Modification bamboo charcoal having Ag and multihole TiO2 and the preparing method

A bamboo charcoal and modification technology, which is applied in the field of modified bamboo charcoal products and its preparation, can solve the problems of no light source, blockage of bamboo charcoal channels, affect photocatalysis and antibacterial effects, etc., and achieve the effect of high negative ion concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

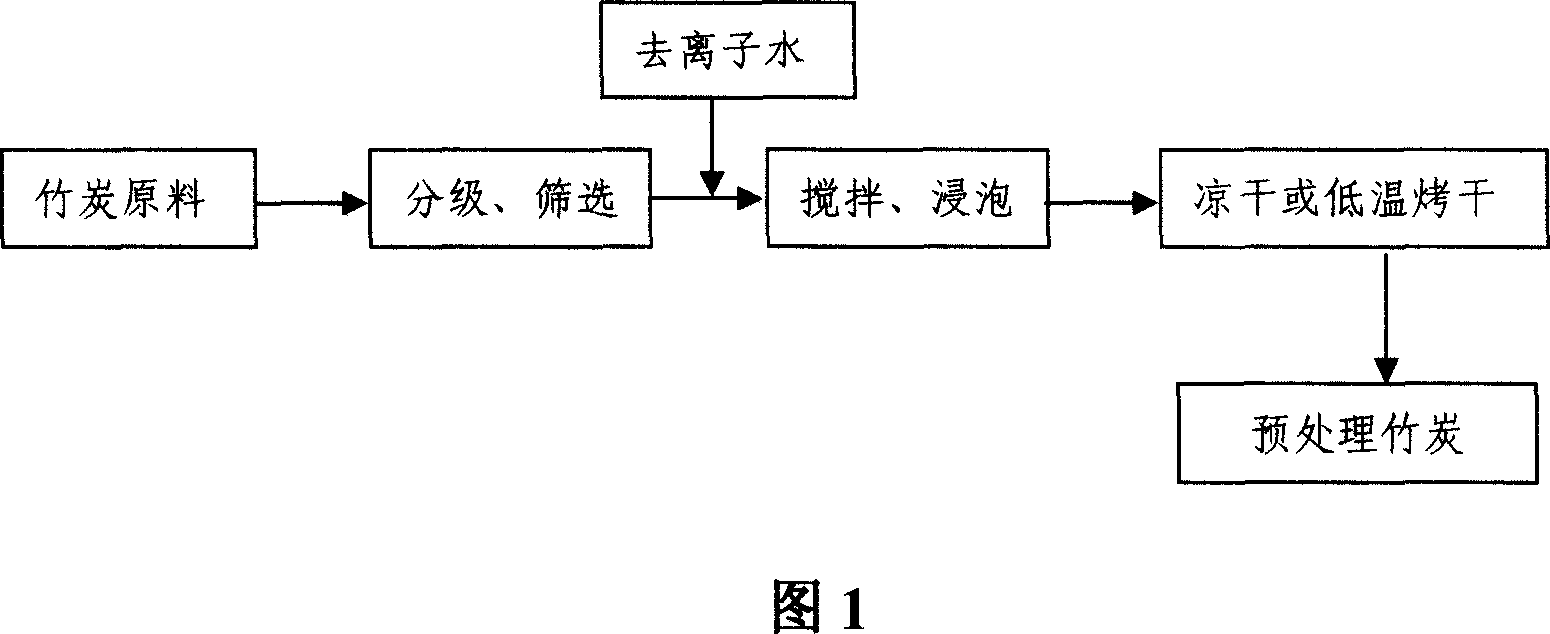

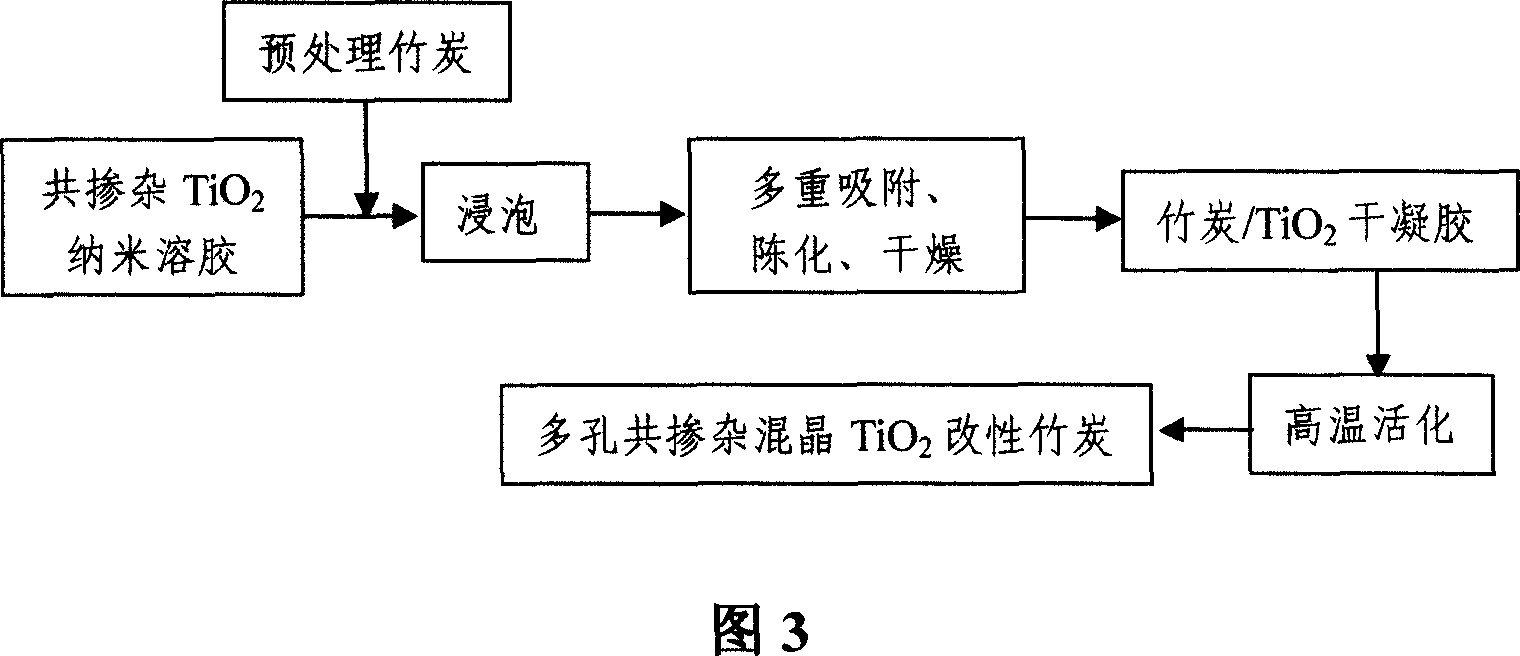

[0031] As shown in Figure 1, the raw materials of modified bamboo charcoal are prepared by grading and screening bamboo charcoal materials, adding deionized water, soaking, stirring, air-drying or low-temperature drying to obtain pre-treated bamboo charcoal raw materials. The specific surface area of the pretreated bamboo charcoal raw material is 100~250m 2 / g.

Embodiment 2

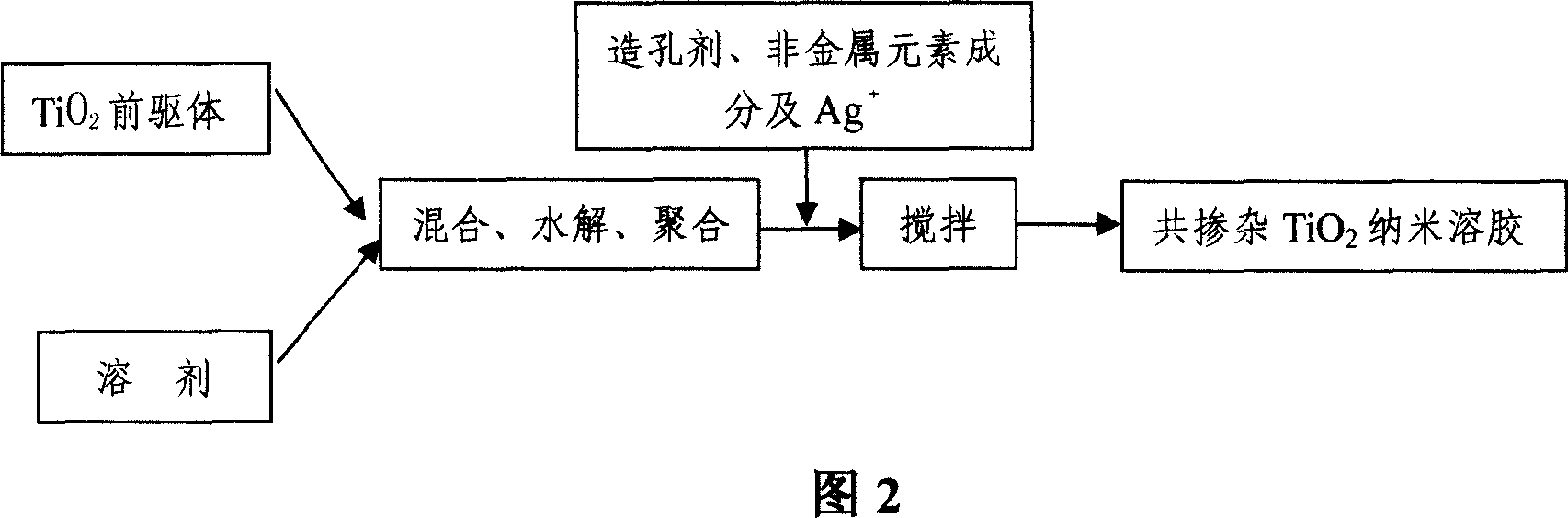

[0033] An Ag / N co-doped TiO containing a pore former as shown in Figure 2 2 The preparation method of nano-sol, the raw material conditions: butyl titanate, absolute ethanol, hydrochloric acid and deionized water as the main raw materials, hexamethylenetetramine as the nitrogen source, the molar ratio of N to Ti is 0.5%; nitric acid; Silver is complexed with citric acid to introduce silver ions, Ag + The molar ratio with Ti is 0.1%, and polyethylene glycol is 3% by weight of the sol.

[0034] At room temperature, slowly drop a certain amount of butyl titanate into absolute ethanol and stir vigorously for 30 minutes to obtain a uniform bright yellow clear solution; then add a certain proportion of deionized water, absolute ethanol, hydrochloric acid, Hexamethylenetetramine, citric acid complexed silver nitrate, and polyethylene glycol constitute a mixed liquid, slowly drip into the above clear solution, control the pH of the solution to about 2, and stir vigorously for 2 hours to p...

Embodiment 3

[0037] A kind of Ag / N co-doped TiO containing pore former 2The preparation method of nano sol, the raw material conditions: butyl titanate, absolute ethanol, hydrochloric acid and deionized water as the main raw materials, hexamethylenetetramine as the nitrogen source, the molar ratio of N to Ti is 1.0%; nitric acid; Silver is complexed with citric acid to introduce silver ions, Ag + The molar ratio with Ti is 0.3%, and polyethylene glycol is 3.5% by weight of the sol.

[0038] At room temperature, slowly drop a certain amount of butyl titanate into absolute ethanol and stir vigorously for 30 minutes to obtain a uniform bright yellow clear solution; then add a certain proportion of deionized water, absolute ethanol, hydrochloric acid, Hexamethylenetetramine, citric acid complexed silver nitrate, and polyethylene glycol constitute a mixed liquid, slowly drip into the above clear solution, control the pH value of the solution to about 2, and stir vigorously for 2 hours to prepare th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com