A kind of high temperature resistant insulating coating and its preparation method and application

An insulating coating and high-temperature-resistant technology, applied in the field of materials, can solve problems such as limited application range, dependence, and difficulty in controlling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

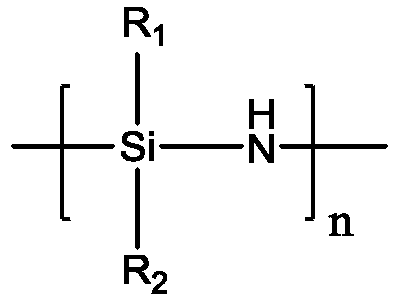

[0061] Take by weighing 100 mass parts of polysilazane resin (OPZ108), adopt 25 mass parts of xylenes to dissolve it and prepare a polysilazane resin solution whose mass fraction is 80wt%, and weigh 10 mass parts of polysiloxane Resin, make it evenly mixed with polysilazane resin, set aside. Add 30 parts by mass of mica powder, 20 parts by mass of talc powder, 15 parts by mass of zirconium boride, 0.5 part by mass of wetting and dispersing agent, and 1 part by mass of anti-settling agent at a rotational speed of 500 r / min. Stir for 40 minutes, ball mill through a ball mill jar until the coating fineness is 35 μm, and set aside.

[0062] Apply it to the surface of a clean steel sheet (8cm*2cm*0.25cm) by spraying, dry in an oven at 160°C for 2 hours, and take it out to obtain a high temperature resistant insulating coating. The thickness of the coating is 30 μm, the adhesion is grade 0, the flexibility is grade 1, the impact resistance is 50kg cm, the dielectric constant in the...

Embodiment 2

[0065] Take by weighing 100 mass parts polysilazane resin (PSN1), adopt the xylene of 25 mass parts to dissolve it, be mixed with the organopolysilazane resin solution that mass fraction is 80wt%, weigh 20 mass parts polysilicon Oxane resin, make it evenly mixed with polysilazane resin, set aside. Add 10 parts by mass of titanium dioxide, 10 parts by mass of mica powder, 40 parts by mass of glass powder, 0.3 parts by mass of a wetting and dispersing agent, and 1 part by mass of an anti-settling agent at a rotational speed of 800 r / min. Stir for 30 minutes, ball mill through a ball mill jar until the coating fineness is 35 μm, and set aside.

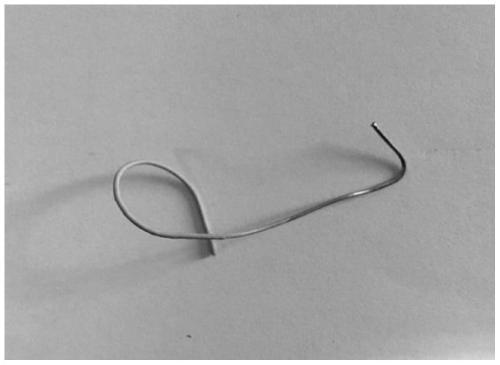

[0066] Apply it to thin conductive wires by dip coating On the surface, dry it in an oven at 230°C for 2 hours, and take it out to obtain a high temperature resistant insulating coating. The thickness of the coating is 11μm, and the insulation voltage is 1000V;

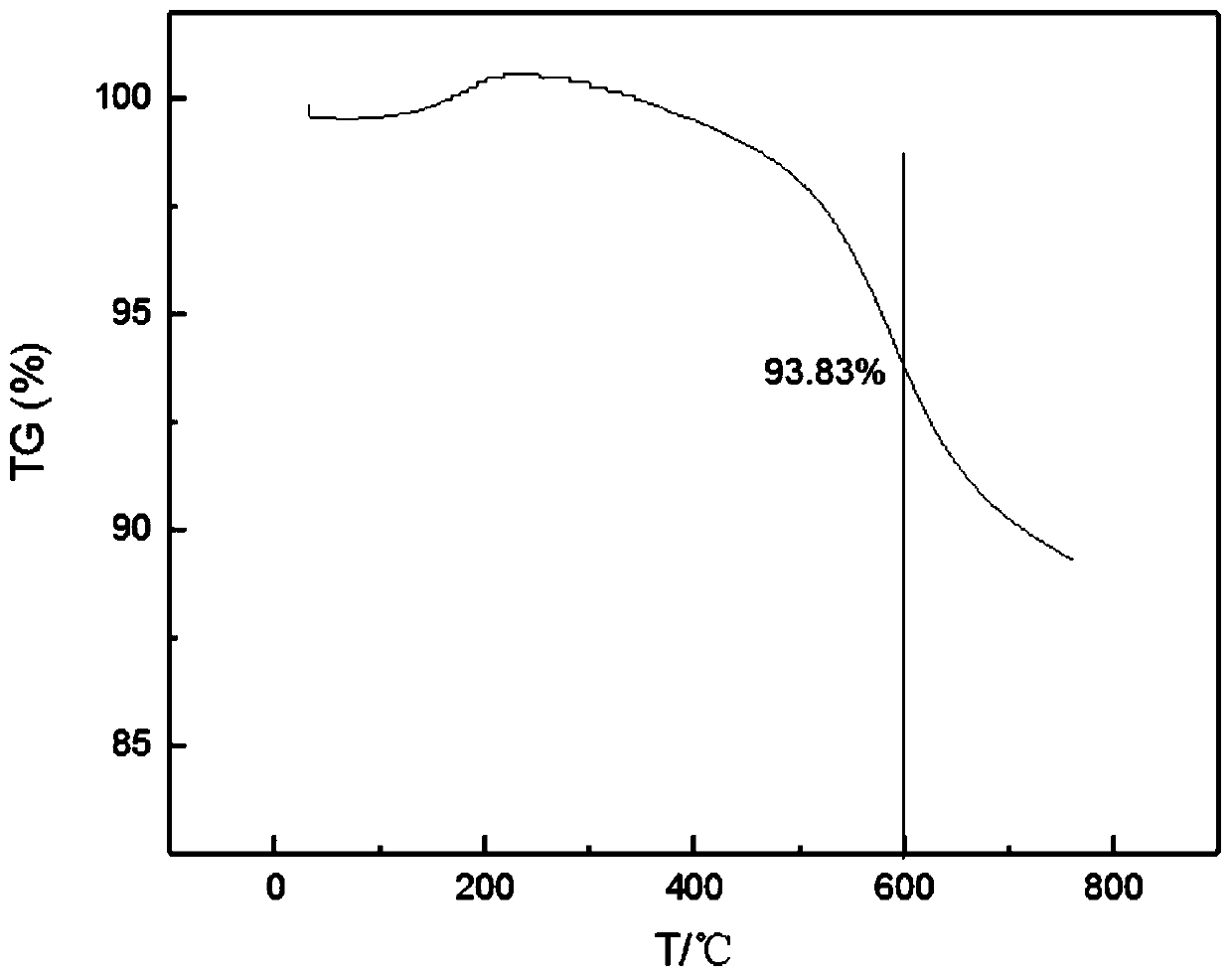

[0067] After the coating was baked at 600°C for 2 hours, the thickness o...

Embodiment 3

[0069] Take by weighing 100 mass parts of polysilazane resin (PHPS), adopt 400 mass parts of toluene to dissolve, be mixed with the polysilazane resin solution that mass fraction is 20wt%, weigh the polysiloxane resin of 1 mass part, Mix it evenly with polysilazane resin and set aside. 20 parts by mass of fumed silica were added at a rotational speed of 500 r / min. Stir for 30min and set aside.

[0070] Apply it to thin conductive wires by dip coating On the surface, dry it in an oven at 200°C for 2 hours, and take it out to obtain a high temperature resistant insulating coating. The thickness of the coating is 1 μm, and the insulation voltage is 300V;

[0071] After the coating is baked at 500°C for 2 hours, the thickness of the coating remains unchanged and the insulation voltage is 200V. It shows that the thin coating still has excellent insulation after being baked at high temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com