Method for making opening and short cutting on single wall Nano carbon tube

A carbon nanotube and short-cut technology, which is applied in the post-processing field of carbon nanotubes, can solve the problems of structural damage of single-walled carbon nanotubes, long time consumption and low yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

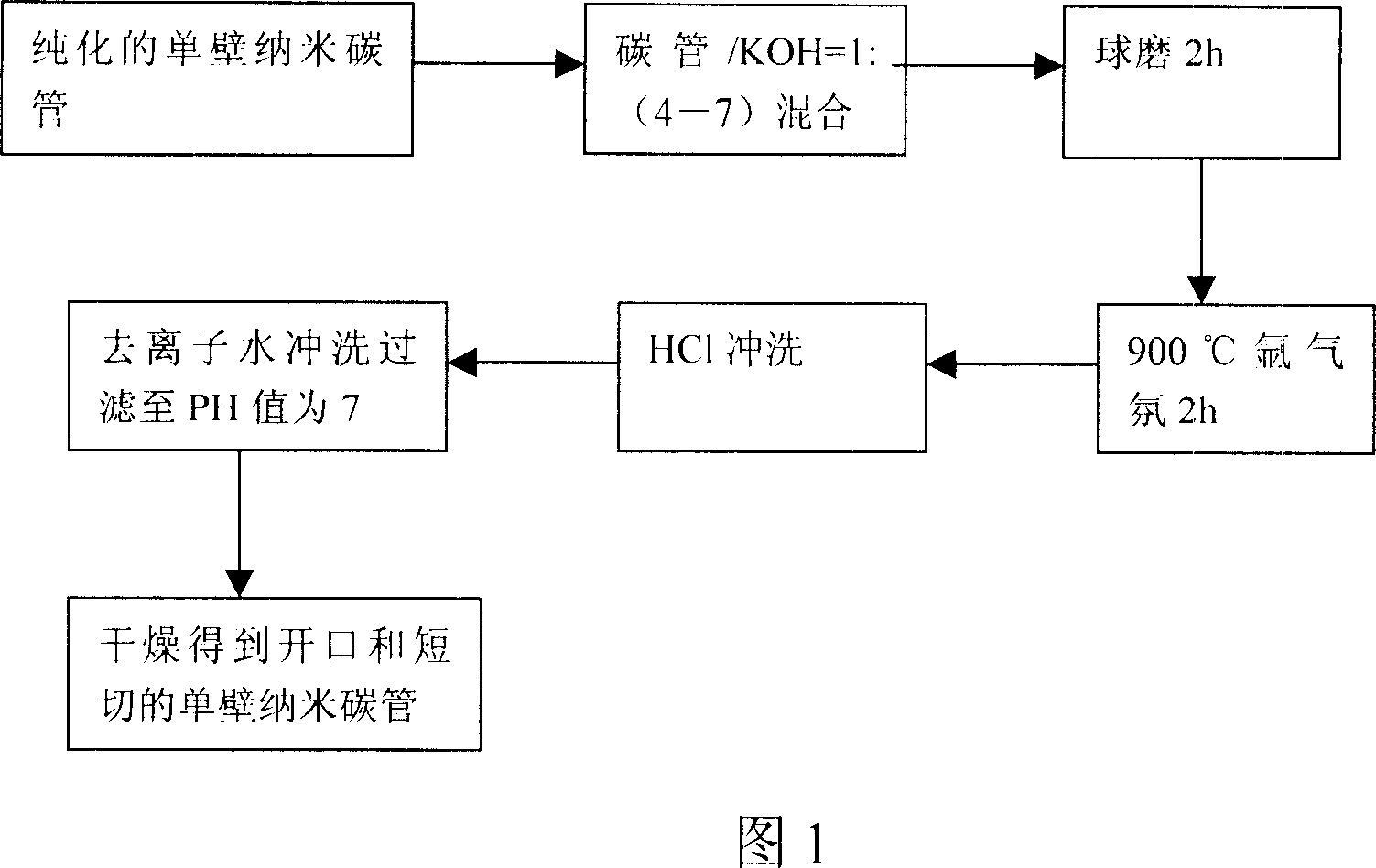

[0017] Take 100 mg of single-walled carbon nanotubes with an average diameter of 1.85 nm after purification, mix them with 600 mg of KOH, and ball mill them on a planetary ball mill at a speed of 500 rpm for 2 h, and then grind them at 15 °C / min under the protection of argon. The heating rate was increased to 900°C for 2 hours, cooled naturally to room temperature, washed with HCl, rinsed with deionized water, and finally pure open and chopped single-walled carbon nanotubes were obtained. Observation by transmission electron microscope shows that the tube bundle length is between 2-3um, and the opening ratio of the sample is 85%.

Embodiment 2

[0019] Take 100 mg of single-walled carbon nanotubes with an average diameter of 1.85 nm after purification, mix them with 400 mg of KOH, and ball mill them on a planetary ball mill at a speed of 500 rpm for 2 h, and then grind them at 15 °C / min under the protection of argon. The heating rate was increased to 900°C for 2 hours, cooled naturally to room temperature, washed with HCl, rinsed with deionized water, and finally pure open and chopped single-walled carbon nanotubes were obtained. Observation by transmission electron microscope shows that the tube bundle length is between 2-3um, and the opening ratio of the sample is 80%.

Embodiment 3

[0021] Take 100 mg of single-walled carbon nanotubes with an average diameter of 1.85 nm after purification, mix them with 400 mg of KOH, and ball mill them on a planetary ball mill at a speed of 500 rpm for 2 h, and then grind them at 15 °C / min under the protection of argon. The heating rate was increased to 900°C for 2 hours, cooled naturally to room temperature, washed with HCl, rinsed with deionized water, and finally pure open and chopped single-walled carbon nanotubes were obtained. Observation by transmission electron microscope shows that the tube bundle length is between 2-3um, and the opening ratio of the sample is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com