Hydrolysis denitrification denitrification system and method

A technology of nitrification, denitrification and denitrification, which is applied in the field of denitrification and denitrification systems, can solve the problems of poor biodegradability of wastewater, difficulty in reaching the standard of total nitrogen in effluent, and unfavorable biological utilization, and achieves good sludge retention capacity and high matrix degradation. Efficiency, the effect of increasing the degree of removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034]In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings. Here, the exemplary embodiments and descriptions thereof of the present invention are only used to explain the present invention, and are not intended to limit the present invention.

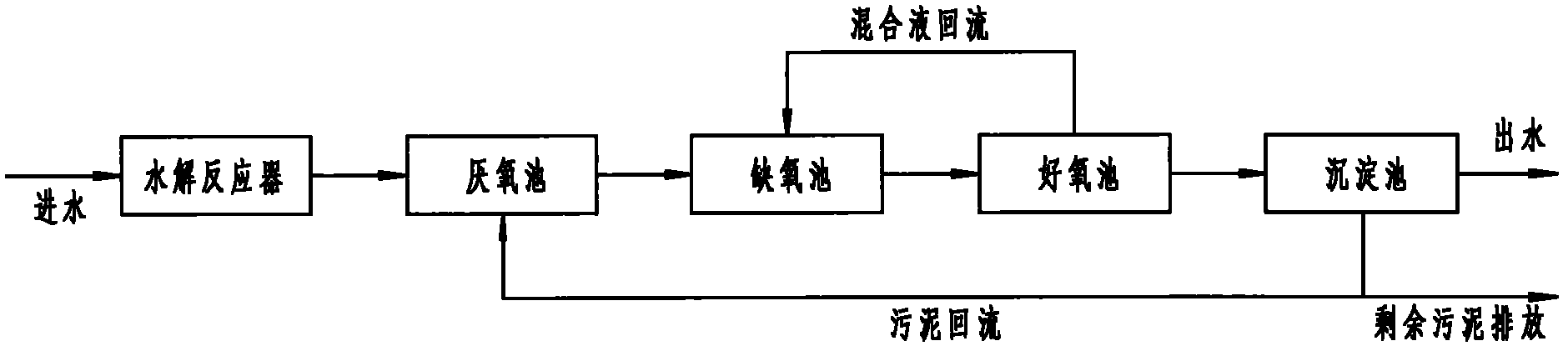

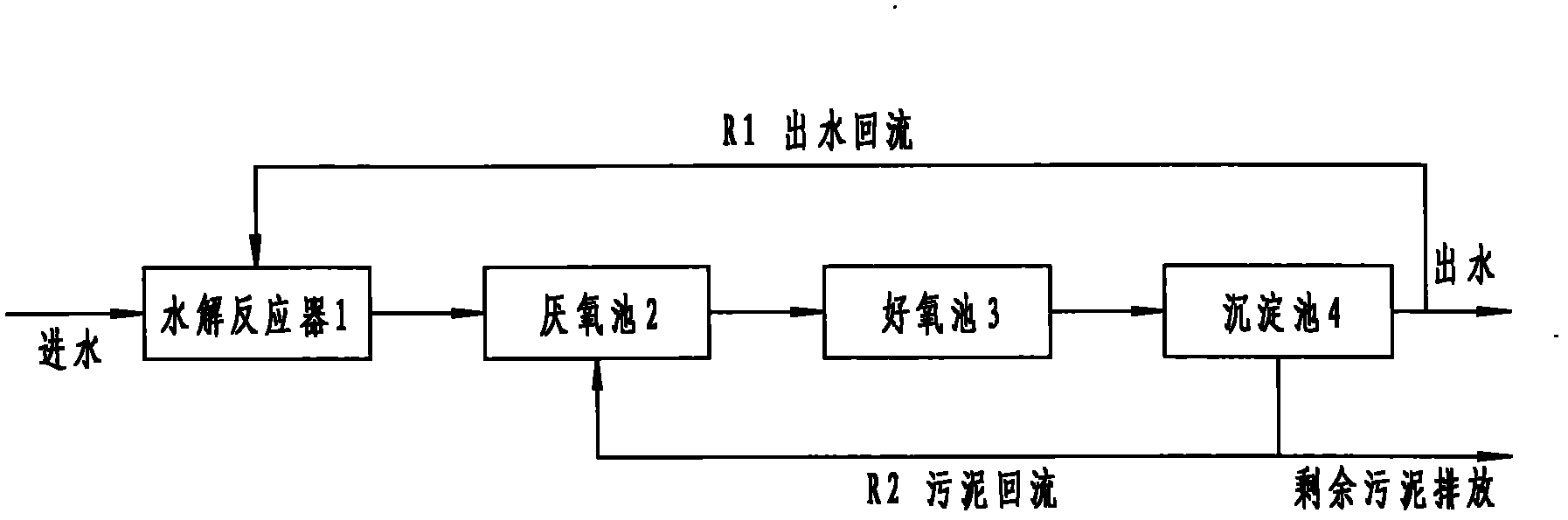

[0035] figure 2 It shows an embodiment of the hydrolysis denitrification denitrification process of the present invention, which transforms the traditional hydrolysis + AAO process facility, cancels the anoxic tank, and cancels the mixed liquid return channel from the aerobic tank to the anoxic tank.

[0036] like figure 2 As shown, the hydrolysis denitrification denitrification system of the present invention is composed of a hydrolysis reactor 1, an anaerobic tank 2, an aerobic tank 3 and a sedimentation tank 4 connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com