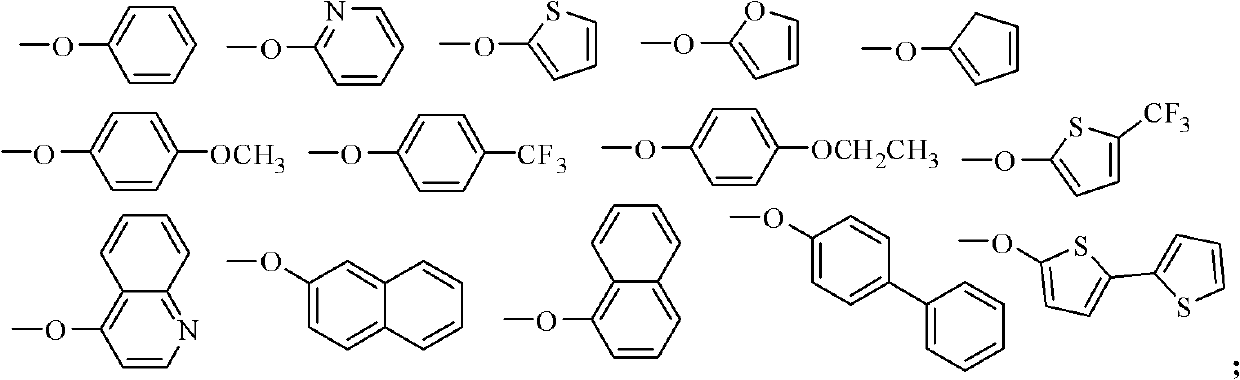

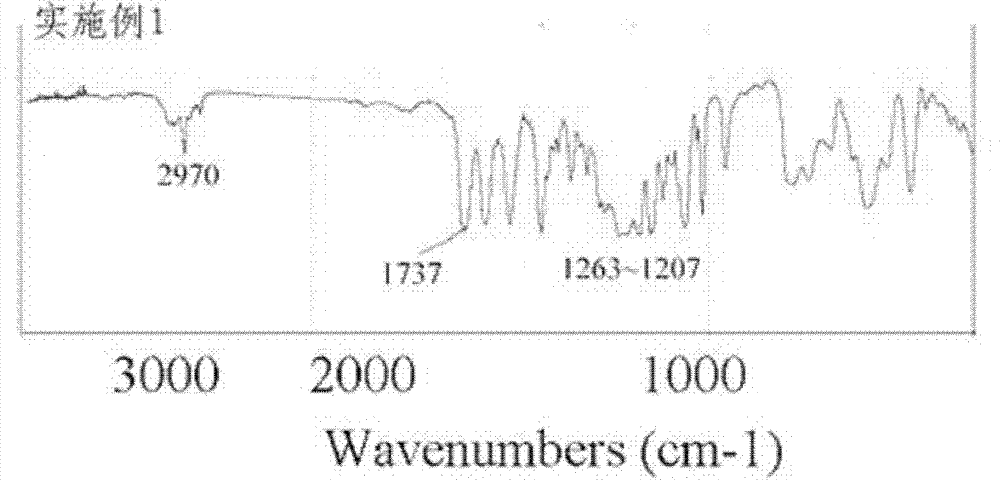

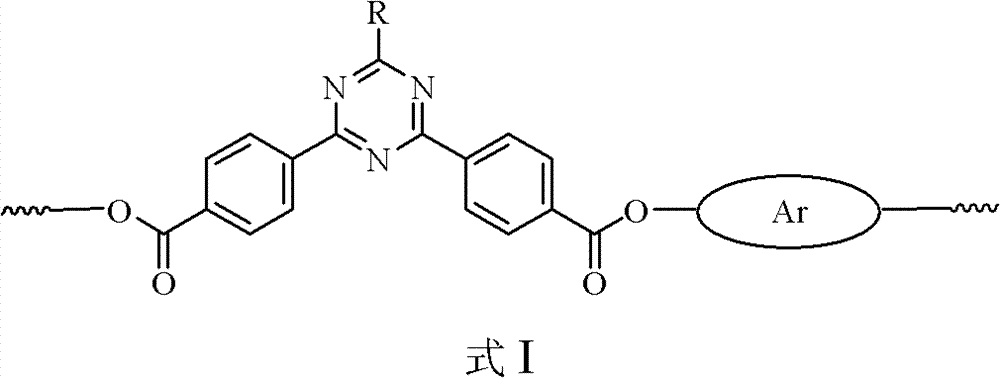

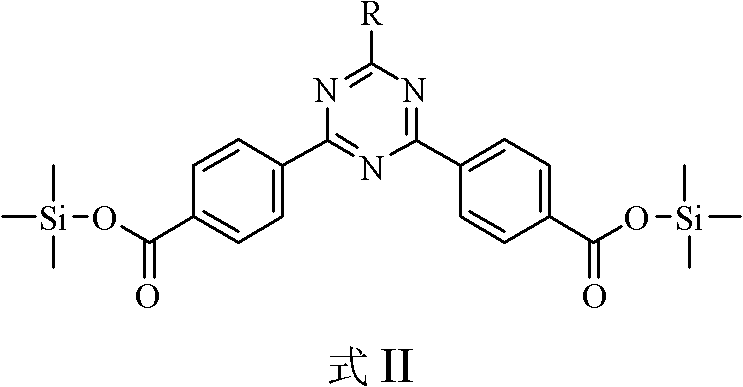

ActiveCN102585186AHigh mechanical strengthGuaranteed high temperature resistanceSilicon organic compoundsPolymer scienceLiquid medium

The invention discloses an aryl-1,3,5-triazine polyarylester and a preparation method thereof, and belongs to the technical field of polymer science. The aryl-1,3,5-triazine polyarylester is characterized in that a macromolecular main chain contains a structural unit like the general formula I. The aryl-1,3,5-triazine polyarylester with high molecular weight, excellent thermal stability and good mechanical strength can be conveniently and rapidly prepared with disilyl ester compound disclosed by the invention and commercial aromatic bisphenol monomer as polycondensation monomers and / or other commercial disilyl ester compounds added at the same time as copolycondensation monomers by the step of step-by-step polycondensation in a high-boiling-point inert liquid medium or in a molten / solid phase state. The polyarylester resins can be used in the fields of heat resistance paints, coating, adhesives, separation membranes, composite materials and the like, and have wide application prospects.

Owner:CENT SOUTH UNIV

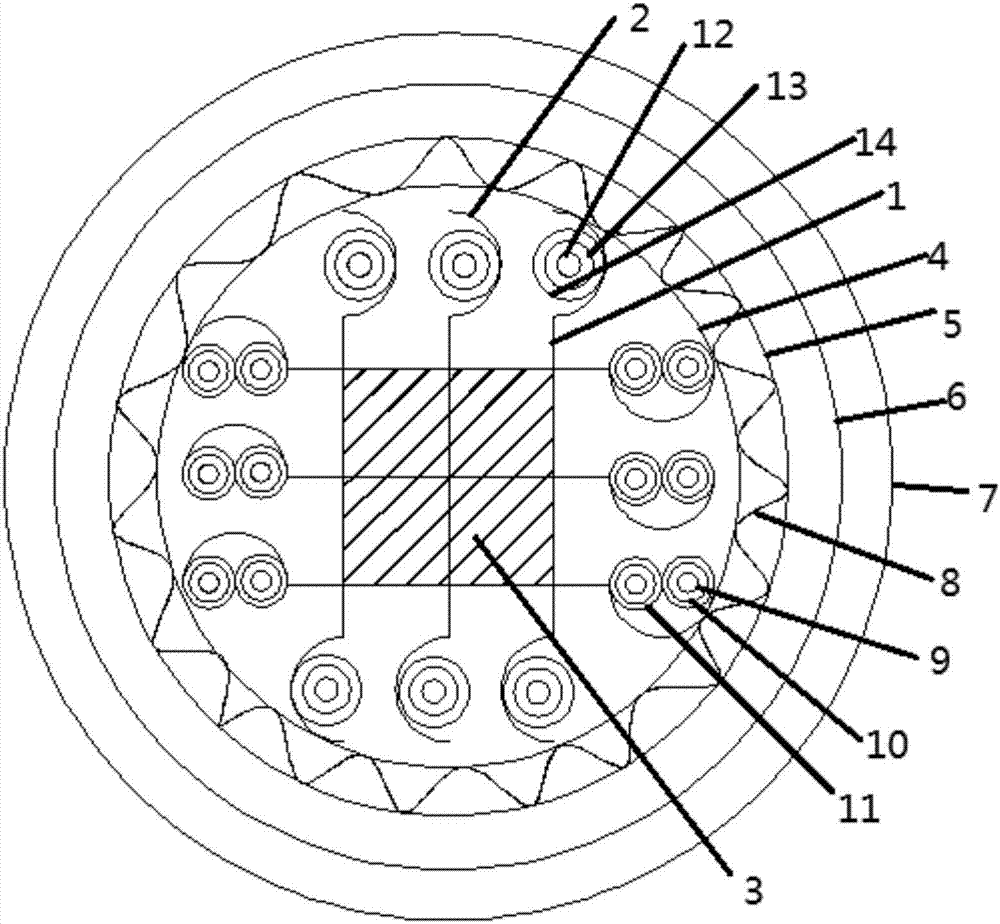

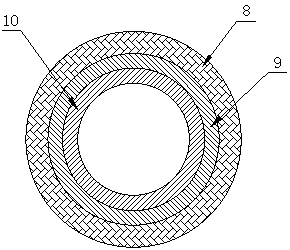

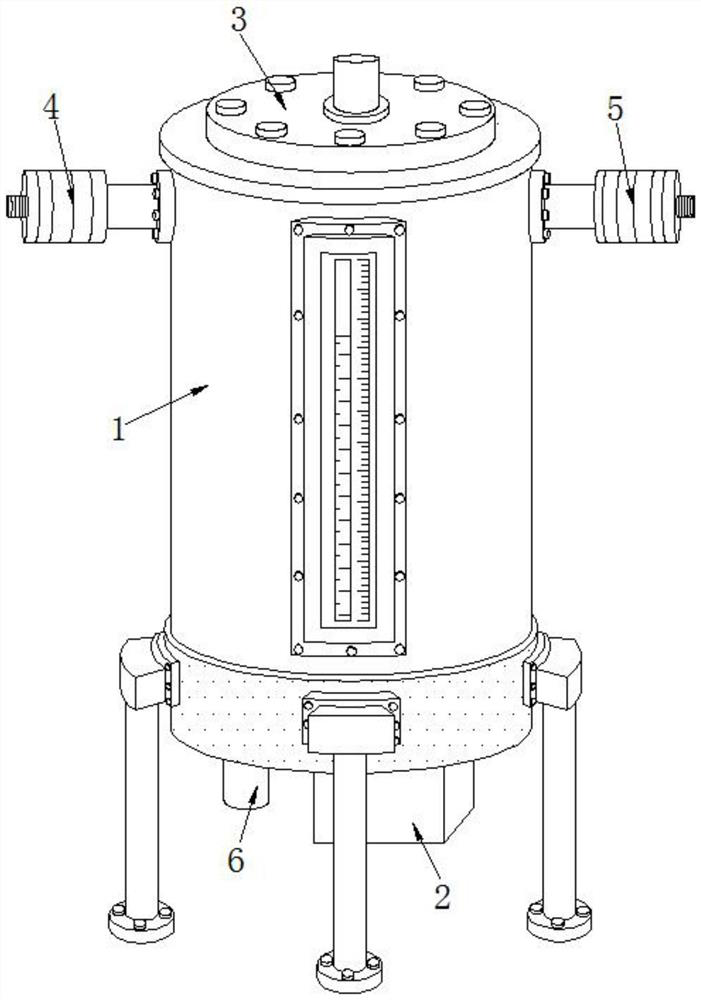

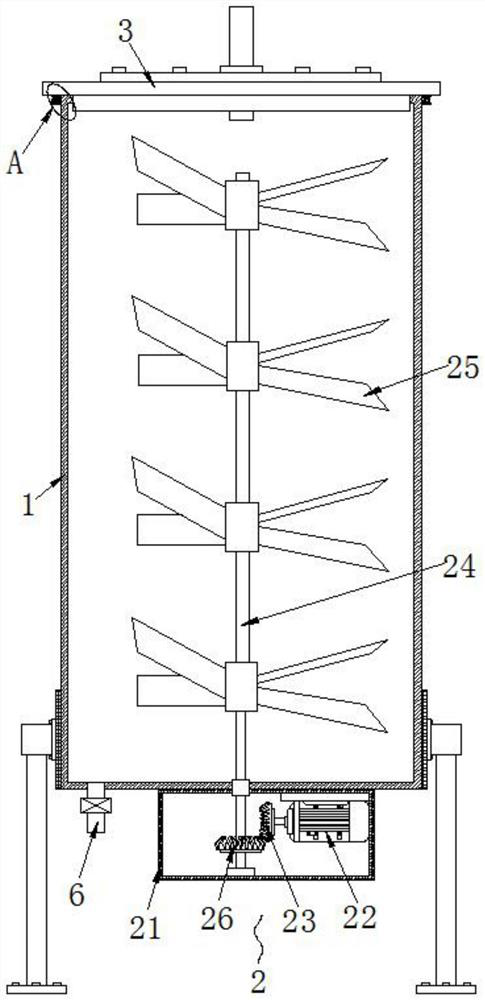

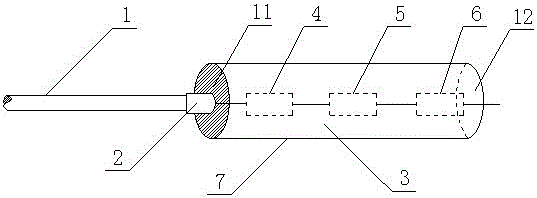

Tensile computer cable

ActiveCN107316692AGood flexibilityGuaranteed FeaturesFlexible cablesFlexible conductorsFiberInterference resistance

The invention discloses a tensile computer cable. The tensile computer cable comprises a silicone rubber framework, wherein the silicone rubber framework has a field-shaped cross section, two ends of three horizontal surfaces and three vertical surfaces of the silicone rubber framework respectively extend towards two ends, semi-circular silicone rubber frameworks are respectively connected with end surfaces after being extended, four cavities in the field-shaped silicone rubber framework are respectively filled with flexible steel ropes, each flexible steel rope comprises an organic fiber rope core, an inner-layer steel rope and an outer-layer steel rope are sequentially arranged outside the organic fiber rope core, an elastic fiber filler is arranged between the inner-layer steel rope and the outer-layer steel rope, two first wire cores which are twisted in a paired way are arranged in the semi-circular silicone rubber frameworks on the three horizontal surfaces, and second wire cores are arranged in the semi-circular silicone rubber frameworks on the three vertical surfaces. The tensile computer cable has the advantages of novel and compact structure, interference resistance, pressure resistance, water prevention, good wear resistance, light weight, high flexibility, long service lifetime, economy and practicability, and is safe to use.

Owner:ANHUI HUININGELECTRIC INSTR & APPLIANCE GRP

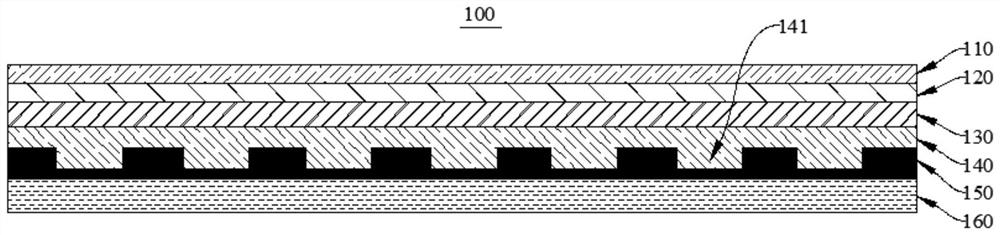

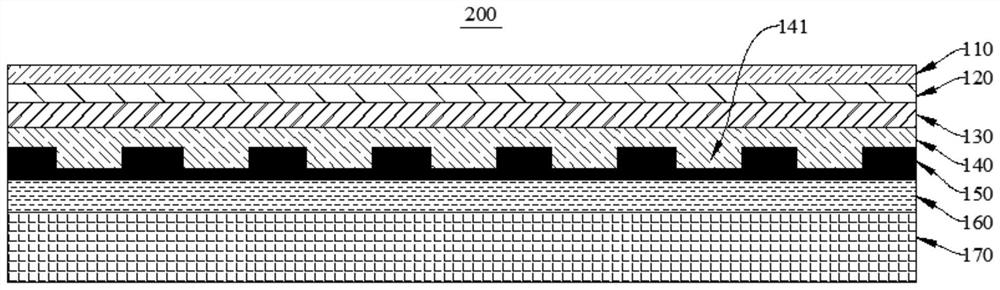

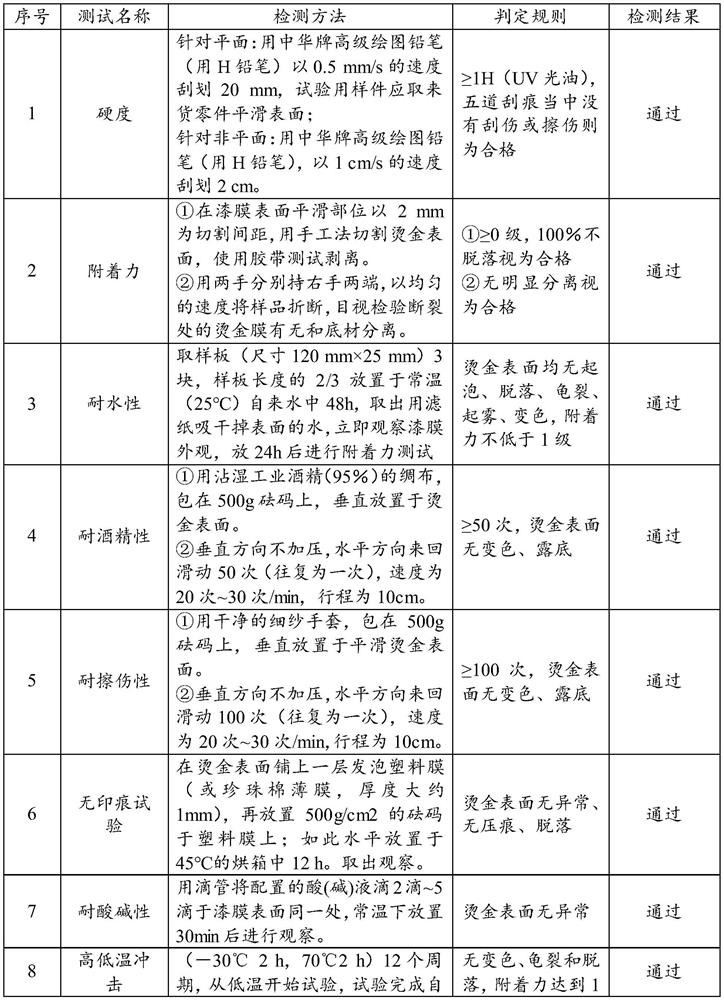

High-temperature-resistant holographic gold stamping film, gold stamping plastic part and preparation method

PendingCN113602032AGuaranteed high temperature resistanceGood effectFireproof paintsDecorative surface effectsMetal coatingHot stamping

The embodiment of the invention provides a high-temperature-resistant holographic gold stamping film, a gold stamping plastic part and a preparation method, and relates to the field of gold stamping films. The high-temperature-resistant holographic gold stamping film comprises a base film, a release layer, a protective layer, a mold pressing layer, a metal coating and an adhesive layer which are sequentially stacked from bottom to top, the surface, close to the metal coating, of the mold pressing layer is provided with a holographic pattern microstructure, and coatings corresponding to the protective layer and the mold pressing layer both contain polyhydroxy acrylic resin, amino resin and isocyanate. The dosage ratio of the amino resin to the isocyanate in the coating corresponding to the protective layer is (2-4):1, and the dosage ratio of the amino resin to the isocyanate in the coating corresponding to the mold pressing layer is (0.5-1):1. The high-temperature-resistant holographic gold stamping film has excellent physical and chemical resistance, can resist high temperature hot stamping and mold pressing, and meets higher decoration requirements in the plastic gold stamping field.

Owner:WUHAN HUAGONG IMAGE TECH & DEV

Antibacterial firefighting garment material

InactiveCN103340485AGuaranteed high temperature resistanceGuaranteed flame retardant propertiesLayered productsProtective garmentBiochemical engineeringCoating

The invention belongs to the technical field of garment materials, and particularly relates to an antibacterial firefighting garment material. The antibacterial firefighting garment material comprises a waterproof layer, a heat insulating layer and an inner layer, wherein the heat insulating layer is arranged on the inner side of the waterproof layer in a heat seal mode, and the inner layer is glued onto the inner side of the heat insulating layer. According to the antibacterial firefighting garment material, the fabric of the inner layer has a stable and lasting antibacterial function after being treated with coating process, sterilization or suppression of breeding of microorganisms on the surface of the garment material can be achieved through contact, and therefore the long-term antibacterial purpose and sterilization are achieved. The antibacterial firefighting garment material is suitable for being used as a firefighting garment material.

Owner:KUSN ZHOUSHI HUIHONG GARMENT FACTORY

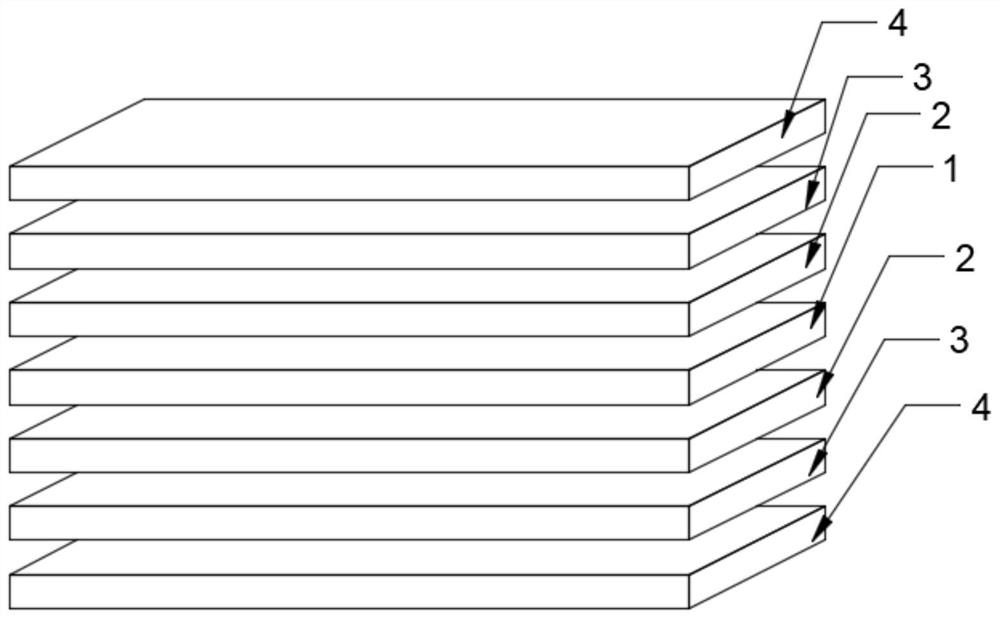

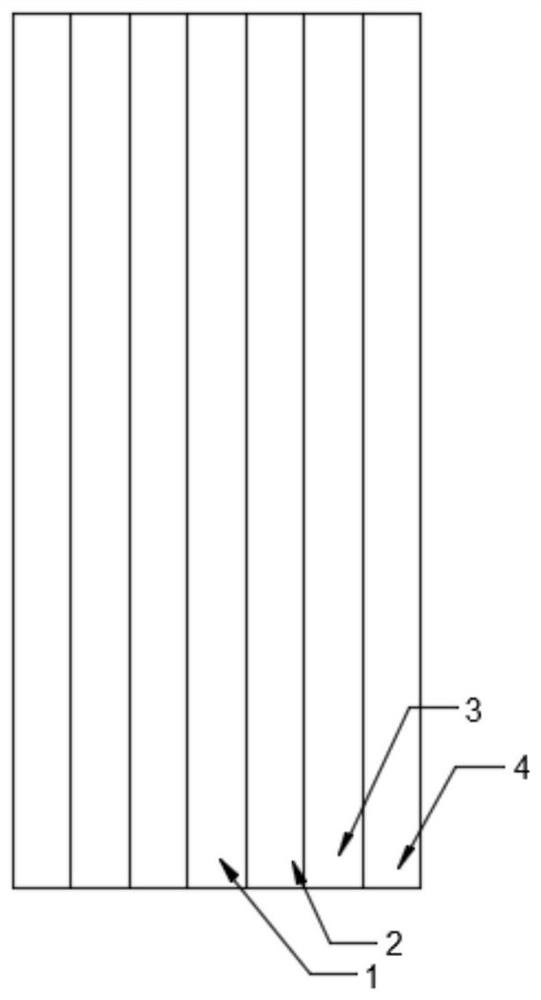

Multi-layer co-extrusion composite light diffusion plate and preparation method thereof

PendingCN113291024AGuaranteed light energy effect characteristicsGuaranteed Optical Performance CharacteristicsSynthetic resin layered productsHigh heatCeramic materials

The invention discloses a multi-layer co-extrusion composite light diffusion plate and a preparation method thereof. The multi-layer co-extrusion composite light diffusion plate comprises flexible diffusion master batch PC material layers, flexible PMMA material layers, high-elasticity light diffusion PET material layers and high-temperature-resistant light diffusion PC material layers, the flexible PMMA material layers are arranged on the two sides of the flexible diffusion master batch PC material layers, the high-elasticity light diffusion PET material layers are arranged on one side of the flexible PMMA material layers, and the high-temperature-resistant light diffusion PC material layers are arranged on one side of the high-elasticity light diffusion PET material layers. The bending performance of the whole composite light diffusion plate can be basically provided through the flexible diffusion master batch PC material layer, and the bending performance of the composite light diffusion plate can be further guaranteed through the flexible PMMA material layer; the elasticity of the composite light diffusion plate can be guaranteed on the basis of the bending performance through the high-elasticity light diffusion PET material layer, the high-temperature resistance of the whole composite light diffusion plate can be guaranteed through the high-temperature-resistant light diffusion PC material layer, and the performance of the plate can be improved to the maximum extent through composite manufacturing of various materials.

Owner:浙江赛宁新材料科技有限公司

Asphalt anti-stripping agent as well as preparation and application methods thereof

PendingCN110734649AHigh temperature resistanceGood water resistance and high temperature resistanceBuilding insulationsSodium lignosulfonateAsphalt

The invention discloses an asphalt anti-stripping agent as well as preparation and application methods thereof, and relates to the technical field of asphalt additives. The asphalt anti-stripping agent comprises the following components in parts by mass: 3.7-6.5 parts of paraffin, 2.2-4.2 parts of fatty acid and 2.5-5.5 parts of sodium lignin sulfonate. The preparation method of the asphalt anti-stripping agent comprises the following steps: adding paraffin, fatty acid and sodium lignin sulfonate into a mixer in parts by mass, and stirring at a temperature of 70 to 90 DEG C until the components are uniformly mixed. The application method of the asphalt anti-stripping agent comprises following steps: 98%-99% of matrix asphalt is heated to 220 DEG C, 1%-2% of the asphalt anti-stripping agentas described in any one of claims 1-2 is added, and an obtained mixture is stirred and mixed at 220 DEG C for 3 hours. The asphalt anti-stripping agent disclosed by the invention is prepared by proportioning low-cost materials at high temperature, has good water resistance and high-temperature resistance, and when the asphalt anti-stripping agent is applied, the asphalt anti-stripping agent and matrix asphalt are mixed and stirred at high temperature, so that the use amount is larger, but the effect is better.

Owner:四川科路泰交通科技有限公司 +1

Manufacturing method of red fluorescent powder for tri-phosphor energy saving lamp

InactiveCN103305223AEasy to handleExpand the scope of operationChemical industryLuminescent compositionsUltrasound attenuationPhosphor

The invention relates to a manufacturing method of red fluorescent powder for a tri-phosphor energy saving lamp. The manufacturing method of the red fluorescent powder comprises the following steps of: firstly, sieving raw materials, namely Y2O3, Eu2O3, LiF, H3BO3 and BaCl2, and then mixing to form a raw material of the red fluorescent powder; secondly, mixing the sieved raw materials, placing the mixed raw materials into a tunnel furnace under the oxidation atmosphere, firing at a high temperature, and cooling to obtain a fired product, namely a primary product; thirdly, grinding the fired fluorescent primary product, sieving with a 100-mesh sieve, throwing the sieved fluorescent powder into a dispersion machine, sieving powder syrup with a 500-mesh water sieve, washing, carrying out suction filtration, drying, and sieving the dried powder with a 200-mesh sieve, thus the red fluorescent powder for the tri-phosphor energy saving lamp is obtained. The obtained fluorescent powder has the characteristics of small high temperature attenuation, moderate particle size and high lighting effect.

Owner:CAIHONG GRP ELECTRONICS CO LTD

High temperature and high pressure resistant packaging method for underground communication device of coiled tubing drilling machine

ActiveCN102797456AImprove high pressure performanceGuaranteed high temperature resistanceConstructionsSolderingHigh pressure

The invention discloses a high temperature and high pressure resistant packaging method for an underground communication device of a coiled tubing drilling machine, which is characterized by comprising the following steps of: making an underground communication circuit board by using a high temperature resistant printed board, high temperature resistant soldering tin and a high temperature resistant circuit element; packaging the underground communication circuit board into an outer pressure resistant cylinder; and providing a high temperature resistant connector assembly for the connection between the underground communication device and an optical cable. The high temperature and high pressure resistant packaging method for the underground communication device of the coiled tubing drilling machine has the beneficial effects that the underground communication device is packaged into the outer pressure resistant cylinder so that the high pressure resistance of the communication device is improved; the printed board, the soldering tin and the circuit element which can stably work in a high temperature environment are adopted so that the high temperature strength of the communication device is improved; a reliable informationized data basis is provided for the drilling construction, the drilling control precision and safety are improved, and the drilling control efficiency is increased; in addition, the high temperature and high pressure resistant packaging method for the underground communication device of the coiled tubing drilling machine has the characteristics of good sealing performance, simplicity in operation, low in cost and the like.

Owner:SICHUAN HONGHUA ELECTRIC

Formula of modified environment-friendly high molecular environment-friendly sheet

InactiveCN108117691AGuaranteed high temperature resistanceGuaranteed portabilityPliabilityPolypropylene

The invention provides a formula of modified environment-friendly high molecular environment-friendly sheet which is prepared from the following components in percentage by mass: 50-55% of grade leveltalc powder, 30-35% of polypropylene resin, 12-15% of high density polyethylene and 2% of a dyeing agent. The formula not only can ensure high-temperature resistance, but also ensure the portability,flexibility and degradability.

Owner:宁波优创环保科技有限公司

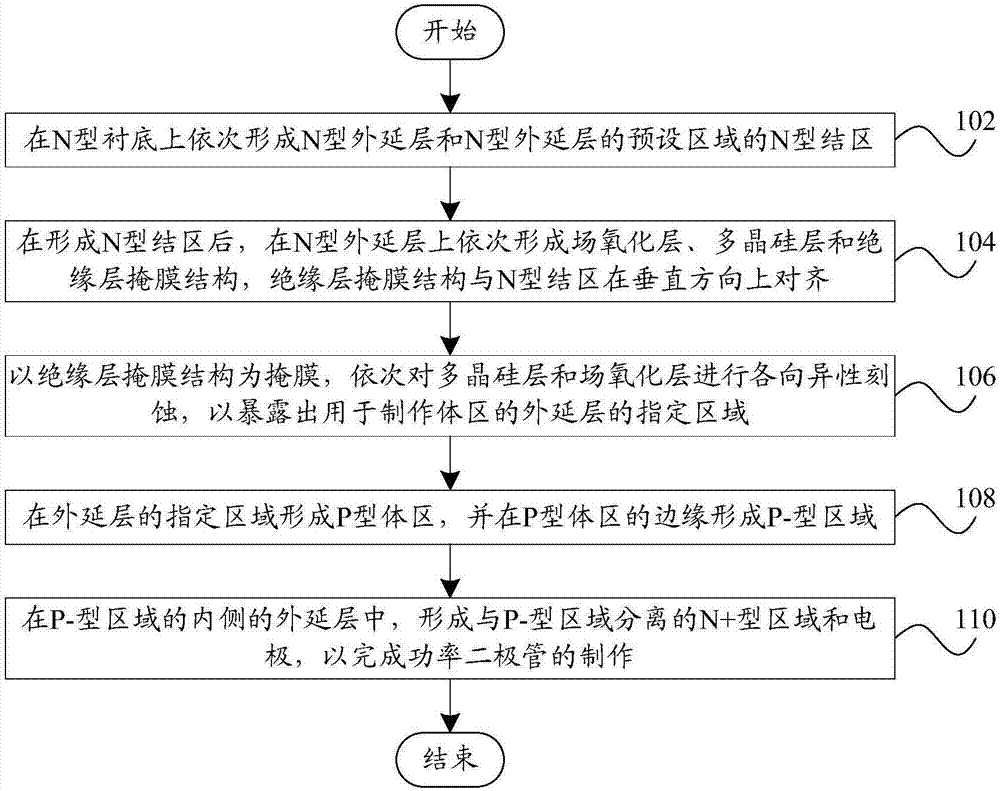

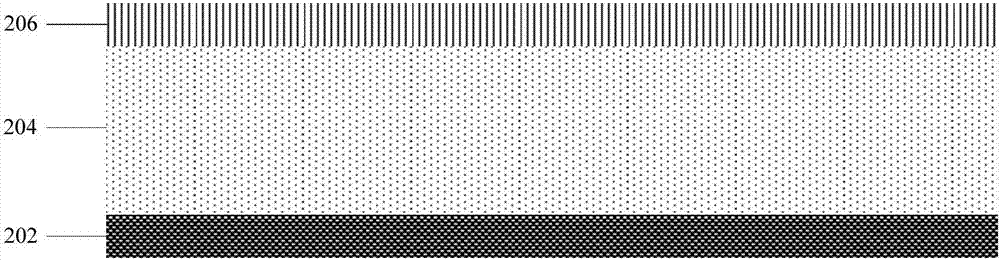

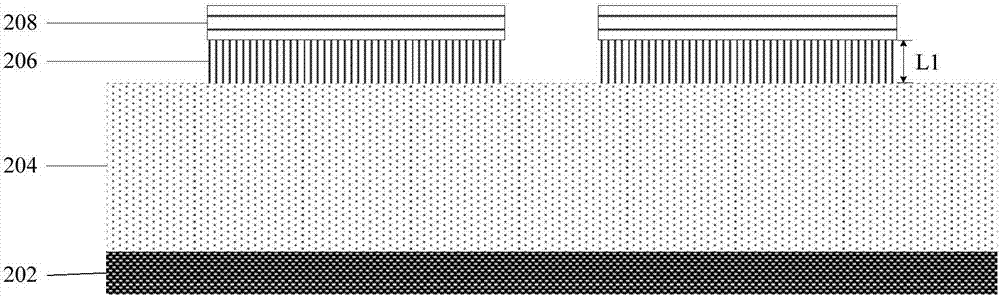

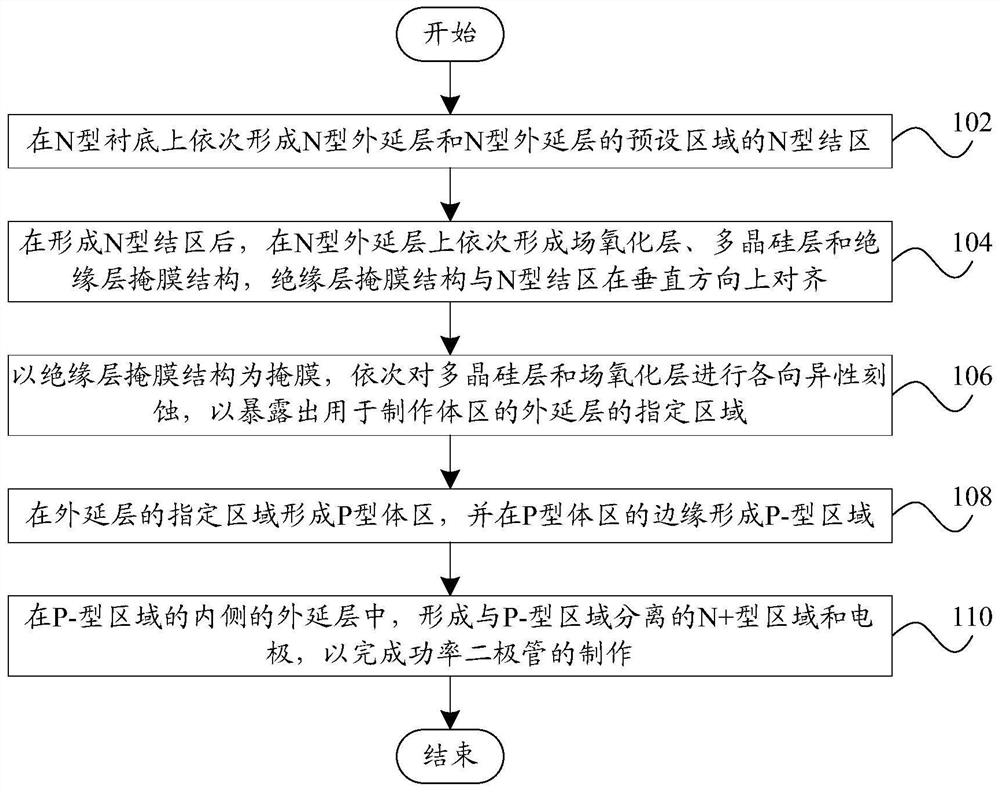

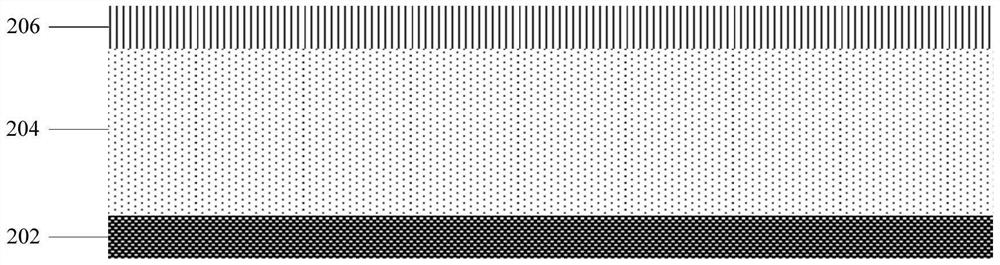

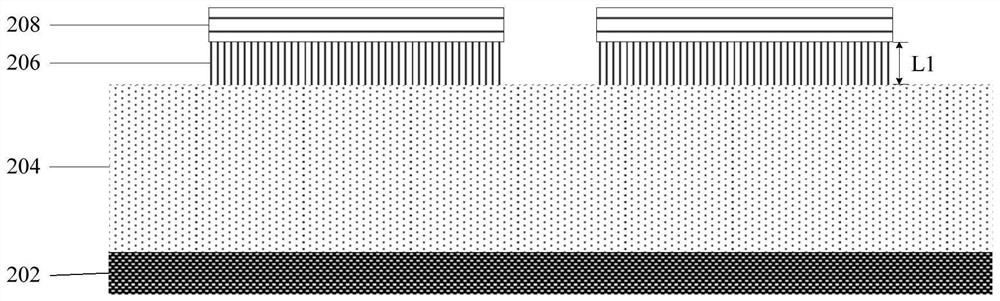

A manufacturing method of a power diode and the power diode

InactiveCN107579120AImprove reliabilityGuaranteed withstand voltage characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesPower diodeAnisotropic etching

The invention provides a manufacturing method of a power diode and the power diode, wherein the manufacturing method comprises the steps of sequentially forming an N type epitaxial layer and an N typejunction region of a preset area of the N type epitaxial layer on an N type substrate; sequentially forming a field oxide layer, a polycrystalline silicon layer and an insulating layer mask structureon the N type epitaxial layer after forming the N type junction area; and the insulating layer mask structure and the N type junction area are vertically aligned; using the insulating layer mask structure as a mask and sequentially carrying out anisotropic etching on the polycrystalline silicon layer and the field oxide layer so as to expose a designated area for manufacturing an epitaxial layerof a body region; forming a P type body region in a prescribed region of the epitaxial layer and forming a P- type region at an edge of the P type body region; and forming an N+ type area and electrode separated from the P- type area in the epitaxial layer on the inner side of the P- type area so as to complete manufacturing of the power diode. Through the technical scheme of the present invention, the on-state pressure drop of the device is reduced, and the reliability of the power diode is further raised.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

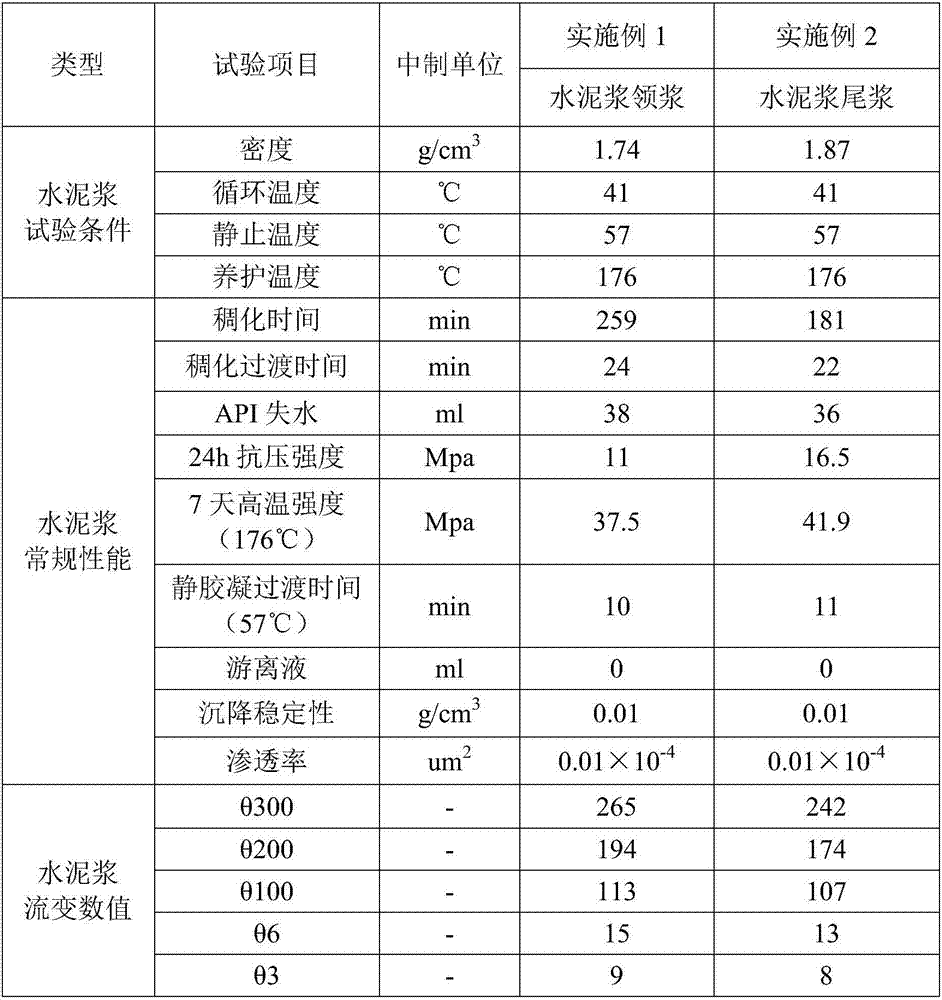

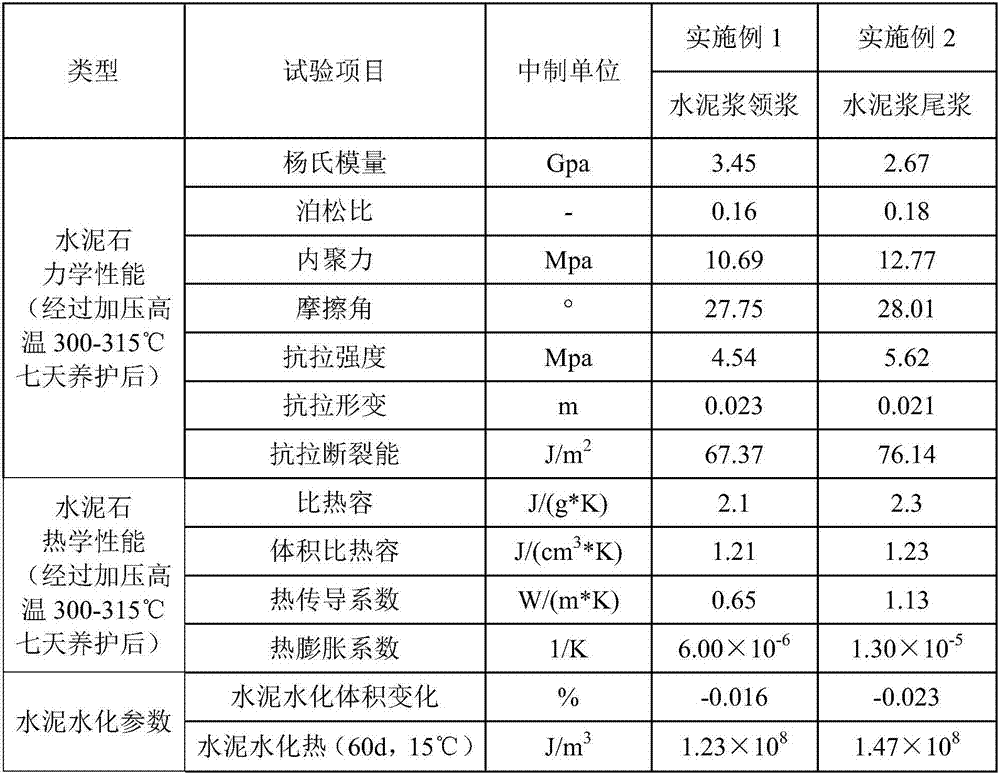

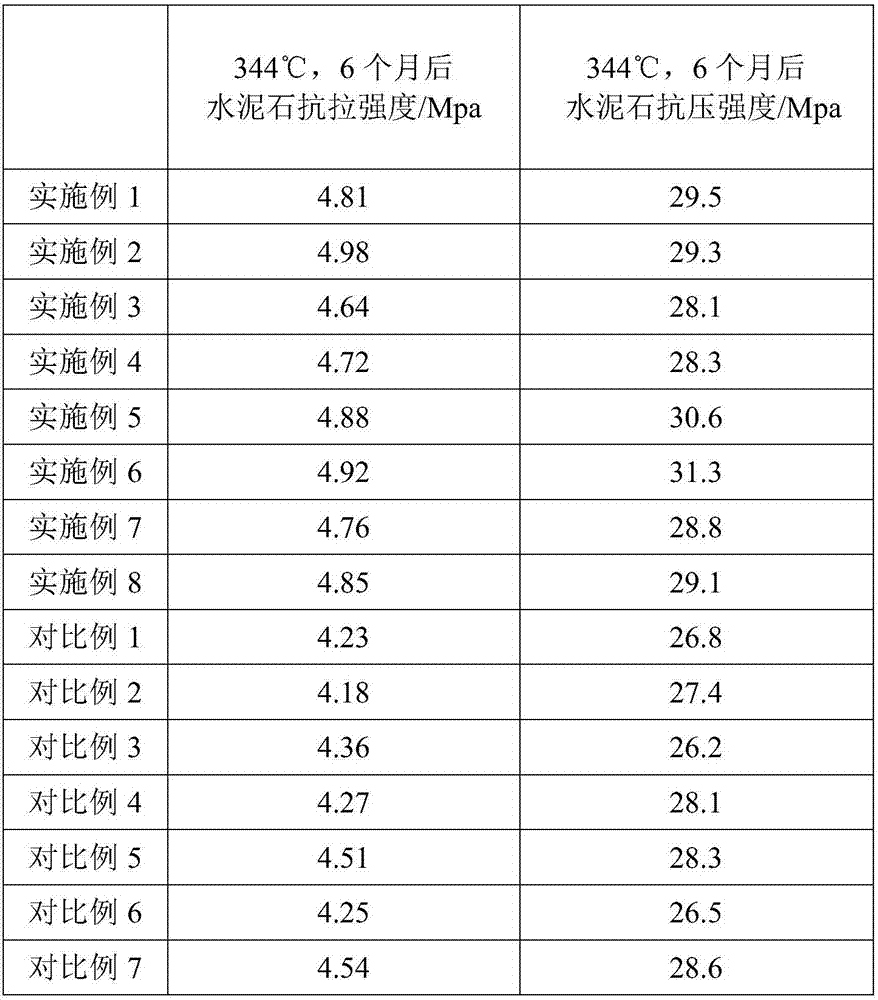

Long-term cement sheath intact type heavy oil thermal recovery well cementing cement slurry and its preparation method

ActiveCN106007545BGuaranteed general performanceEnsure that the cement slurry system has conventional comprehensive performanceDrilling compositionFiberClay minerals

The invention provides a cement slurry with long-term-integrity cement sheath for a heavy-oil thermal-recovery well. The cement slurry comprises, by weight, 100 parts of thermally responsive cement, 25 to 65 parts of water and 0.2 to 8 parts of a cement slurry aid. The thermally responsive cement comprises 30 to 60 parts of oil well cement, 10 to 20 parts of active silicon powder, 0 to 10 parts of hollow glass beads and 10 to 50 parts of a thermally responsive composite material. The thermally responsive composite material comprises 20 to 30 parts of clay mineral, 10 to 20 parts of fly ash and / or vulcanic ash, 5 to 20 parts of rubber powder and / or latex powder, 3 to 10 parts of carbon fiber, 10 to 15 parts of nanometer silicon dioxide, 5 to 10 parts of calcined magnesia, 10 to 20 parts of ultrafine superfine slag powder and 5 to 10 parts of inorganic whiskers. The cement slurry provided by the invention can solidify at normal temperature; and set cement can resist long-term high temperature, and the mechanical properties and thermal properties of the set cement in a high temperature environment are integrally adaptive to strata and casing pipes.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

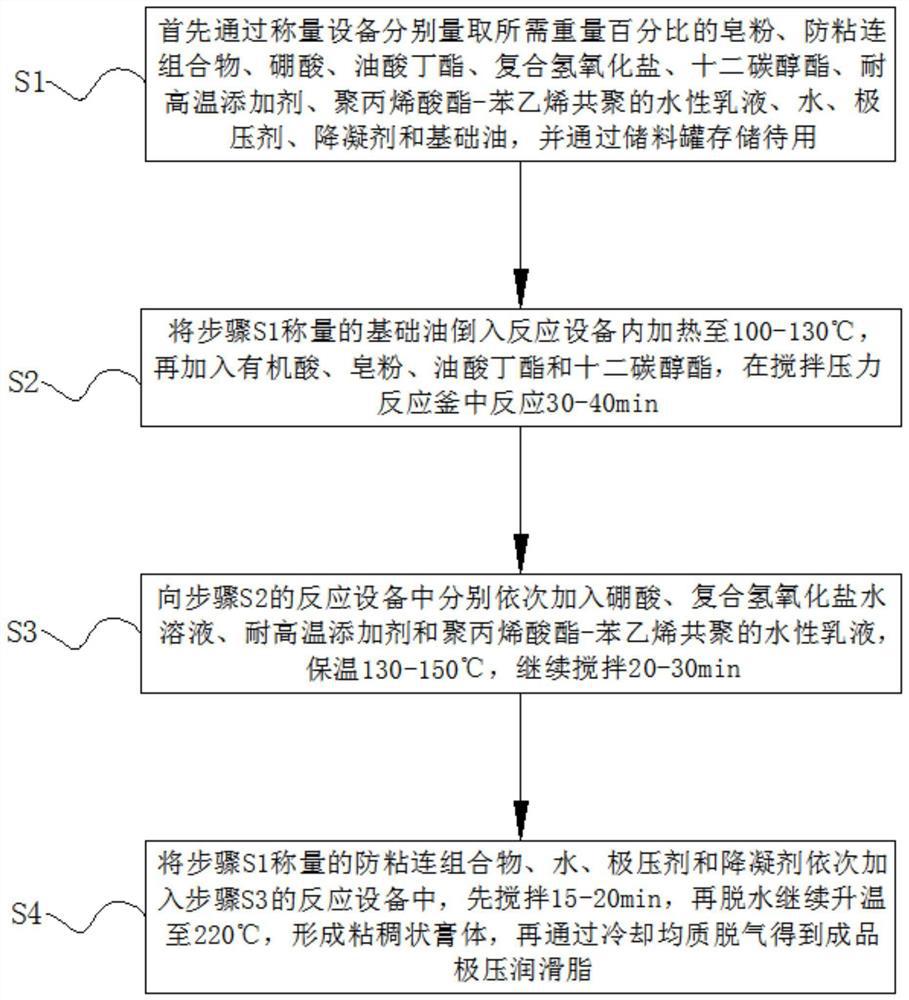

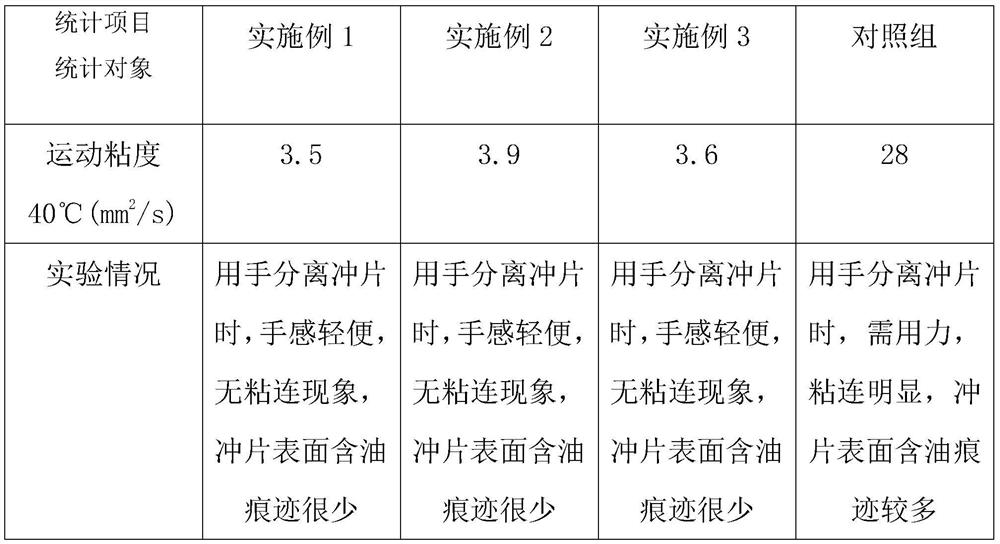

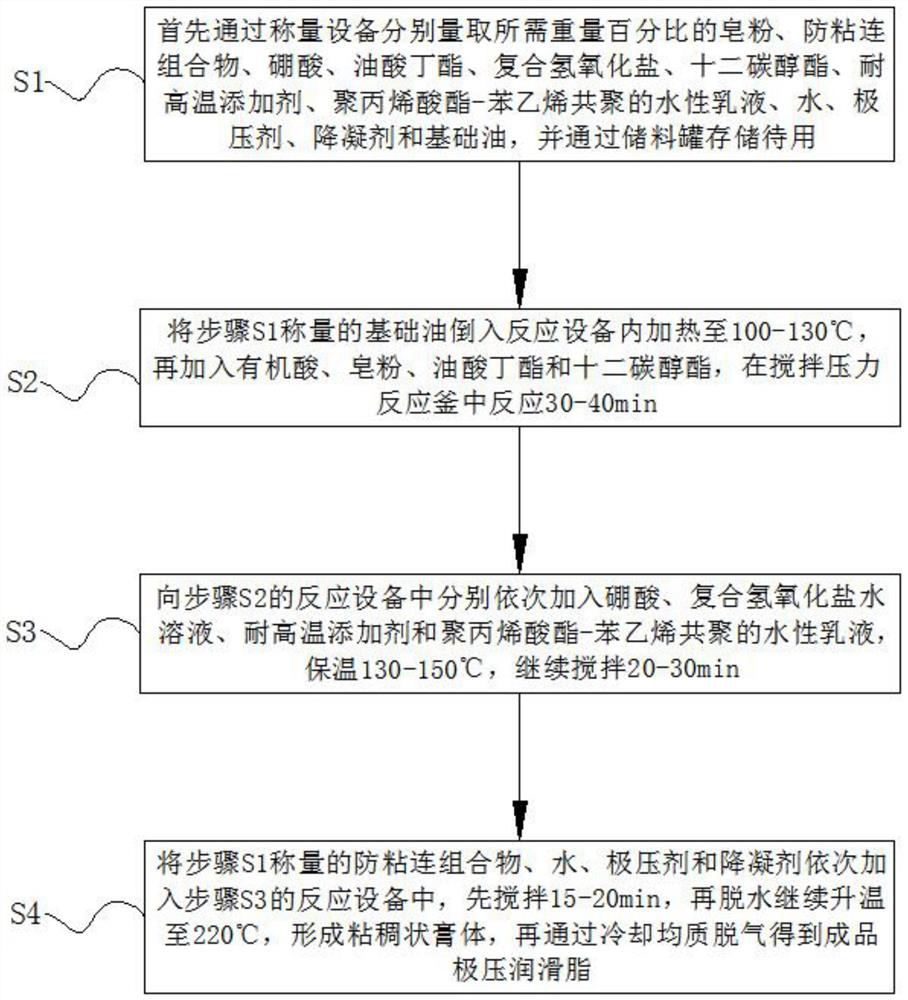

Extreme pressure lubricating grease and preparation method thereof

The invention discloses extreme pressure lubricating grease and a preparation method thereof. The lubricating oil comprises the following raw materials in percentage by weight: 10-20% of soap powder, 1-3% of an anti-adhesion composition, 5-10% of boric acid, 1-3% of butyl oleate, 1-5% of composite hydroxide salt, 1-3% of 2, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, 1.5-2.3% of a high-temperature-resistant additive, 1-3% of a polyacrylate-styrene copolymerized water-based emulsion, 1-5% of water, 0.5-1% of an extreme pressure agent, 0.5-1% of a pour point depressant and the balance of base oil, the invention relates to the technical field of lubricating grease. According to the extreme pressure lubricating grease and the preparation method thereof, the anti-adhesion effect of the lubricating grease can be improved on the basis of ensuring high temperature resistance, high pressure resistance and aging resistance of the lubricating grease, and the purpose of reducing the adhesion of the lubricating grease by adding an anti-adhesion composition and a high-carbon organic matter into the lubricating grease is well achieved; the lubricating grease is prevented from being unevenly adhered to a smeared mechanical structure in a large area, the compression resistance and the high temperature resistance of the lubricating grease are guaranteed, and the aging time and the service life of the lubricating grease are prolonged.

Owner:姚文兵

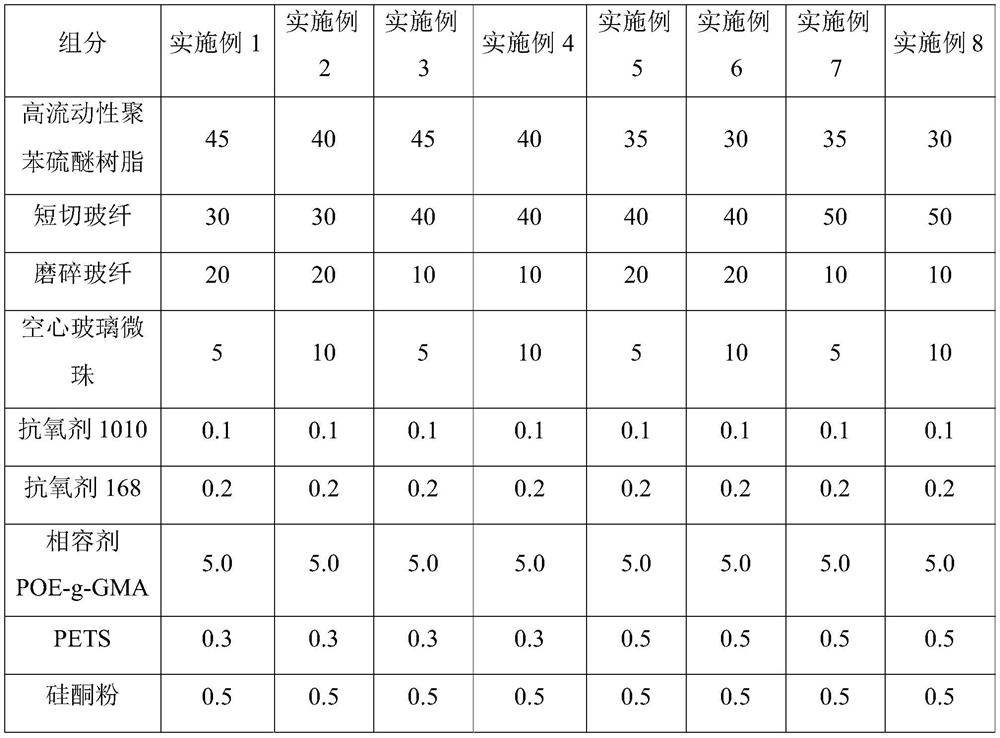

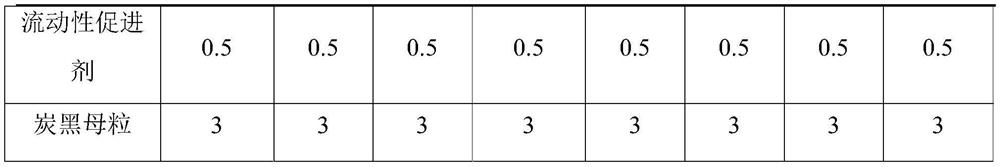

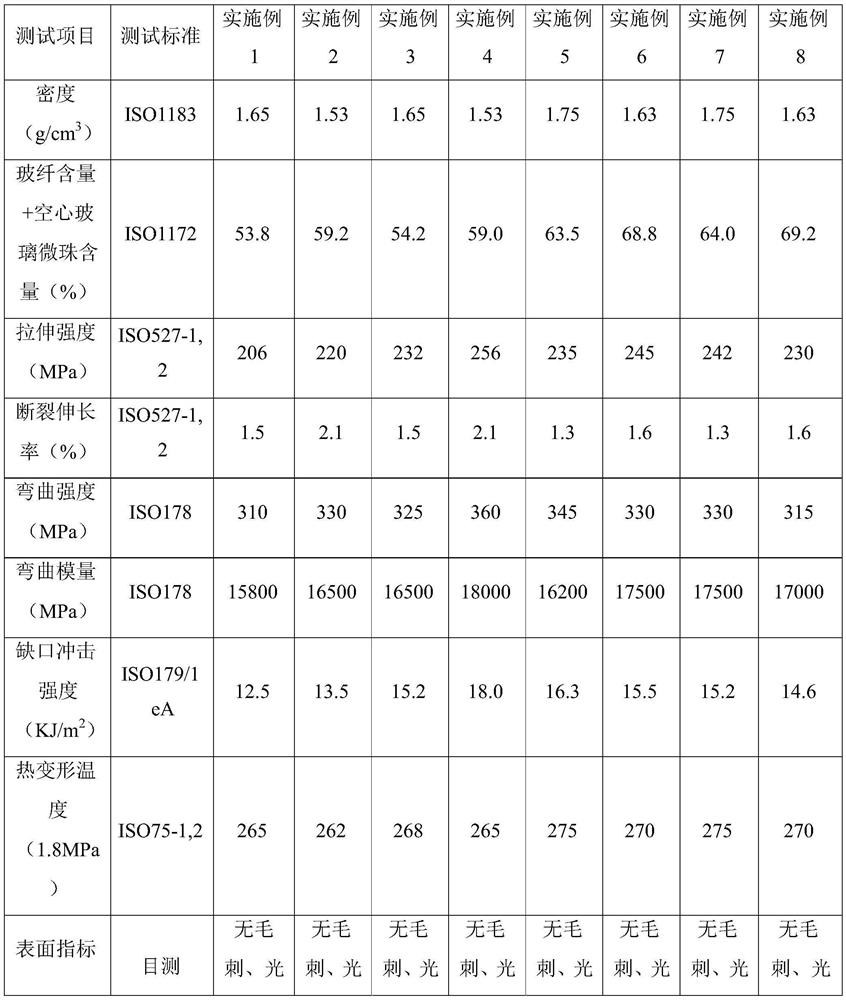

Reinforced polyphenylene sulfide composite material with low floating fiber, low warping and high glass fiber content, and preparation method thereof

PendingCN112812562AReduce manufacturing costImprove mechanical propertiesCoatingsPhenyl sulfideFiber

The invention relates to a reinforced polyphenylene sulfide composite material with low floating fiber, low warping and high glass fiber content, and a preparation method of the reinforced polyphenylene sulfide composite material, and belongs to the technical field of polyphenylene sulfide composite materials. The reinforced polyphenylene sulfide composite material provided by the invention comprises the following raw materials in parts by mass: 20-70 parts of high-fluidity polyphenylene sulfide resin, 30-50 parts of chopped glass fiber, 0.1-20 parts of ground glass fiber, 0.1-10 parts of hollow glass micro-beads, 0.1-5 parts of carbon black master batch, 0.2-1.0 part of an antioxidant, 0.2-1.0 part of a lubricant, 0.3-10.0 parts of a compatilizer, and 0.1-1.0 part of a flow promoter. According to the invention, the reinforced polyphenylene sulfide composite material with low floating fiber, low warping and high glass fiber content is smooth and flat in surface, low in floating fiber, free of obvious warping, high in glass fiber content and excellent in mechanical property; and the invention also provides a preparation method which is simple and easy to implement and reduces the production cost.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

Intelligent power distribution box

InactiveCN108864848AImprove high temperature resistanceExcellent high temperature resistance characteristics ensure high temperature resistanceAntifouling/underwater paintsConjugated diene hydrocarbon coatingsTO-18Adhesion force

The invention discloses an intelligent power distribution box and relates to the technical field of power distribution boxes. The intelligent power distribution box comprises a shell, wherein the surface of the shell is coated with protection coating; the chemical content of the protection coating is as follows in percentage by mass: 16 percent to 18 percent of MA-2 thermosetting acrylic resin, 5percent to 7 percent of polyethersulfoneketone, 3 percent to 4 percent of nitrile butadiene rubber, 0.6 percent to 0.7 percent of phosphate, 0.5 percent to 0.9 percent of a dispersant, 1.1 percent to1.4 percent of a plasticizer, 0.5 percent to 0.8 percent of silicate, 2.6 percent to 2.9 percent of an accelerator and the balance of filler and auxiliary agents. The protection coating prepared by the invention has relatively good high temperature resisting performance and corrosion resisting performance; the wear resisting performance and the adhesion force on the shell are also remarkably improved.

Owner:荣马电器有限公司

Method for preparing wear-resistant and high-temperature-resistant material

InactiveCN110746727AImprove wear resistanceImprove high temperature resistanceRubber materialPolymer science

The invention discloses a method for preparing a wear-resistant and high-temperature-resistant material and in particular relates to the field of preparation of novel materials. Main materials used inthe method comprise the following raw materials in parts by weight: 80-120 parts of acrylate rubber, 0.8-1.4 parts of stearic acid, 17-25 parts of carbon black, 4-6 parts of zinc oxide, 0.5-1.8 partsof sulfur and 10-20 parts of montmorillonite. The method comprises the following specific processing steps: preparing raw materials, crushing the raw materials, performing refining of a first round,performing refining of a second round, and vulcanizing a blank material. Due to addition of the montmorillonite and optimization of the preparation method, a rubber material of a long service life canbe prepared, and a continuous sealing effect can be ensured; in addition, on premise that the wearing resistance and the high temperature resistance of a composite material are ensured, the tensile strength of the acrylate rubber can be effectively maintained, and the property that damage is not caused by stress deformation of the acrylate rubber when the montmorillonite is added is not changed.

Owner:王佩洁

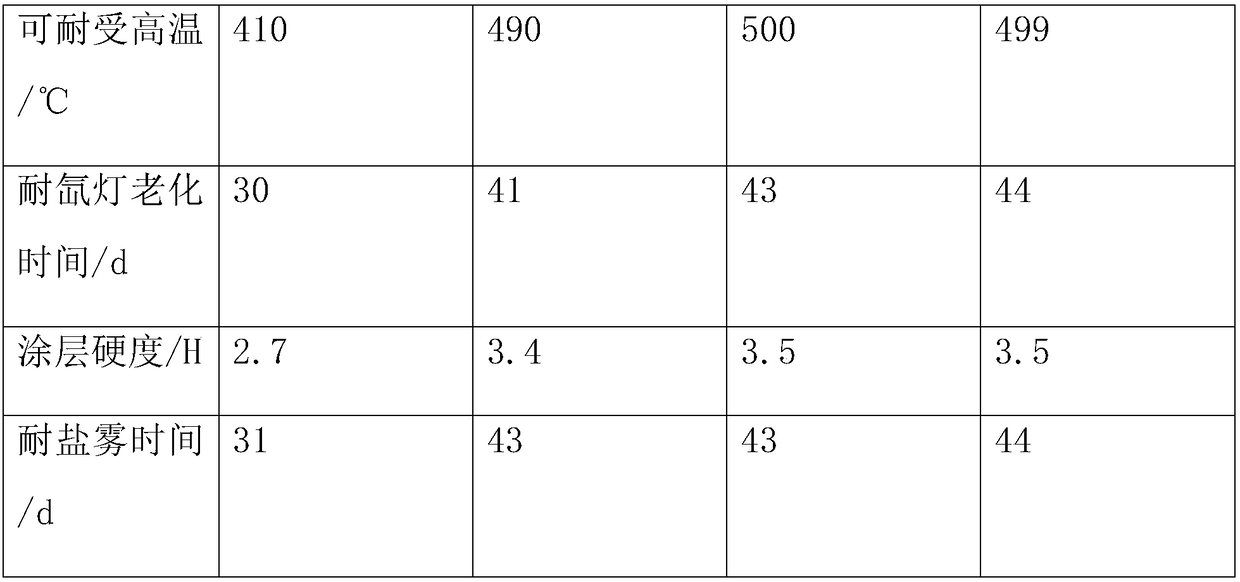

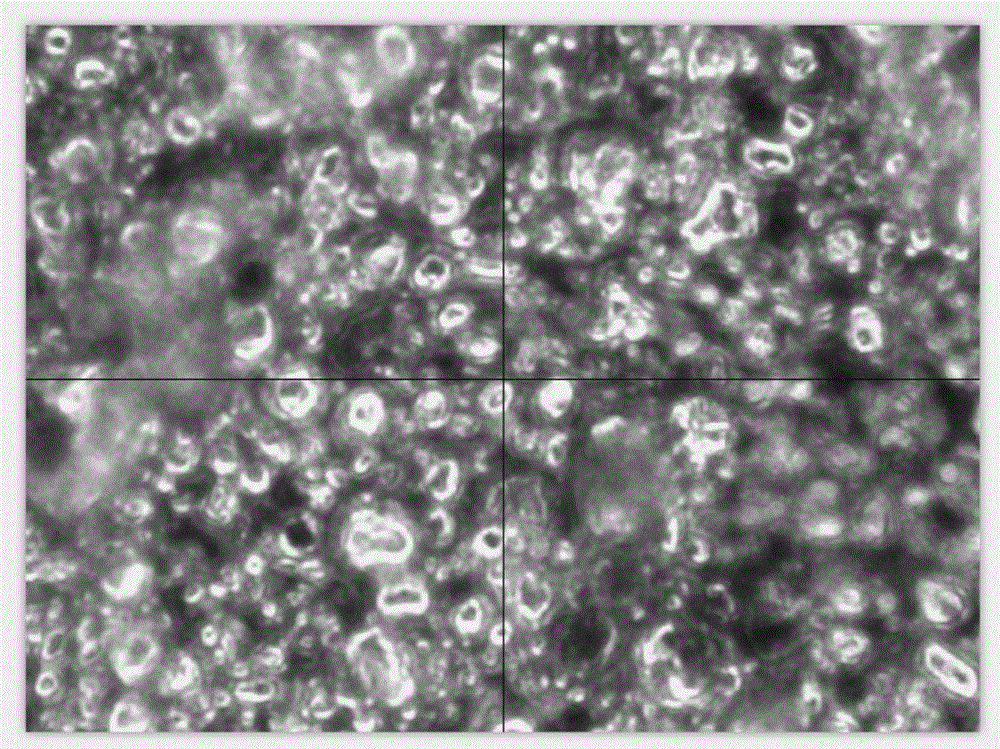

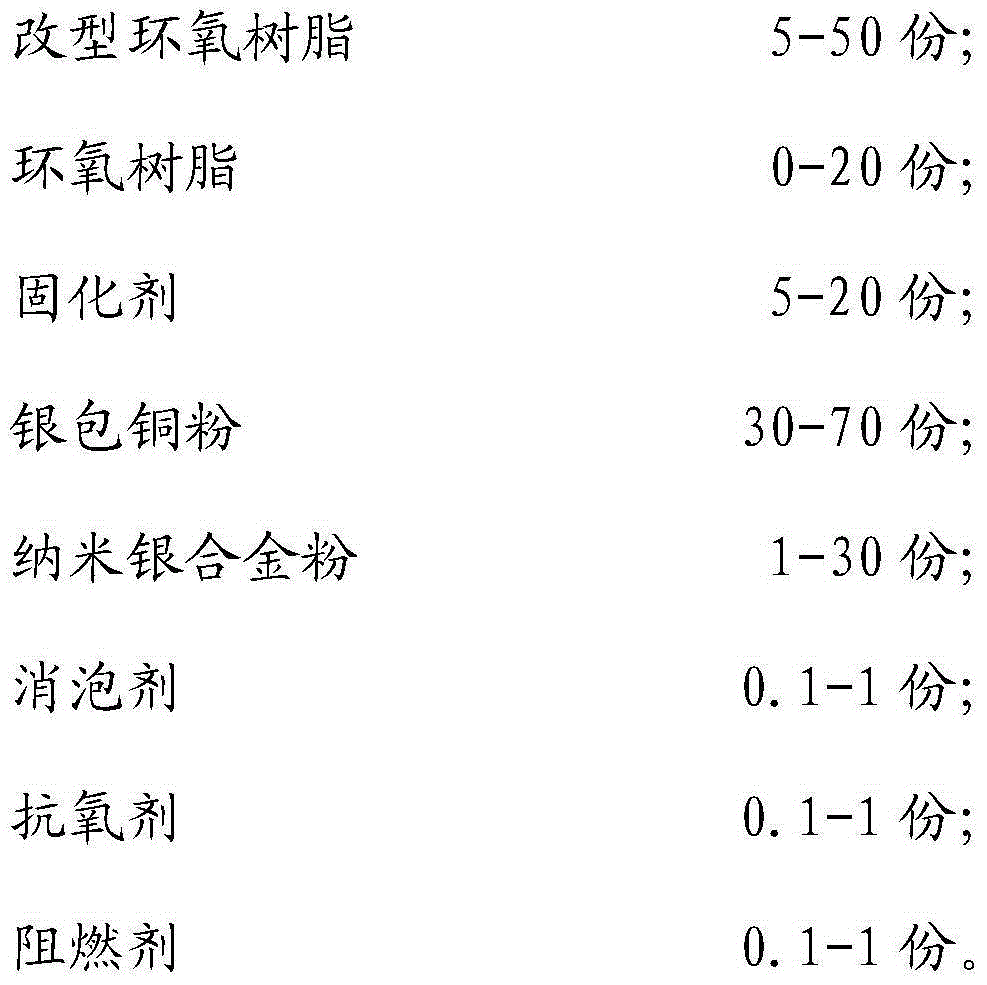

A kind of novel conductive glue and preparation method thereof

ActiveCN103980854BImprove reliabilityImprove conductivityEpoxy resin adhesivesElectrically-conducting adhesivesEpoxyScreen printing

The invention discloses a novel conductive adhesive. The novel conductive adhesive is prepared from the following raw materials in parts by weight: 5-50 parts of modified epoxy resin, 0-20 parts of epoxy resin, 5-20 parts of curing agent, 30-70 parts of silver coated copper powder, 1-30 parts of nano-silver alloy powder, 0.1-1 part of defoaming agent, 0.1-1 part of antioxidant and 0.1-1 part of flame retardant. The preparation method comprises the following steps of weighing the raw materials according to the ratio of the formula of the conductive adhesive, mixing and stirring the raw materials uniformly, finally stirring and defoaming the raw materials by using a vacuum defoaming stirrer, thereby obtaining the conductive adhesive after stirring and defoaming. The novel conductive adhesive has the characteristics of long period of use, suitable viscosity for silk screen printing, high temperature resistance, low expansion coefficient, high conductivity and long shelf time.

Owner:深圳明阳电路科技股份有限公司

Aryl-1,3,5-triazine polyarylester and preparation method thereof

ActiveCN102585186BHigh mechanical strengthGuaranteed high temperature resistanceSilicon organic compoundsLiquid mediumPolymer science

The invention discloses an aryl-1,3,5-triazine polyarylester and a preparation method thereof, and belongs to the technical field of polymer science. The aryl-1,3,5-triazine polyarylester is characterized in that a macromolecular main chain contains a structural unit like the general formula I. The aryl-1,3,5-triazine polyarylester with high molecular weight, excellent thermal stability and good mechanical strength can be conveniently and rapidly prepared with disilyl ester compound disclosed by the invention and commercial aromatic bisphenol monomer as polycondensation monomers and / or other commercial disilyl ester compounds added at the same time as copolycondensation monomers by the step of step-by-step polycondensation in a high-boiling-point inert liquid medium or in a molten / solid phase state. The polyarylester resins can be used in the fields of heat resistance paints, coating, adhesives, separation membranes, composite materials and the like, and have wide application prospects.

Owner:CENT SOUTH UNIV

Extreme pressure lubricating grease and preparation method thereof

The preparation method specifically comprises the following steps: S1, burdening, S2, primary reaction, S3, secondary reaction, and S4, sequentially adding an anti-adhesion composition, water, an extreme pressure agent and a pour point depressant weighed in the step S1 into reaction equipment in the step S3, stirring for 15-20 minutes, dehydrating, continuously heating to 220 DEG C to form viscous paste, and cooling to room temperature to obtain the extreme pressure lubricating grease. The invention relates to the technical field of lubricating grease. According to the extreme pressure lubricating grease and the preparation method thereof, the anti-adhesion effect of the lubricating grease can be improved on the basis of ensuring high temperature resistance, high pressure resistance and aging resistance of the lubricating grease, and the purpose of reducing the adhesion of the lubricating grease by adding an anti-adhesion composition and a high-carbon organic matter into the lubricating grease is well achieved; the lubricating grease is prevented from being unevenly adhered to a smeared mechanical structure in a large area, the compression resistance and the high temperature resistance of the lubricating grease are guaranteed, and the aging time and the service life of the lubricating grease are prolonged.

Owner:TIANJIN JINHAILI GREASE CO LTD

Adhesive metal pond porcelain glaze

ActiveCN103693852BHigh temperature resistantGuaranteed high temperature resistanceFritTemperature resistance

The invention discloses a metal enamel glaze with strong adherence, comprising an enamel base coat and an enamel cover glaze. According to the metal enamel glaze with strong adherence disclosed by the invention, the enamel base coat is coated on a green body, so that the green body has the characteristic of high-temperature resistance, and simultaneously has better corrosion resistance, and the glaze surface can keep the characteristic of corrosion resistance for a long period of time in a high-temperature environment.

Owner:佛山市中成釉料有限公司

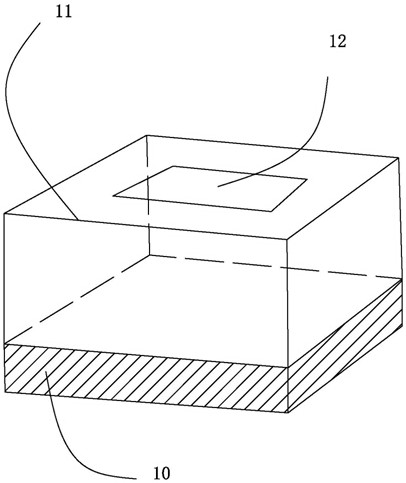

Reversible temperature display paint and preparation method, fuse fuse core and fuse

ActiveCN108467659BRealize self-cleaning functionImprove liquidityAntifouling/underwater paintsPaints with biocidesWorking temperatureColor changes

The invention relates to the technical field of fuses, specifically to a reversible temperature-indicating paint and a preparation method thereof, and a fusible fuse core and a fuse. The intelligent early-warning fuse provided by the invention has the following advantages: the fuse is simultaneously monitored and warned through monitoring of a plurality of parameters, so a worker is helped to do relative preparation work in advance; through detachable arrangement of a shell, a fusible core and an electrode, the intelligent early-warning fuse can be continuously used by replacement of the fusecore, so the cost of usage is saved; meanwhile, a storage groove is arranged to store fusible cores with different sizes, so the use flexibility of the fuse is improved; and through detachable combination of a ceramic material and transparent plastic, the weight of the shell is reduced, and high-temperature resistance and reliability of the shell can be guaranteed. The preparation method for the fusible fuse core provided by the invention has the following advantages: through coating of a temperature-indicating layer, a worker can conveniently observe color changes and pays attention to the working temperature of the fuse in real time, so adjustment is realized in advance.

Owner:SUZHOU MAICHUANG INFORMATION TECH

A kind of heat-resistant self-adhesive enameled wire varnish and preparation method thereof

ActiveCN104559752BGuaranteed high temperature resistanceCompatible with thermoplastic processing propertiesEpoxy resin coatingsEpoxyPolyetherimide

The invention relates to heat-resistant self-adhesive enamelled wire paint. The heat-resistant self-adhesive enamelled wire paint disclosed by the invention comprises the following raw materials in parts by weight: 160-350 parts of dimethylbenzene, 430-620 parts of N-methylpyrrolidone, 169-191 parts of polyetherimide resin, 10-18.3 parts of boron phenolic resin, 19-33.8 parts of phenol formaldehyde epoxy resin, and 0.2-0.3 part of a slipping agent. The heat-resistant self-adhesive enamelled wire paint disclosed by the invention has good heat resistance and wet-sticky-resistant property, and can meet production requirements under high-temperature and high-humidity weather conditions.

Owner:江苏佳禾电子材料有限公司

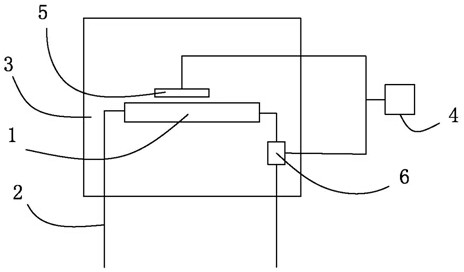

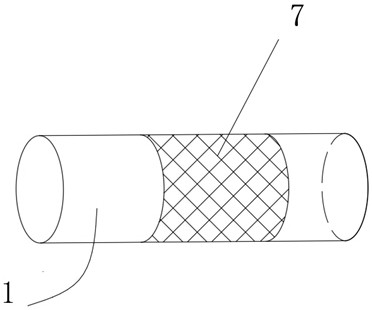

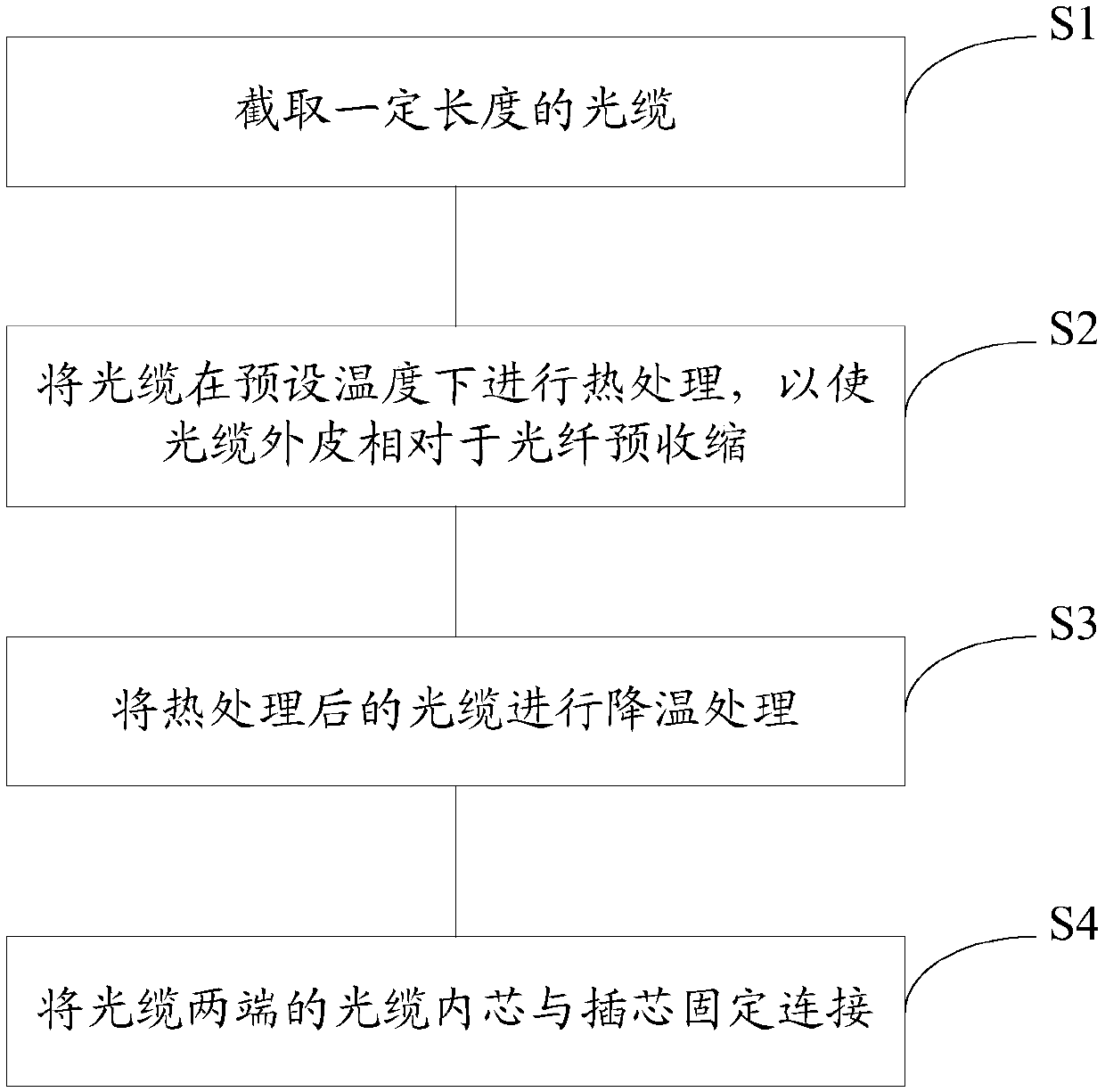

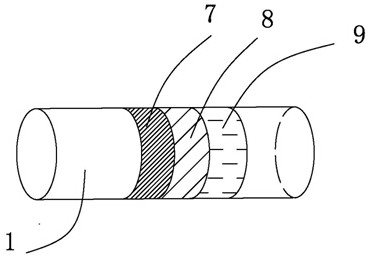

A kind of optical cable preparation method

ActiveCN106125217BGuaranteed high temperature resistanceImprove signal transmission performanceFibre mechanical structuresOptical fiber cableHeat treated

An optical cable preparation method disclosed by the present invention comprises the steps of S1 intercepting an optical cable of a certain length; S2 processing the optical cable thermally under a preset temperature to pre-shrink the scarfskin of the optical cable relative to an optical fiber; S3 cooling the optical cable after the thermal processing; S4 fixedly connecting the inner core at the two ends of the optical cable with a ferrule. According to the present invention, by processing the scarfskin of the optical cable thermally, the scarfskin of the optical cable pre-shrinks relative to the inner core of the optical cable, and subsequently, the scarfskin of the optical cable does not shrink again when passing a high temperature, thereby not damaging the inner core of the optical cable, guaranteeing the high temperature resistant capability of the optical cable, and improving the signal transmission effect of the optical cable.

Owner:SUZHOU AGIX OPTICAL TECH COMPANY

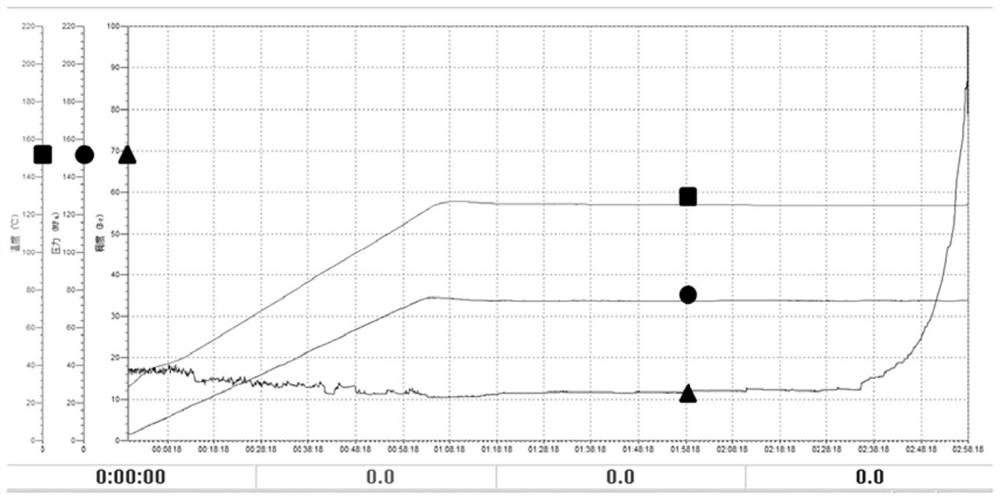

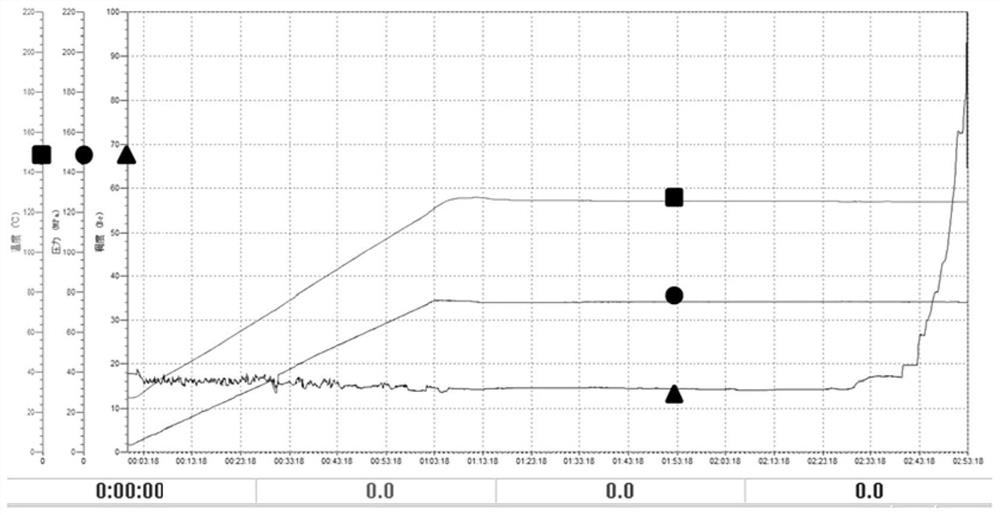

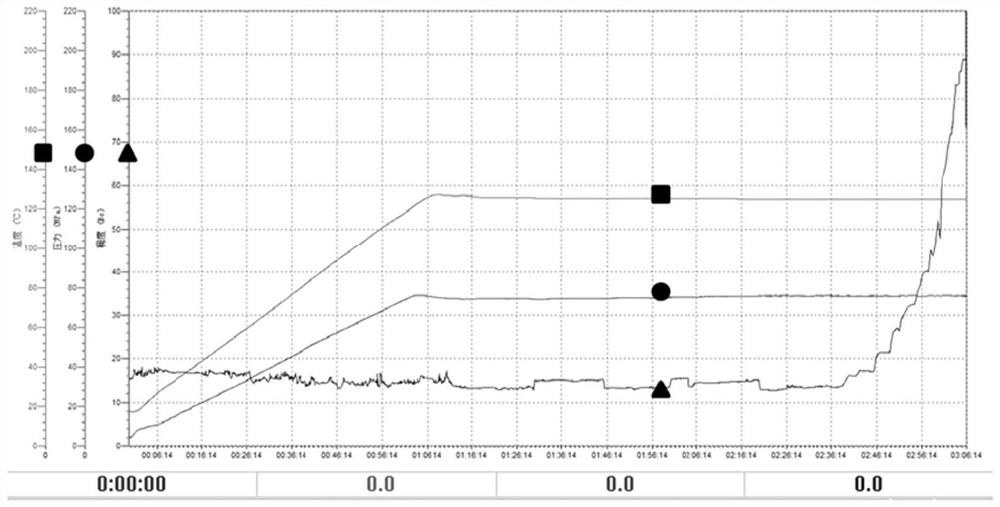

Multistage adsorption polymer fluid loss agent and preparation method thereof

ActiveCN114292634AImprove the \"drum kit\"Improve the phenomenon of \"core wrapping\"Drilling compositionPolymer scienceBiopolymer

The invention discloses a multistage adsorption polymer fluid loss agent and a preparation method thereof, and belongs to the technical field of oil field chemicals and additives for oil well cement well cementation. The multistage adsorption polymer fluid loss agent comprises the following components in percentage by weight: 35%-60% of a biopolymer, 20%-40% of a terpolymer and 10%-30% of a quadripolymer. The multi-stage adsorption polymer fluid loss agent provided by the invention can be used for ultra-high-temperature deep well cementation, the applicable temperature can reach 30-210 DEG C, and the multi-stage adsorption polymer fluid loss agent can effectively inhibit poor stability of cement paste caused by excessive dispersion at high temperature and improve the condition of abnormal gelatinization of the cement paste caused by excessive strong adsorption groups; the adaptability of the polymer fluid loss agent in an oil well cement slurry system is improved.

Owner:成都欧美克石油科技股份有限公司

High temperature and high pressure resistant packaging method for downhole communication device of coiled tubing drilling rig

ActiveCN102797456BImprove high pressure performanceGuaranteed high temperature resistanceConstructionsCoiled tubingSoldering

The invention discloses a high temperature and high pressure resistant packaging method for an underground communication device of a coiled tubing drilling machine, which is characterized by comprising the following steps of: making an underground communication circuit board by using a high temperature resistant printed board, high temperature resistant soldering tin and a high temperature resistant circuit element; packaging the underground communication circuit board into an outer pressure resistant cylinder; and providing a high temperature resistant connector assembly for the connection between the underground communication device and an optical cable. The high temperature and high pressure resistant packaging method for the underground communication device of the coiled tubing drilling machine has the beneficial effects that the underground communication device is packaged into the outer pressure resistant cylinder so that the high pressure resistance of the communication device is improved; the printed board, the soldering tin and the circuit element which can stably work in a high temperature environment are adopted so that the high temperature strength of the communication device is improved; a reliable informationized data basis is provided for the drilling construction, the drilling control precision and safety are improved, and the drilling control efficiency is increased; in addition, the high temperature and high pressure resistant packaging method for the underground communication device of the coiled tubing drilling machine has the characteristics of good sealing performance, simplicity in operation, low in cost and the like.

Owner:SICHUAN HONGHUA ELECTRIC

Preparation method of power diode and power diode

InactiveCN107579120BImprove reliabilityGuaranteed withstand voltage characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesPower diodeEngineering

The invention provides a manufacturing method of a power diode and the power diode, wherein the manufacturing method comprises the steps of sequentially forming an N type epitaxial layer and an N typejunction region of a preset area of the N type epitaxial layer on an N type substrate; sequentially forming a field oxide layer, a polycrystalline silicon layer and an insulating layer mask structureon the N type epitaxial layer after forming the N type junction area; and the insulating layer mask structure and the N type junction area are vertically aligned; using the insulating layer mask structure as a mask and sequentially carrying out anisotropic etching on the polycrystalline silicon layer and the field oxide layer so as to expose a designated area for manufacturing an epitaxial layerof a body region; forming a P type body region in a prescribed region of the epitaxial layer and forming a P- type region at an edge of the P type body region; and forming an N+ type area and electrode separated from the P- type area in the epitaxial layer on the inner side of the P- type area so as to complete manufacturing of the power diode. Through the technical scheme of the present invention, the on-state pressure drop of the device is reduced, and the reliability of the power diode is further raised.

Owner:PEKING UNIV FOUNDER GRP CO LTD +1

An intelligent early warning fuse

ActiveCN108508321BIncreased flexibility of useReduce weightFuses testingShort-circuit testingWorking temperatureMechanical engineering

The invention relates to the technical field of fuses, in particular to an intelligent early warning fuse and a method for preparing a fusible core of the early warning fuse. The fuse is monitored andearly warned by monitoring multiple parameters simultaneously, and thus workers are helped to make relevant preparation work in advance. A housing is detachably arranged, the fusible core and an electrode are detachably arranged, the fuse can be continuously used only by replacing the fusible core, and the use cost is saved. In addition, different specifications of fusible cores are stored by forming storage grooves, and the use flexibility of the fuse is also improved. By detachably combining a ceramic material and a transparent plastic, the high temperature resisting characteristic and reliability of the fuse can be also ensured while the weight of the housing is lightened. According to the method for preparing the fusible core of the early warning fuse, workers can conveniently pay close attention to the working temperature of fuses by coating multiple coating sections and observing color change of temperature layers in real time, and thus advanced adjustment is made.

Owner:东莞市安都电子有限公司

A kind of high temperature resistant insulating coating and its preparation method and application

The invention discloses a high-temperature-resistant insulation coating and a preparation method and application thereof. Slurry for preparing the high-temperature-resistant insulation coating is at least prepared from the following components in parts by mass: (a) 100 parts of polysilazane resin, (b) 1-100 parts of polysiloxane resin containing active functional groups, (c) 5-100 parts of a filler, and (d) 0-10 parts of an assistant. By adopting the polysilazane resin as a primary film forming substance and adopting the polysiloxane resin containing the active functional groups as a secondaryfilm forming substance, the high-temperature-resistant property is ensured, and the coating also has good tenacity; the preparation method is simple and does not rely on special equipment; the temperature-resistant property of the high-temperature-resistant insulation coating prepared through the method can be appropriately adjusted according to actual needs so as to adapt to different application fields; and the preparation method is wide in application range and can be suitable for various insulation objects, strips, pipes, wires and the like.

Owner:北京和尔泰新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com