Fluidized bed thermal desorption device

A fluidized bed and thermal desorption technology, applied in lighting and heating equipment, incinerators, combustion methods, etc., can solve the problems of low heat utilization rate, large heat loss, low processing capacity of polluted soil, etc., and achieve large processing capacity , strong heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

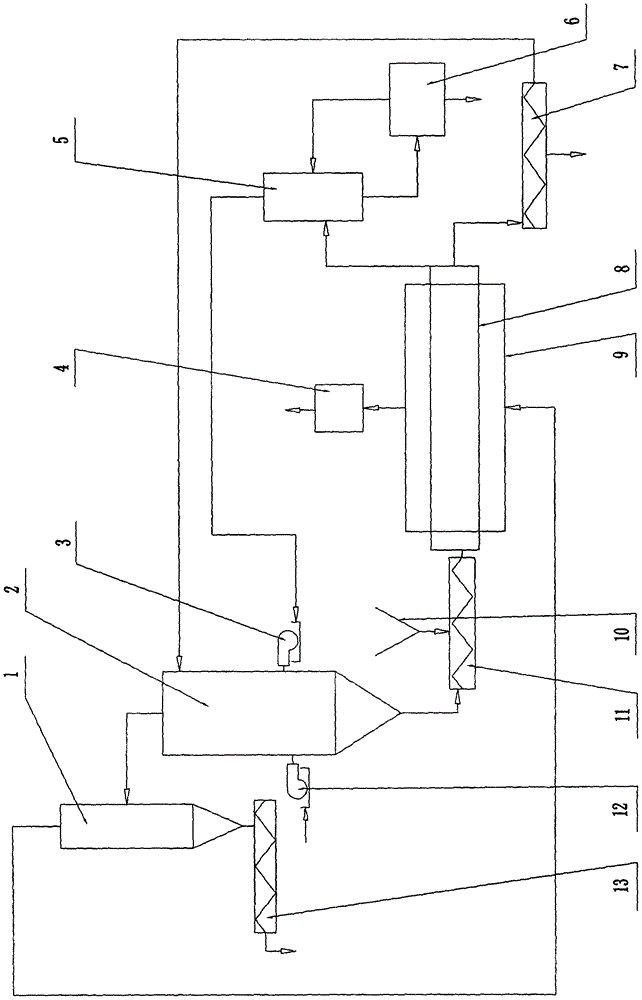

[0014] The fluidized bed thermal desorption equipment of the present invention will be further described in detail in conjunction with the accompanying drawings and specific embodiments:

[0015] Such as figure 1 As shown, in this specific embodiment, the fluidized bed thermal desorption equipment of the present invention includes a thermal desorption device, a tail gas processor 4, a screening machine 7, a quenching tower 5, an oil-water separator 6, a cyclone dust collector 1, and a slag discharger. machine 13, a fluidized bed 2 for containing sand, and a first burner 12 and a second burner 3 for heating the sand in the fluidized bed 2, the first burner 12 adopts natural gas, diesel oil or biomass Fuel, thermal desorption device comprises thermal desorption chamber 8 and flue gas jacket 9, and the inlet of thermal desorption chamber 8 adopts pipeline to be connected with the sand outlet of fluidized bed 2, and the feed of thermal desorption chamber 8 The mouth is also conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com