Preparation method of material for abdominal wall defect intraperitoneal repair, and obtained material thereof

An intraperitoneal and abdominal wall technology, applied in the field of medical devices and their preparation, can solve the problems of dependence on imports, high price, unfavorable wide application, etc., and achieves good anti-adhesion and antibacterial properties, good biocompatibility, and good mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

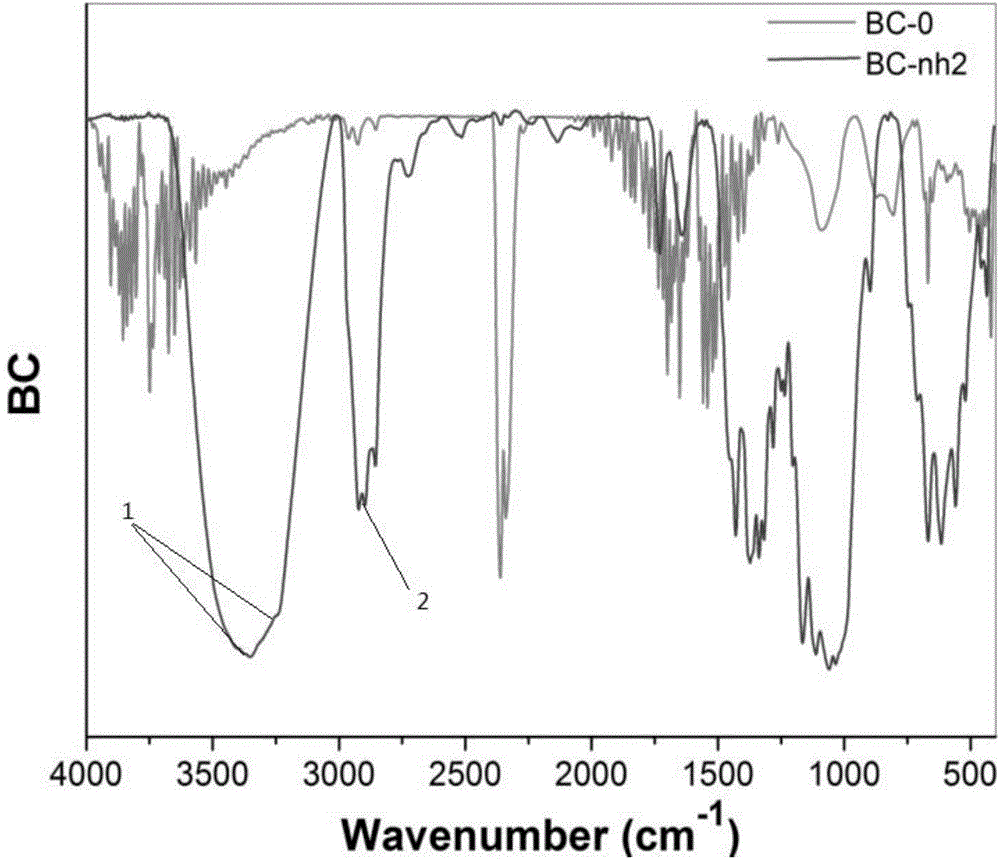

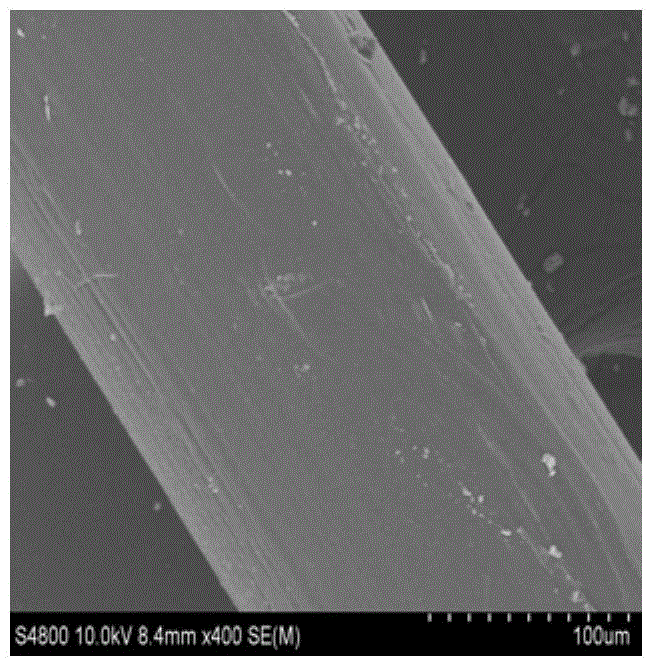

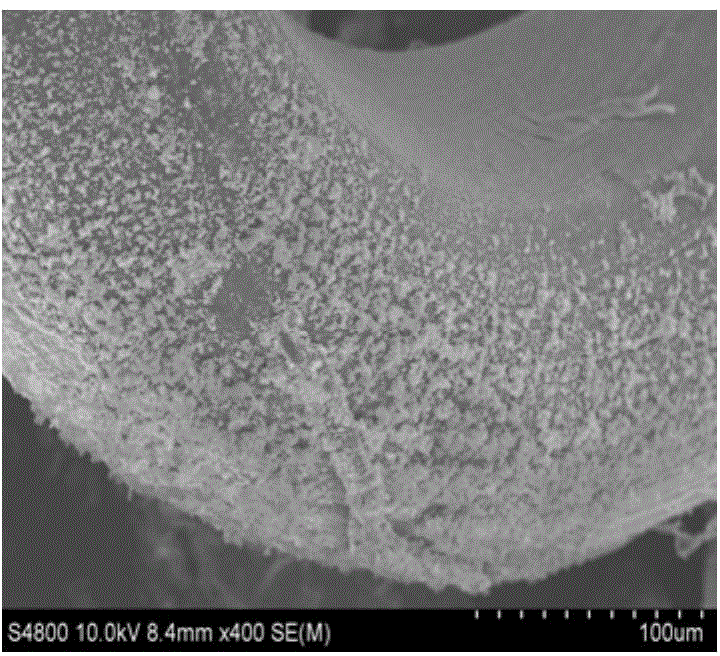

Embodiment 1

[0042] The 0.3810g bacterial cellulose obtained by the cultivation of Acetobacter xylinum was added to 19mmol / L cerium ammonium nitrate solution and activated at room temperature for 3h, and after elution and drying, 50ml of dimethylaminoethyl methacrylate with a mass fraction of 9% was added The solution was grafted, and 5ml of 45% nitric acid aqueous solution and 1g of copper powder were added, and then reacted under nitrogen atmosphere for 6h. Take out the bacterial cellulose and wash it with water, then add it to 50ml brominated n-butane and acetone solution (volume ratio is 1:3.5), take it out after shaking and reacting at 40°C for 8h, then add it to 50ml brominated dodecane and acetone solution (1:4 by volume), continue to react at 40°C for 8h, wash with 95% ethanol and dry. A certain amount of bacterial cellulose obtained above was activated by a 10% ethylenediamine solution for 2 hours by mass fraction, and then dissolved in a mixed solution of 73.3ml lithium chloride ...

Embodiment 2

[0048] Add 0.4 g of bacterial cellulose obtained by culturing Acetobacter xylinum into 20 mmol / L cerium ammonium nitrate solution for activation at room temperature for 2 h, and add 55 ml of dimethylaminoethyl methacrylate with a mass fraction of 10% after eluting and drying The solution was grafted, and 5ml of 45% nitric acid aqueous solution and 1g of copper powder were added, and then reacted under nitrogen atmosphere for 6h. Take out the bacterial cellulose and wash it with water, then add it to 50ml brominated n-butane and acetone solution (volume ratio is 1:4), take it out after shaking and reacting at 45°C for 10h, then add it to 50ml brominated dodecane and acetone solution (1:4 by volume), continue to react at 45°C for 10h, wash with 95% ethanol and dry. A certain amount of bacterial cellulose obtained above was activated by a mass fraction of 10% ethylenediamine solution for 2 h, and then dissolved in a mixed solution of 39 ml of lithium chloride and N-dimethylacetam...

Embodiment 3

[0051] Add 0.8 g of bacterial cellulose obtained by Acetobacter xylinum culture into 21 mmol / L cerium ammonium nitrate solution for activation at room temperature for 2 h, elute and dry, then add 80 ml of dimethylaminoethyl methacrylate with a mass fraction of 15% The solution was grafted, and 6ml of 45% nitric acid aqueous solution and 1g of copper powder were added, and then reacted under nitrogen atmosphere for 8h. Take out the bacterial cellulose and wash it with water, then add it to 80ml brominated n-butane and acetone solution (volume ratio is 1:4), take it out after shaking and reacting at 45°C for 8h, then add it to 80ml brominated dodecane and acetone solution (1:4 by volume), continue to react at 45°C for 8h, wash with 95% ethanol and dry. A certain amount of bacterial cellulose obtained above was activated with a mass fraction of 10% ethylenediamine solution for 2 hours, and then dissolved in a mixed solution of 39ml lithium chloride and N-dimethylacetamide (mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com