Liquid crystal panel and its producing method

A liquid crystal panel and liquid crystal layer technology, applied in nonlinear optics, instruments, optics, etc., can solve the problems of reduced contrast and aperture ratio, lower aperture ratio, and waste of aperture ratio, so as to improve image contrast, increase aperture ratio, and avoid Effects of misalignment problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

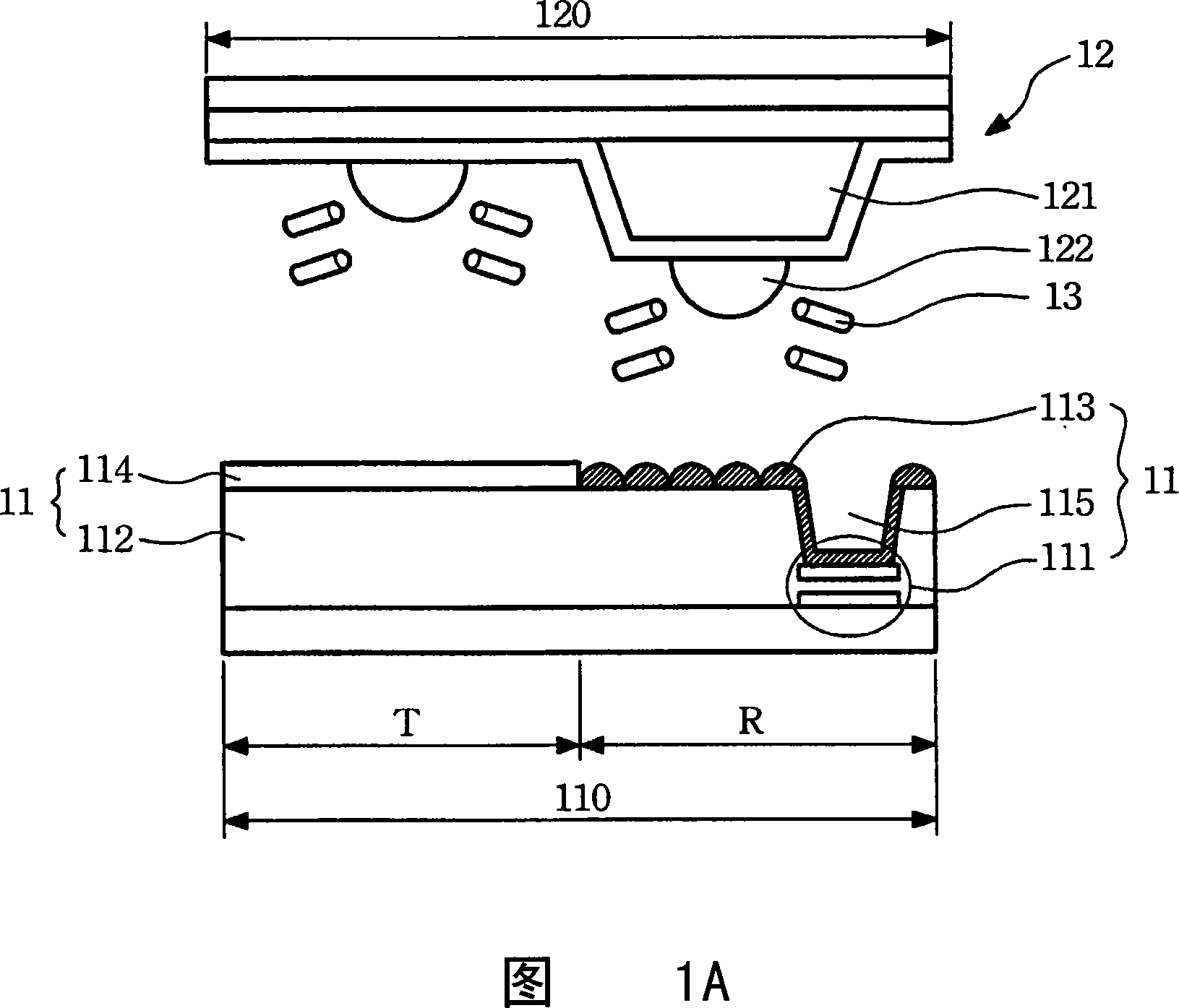

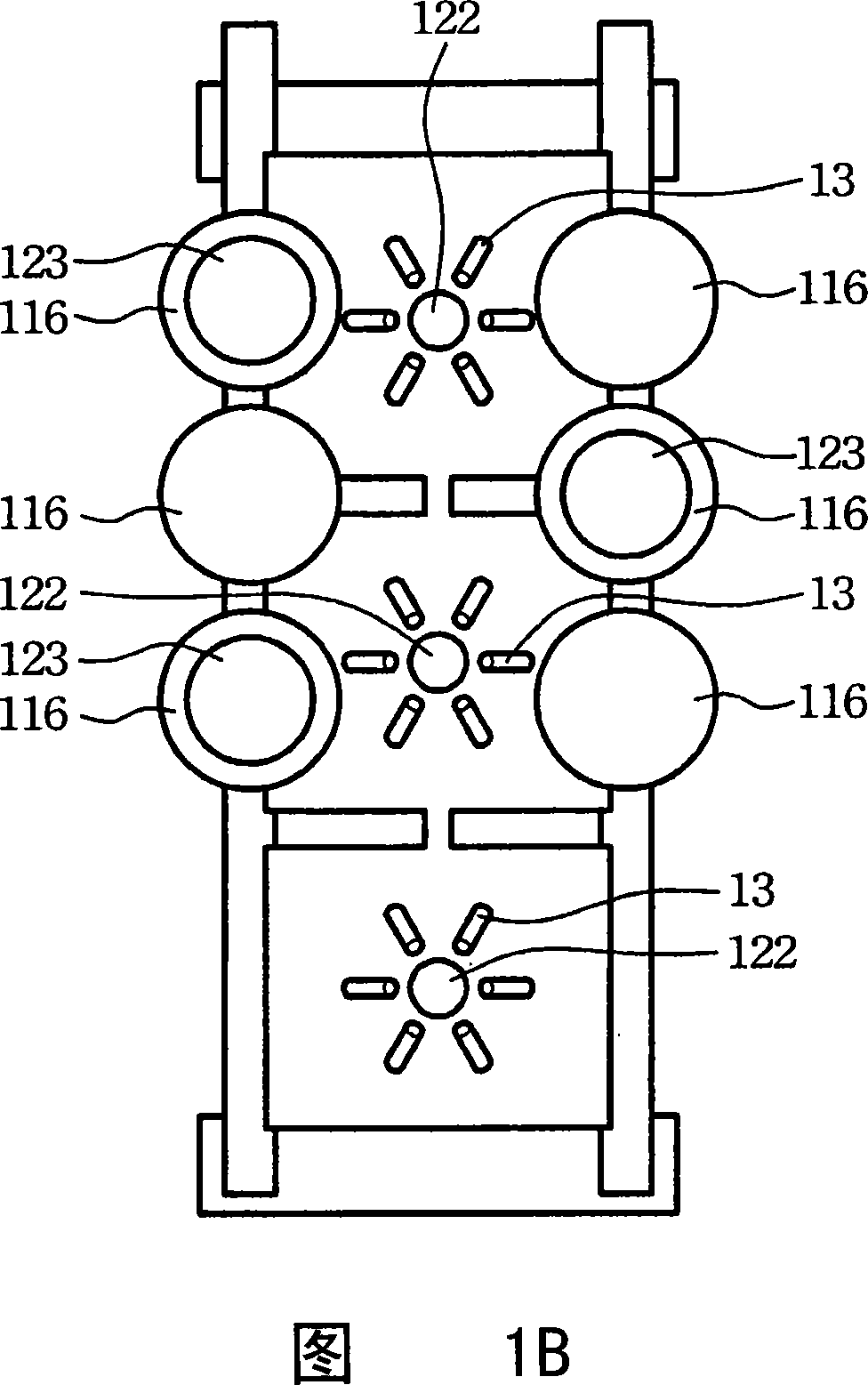

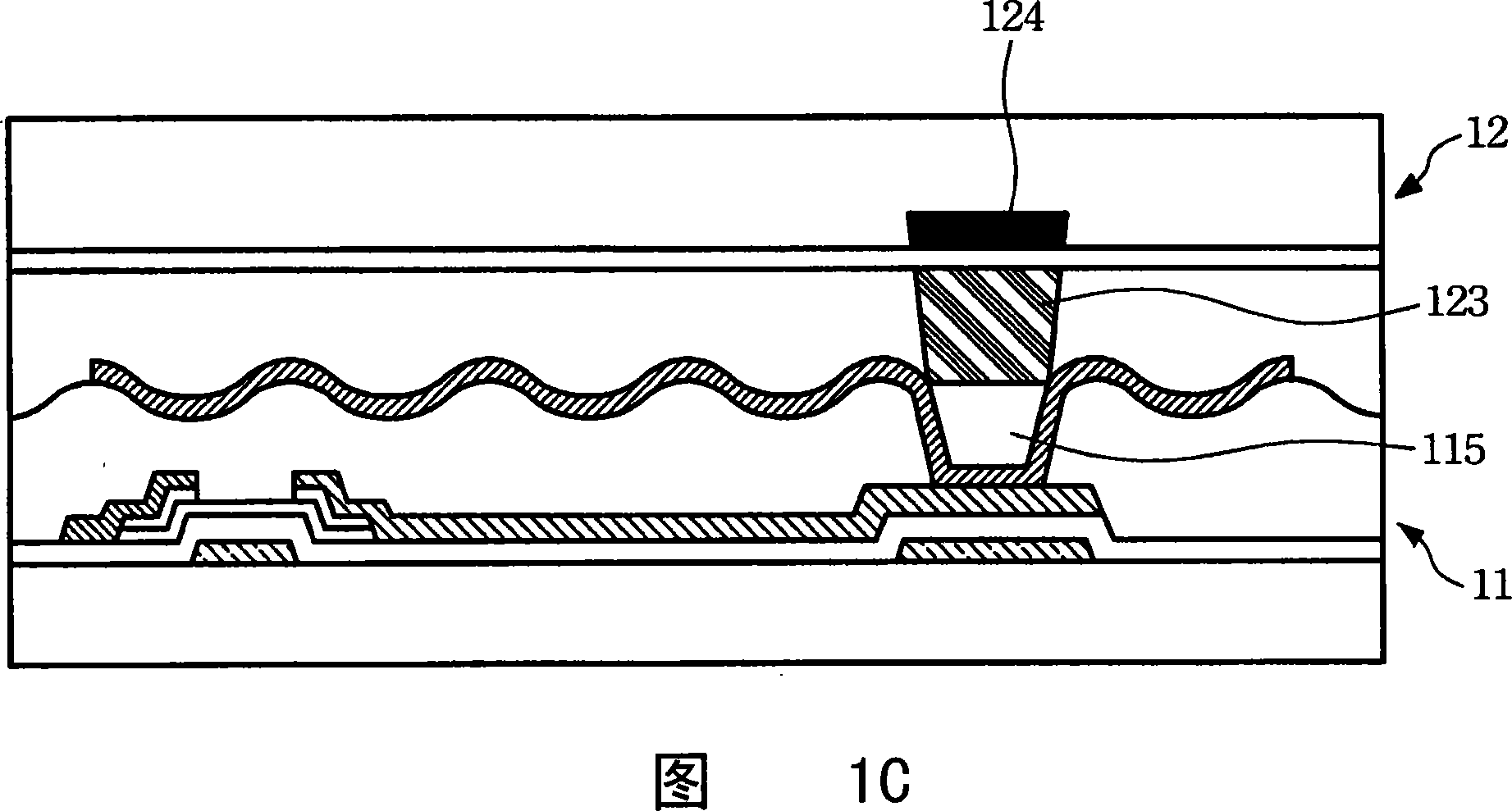

[0028] In FIG. 1C , since the spacer 123 must just abut against both sides of the opening of the contact hole 115 , the panel spacing can be maintained stably. In this way, slight errors in the manufacturing process, such as: the width of the spacer, the opening width of the contact hole, and the alignment error between the array substrate and the color filter during assembly, etc., are very likely to cause errors in the cell gap of the panel and lead to a poor yield loss situation.

[0029] In view of this, in order to improve the problems of poor contrast and reduced aperture ratio caused by conventional liquid crystal display technology, the present invention proposes a new design, which can not only increase the aperture ratio of liquid crystal display, but also further Improve its image contrast.

[0030] The present invention is hereby described in detail in conjunction with the drawings, and the preferred embodiments and related application descriptions thereof are lis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com