A kind of novel conductive glue and preparation method thereof

A conductive adhesive and epoxy resin technology, applied in conductive adhesives, adhesives, epoxy resin adhesives, etc., can solve the problems of high temperature resistance, low expansion coefficient, high conductivity, insufficient high temperature resistance performance, and reduced reliability. Achieve the effect of high heat resistance, long service life and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with specific embodiment, the present invention is described further:

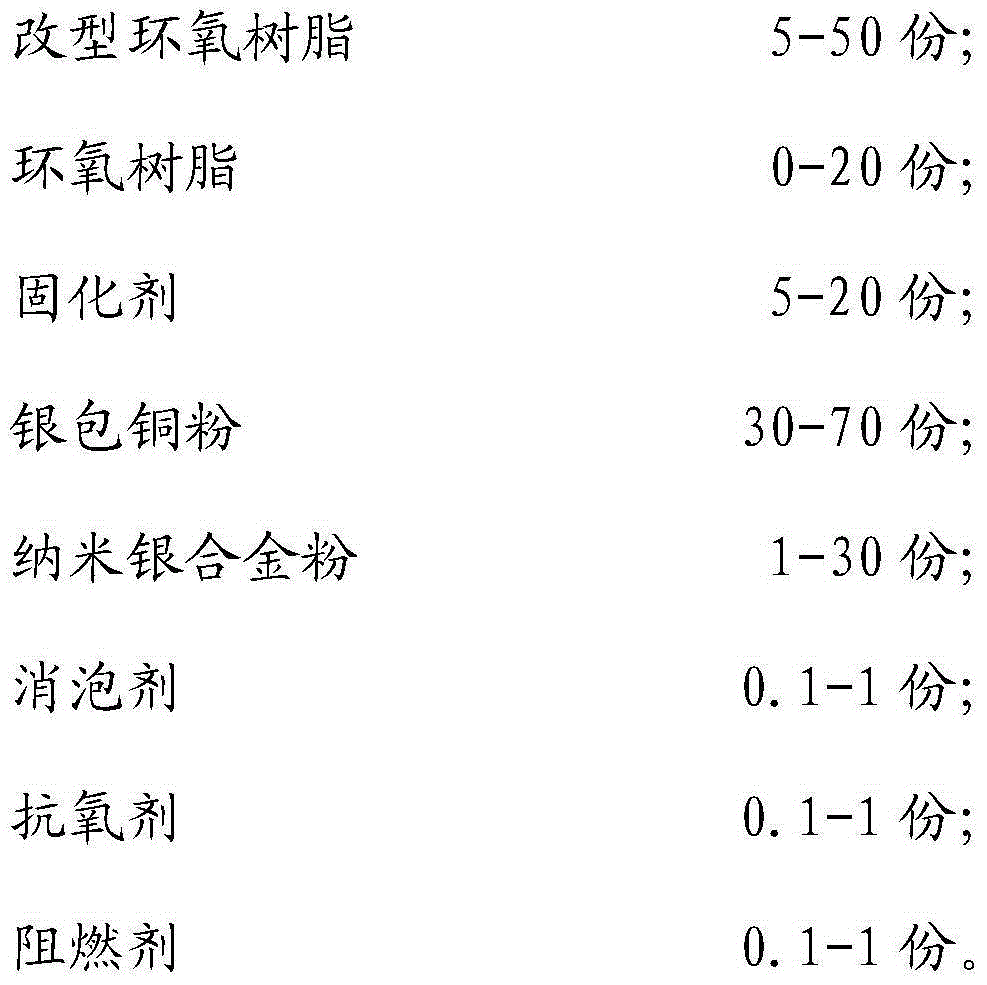

[0024] A novel conductive adhesive is prepared from the following raw materials in parts by weight:

[0025]

[0026] A preparation method of a novel conductive adhesive is carried out in the following steps:

[0027] Weigh the raw materials according to the formula described above for the conductive adhesive, mix and stir the raw materials evenly, and finally use a vacuum defoaming mixer to stir and defoam, and the conductive adhesive is obtained after completion.

[0028] The epoxy resin is one of low-viscosity bisphenol A epoxy resin, glycidyl ester epoxy resin, and glycidyl ether epoxy resin, with a viscosity range of 1000-13000cps at 25°C; preferably, the The epoxy resin is E-51 type epoxy resin or TDE-85 type epoxy resin, which has the characteristics of low viscosity.

[0029] The modified epoxy resin is nano-silver modified epoxy resin, and its preparation method i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com