Aryl-1,3,5-triazine polyarylester and preparation method thereof

A technology of polyarylate and aryl, which is applied in the field of polymer science and can solve problems such as unseen patent technology reports

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

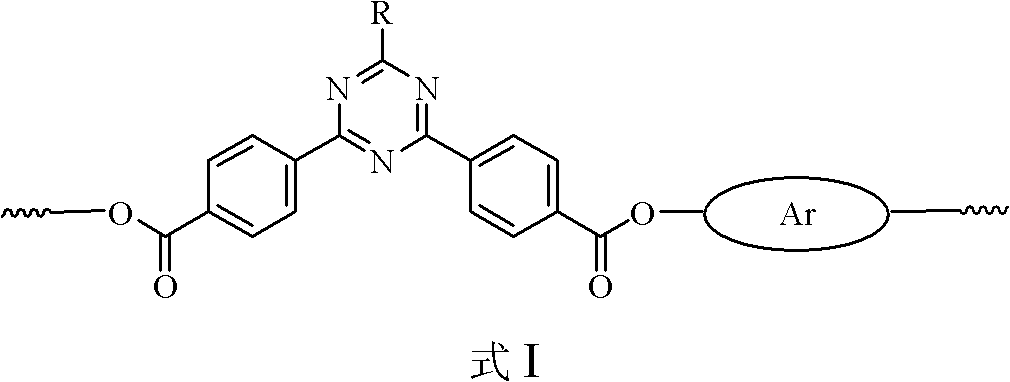

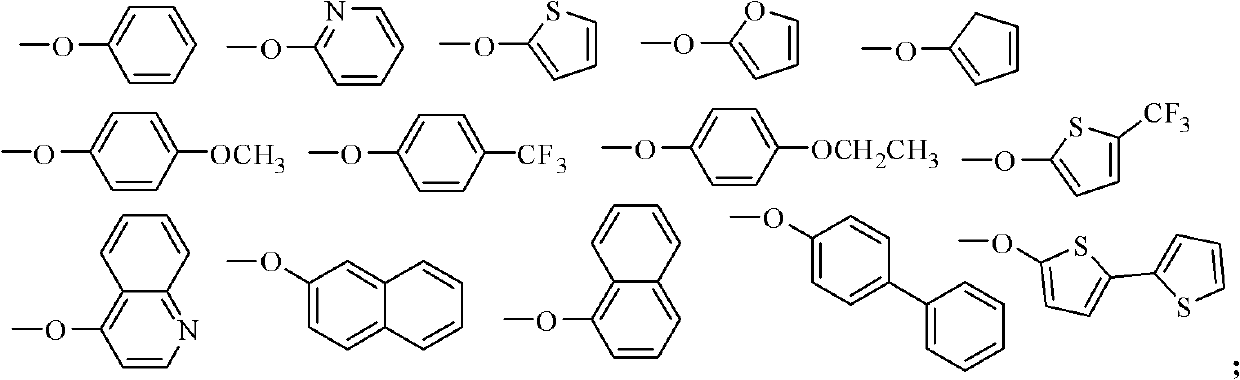

Method used

Image

Examples

Embodiment 1

[0058] In a 100mL three-necked flask equipped with a mechanical stirrer, a condenser, a desiccator and an air duct, first heat it to 100°C, fill / discharge nitrogen three times, and add bis(trimethylsilyl)-4,4′-(6-methyl 20mmol of oxy-1,3,5-triazine-2,4-diphenyl)diphenyl ester and 20mmol of hydroquinone were gradually heated from room temperature to 260°C under a nitrogen atmosphere, and the heating temperature interval was 40°C. At each temperature point, the reaction duration was 0.4 h. Control the temperature at 260°C for 4h. The system was vacuumed and decompressed to 80KPa, and the reaction was continued for 3h. After cooling down, add 500mL of methanol as a precipitant. The polymer is crushed, repeatedly washed with deionized water, sucked dry, and vacuum-dried to obtain aryl-1,3,5-triazine polyarylate resin. The resin is light yellow powder;

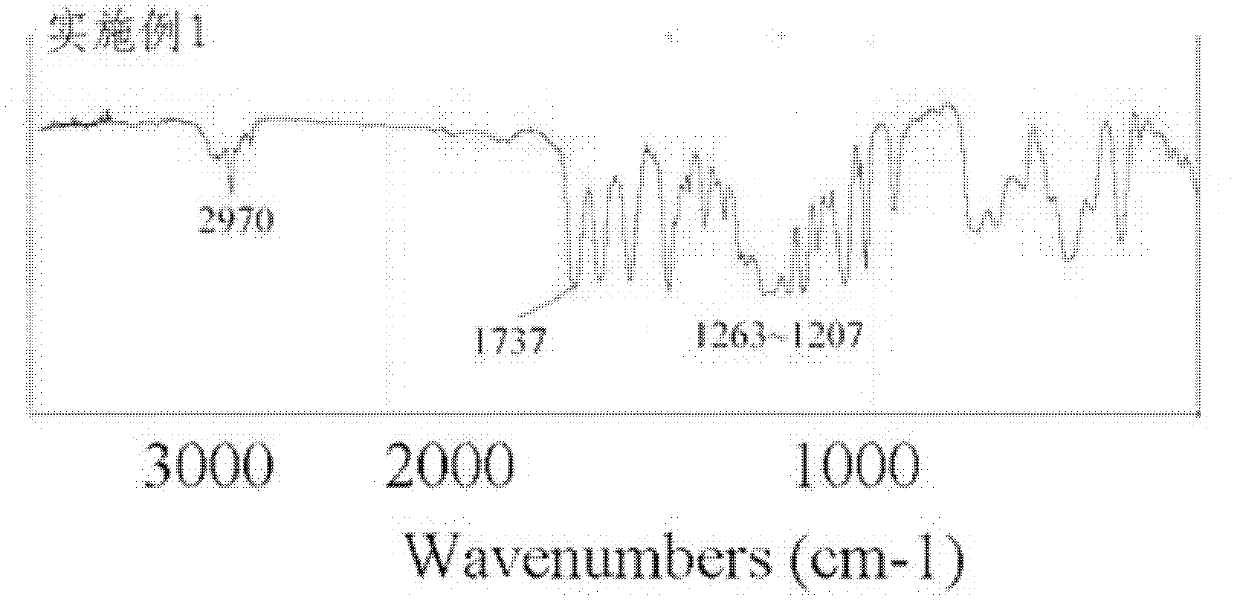

[0059] Taking the aryl-1,3,5-triazine-containing polyarylate resin of this example as an example, the polymer structure was c...

Embodiment 2

[0065]In a 100mL three-neck flask equipped with a mechanical stirrer, a condenser, a desiccator and an air duct, first heat it to 100°C, fill / discharge nitrogen three times, and add bis(trimethylsilyl)-4,4′-(6-benzene Oxy-1,3,5-triazine-2,4-diphenyl)diphenyl ester 20mmol and resorcinol 20mmol, add anhydrous sulfolane 30mL as an inert reaction medium, gradually change from room temperature to Heating to 220°C, the heating interval value is 30°C. At each temperature point, the reaction duration was 0.5 h. Control the temperature at 220°C for 4h. The system was vacuumed and decompressed to 80KPa, and the reaction was continued for 3h. After cooling down, 500 mL of acetone was added as a precipitating agent. The polymer is crushed, repeatedly washed with deionized water and methanol, sucked dry, and vacuum-dried to obtain aryl-1,3,5-triazine polyarylate resin. The resin is off-white powder;

[0066] The solubility test results of the polymer in this embodiment show that the r...

Embodiment 3

[0069] In a 100mL three-neck flask equipped with a mechanical stirrer, a condenser, a desiccator, and an air duct, first heat it to 100°C, fill / release nitrogen three times, and add bis(trimethylsilyl)-4,4′-(6-linked Thiphenoxy-1,3,5-triazine-2,4-diphenyl)diphenyl ester 20mmol and bisphenol A 20mmol, add anhydrous sulfolane and NMP (V:V=1) to add a total of 30mL as Inert reaction medium. Under a nitrogen atmosphere, gradually heat from room temperature to 260°C, with a temperature interval of 40°C. At each temperature point, the reaction duration was 0.4 h. Control the temperature at 260°C for 4h. The system was vacuumed and decompressed to 80KPa, and the reaction was continued for 3h. After cooling down, 500 mL of acetone was added as a precipitating agent. The polymer is crushed, repeatedly washed with deionized water and acetone, sucked dry, and vacuum-dried to obtain aryl-1,3,5-triazine polyarylate resin. The resin is white powder;

[0070] Shown by the solubility te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com