Carrageenan extraction equipment and process

An extraction equipment and carrageenan technology, applied in solvent extraction, solid solvent extraction, cleaning methods using liquids, etc., can solve the problems of incomplete removal of the skin, many impurities in the glue, and low dissolution efficiency of raw materials, so as to save boiling glue time, increase the degree of fragmentation, and the effect of easy dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

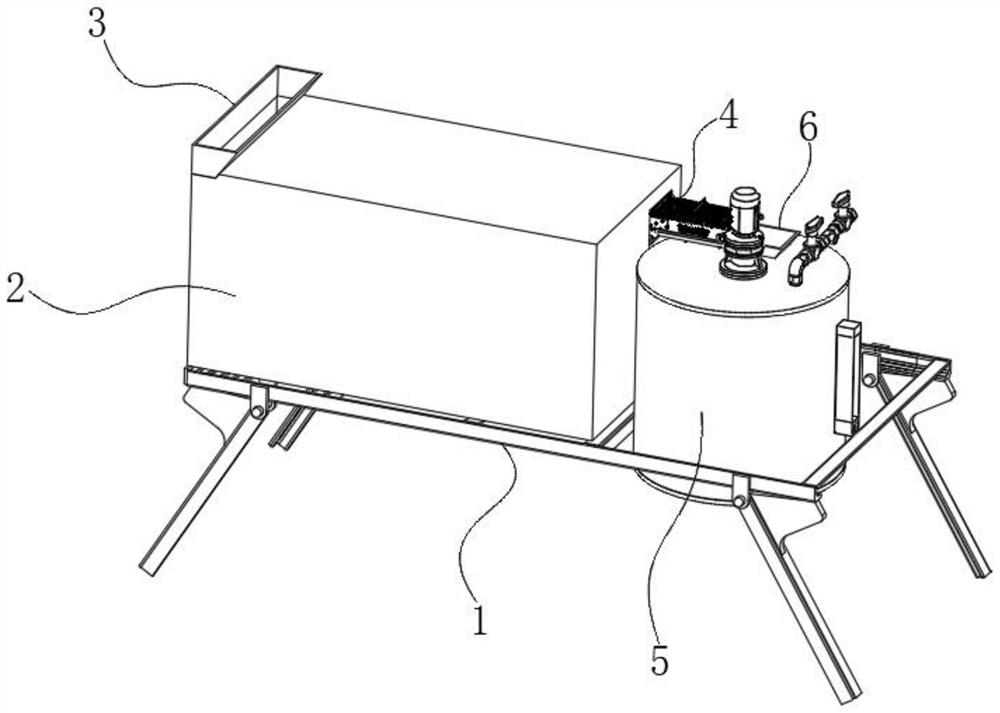

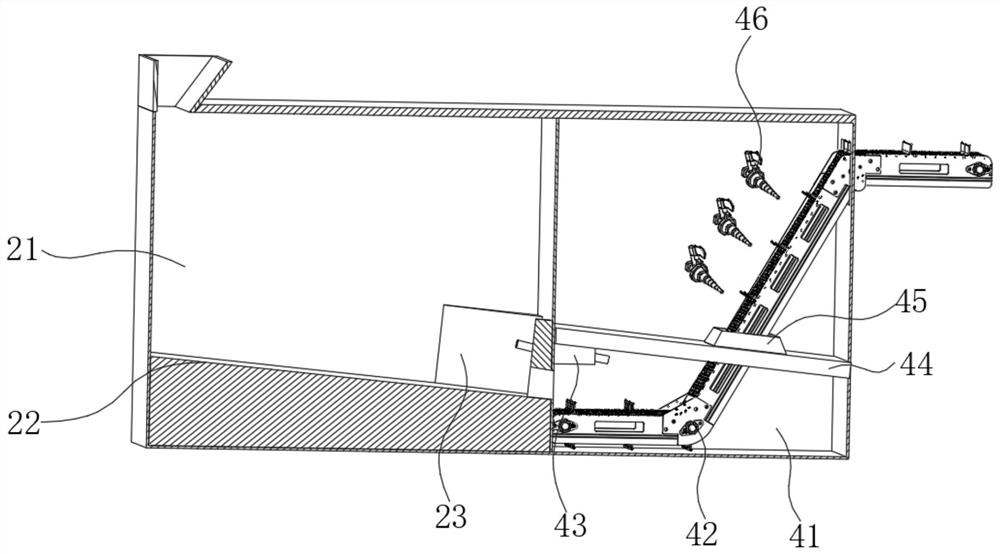

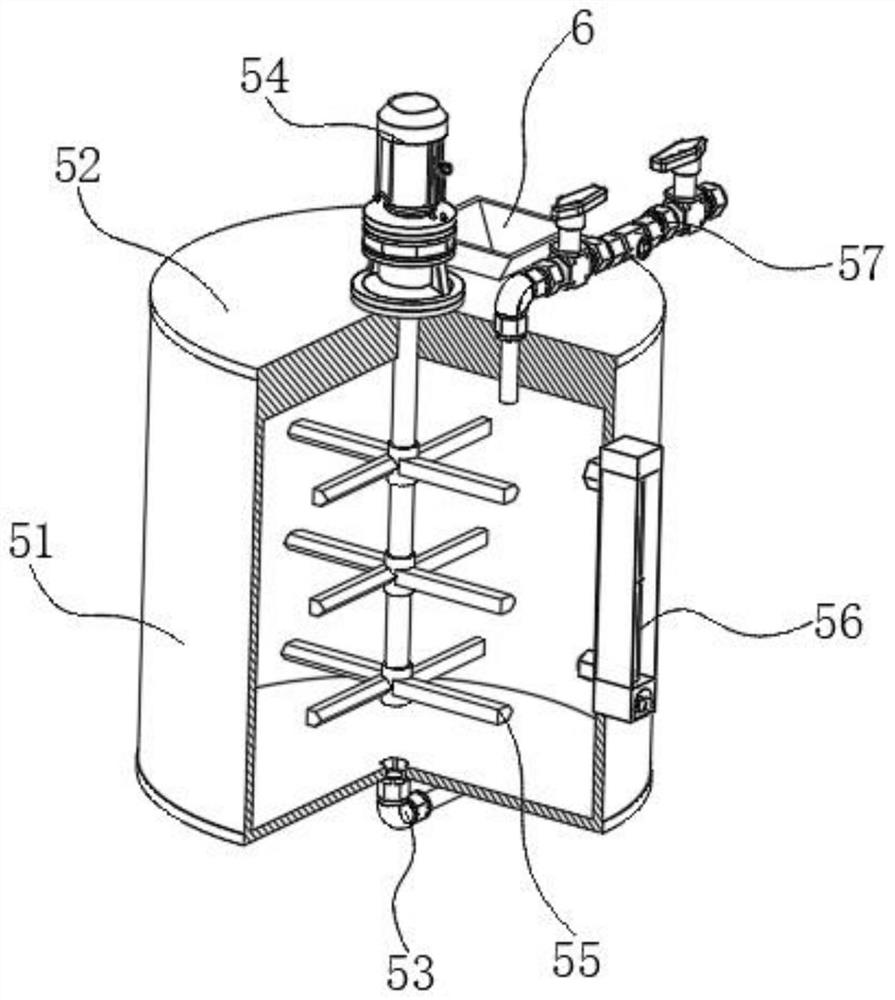

[0037] see Figure 1~5 , the present invention provides a carrageenan extraction device: including a base 1, a raw material processing bin 2, a cleaning component 4, a glue boiling component 5 and an extrusion component 6;

[0038] The upper end surface of the base 1 is fixed with a raw material processing bin 2 and a glue cooking assembly 5, and a raw material inlet 3 is fixed on the upper end surface of the raw material processing bin 2 away from the glue cooking assembly 5, and the side of the raw material inlet 3 Inclining towards the side wall of the raw material processing bin 2, the raw material can slide into the interior along the side wall of the raw material processing bin 2, that is to say, it prevents the raw material from directly falling in the middle of the raw material processing bin 2, thereby increasing the soaking time of the raw material;

[0039] An extruding assembly 6 is provided on one side of the upper end surface of the gelatinizing assembly 5, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com