Battery diaphragm and preparation method thereof, and lithium ion battery containing diaphragm

A technology of battery diaphragm and diaphragm, which is applied in the direction of secondary battery, battery pack parts, secondary battery repair/maintenance, etc. It can solve the problem of easy puncture, high porosity, and poor liquid absorption and liquid retention capacity of polyolefin diaphragm and other problems, to achieve the effect of improving mechanical properties and heat resistance, high mechanical strength, and good corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

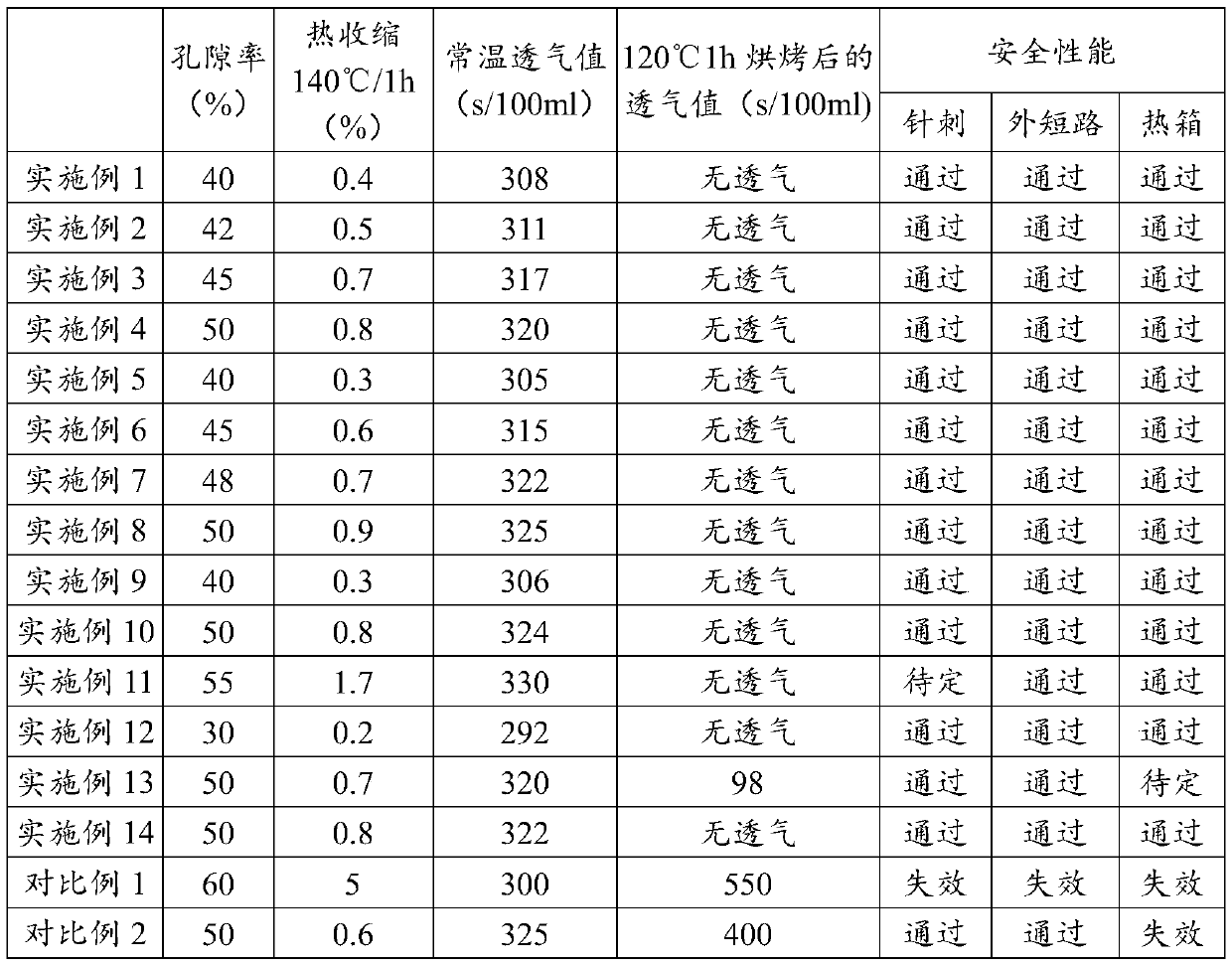

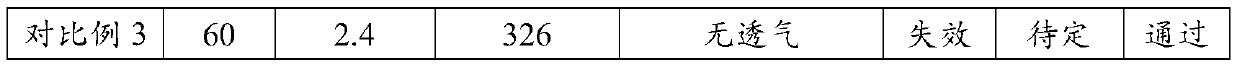

Examples

Embodiment 1

[0028] Preparation of positive electrode sheet:

[0029] Lithium cobaltate, conductive agent superconducting carbon (Super-P), and binder polyvinylidene fluoride (PVDF) were mixed uniformly at a mass ratio of 97:1.5:1.5 to make a lithium-ion battery cathode slurry with a certain viscosity. The slurry is coated on the aluminum foil of the current collector, and then cold pressed after drying at 85°C; then edge trimming, cutting, and slitting are performed, and after slitting, dry at 110°C for 4 hours under vacuum conditions, and weld the tabs. Made into lithium-ion battery cathode sheet.

[0030] Preparation of negative electrode sheet:

[0031] Make a slurry of graphite and conductive agent superconducting carbon (Super-P), thickener sodium carboxymethyl cellulose (CMC), and binder styrene-butadiene rubber (SBR) at a mass ratio of 96:2.0:1.0:1.0 , coated on the current collector copper foil and dried at 85°C, trimmed, cut into pieces, slitting, and dried at 110°C for 4 hours...

Embodiment 2

[0039] Different from Example 1 is the preparation of diaphragm:

[0040] 1) Mix glass fibers with a diameter of 0.3 μm and polymethacrylic acid accounting for 6% of the glass fiber mass, add deionized water and stir evenly to form a slurry. The viscosity of the slurry is 2500mPa·s, and the solid content of the slurry is 45%;

[0041] 2) Coating and forming the slurry obtained in 1), dehydrating and drying to obtain a diaphragm base layer, the thickness of the diaphragm base layer is 10 μm, and the porosity of the diaphragm base layer is 42%;

[0042]3) Add polystyrene to NMP solvent, then add polymethyl acrylate, stir evenly, and apply spray coating or gravure coating on the base layer of the diaphragm to form a hot-melt polymer layer. The hot-melt polymer The coating mass of the layer is 0.6% of the mass of the base layer of the separator, and the thickness of the hot-melt polymer layer is 4 μm.

[0043] The rest are the same as in Embodiment 1, and will not be repeated he...

Embodiment 3

[0045] Different from Example 1 is the preparation of diaphragm:

[0046] 1) Mix glass fibers with a diameter of 0.4 μm and polymethyl acrylate accounting for 7% of the glass fiber mass, add deionized water and stir evenly to form a slurry. The viscosity of the slurry is 3000mPa·s, and the solid content of the slurry is 50%;

[0047] 2) Coating and forming the slurry obtained in 1), dehydrating and drying to obtain a diaphragm base layer, the thickness of the diaphragm base layer is 11 μm, and the porosity of the diaphragm base layer is 45%;

[0048] 3) Add polyvinyl chloride to NMP solvent, then add polyethyl acrylate, stir evenly, and apply spray coating or gravure coating on the base layer of the diaphragm to form a hot-melt polymer layer. The hot-melt polymer The coating mass of the layer is 0.7% of the mass of the base layer of the separator, and the thickness of the hot-melt polymer layer is 5 μm.

[0049] The rest are the same as in Embodiment 1, and will not be repea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com