Electric heater, defroster, air-conditioning heating system and automobile

A technology for electric heaters and defrosters, which is applied in the fields of defrosters, air-conditioning and heating systems, automobiles, and electric heaters. Energy, improved vibration resistance, and easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

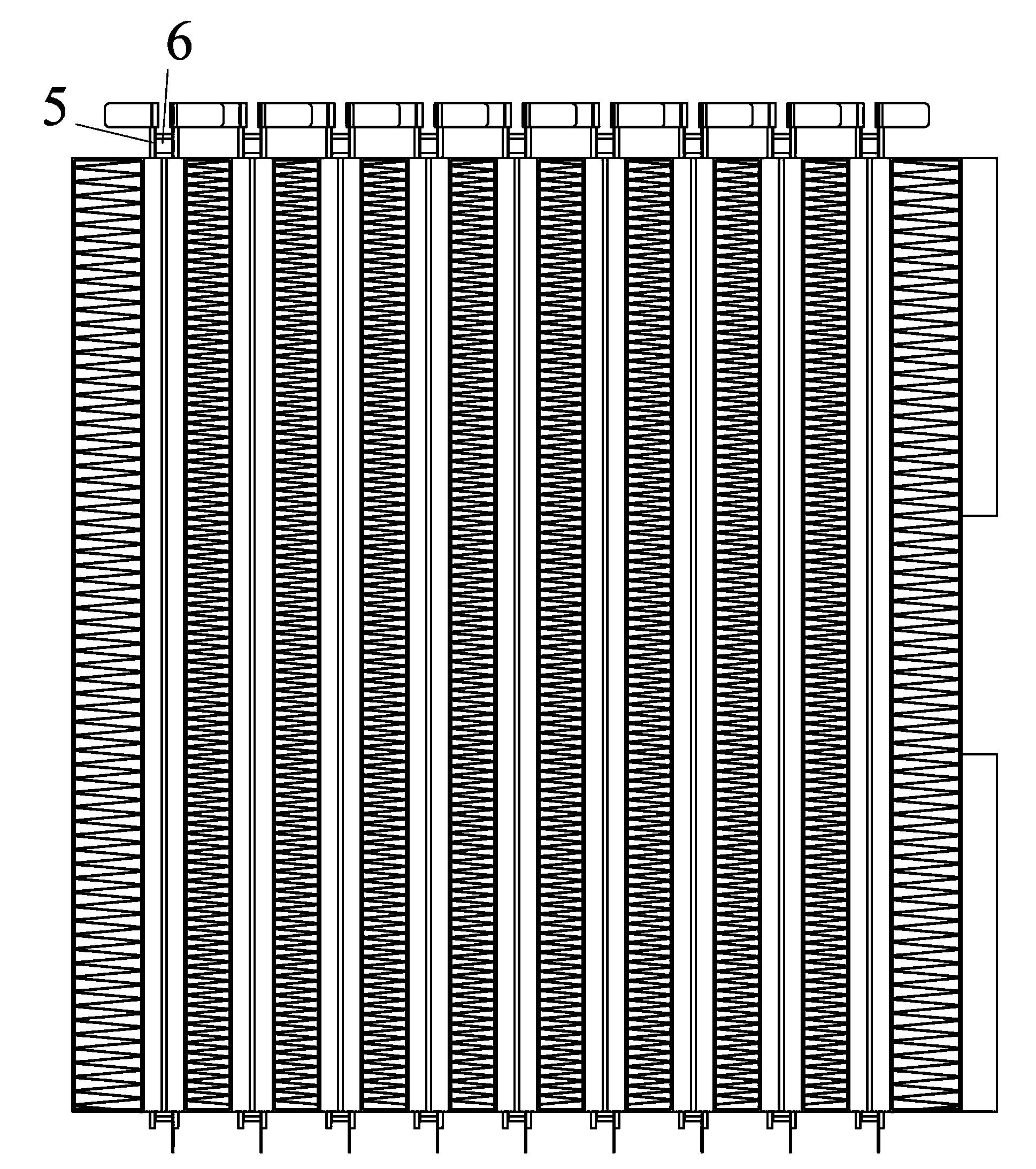

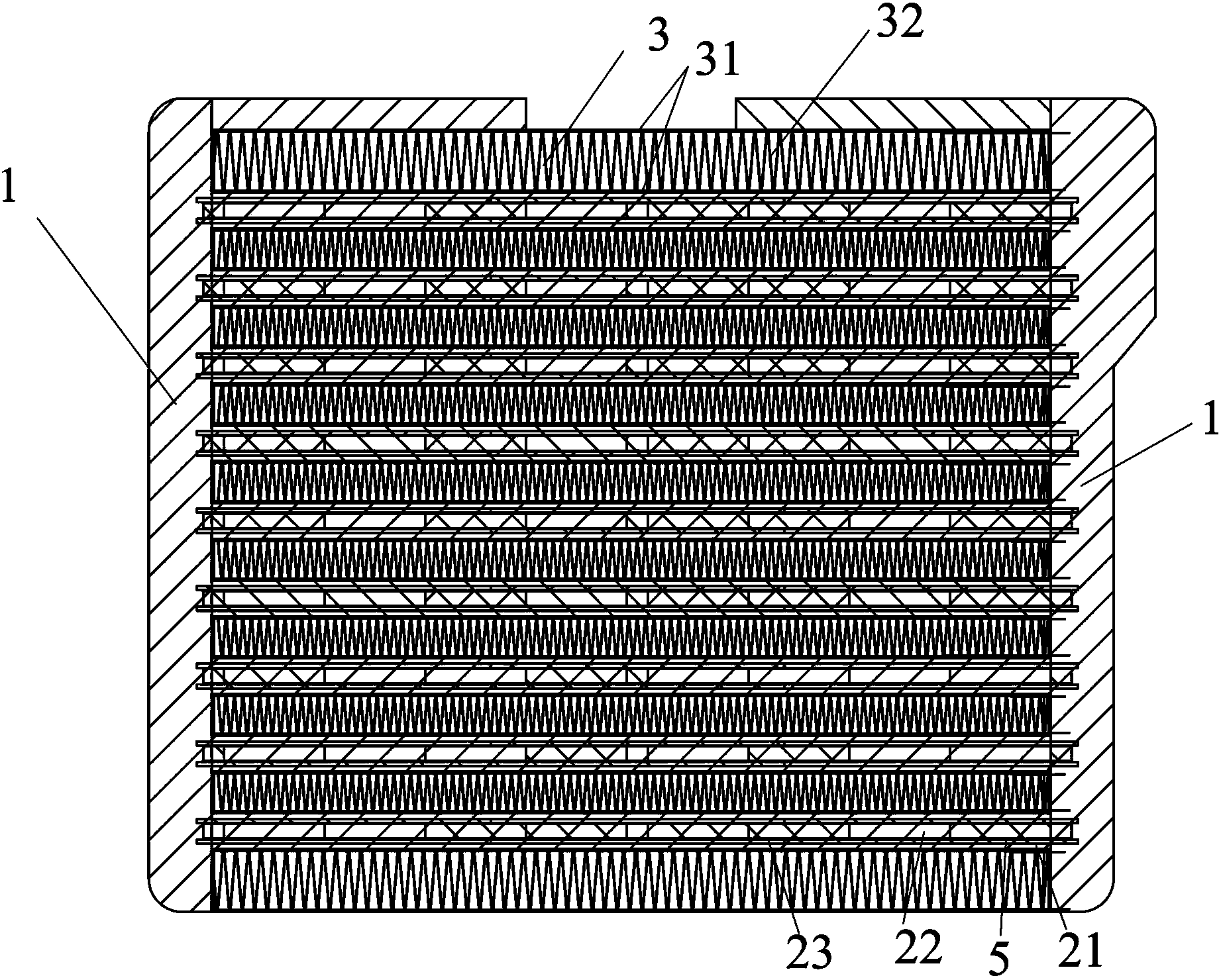

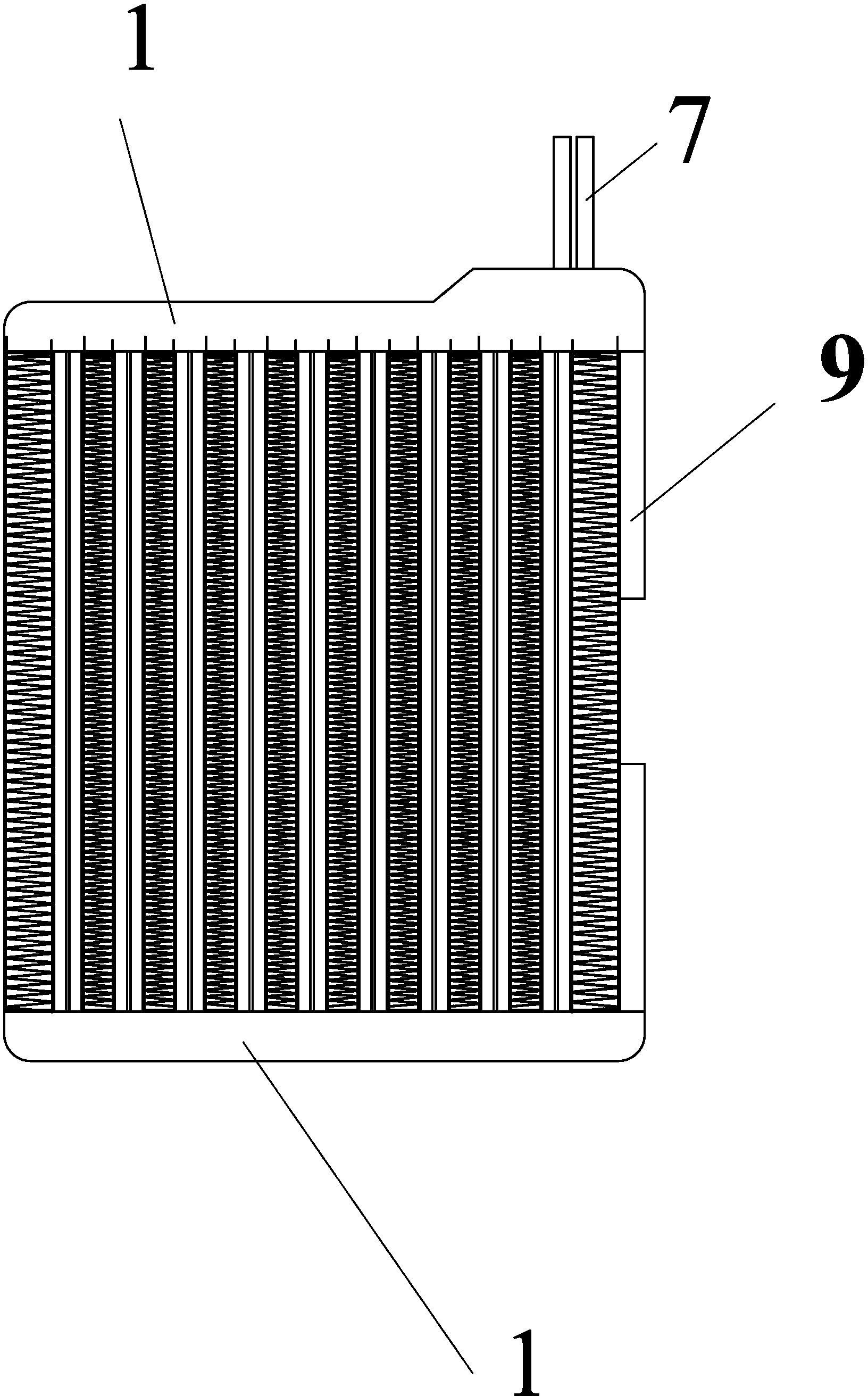

[0080] In such Figure 5 The aluminum through-tube shown (the thickness of the radiating wall is 1.35mm, the thickness of the force-bearing wall is 0.9mm, the force-bearing wall is recessed inward, the outer height is 9.2mm, the inner height is 6.5mm), including the installation of PTC thermistors , PTC thermistor and the wall of the aluminum tube clamp the alumina ceramic plate to form the heating element. After the heating element and the heat sink are arranged at intervals, they are bonded to form the main part by thermal silica gel, and the outermost heat sink on one side is riveted There are 4 temperature sensors, custom-made fixtures are placed on both ends of the main part, and filled with silica gel with heat-resistant temperature of 280℃, thermal conductivity of 1.4 W / (m·K), and adhesiveness of 4MPa until Silica gel fills the space between the mold and the main part, solidifies, and electrically connects the conductive sheet of the PTC thermistor extending out of the al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Heat resistance temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com