Heat-resistant self-adhesive enamelled wire paint and preparation method thereof

A self-adhesive enameled wire paint, heat-resistant technology, applied in coatings, epoxy resin coatings, etc., can solve the problems of difficult to overcome the wet adhesion defect of enameled wire, unable to meet production needs, easy cracking and aging of paint film, etc. Strength and molding mechanical strength, good for stability, and the effect of improving alignment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

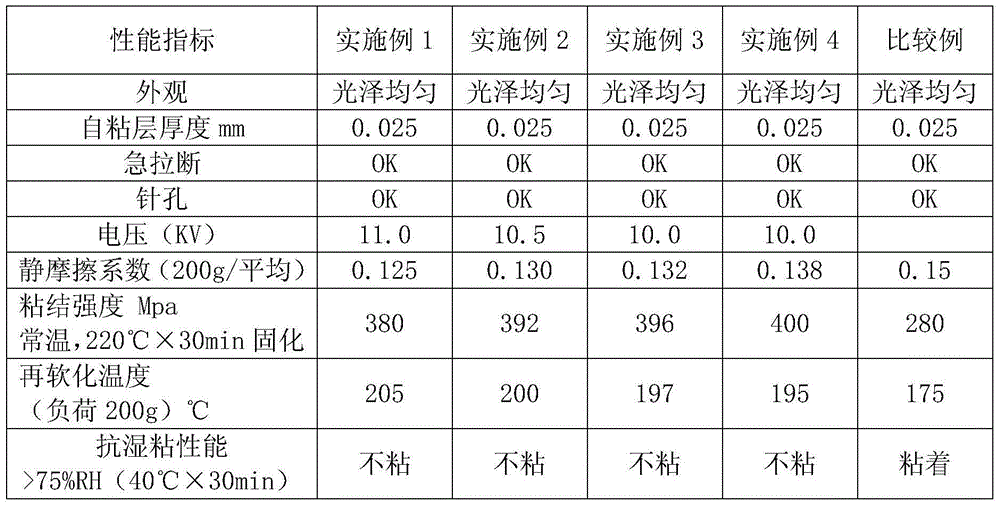

Embodiment 1

[0030] Add 350 parts of xylene and 430 parts of N-methylpyrrolidone (water content ≤ 0.05%) into a reaction kettle with a stirrer, stir and mix evenly, turn on and heat to 50°C, adopt a step-by-step feeding method, and put 169 parts in 15 minutes Parts of polyetherimide resin (heat distortion temperature is 208°C under the condition of 1.82Mpa) particles, and at the same time, stir and gradually increase the temperature to 110°C, keep it for 2h, until it is completely dissolved, and obtain mixture A; cool mixture A to 60°C , put in 17.2 parts of FB resin, keep warm for 1.5h, until the resin is uniform, then cool down to 45°C, add 33.8 parts of preheated phenol-formaldehyde epoxy resin, keep warm for 1h, until the mixture is evenly stirred to obtain mixture B; Put 0.2 parts of BYK-310 slip agent into the mixture, stir evenly and then filter, the obtained filtrate is heat-resistant self-adhesive wire enamel.

[0031] The heat-resistant self-adhesive wire enamel prepared in this ...

Embodiment 2

[0033] Add 270 parts of xylene and 510 parts of N-methylpyrrolidone (water content ≤ 0.05%) into a reactor with a stirrer, stir and mix evenly, turn on and heat to 55°C, adopt a step-by-step feeding method, and put 176 Parts of polyetherimide resin (heat distortion temperature is 210°C under the condition of 1.82Mpa) particles, and while stirring, the temperature is gradually raised to 105°C, and the temperature is kept for 2.5h until it is completely dissolved to obtain the mixture A; the mixture A is cooled to 60 ℃, put in 17.6 parts of FB resin, keep it warm for 1.5h, until the resin is uniform, then cool down to 45°C, add 26.4 parts of preheated phenol-formaldehyde epoxy resin, keep it warm for 1.5h, until it is evenly stirred to obtain mixture B; Put 0.2 parts of BYK-310 slip agent into the mixture B, stir well and then filter, the obtained filtrate is heat-resistant self-adhesive wire enamel.

[0034] The heat-resistant self-adhesive wire enamel prepared in this example ...

Embodiment 3

[0036] Add 230 parts of xylene and 550 parts of N-methylpyrrolidone (water content ≤ 0.05%) into a reaction kettle with a stirrer, stir and mix evenly, turn on and heat to 60°C, adopt a step-by-step feeding method, and put 183 Parts of polyetherimide resin (heat distortion temperature is 208°C under the condition of 1.82Mpa) particles, and at the same time, stir and gradually increase the temperature to 110°C, keep it for 3h, until it is completely dissolved, and obtain mixture A; cool mixture A to 65°C , put in 18.3 parts of FB resin, keep it warm for 1 hour, until the resin is uniform, then cool down to 50°C, add 18.7 parts of preheated phenol-formaldehyde epoxy resin, keep it warm for 1 hour, until it is evenly stirred to obtain mixture B; Add 0.2 parts of BYK-310 slip agent, stir evenly and then filter, the obtained filtrate is heat-resistant self-adhesive wire enamel.

[0037] The heat-resistant self-adhesive wire enamel prepared in this example is a transparent homogeneo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com