Arc source of dynamic controlled arc ion plating

An arc ion plating and dynamic control technology, applied in ion implantation plating, sputtering plating, vacuum evaporation plating, etc., can solve problems such as difficulty in popularization and application, improve discharge form and work stability, easy to popularize, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] attached image 3 It is a schematic diagram of a dynamically controlled arc ion plating arc source device according to Embodiment 1 of the present invention.

[0060] The dynamically controlled arc ion plating arc source device mainly includes: target 1; target base 2; target bottom column 3; insulating ring 4; yoke 5; main control magnetic field generating device coil 6; water inlet 7; water outlet 8; arc starting coil 9; arc starting needle 10; auxiliary magnetic field generating device coil 11; shielding cover 12; bolt 13; The insulating ring 4 is used for the insulation between the bottom column 3 of the target and the coil 11 of the auxiliary magnetic field generator. The coil 6 of the main control magnetic field generator is set on the magnetic guide column 19 in the yoke 5 and placed behind the target 1 together. The coil 11 of the auxiliary magnetic field generator is set outside the cylinder of the target base 2 . The circulating water circulates through the ...

Embodiment 2

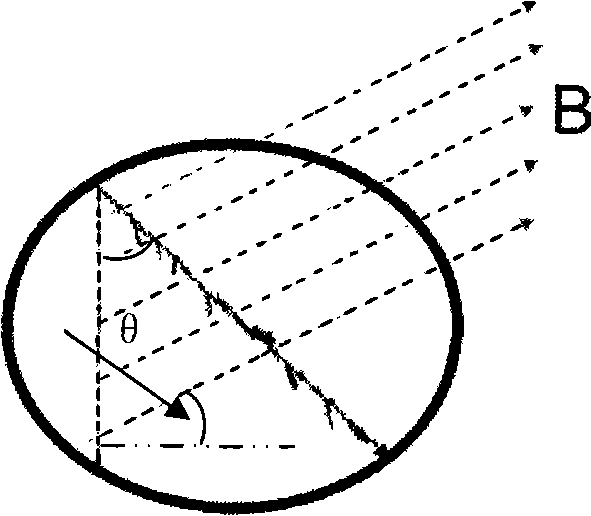

[0065] attached Figure 5 It is a schematic diagram of an adjustable statically controlled arc ion plating arc source device according to Embodiment 2 of the present invention. The basic structure is the same as that of Embodiment 1, except that the inner side of the top end of the magnetic tube 20 of the yoke 5 adopts an outward 15° slope structure, and the slope at the top of the magnetic column 19 is an axisymmetric boss shape (narrow at the top and wide at the bottom). ), the slope at the top of the magnetic cylinder is symmetrical to the slope at the top of the magnetic column, and the slope of the magnetic yoke is W-shaped. The coil 6 of the main control magnetic field generating device passes direct current to generate a certain arched magnetic field; the coil 11 of the auxiliary magnetic field generating device passes direct current of different sizes to generate a certain reverse magnetic field, and the coupling of the two magnetic fields generates static magnetic lin...

Embodiment 3

[0068] attached Figure 7 It is a schematic diagram of a dynamically controlled arc ion plating arc source device according to Embodiment 3 of the present invention. The basic structure is the same as that of Embodiment 2, except that the inside of the top end of the magnetic permeable cylinder 20 of the yoke 5 adopts a 30° outward slope structure.

[0069] The coils in the main control magnetic field generator and the auxiliary magnetic field generator are individually regulated by the voltage regulating power supply, the coil of the main control magnetic field generator passes a 2A direct current to form an arched magnetic field with a fixed configuration on the target surface, and the coil of the auxiliary magnetic field generator is turned on and off Directional alternating current adjusts the distribution of the arched magnetic field, the magnitude of the alternating current changes continuously (0-2A), and the direction remains unchanged, thereby continuously changing th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com