Asphalt anti-stripping agent as well as preparation and application methods thereof

An anti-stripping agent and anti-stripping technology, which is applied in the field of asphalt additives, can solve problems such as insufficient water resistance and poor high temperature resistance, and achieve the effects of improving service life, ensuring water resistance and high temperature resistance, and short mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

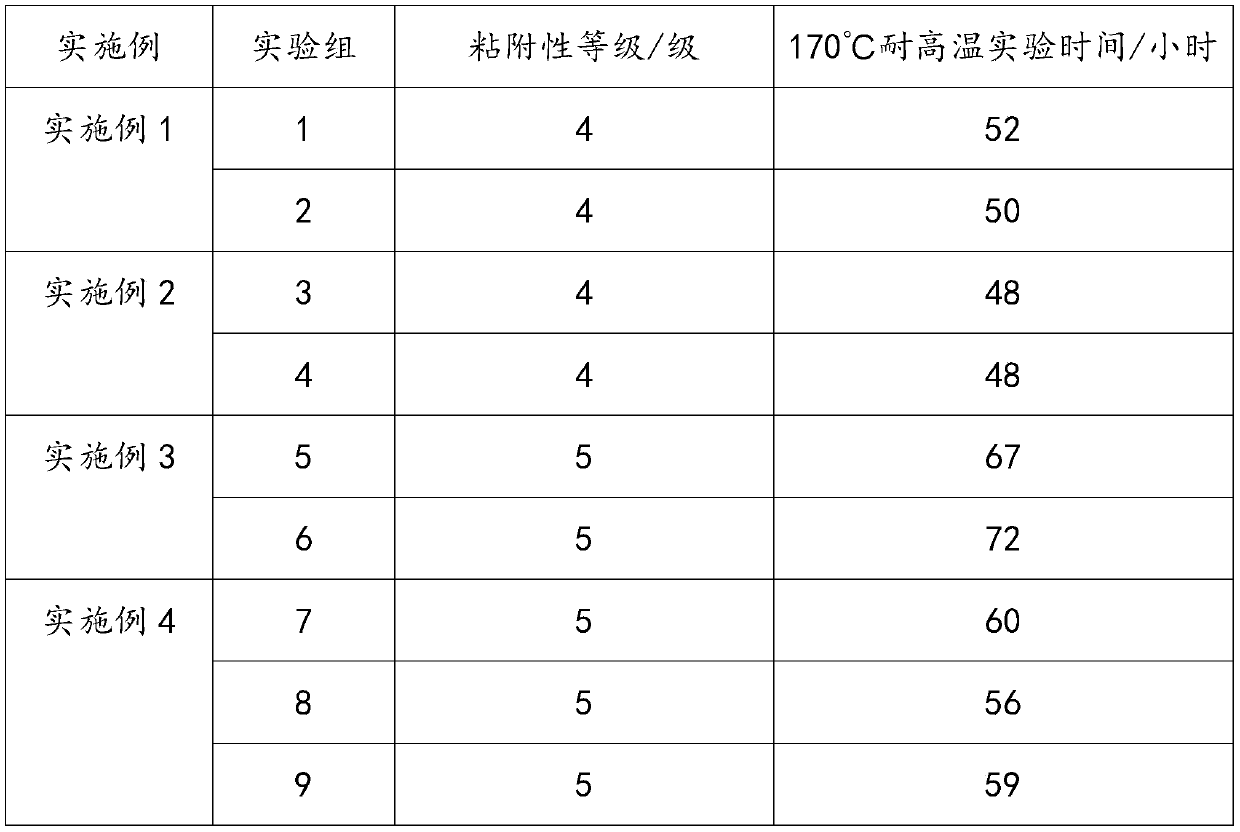

Examples

Embodiment 1

[0023] This embodiment provides an asphalt anti-stripping agent, which comprises 3.7 parts of paraffin wax, 4.2 parts of fatty acid, and 5.5 parts of sodium lignosulfonate in parts by mass.

[0024] The preparation method of the above-mentioned asphalt anti-stripping agent is as follows: adding paraffin wax, fatty acid and sodium lignosulfonate into a mixer according to the mass ratio, and stirring at a temperature of 90° C. until uniformly mixed.

[0025] The application method of the above-mentioned asphalt anti-stripping agent is as follows: by weight percentage, heat 99% of the base asphalt to 220° C., add 1% of the prepared asphalt anti-stripping agent, and stir and mix at a temperature of 220° C. for 3 hours.

Embodiment 2

[0027] This embodiment provides an asphalt anti-stripping agent, which comprises 6.5 parts of paraffin wax, 2.2 parts of fatty acid, and 2.5 parts of sodium lignosulfonate in parts by mass.

[0028] The preparation method of the above-mentioned asphalt anti-stripping agent is as follows: adding paraffin wax, fatty acid and sodium lignosulfonate into a mixer according to the mass ratio, and stirring at a temperature of 70° C. until uniformly mixed.

[0029] The application method of the above-mentioned asphalt anti-stripping agent is as follows: by weight percentage, heat 98% of the base asphalt to 220° C., add 2% of the prepared asphalt anti-stripping agent, and stir and mix at a temperature of 220° C. for 3 hours.

Embodiment 3

[0030] Embodiment 3: This embodiment provides an asphalt anti-stripping agent, which includes 4 parts of paraffin wax, 3 parts of fatty acid, and 3 parts of sodium lignosulfonate in parts by mass.

[0031] The preparation method of the above-mentioned asphalt anti-stripping agent is as follows: adding paraffin wax, fatty acid and sodium lignosulfonate into a mixer according to the mass ratio, and stirring at a temperature of 80° C. until uniformly mixed.

[0032] The application method of the above-mentioned asphalt anti-stripping agent is as follows: by weight percentage, heat 98.5% of the base asphalt to 220°C, add 1.5% of the prepared asphalt anti-stripping agent, and stir and mix at a temperature of 220°C for 3 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com