High efficiency air purification material

A technology for purifying materials and high-efficiency air, which is used in gas treatment, chemical instruments and methods, and dispersed particle separation to achieve the effects of good product stability, simple production process, and stable air purification capability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

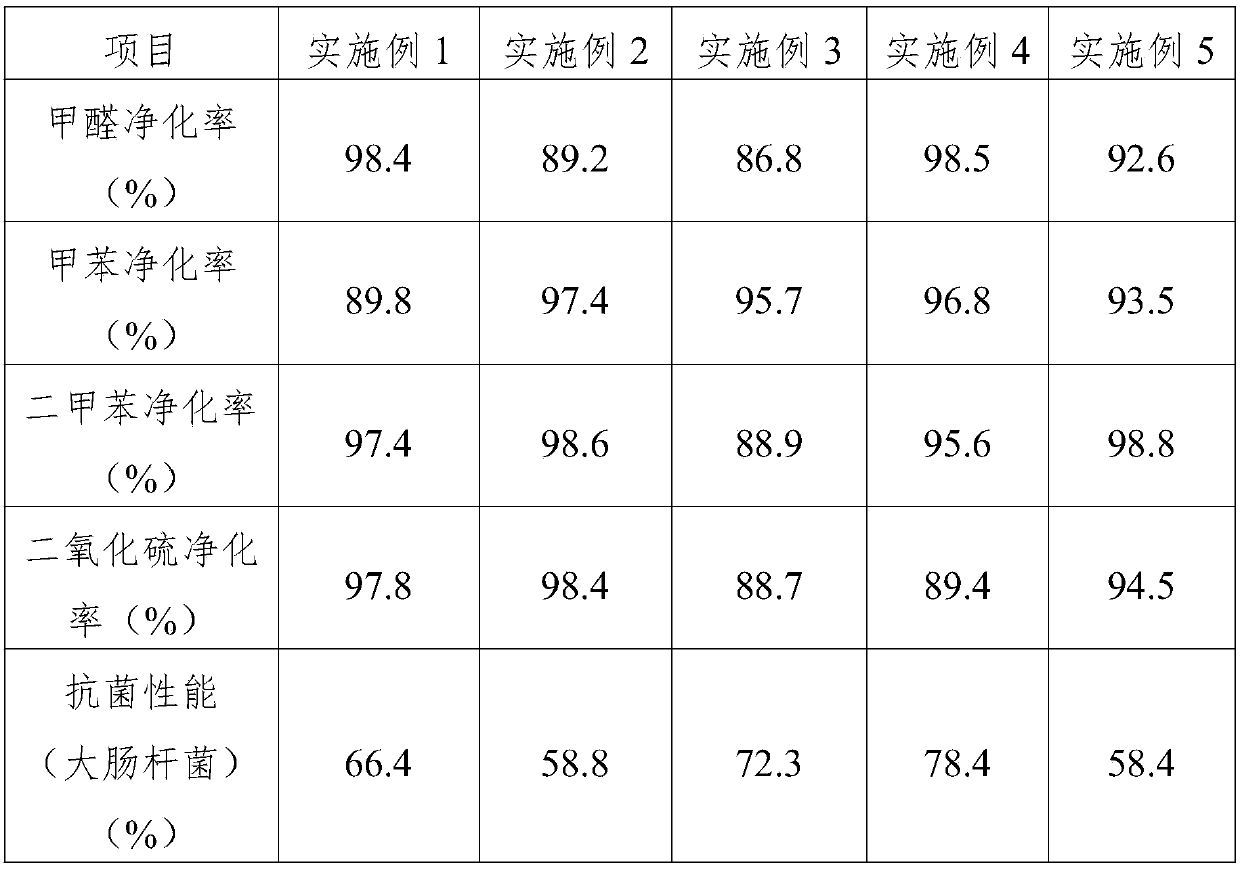

Examples

Embodiment 1

[0021] A high-efficiency air purification material, comprising the following raw materials in parts by weight: 80-120 parts of tourmaline, 40-60 parts of bentonite, 25-30 parts of montmorillonite, 18-24 parts of nano-manganese dioxide, and 12-15 parts of nano-titanium dioxide , 12-18 parts of cerium oxide, 10-14 parts of molybdenum oxide, 8-14 parts of nickel oxide, 12-16 parts of chitin nanofibers, 15-18 parts of sodium citrate and 30-60 parts of ethylene glycol dimethacrylate share.

[0022] Preferably, a high-efficiency air purification material comprises the following raw materials in parts by weight: 80 parts of tourmaline, 45 parts of bentonite, 25 parts of montmorillonite, 20 parts of nano-manganese dioxide, 12 parts of nano-titanium dioxide, 14 parts of cerium oxide, 10 parts of molybdenum, 8 parts of nickel oxide, 15 parts of chitin nanofibers, 16 parts of sodium citrate and 30 parts of ethylene glycol dimethacrylate.

[0023] A preparation method of high-efficiency ...

Embodiment 2

[0028] A high-efficiency air purification material, comprising the following raw materials in parts by weight: 80-120 parts of tourmaline, 40-60 parts of bentonite, 25-30 parts of montmorillonite, 18-24 parts of nano-manganese dioxide, and 12-15 parts of nano-titanium dioxide , 12-18 parts of cerium oxide, 10-14 parts of molybdenum oxide, 8-14 parts of nickel oxide, 12-16 parts of chitin nanofibers, 15-18 parts of sodium citrate and 30-60 parts of ethylene glycol dimethacrylate share.

[0029]Preferably, a high-efficiency air purification material includes the following raw materials in parts by weight: 100 parts of tourmaline, 50 parts of bentonite, 26 parts of montmorillonite, 18 parts of nano-manganese dioxide, 14 parts of nano-titanium dioxide, 12 parts of cerium oxide, 12 parts of molybdenum, 10 parts of nickel oxide, 12 parts of chitin nanofibers, 15 parts of sodium citrate and 45 parts of ethylene glycol dimethacrylate.

[0030] A preparation method of high-efficiency ...

Embodiment 3

[0035] A high-efficiency air purification material, comprising the following raw materials in parts by weight: 80-120 parts of tourmaline, 40-60 parts of bentonite, 25-30 parts of montmorillonite, 18-24 parts of nano-manganese dioxide, and 12-15 parts of nano-titanium dioxide , 12-18 parts of cerium oxide, 10-14 parts of molybdenum oxide, 8-14 parts of nickel oxide, 12-16 parts of chitin nanofibers, 15-18 parts of sodium citrate and 30-60 parts of ethylene glycol dimethacrylate share.

[0036] Preferably, a high-efficiency air purification material includes the following raw materials in parts by weight: 120 parts of tourmaline, 40 parts of bentonite, 27 parts of montmorillonite, 22 parts of nano-manganese dioxide, 15 parts of nano-titanium dioxide, 16 parts of cerium oxide, 11 parts of molybdenum, 14 parts of nickel oxide, 14 parts of chitin nanofibers, 17 parts of sodium citrate and 50 parts of ethylene glycol dimethacrylate.

[0037] A preparation method of high-efficiency...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com