Angular displacement sensor

An angular displacement sensor and sensor technology, which is applied in the direction of using an electric/magnetic device to transmit sensing components, can solve the problems of difficult to ensure production consistency, difficult to meet accurate measurement, and difficult to process and produce, and achieve a reduction in shape and position tolerances. requirements, the magnetic field change rate is enhanced, and the effect of improving the linearity of the signal output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

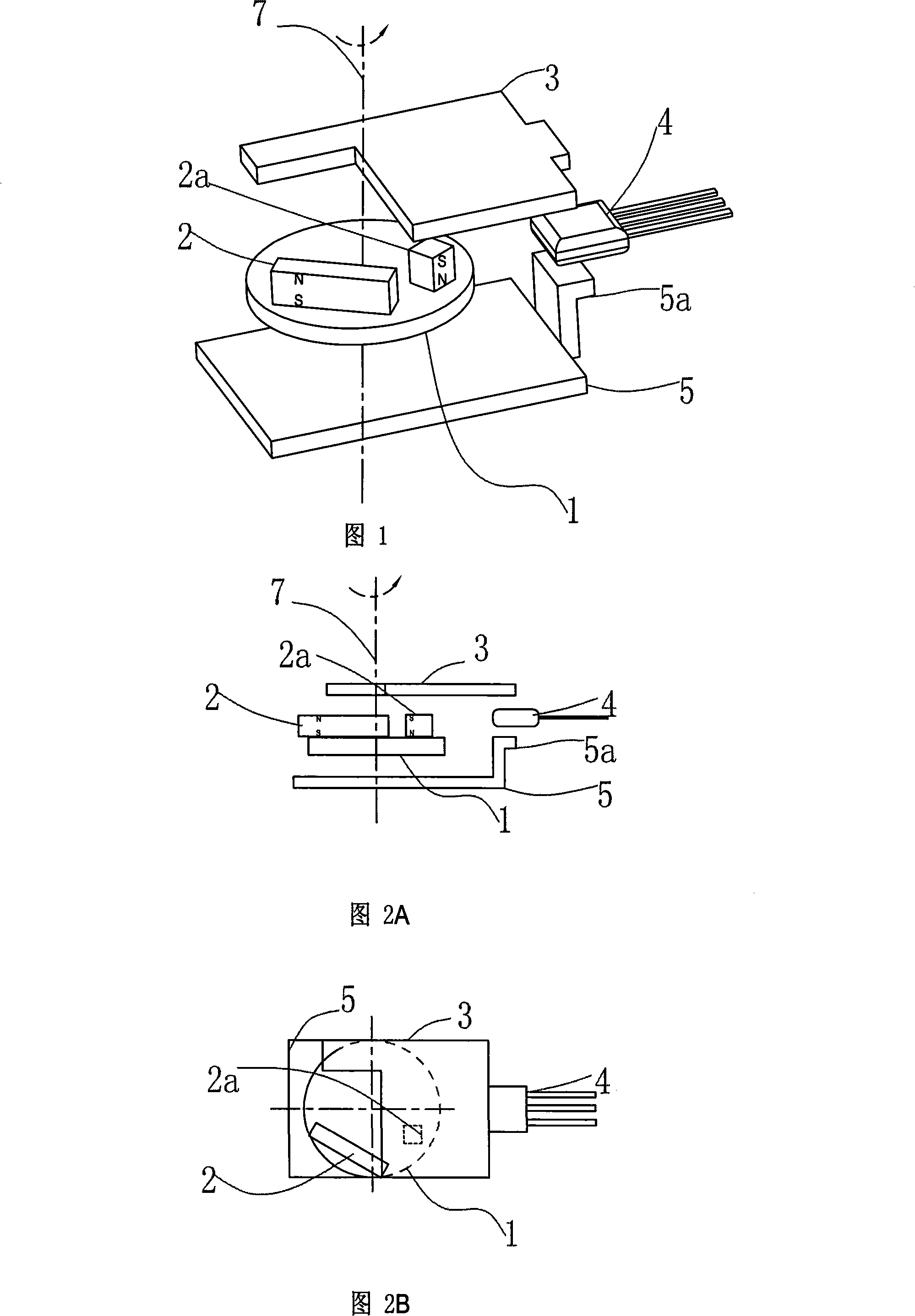

[0053] Embodiment 1 of the present invention in the measurement of throttle body angular displacement will be described in detail below in conjunction with accompanying drawings 1 to 3 .

[0054] Fig. 1 is an axial view of Embodiment 1 of an angular displacement sensor.

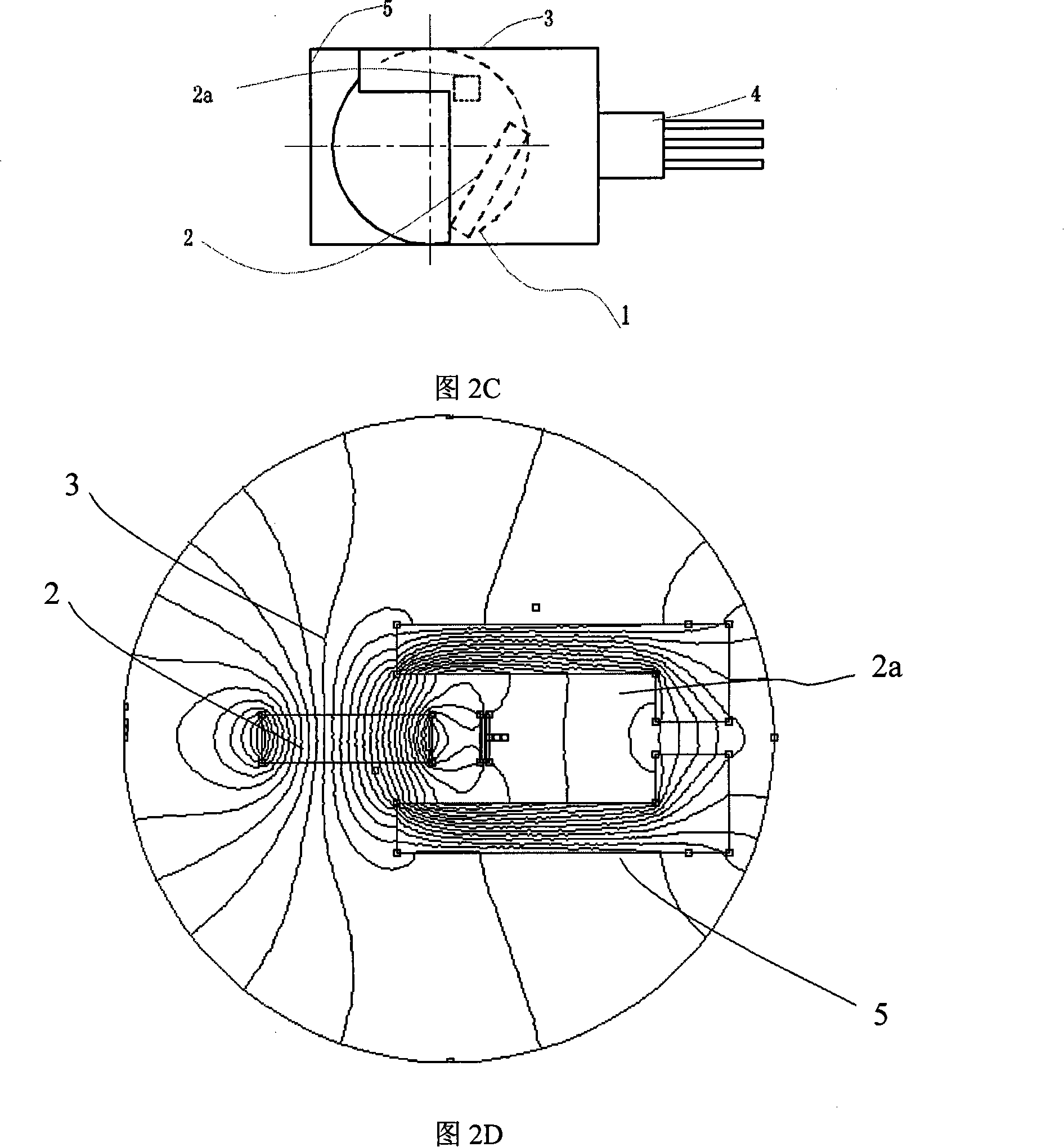

[0055]As shown in the figure, the rotating body 1 includes a magnetic element 2 and a reference magnetic element 2a; the magnetization directions of the magnetic element 2 and the reference magnetic element 2a are parallel to the rotation center of the rotating body, but the magnetization directions of the two are opposite, and their respective The polarity after magnetization is shown in Figure 2(A).

[0056] The sensor structure also includes an upper yoke 3 and a lower yoke 5; the lower yoke 5 has an upper protrusion 5a.

[0057] The Hall sensor 4 is installed between the parallel magnetic fields formed by the lower yoke 3 and the upper yoke 5 , and the magnetic flux detection direction of the Hall sensor...

Embodiment 2

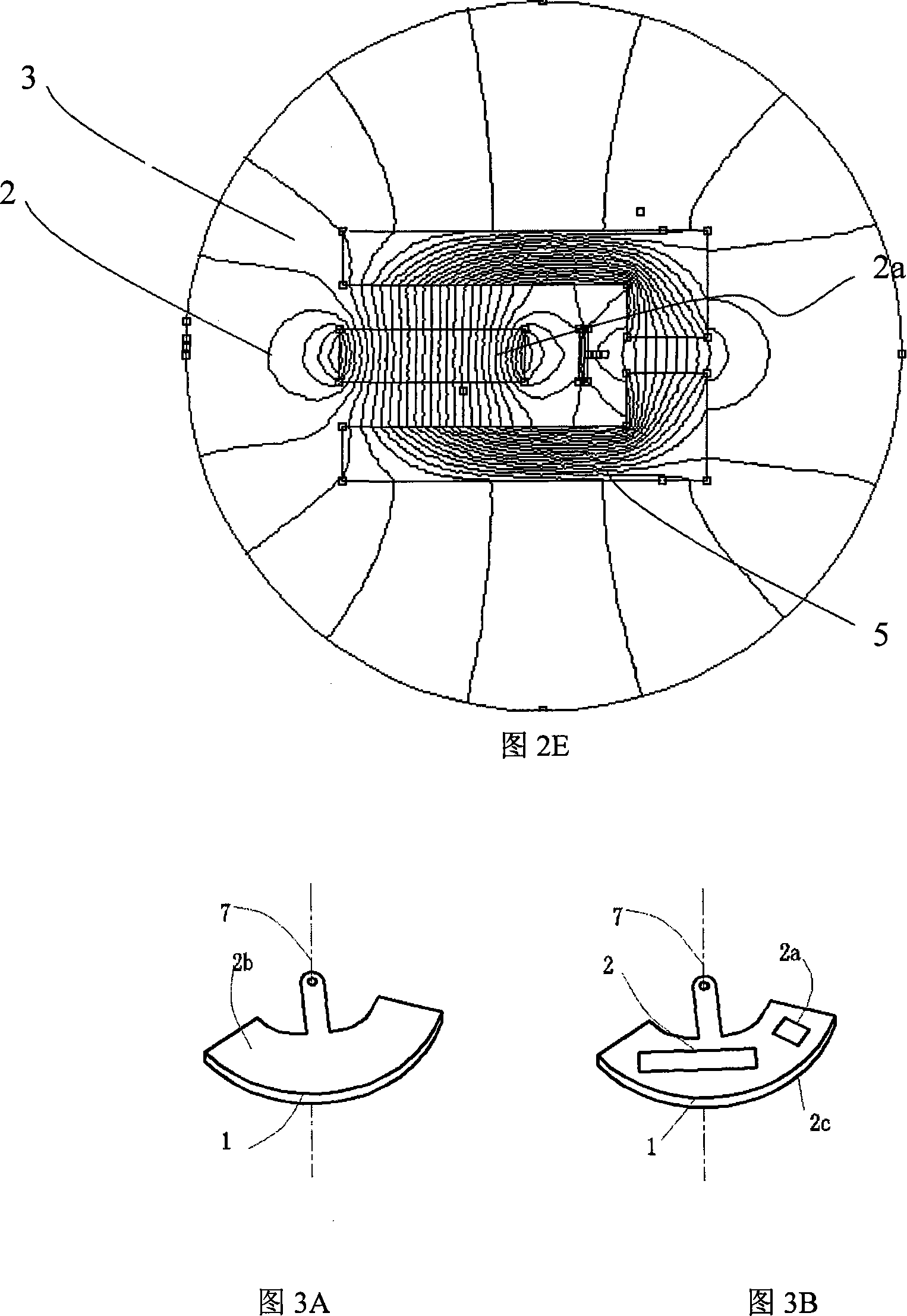

[0065] The difference from the first embodiment is that the addition of the lower protrusion 2b of the upper yoke can improve the sensitivity of the sensor and the linearity of the output signal. Fig. 5 is an axial view of an angular displacement sensor in the second embodiment. Fig. 6 is a side view of an angular displacement sensor in the second embodiment.

Embodiment 3

[0067] When the temperature stability of the magnetic element is good, or the temperature of the operating environment changes little, in order to further save costs, on the basis of the first embodiment, the reference magnetic element 2b is removed. At the same time, in certain occasions, in order to facilitate the axial installation of the lower yoke 5, the installation position of the magnetic detection element 4 is changed. This forms embodiment three. Fig. 7 is a side view of an angular displacement sensor in the third embodiment.

[0068] In order to simplify the product structure, improve the consistency of product production, improve the assembly reliability and manufacturability of the product, and greatly reduce the production cost, in this embodiment, the magnetic element 2b is made by injection molding or integral gluing, that is, the entire magnetic element 2b is made by injection molding. The magnetic element 2b is replaced by a molded or glued integrally formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com