Rare-earth fireproof heat-insulating material and preparation method therefor

A technology for fire-proof heat preservation and heat preservation material, applied in the field of heat preservation material, can solve the problem of difficult to meet the requirements of mechanical strength, achieve good hydrophobicity and air permeability, improve fire resistance and heat preservation performance, and improve the effect of fire and heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

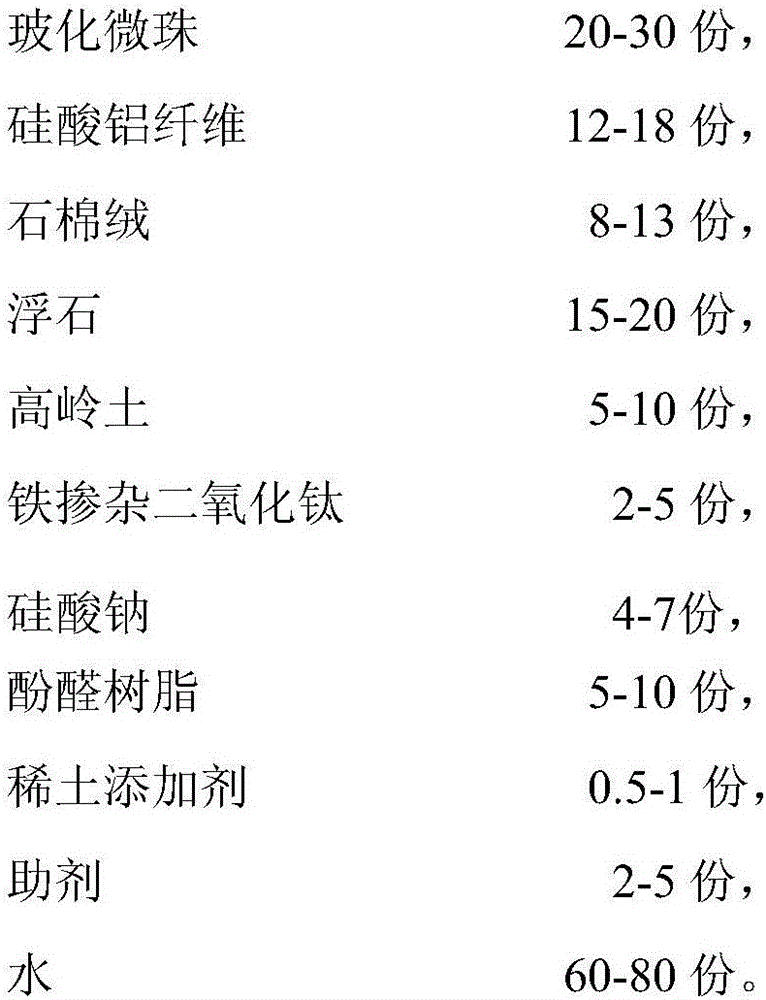

[0023] Rare earth fireproof and thermal insulation materials, including the following components in parts by mass:

[0024]

[0025] Among them, the particle size of pumice is 220 mesh.

[0026] The particle size of iron-doped titanium dioxide is 50-75nm.

[0027] The rare earth additive is lanthanum nitrate.

[0028] The auxiliary agent is white carbon black, polyethylene glycol and methyl hydroxyethyl cellulose ether, and its weight ratio is 4:1:2.

[0029] According to the proportioning ratio of the rare earth fireproof and thermal insulation material, it is prepared as follows:

[0030] (1) Take pumice, kaolin and additives in a ball mill, and ball mill and mix them at 115°C for 0.5h to obtain a ball mill mixture;

[0031] (2) Take vitrified microspheres, aluminum silicate fibers and asbestos wool, add water, mix well, add the ball mill mixture whose temperature drops to 45°C, stir for 12 minutes, then add iron-doped titanium dioxide and rare earth additives , stir ...

Embodiment 2

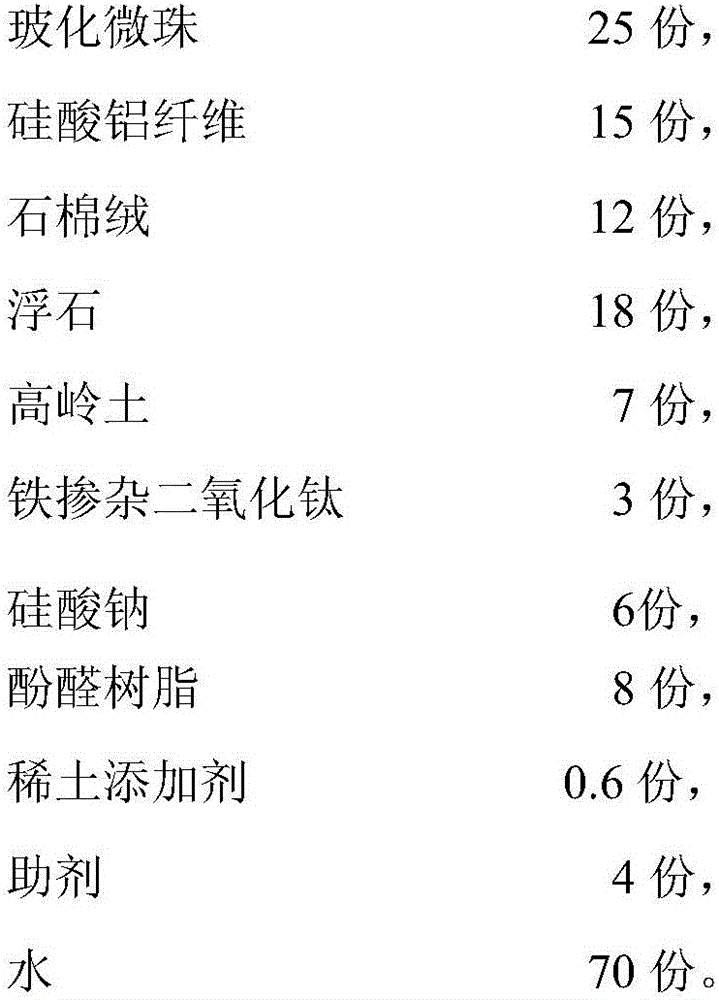

[0035] Rare earth fireproof and thermal insulation materials, including the following components in parts by mass:

[0036]

[0037] Wherein, the particle size of the pumice is 200 mesh.

[0038] The particle size of iron-doped titanium dioxide is 50-75nm.

[0039] The rare earth additive is lanthanum nitrate.

[0040] The auxiliary agent is white carbon black, polyethylene glycol and methyl hydroxyethyl cellulose ether, and its weight ratio is 3:1:2.

[0041] According to the proportioning ratio of the rare earth fireproof and thermal insulation material, it is prepared as follows:

[0042] (1) Take pumice, kaolin and additives in a ball mill, and ball mill and mix them for 1 hour at 110° C. to obtain a ball mill mixture;

[0043] (2) Take vitrified microbeads, aluminum silicate fibers and asbestos wool, add water, mix well, add the ball mill mixture whose temperature drops to 30°C, stir for 10 minutes, add iron-doped titanium dioxide and rare earth additives , stir ev...

Embodiment 3

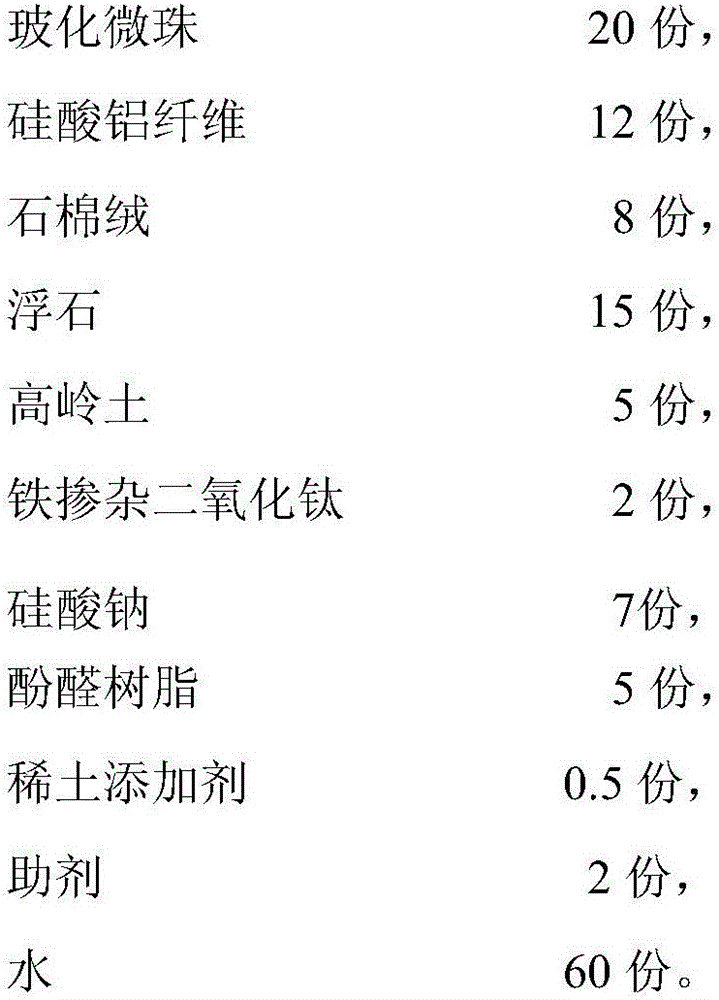

[0047] Rare earth fireproof and thermal insulation materials, including the following components in parts by mass:

[0048]

[0049] Wherein, the particle size of the pumice is 250 mesh.

[0050] The particle size of iron-doped titanium dioxide is 50-75nm.

[0051] The rare earth additive is lanthanum nitrate.

[0052] The auxiliary agent is white carbon black, polyethylene glycol and methyl hydroxyethyl cellulose ether, and its weight ratio is 5:1:3.

[0053] According to the proportioning ratio of the rare earth fireproof and thermal insulation material, it is prepared as follows:

[0054] (1) Take pumice, kaolin and additives in a ball mill, and ball mill and mix them at 125°C for 0.5h to obtain a ball mill mixture;

[0055] (2) Take vitrified microspheres, aluminum silicate fibers and asbestos wool, add water, mix well, add the ball mill mixture whose temperature drops to 50°C, stir for 15 minutes, then add iron-doped titanium dioxide and rare earth additives , stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com