High temperature and high pressure resistant packaging method for underground communication device of coiled tubing drilling machine

A technology of a communication device and a packaging method, applied in the direction of construction, etc., can solve problems such as affecting the normal operation of the underground communication system, increasing the hidden danger of drilling construction safety, limiting drilling efficiency, etc., and achieving the effects of low cost, good sealing performance, and improved accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

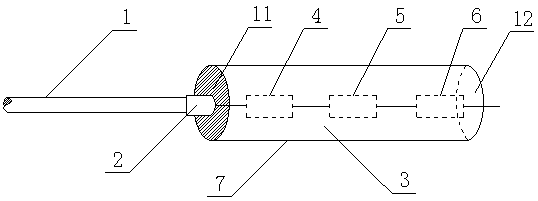

[0024] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0025] A high-temperature-resistant and high-pressure-resistant packaging method for a downhole communication device of a coiled tubing drilling rig, which includes the following features:

[0026] (1) Select high temperature resistant printed boards, solder and circuit components to make underground communication circuit boards;

[0027] (2) Encapsulate the downhole communication circuit board in the pressure-resistant outer cylinder 7, which includes the following steps:

[0028] S1: making the pressure-resistant outer cylinder 7, which includes the following steps:

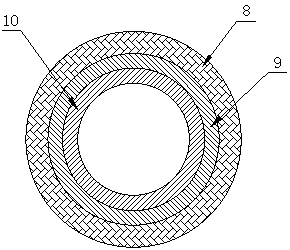

[0029] S101: making a mounting cylinder 10 made of metal materials such as aluminum and copper by using a molding die;

[0030] S102: using a forming mold to make a pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com