Capacitive sensor

A capacitive sensor and cable technology, which is applied in the field of sensors, can solve the problems of high cost, sudden change in capacitance value, and high process difficulty, and achieve the effects of ensuring high temperature resistance, convenient online monitoring, and reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

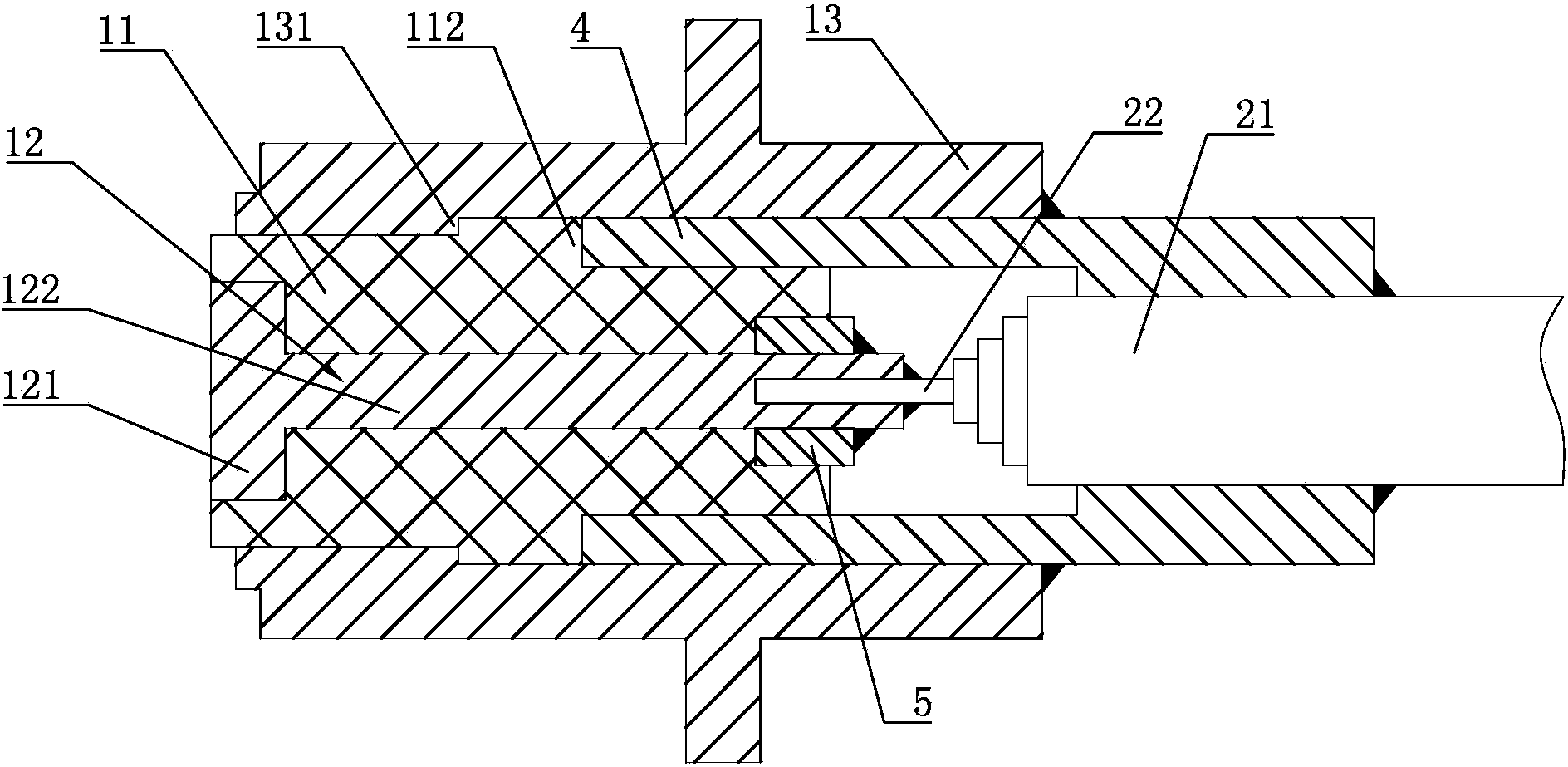

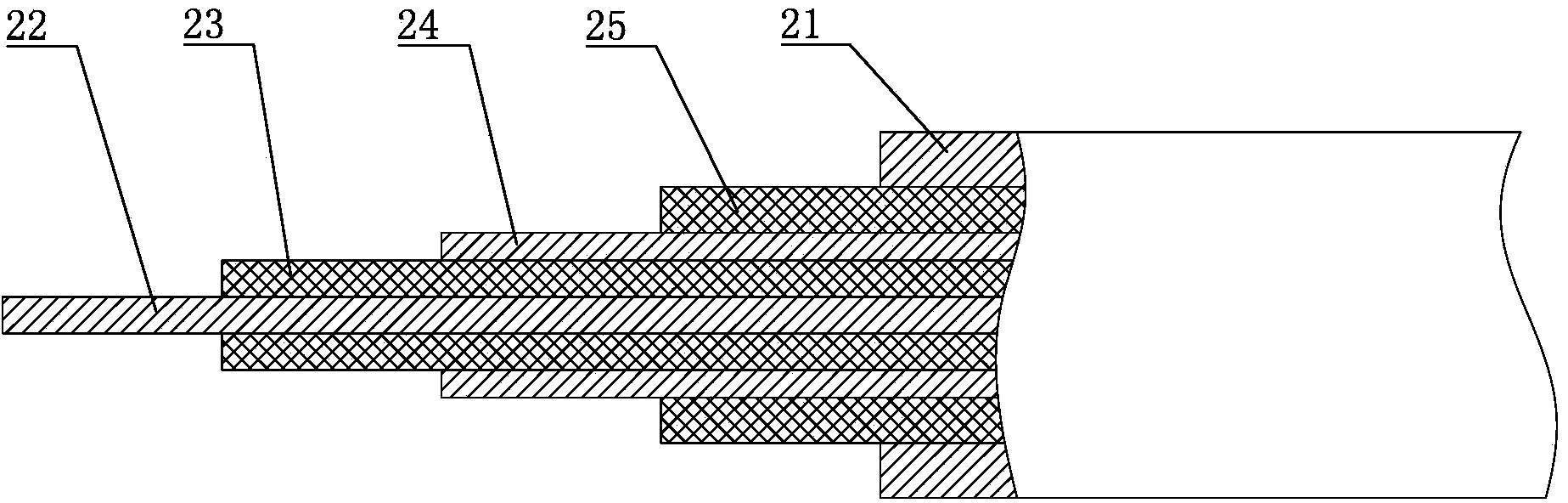

[0016] Embodiment 1: a capacitance sensor, including a high temperature probe, a high temperature hard cable and a low temperature flexible cable, such as figure 1 As shown, the high-temperature probe includes a ceramic insulating ring 11 using 99 alumina ceramics and a core pole 12 and a metal jacket 13 of Kovar alloy with the closest thermal expansion coefficient to 99 alumina ceramics. On the ring wall of the ceramic insulating ring 11 The wall thickness D at the thinnest part is D=0.2mm. The core pole 12 includes a clamping ring 121 and a connecting rod 122. One end of the ceramic insulating ring 11 is provided with a clamping cavity matching the clamping ring 121. The high temperature hard cable It includes a metal outer shielding layer 21 and a high-temperature core wire 22, the high-temperature core wire 22 is fixedly connected to the connecting rod 122 by laser welding, the outer wall of the ceramic insulating ring 11 is provided with a positioning convex ring 112 protr...

Embodiment 2

[0019] Embodiment 2: The remaining parts are the same as Embodiment 1, except that the value of the outer diameter of the high-temperature core wire 22 is 0.6 mm, the value of the wall thickness of the high-temperature inner insulating layer 23 is 0.4 mm, and the value of the high-temperature inner shielding layer 24 is 0.6 mm. The value of the layer wall thickness is 0.3 mm, the value of the layer wall thickness of the high-temperature outer insulating layer 25 is 1.1 mm, and the value of the layer wall thickness of the metal outer shielding layer 21 is 0.32 mm.

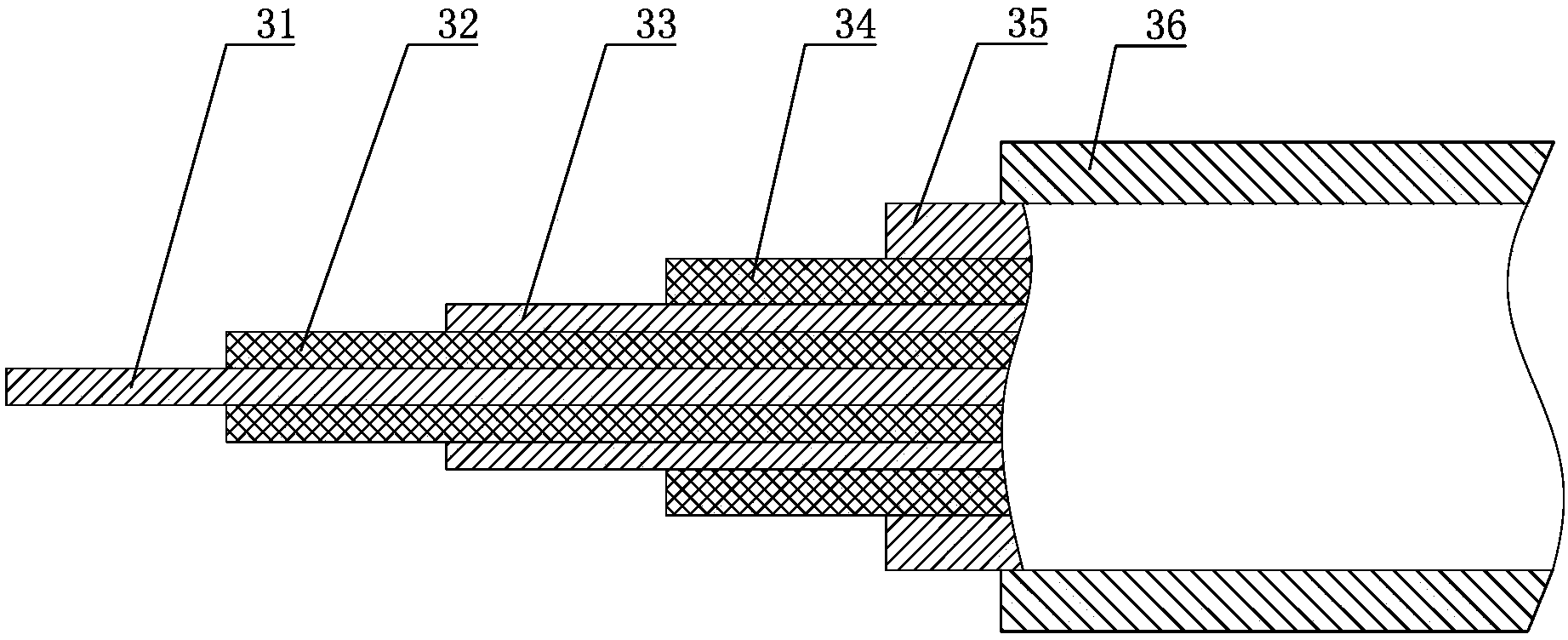

[0020] The value of the outer diameter of the low-temperature core wire 31 is 0.3 mm, the value of the wall thickness of the low-temperature inner insulating layer 32 is 0.4 mm, the value of the wall thickness of the low-temperature inner shielding layer 33 is 0.4 mm, and the value of the layer wall thickness of the low-temperature outer insulating layer 34 is 0.4 mm. The wall thickness has a value of 1.5 mm, and the...

Embodiment 3

[0021] Embodiment 3: the rest is the same as Embodiment 1, the difference is that the value of the outer diameter of the high temperature core wire 22 is 0.4 mm, the value of the wall thickness of the high temperature inner insulating layer 23 is 0.3 mm, and the value of the high temperature inner shielding layer 24 is 0.4 mm. The value of the layer wall thickness is 0.25 mm, the value of the layer wall thickness of the high temperature outer insulating layer 25 is 0.8 mm, and the value of the layer wall thickness of the metal outer shielding layer 21 is 0.26 mm.

[0022]The value of the outer diameter of the low-temperature core wire 31 is 0.25 mm, the value of the wall thickness of the low-temperature inner insulating layer 32 is 0.3 mm, the value of the layer wall thickness of the low-temperature inner shielding layer 33 is 0.3 mm, and the value of the layer wall thickness of the low-temperature outer insulating layer 34 is 0.3 mm. The wall thickness has a value of 1 mm, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com