A kind of optical cable preparation method

A technology of optical cable and optical fiber, which is applied in the field of optoelectronic communication, can solve the problems of optical cable sheath shrinkage, damage, optical fiber bending, etc., and achieve the effects of avoiding optical fiber rupture, improving signal transmission effect, and ensuring high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

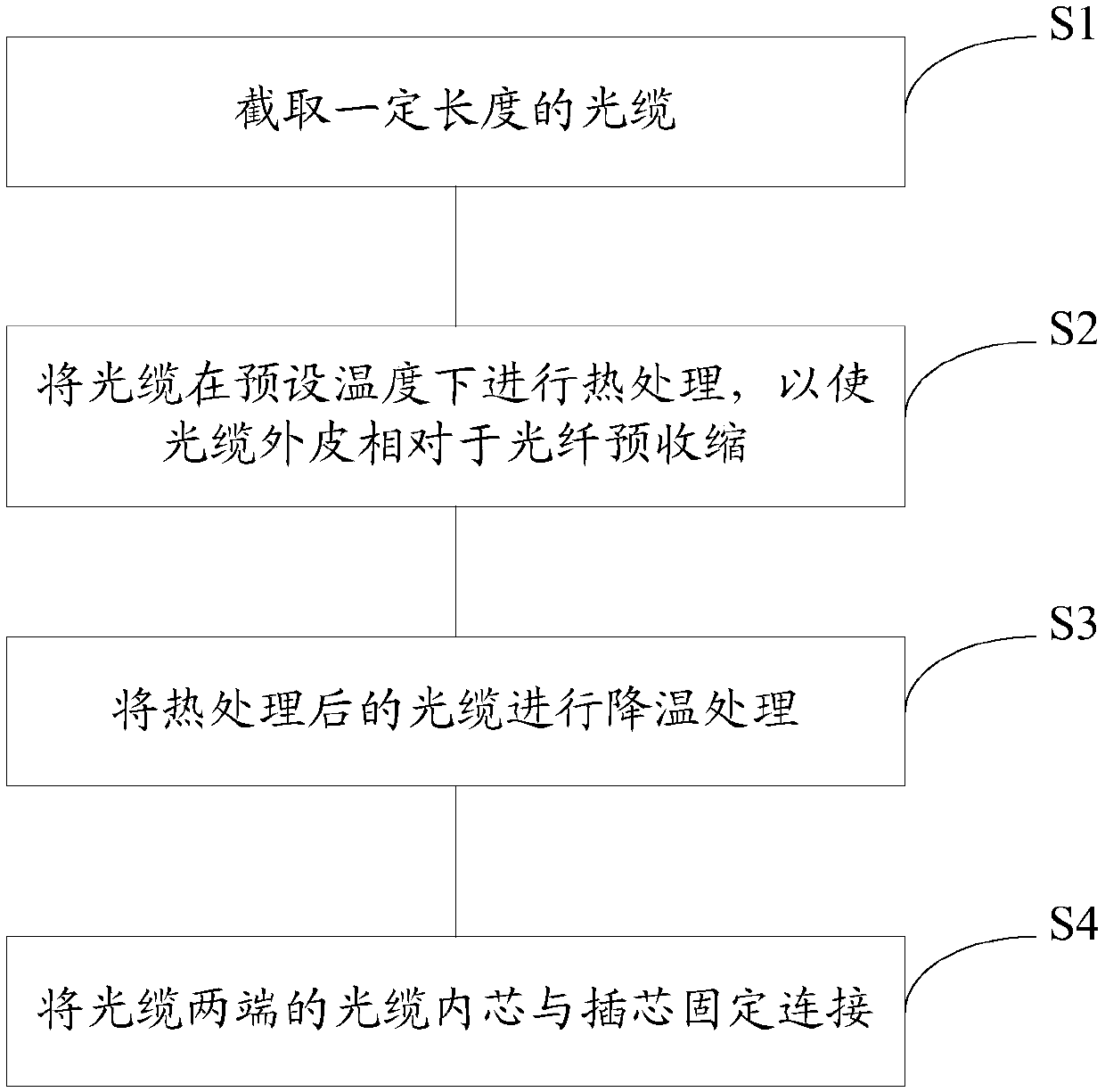

[0036] ginseng figure 1 As shown, the invention discloses a method for preparing an optical cable, comprising the following steps:

[0037] S1, intercepting a certain length of optical cable;

[0038] S2, performing heat treatment on the optical cable at a preset temperature, so that the outer sheath of the optical cable is pre-shrunk relative to the optical fiber;

[0039] S3, performing cooling treatment on the heat-treated optical cable;

[0040] S4. Fixedly connect the inner core of the optical cable at both ends of the optical cable to the ferrule.

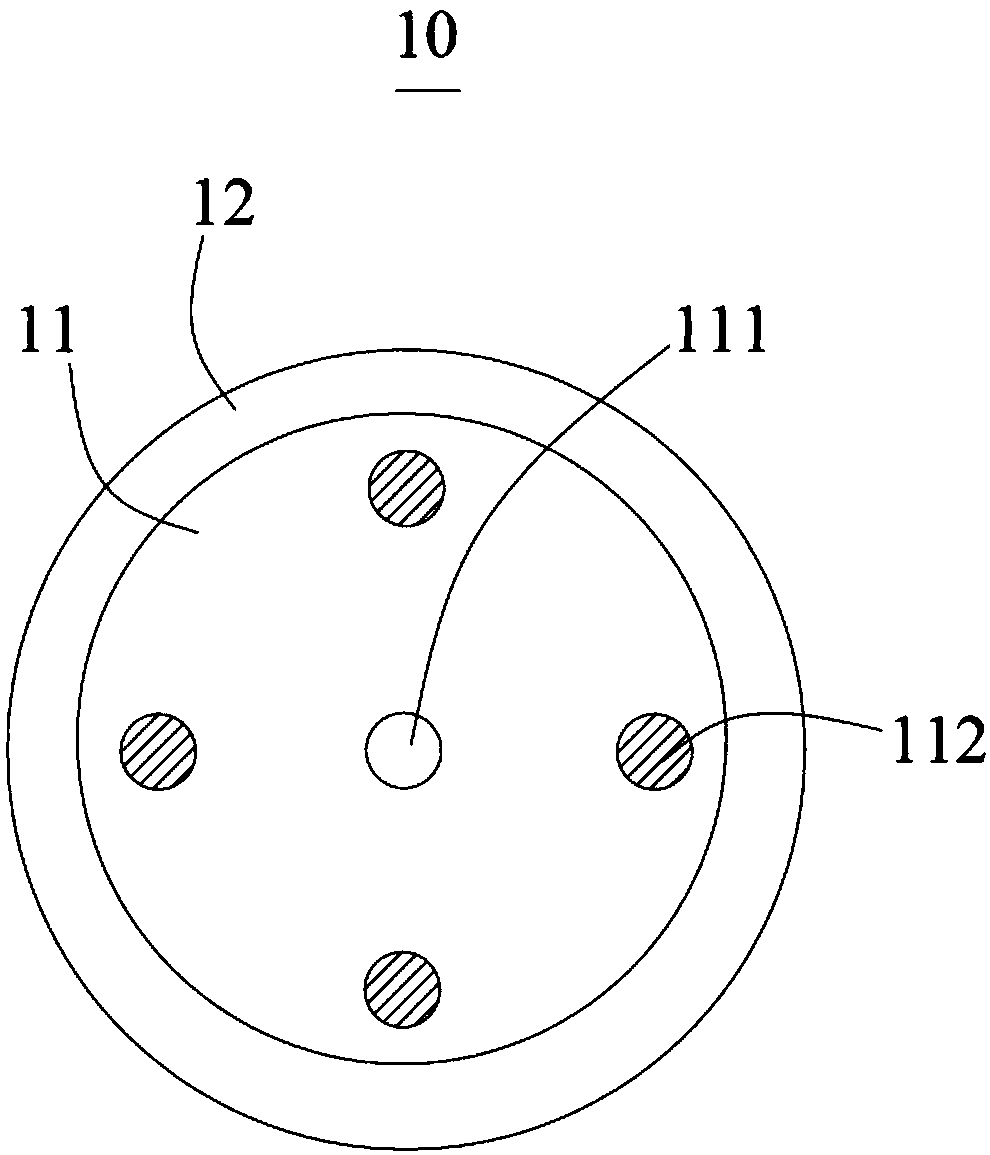

[0041] ginseng figure 2 As shown, the optical cable 10 of the present invention includes an optical cable inner core 11 and an optical cable sheath 12 , the optical cable inner core 11 includes at least one optical fiber 111 for information transmission and multiple strands of aramid fibers 112 evenly distributed around the optical fiber 111 . Through the multi-strand aramid fiber evenly distributed around the optical fi...

no. 1 approach

[0051] In a first embodiment of the present invention, a method for preparing an optical cable includes the following steps:

[0052] 1.1, intercept a certain length of optical cable, the optical cable includes the inner core of the optical cable and the sheath of the optical cable, the optical cable in this embodiment is OFNP (indoor single-mode optical cable), or OFNR (multi-mode indoor optical cable), or LSZH (low-smoke, halogen-free, flame-retardant fiber optic cable);

[0053] 1.2. Coil the optical cable according to the preset specifications, then place the coiled optical cable in an oven, control the temperature in the oven to 70°C, and heat-treat for 1 hour to pre-shrink the outer sheath of the optical cable relative to the optical fiber;

[0054] 1.3. Remove the heat-treated optical cable from the oven, perform cooling treatment, and cool to room temperature;

[0055] 1.4. Apply adhesive to the inner core of the optical cable and the ferrule at both ends of the optic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com