Method and equipment for electromagnetic composite double-face submerged arc welding of diphase stainless steel thick plate

A duplex stainless steel and submerged arc welding technology, which is applied in arc welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of cumbersome process and submerged arc welding quality of duplex stainless steel, so as to avoid material waste and reduce Effects of small chemical heterogeneity and sensitivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0044] Example 1: Electromagnetic composite submerged arc welding of 2205 duplex stainless steel with a plate thickness of 6mm, using E2209 welding wire, for the construction of chemical ships; Clean up the oil and moisture on the end face of the joint and dry it. Ceramic liners are used on the back of the weld seam; bottom welding and cover welding are performed by MIG welding. The welding current is 120-160A, the welding speed is 35-50cm / min, and the shielding gas It is 99.9% argon, the shielding gas flow rate is 18L / min, the shielding gas is passed for 25s before the welding arc is started, and the shielding gas is kept for 30s after the arc is extinguished; the electromagnetic composite submerged arc welding method without opening the groove is adopted , The welding process parameters are as follows: excitation current is 5-20A, magnetic field frequency is 3-15Hz, welding current is 350-600A, welding wire diameter is 2.4mm, welding voltage is 30-45V, welding speed is 15-60m...

example 2

[0045] Example 2: Electromagnetic composite submerged arc welding of 2205 duplex stainless steel with a plate thickness of 12mm, using ER2209 welding wire, the joint adopts I-shaped groove, the assembly gap is 2mm, the end surface of the joint is machined to be smooth and smooth, and the oil and water on the end surface of the joint are cleaned before welding , and dry, the back of the weld is connected with argon + 10% nitrogen as a shielding gas, and the flow rate of the shielding gas is 16L / min; the MAG welding method is used for bottom welding and cover welding, and the welding current is 140-180A. The speed is 30-45cm / min, the shielding gas is argon + 10% nitrogen mixed gas, the shielding gas flow rate is 22L / min, the shielding gas is used for 25s before the welding arc starts, and the shielding gas is kept for 30s after the arc is extinguished; The electromagnetic composite double-sided submerged arc welding method without groove is adopted, and the welding process parame...

example 3

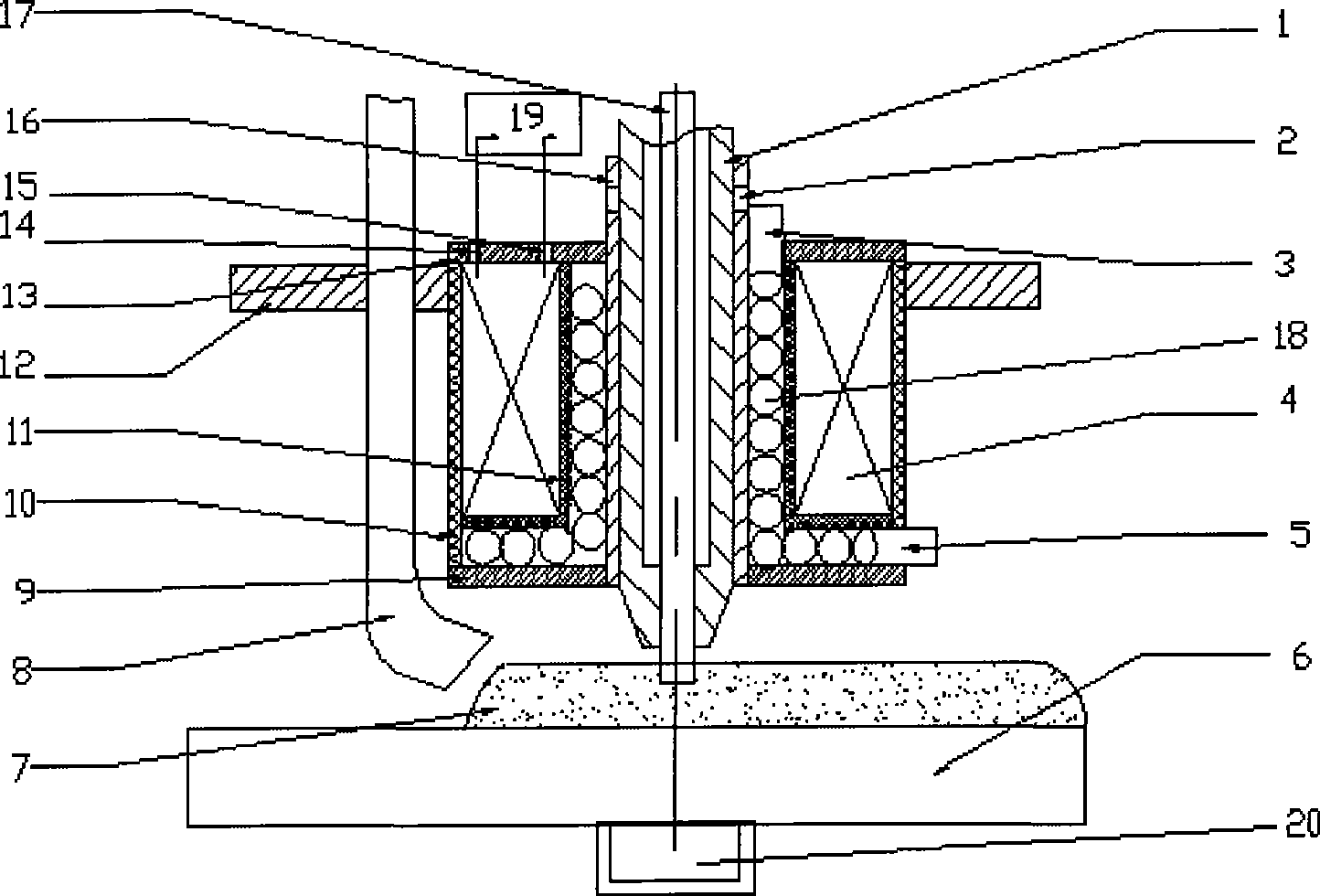

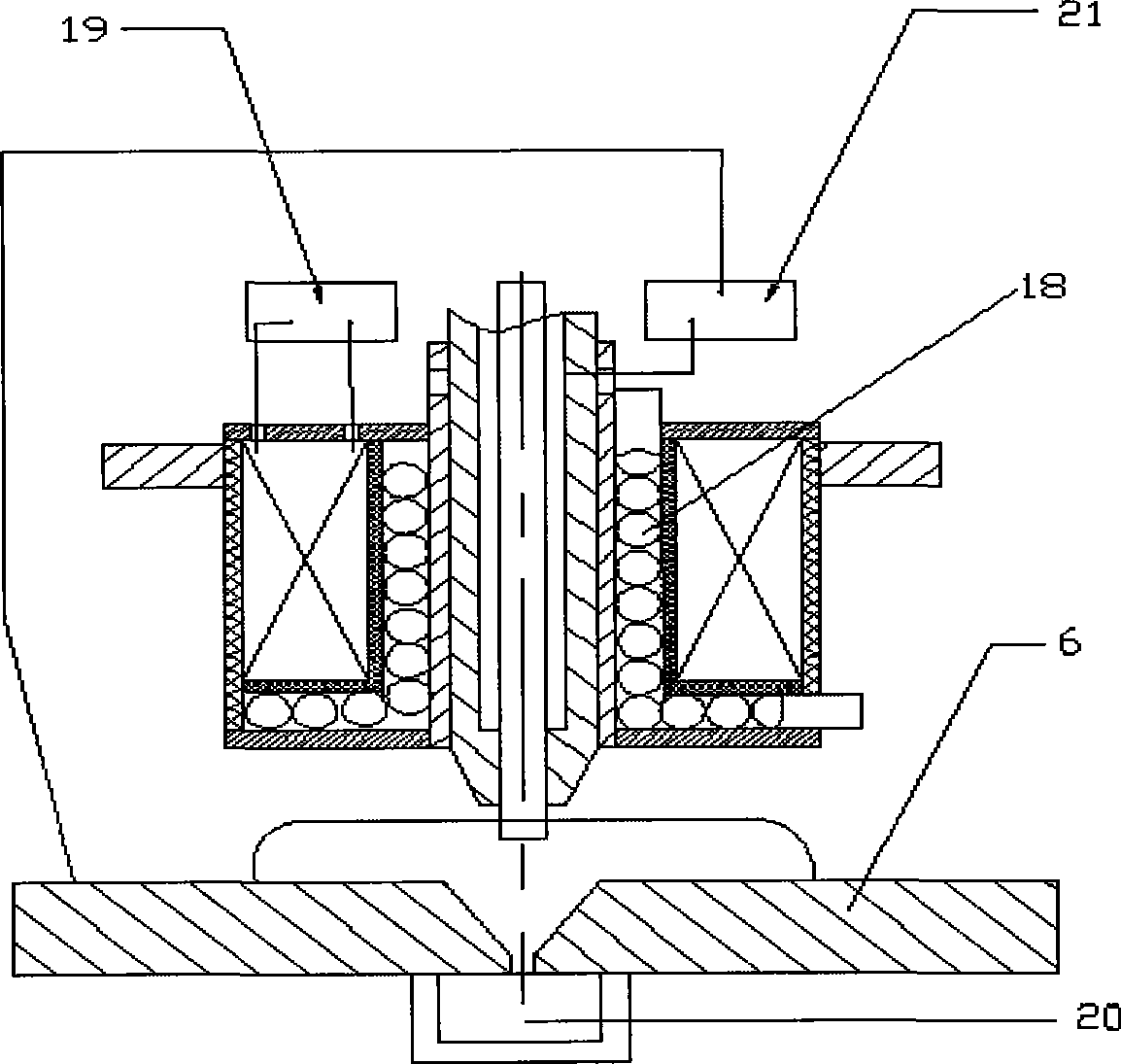

[0046] Example 3: The magnetically permeable magnetic core 16 is a Q235 steel pipe with an outer diameter of ф40mm, and three threaded holes 2 are drilled at a distance of 5mm from the upper end of the magnetically permeable core, with a diameter of ф5mm. Here, it cooperates with the top tightening screw to fix the water-cooled excitation coil 4; The upper retaining ring 13 and the lower retaining ring 9 are made of red copper, with an outer diameter of ф80mm and a thickness of 2mm. On the upper retaining ring 13, a ф3mm wire inlet 14 and a ф3mm wire outlet 15 are drilled. The upper retaining ring 13 is at ф42mm Drill a ф7mm water outlet port 3 on the circumference; the outer diameter of the cooling copper pipe is ф6mm; lay a 1mm thick insulating layer 11 on the cooling copper pipe; wrap a 1mm protective layer 10 around the coil.

[0047] In actual welding, according to different welding processes, base metal materials, welding materials and joint forms, etc., the electromagnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com