Environment-friendly type common cotton thread detonating cord

A detonating cord, environmentally friendly technology, applied in the field of detonating cords to achieve the effects of no air pollution, good waterproof performance, and no environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described by using the accompanying drawings and examples.

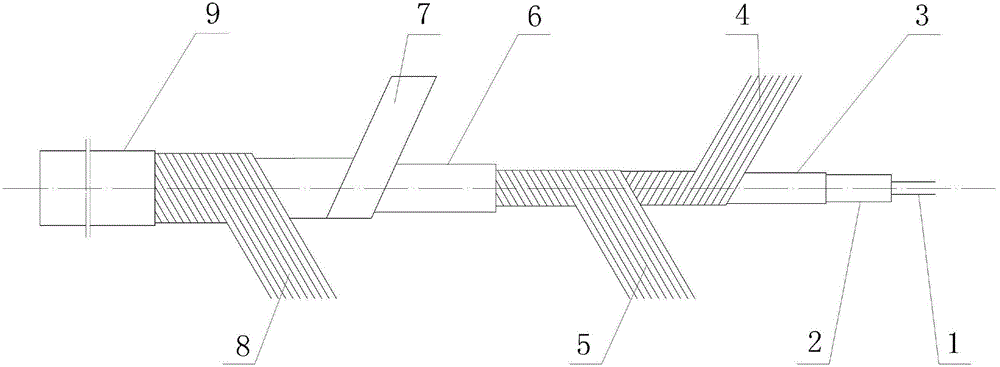

[0015] Such as figure 1 As shown, an environment-friendly ordinary cotton thread detonating cord of the present invention includes a core wire 1, a Taian drug core 2, a detonating cord cord stem 3, a polypropylene flat yarn layer 4, a cotton yarn layer 5, a waterproof and environmentally friendly coating layer 6, and an outer fuse Paper strip layer 7, outer cotton yarn layer 8, outer coating layer 9.

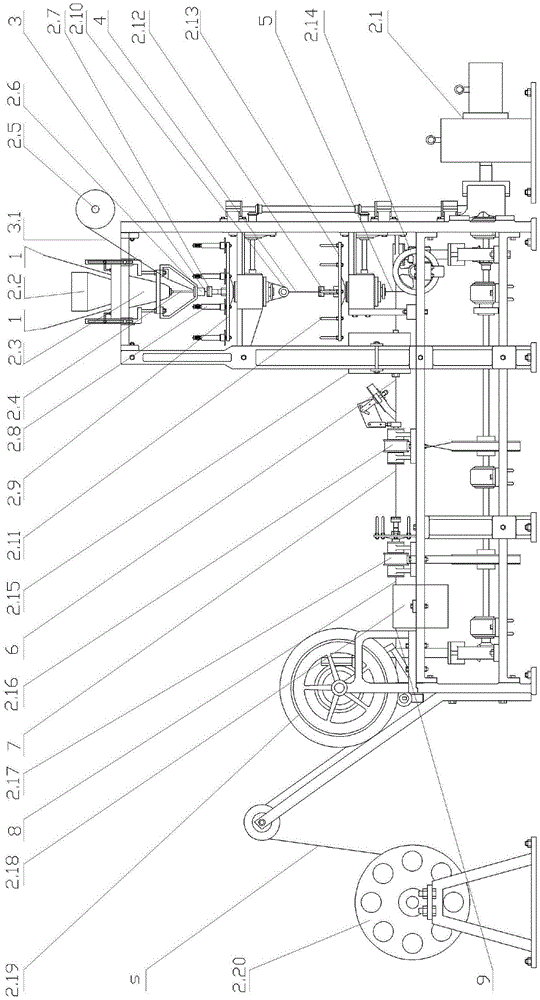

[0016] Such as figure 2 As shown, the overall structure of the detonating cord cable making machine includes a deceleration motor 2.1, a funnel 2.2, a glass medicine tank medicine hopper 2.3, a medicine medicine pipe 2.4, a fuse paper spindle shaft 2.5, a paper mold 2.6, and a layer of wire reel splitter nozzle 2.7 , polypropylene flat ribbon spindle shaft 2.8, first-layer wire reel 2.9, control break, fine drug probe 2.10, cotton yarn spindle 2.11, second-layer wire reel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com