High-temperature-resistant holographic gold stamping film, gold stamping plastic part and preparation method

A high-temperature-resistant, hot-stamping film technology, applied in coatings, polyurea/polyurethane coatings, and processes for producing decorative surface effects, can solve decorative effect discounts, holographic pattern distortion, and ordinary holographic hot-stamping films that cannot meet requirements, etc. problem, to achieve the effect of ensuring high temperature resistance and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

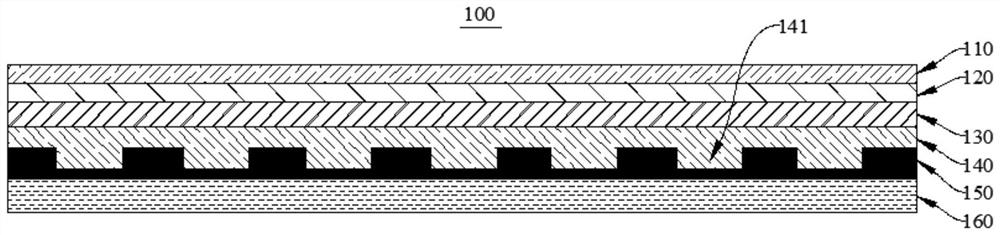

[0044] Please see figure 1 , a high temperature resistant holographic bronzing film 100 provided in this embodiment, which includes a base film 110, a release layer 120, a protective layer 130, a molded layer 140, a metal plating layer 150 and an adhesive layer 160, which are stacked sequentially from bottom to top. The surface of the layer 140 near the metal plating layer 150 has a holographic pattern microstructure 141 , and the holographic pattern microstructure 141 is molded on the molded layer 140 .

[0045] In the embodiment of the present application, the base film 110 is a PET film with a thickness of 10-25 μm, optionally 15-19 μm. In this embodiment, the base film 110 is a high brightness PET film with a thickness of 19 μm.

[0046] In the embodiment of the present application, the release layer 120 is made of water-based polyurethane wax with a thickness of 0.5-1.5 μm. In this embodiment, the release layer 120 is coated with water-based polyurethane and has a thick...

no. 2 example

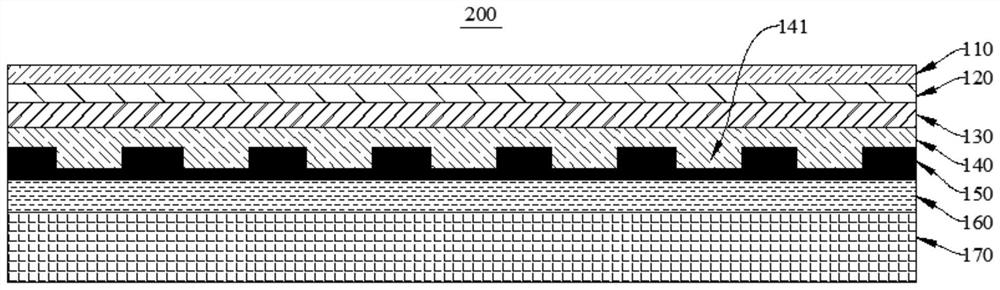

[0093] Please see figure 2 , a hot stamping plastic part 200 provided in this embodiment, which includes the release layer 120, protective layer 130, molded layer 140, metal plating layer 150, glue layer 160, and plastic substrate 170. The material of the plastic substrate 170 is one of PS, ABS, PP, PET and ASA. Wherein, the bronzing pattern layer composed of the release layer 120 , the protective layer 130 , the molded layer 140 , the metal plating layer 150 and the adhesive layer 160 on the surface of the plastic substrate 170 has a decorative effect.

[0094] The embodiment of the present application also provides a method for preparing the above-mentioned hot stamping plastic part 200 , where the side of the high temperature resistant holographic hot stamping film 100 with the adhesive layer 160 is hot stamped on the plastic substrate 170 , and then the base film 110 is peeled off. The pressure of bronzing is 0.5-0.8Mpa, and the temperature is 220-300°C.

[0095] Speci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com