Preparation method of farmland heavy metal contaminated soil repairing mineralizer

A technology that pollutes soil and heavy metals. It is applied in the field of soil pollution control and environmental protection. It can solve the problems of high preparation cost, many raw material components, and high raw material cost, and achieve the effects of uniform distribution, easy availability of raw materials, and reduced preparation cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] The preparation method of the remediation mineralizer for farmland heavy metal polluted soil in this example comprises the following steps:

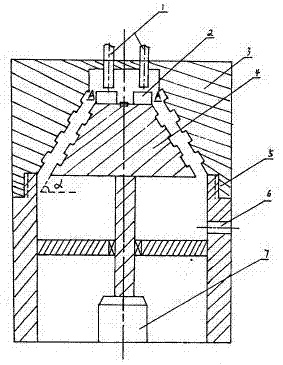

[0024] (1) Select a fully back-mixed liquid membrane reactor for liquid-liquid two-phase co-precipitation reaction, such as figure 1 As shown, it consists of a closed casing as the stator 3. There is a rotatable cone-shaped rotor 4 installed on the motor shaft 7 in the stator 3. The outer surface of the rotor 4 and the inner surface of the stator have grooves respectively. 4 The end with a small cross-sectional area is equipped with a liquid distributor 2, and the stator 3 is provided with a raw material liquid inlet 1 and a material outlet 6. The liquid inlet 1 is located at the end of the rotor 4 with a small cross-sectional area, and the material outlet 6 is located at the rotor. 4 The end with a large cross-sectional area, and there is a gap between the inner surface of the stator 3 and the outer surface of the rotor 4 that ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com