Patents

Literature

49results about How to "Secure safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

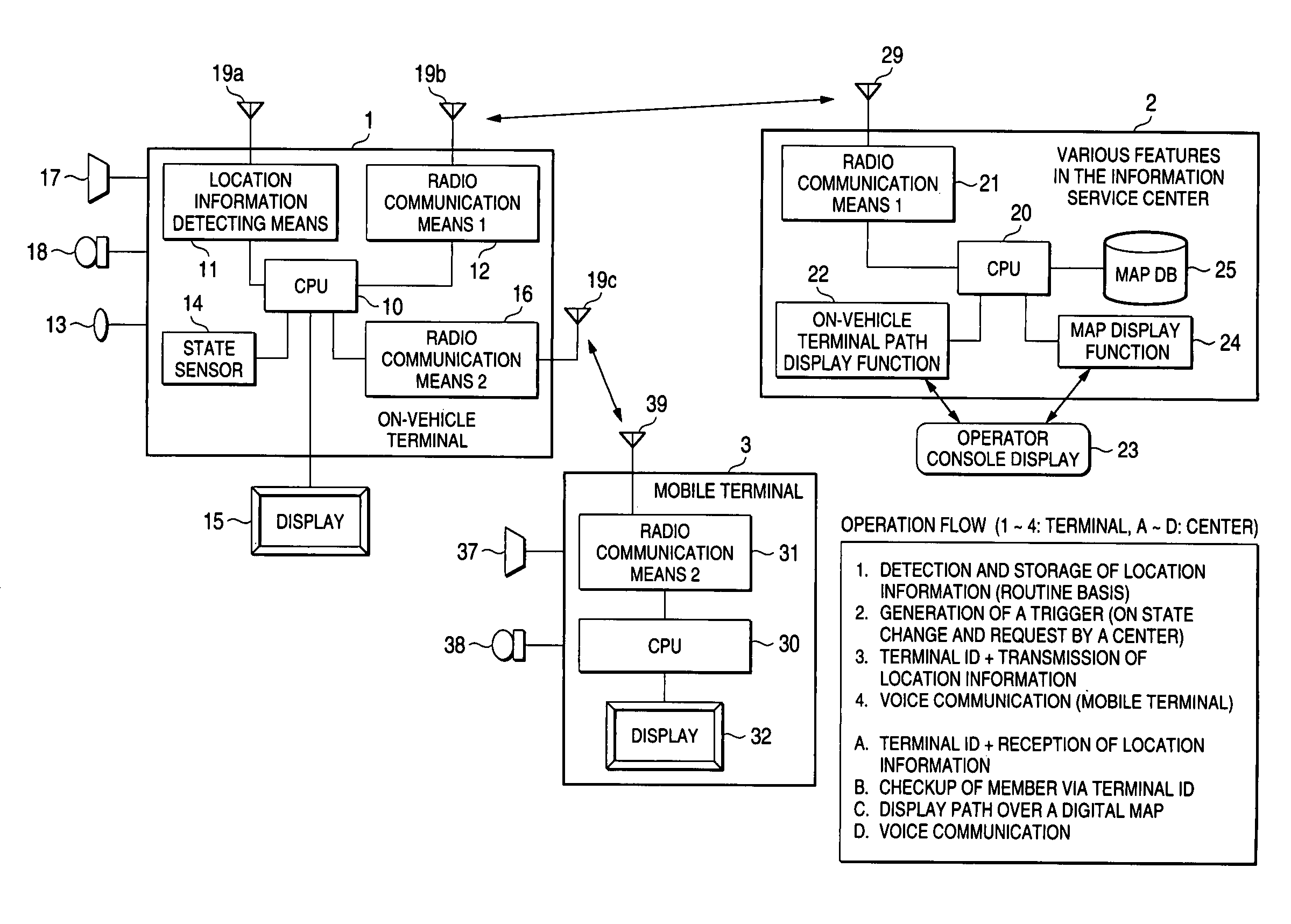

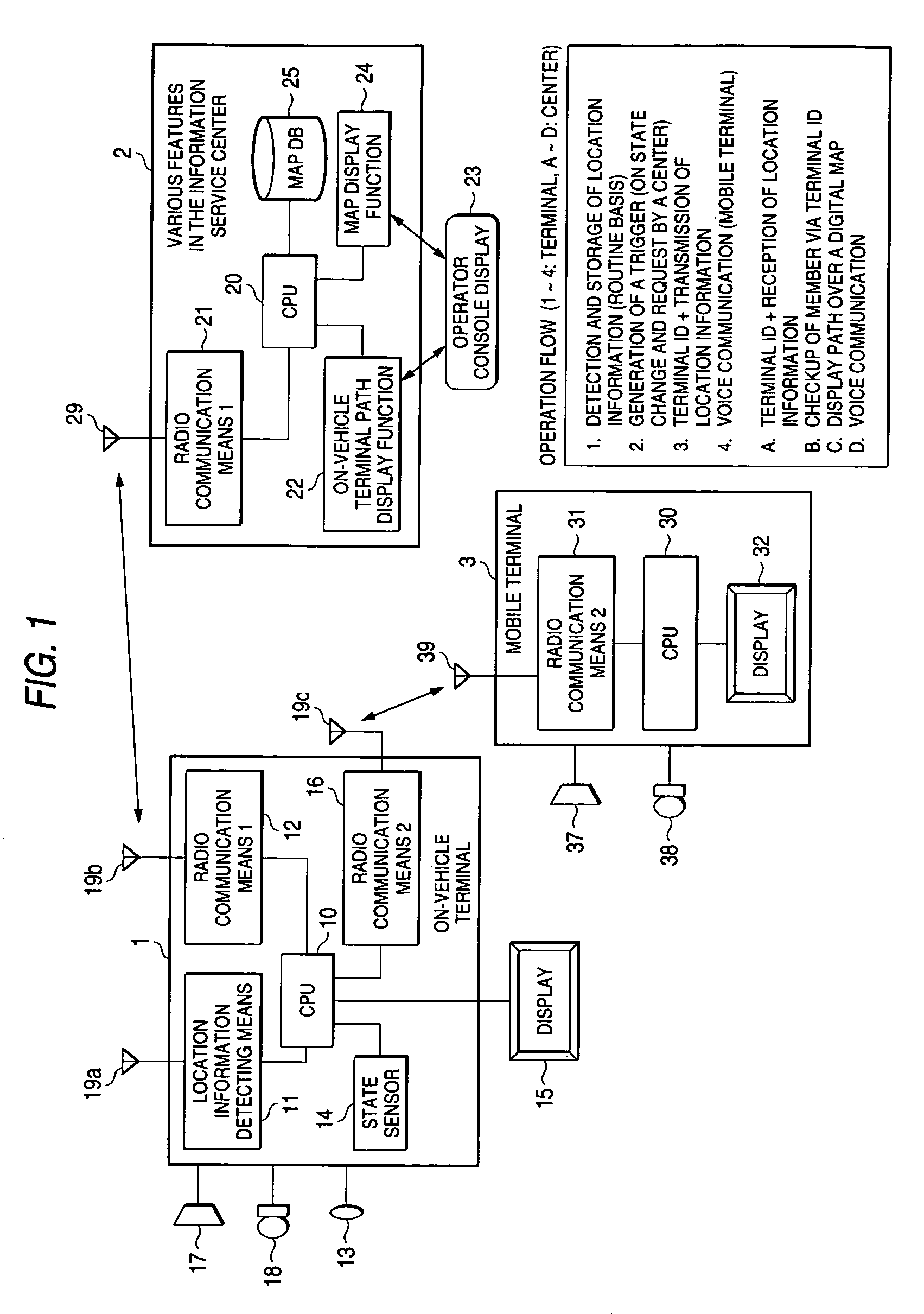

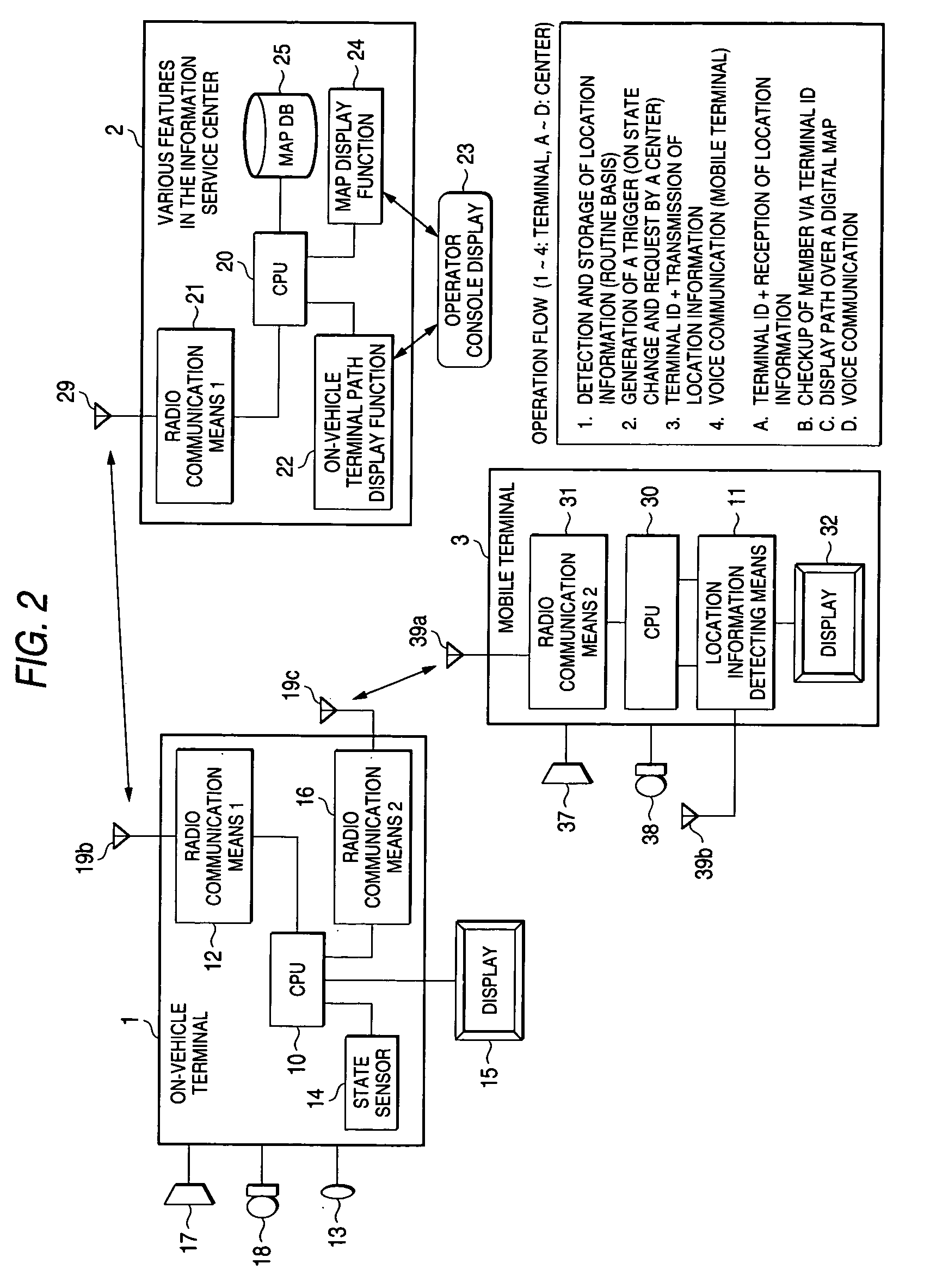

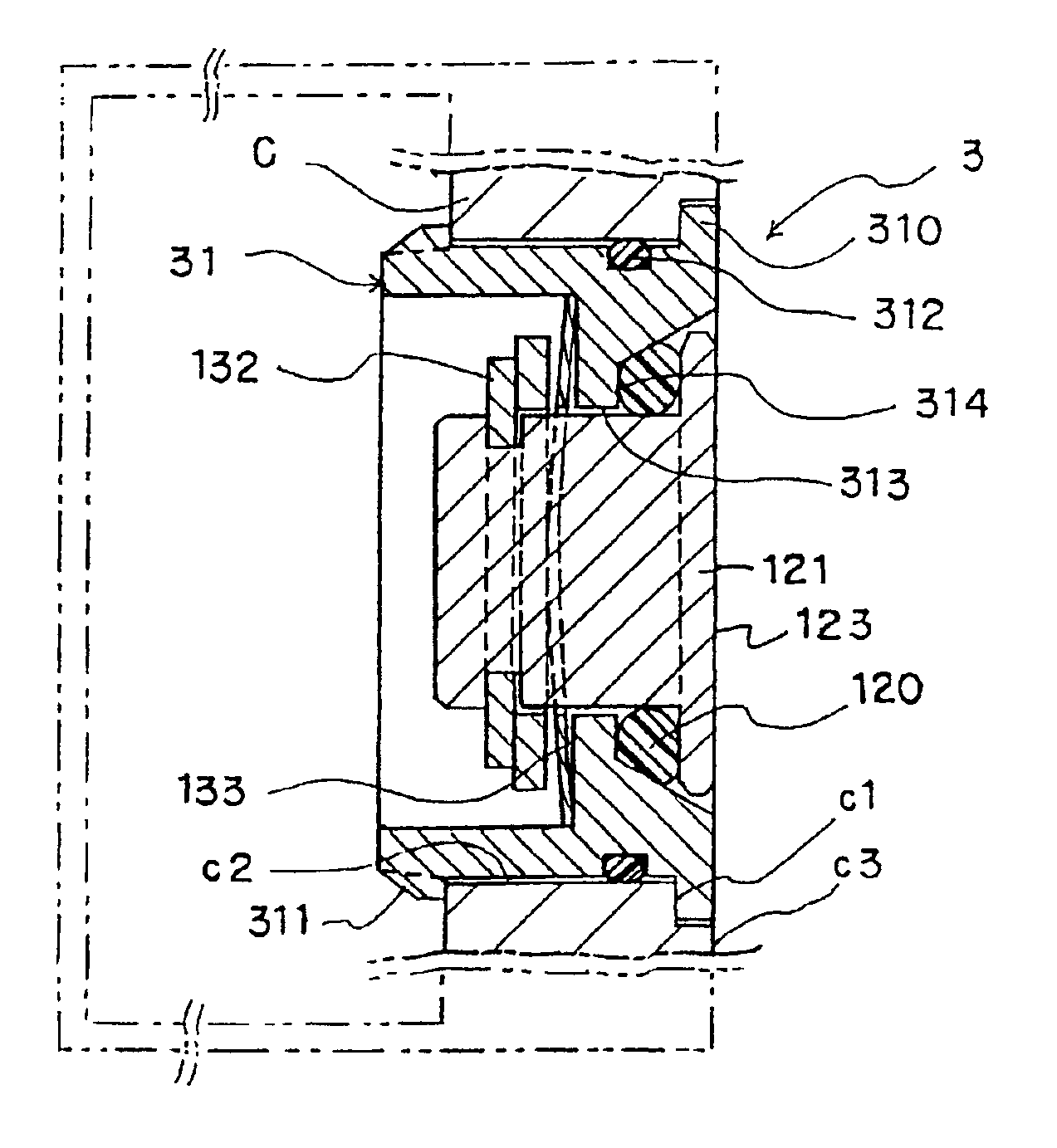

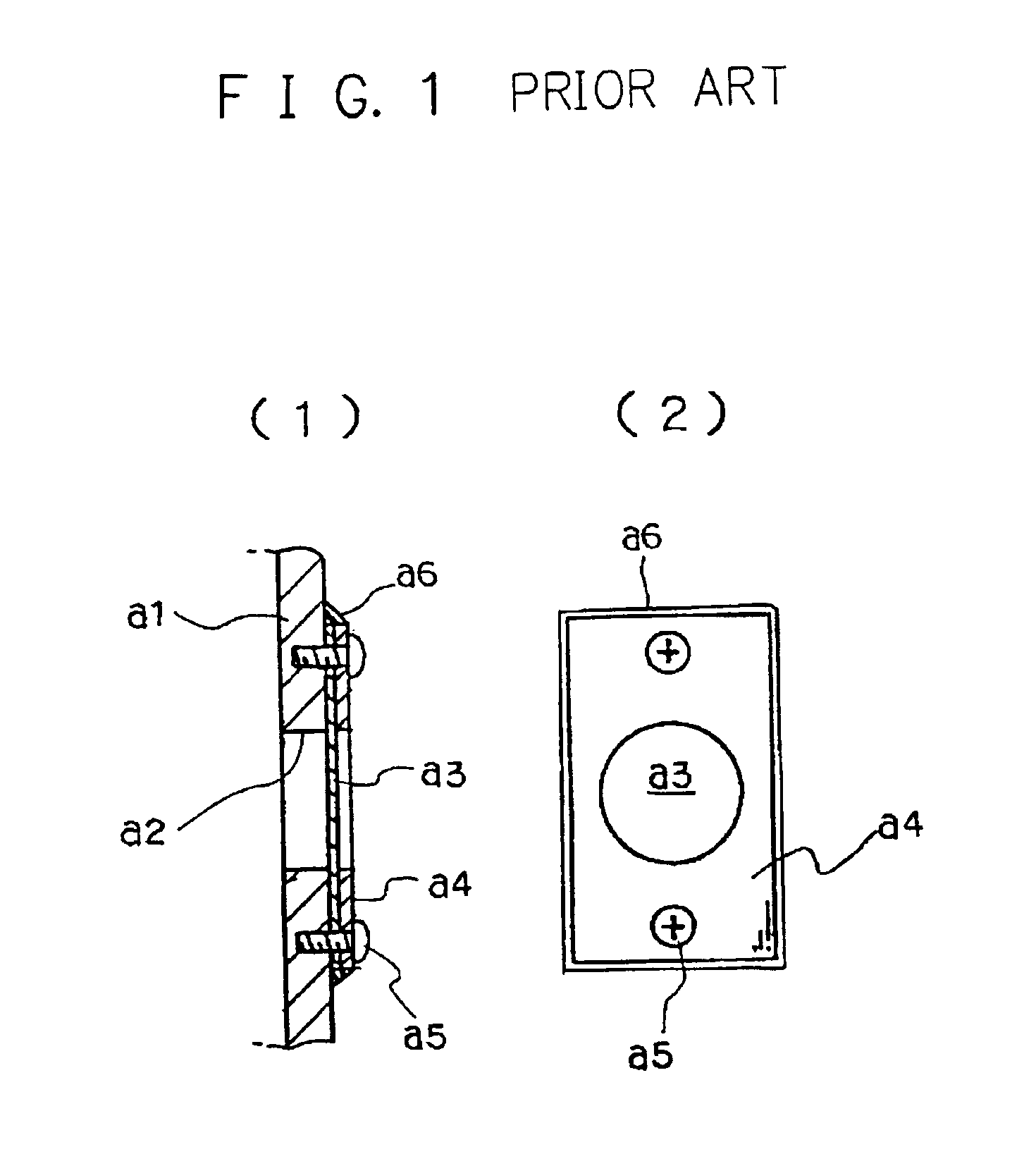

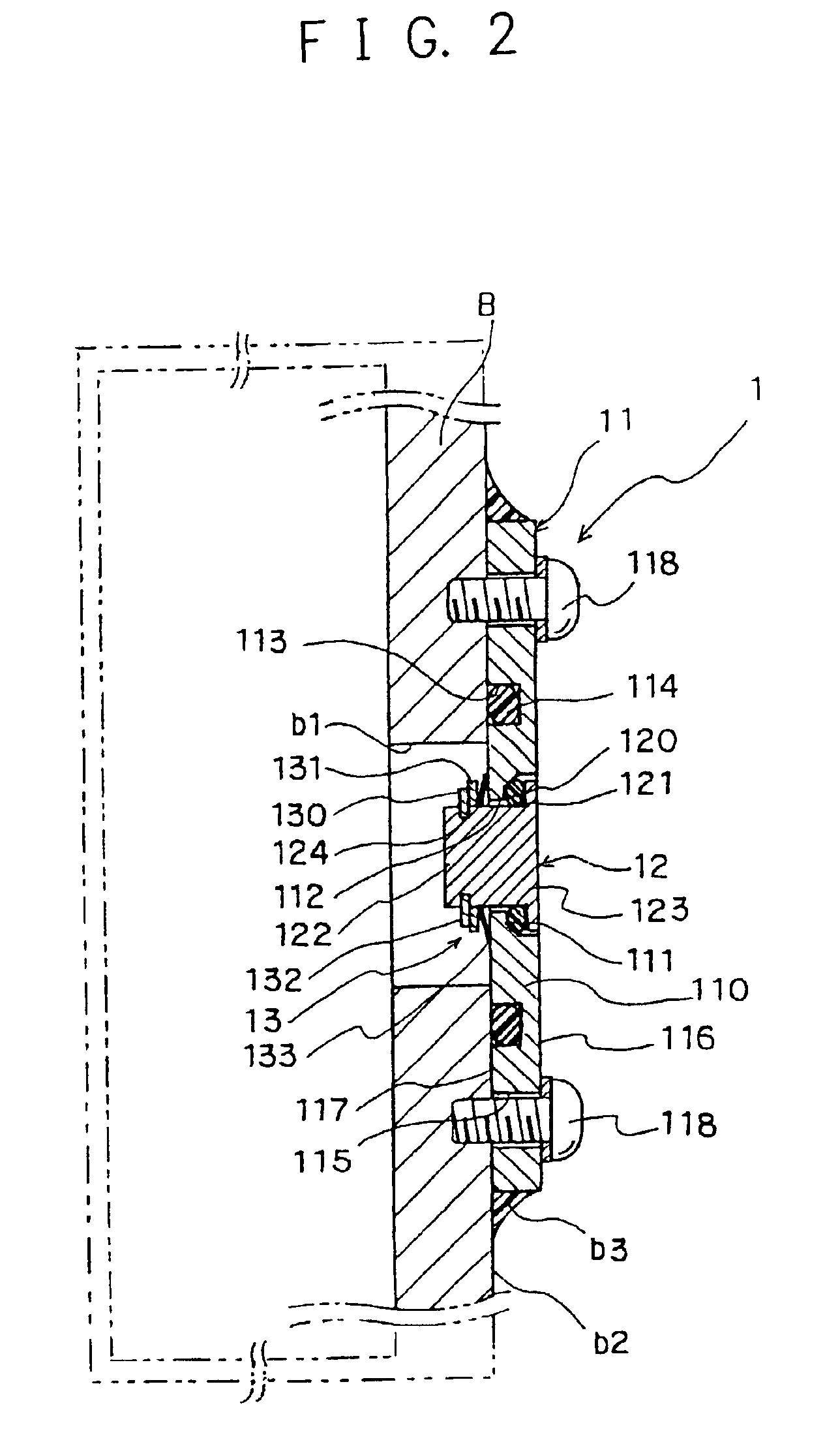

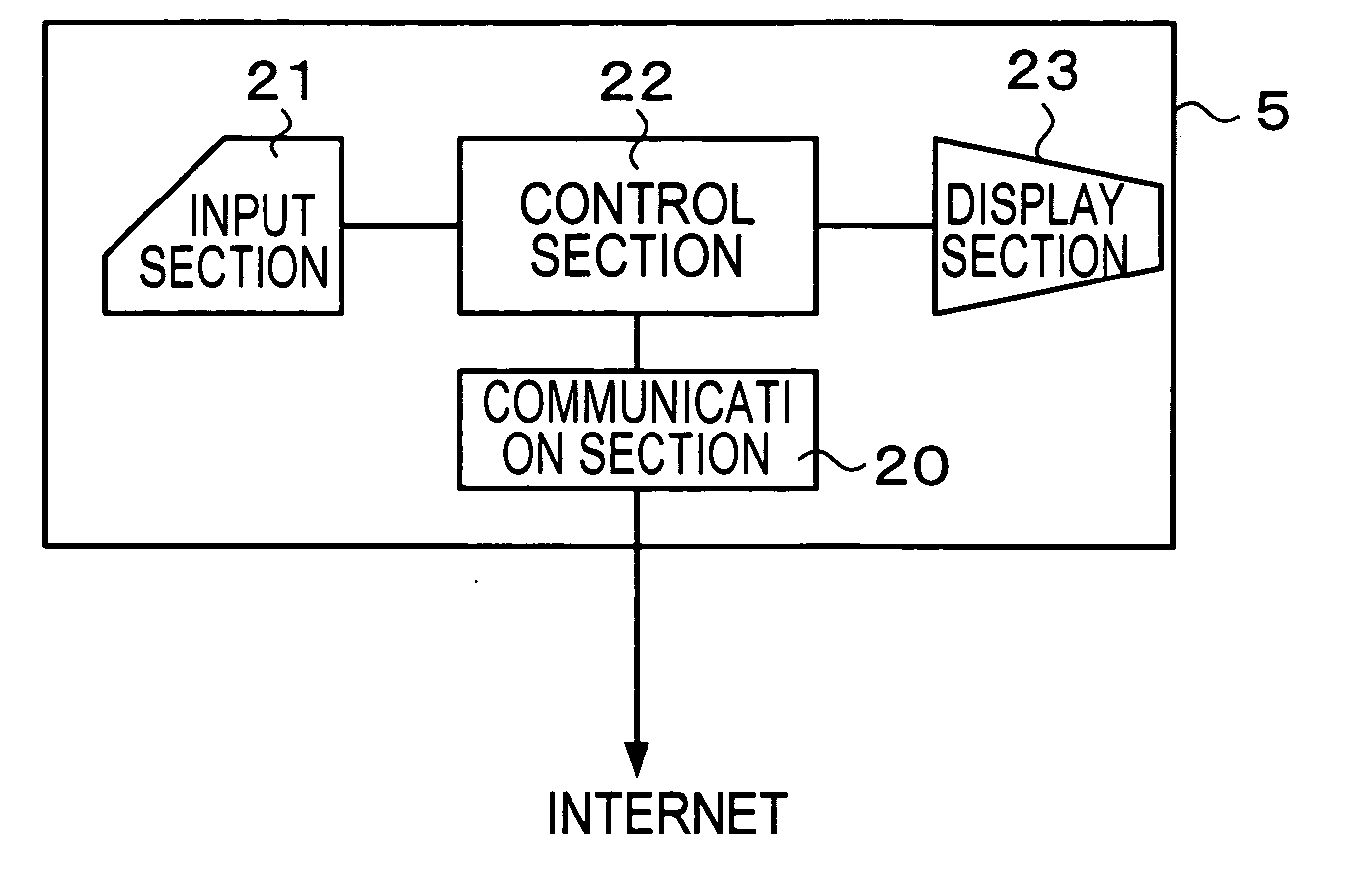

On-board communication terminal and information service center communicating with on-board communication terminal

InactiveUS7200409B1Safer judgementSecure safetyRoad vehicles traffic controlSubstation equipmentTelecommunications equipmentOn board

The invention provides an on-vehicle communication terminal that secures a report to a center and safety of a crew by providing short-range radio communication means in the on-vehicle communication terminal, separately configuring a mobile terminal provided with a part of the functions of a conventional on-vehicle terminal detached therefrom, and letting the crew who are escaping carry a mobile terminal.That is, an on-vehicle terminal (1) according to the invention includes location information detecting means (11), state sensor (14) for detecting an abnormal state and outputting the state information, first radio communication means (12) for transmitting predetermined data including state information, location information on a plurality of locations and a terminal ID to the information service center (2) on occurrence of a predetermined event, and second radio communication means (16) for providing radio communications between the on-vehicle terminal (1) and the mobile terminal (3). The mobile terminal (3) includes second radio communication means (31) and further location information detecting means (11) and a state sensor (14). Thus, by configuring an on-vehicle communication terminal with a combination of the on-vehicle terminal (1) and the mobile terminal (3), the crew can report to the information service center (2) while securing safety in the event of an accident.

Owner:PANASONIC CORP

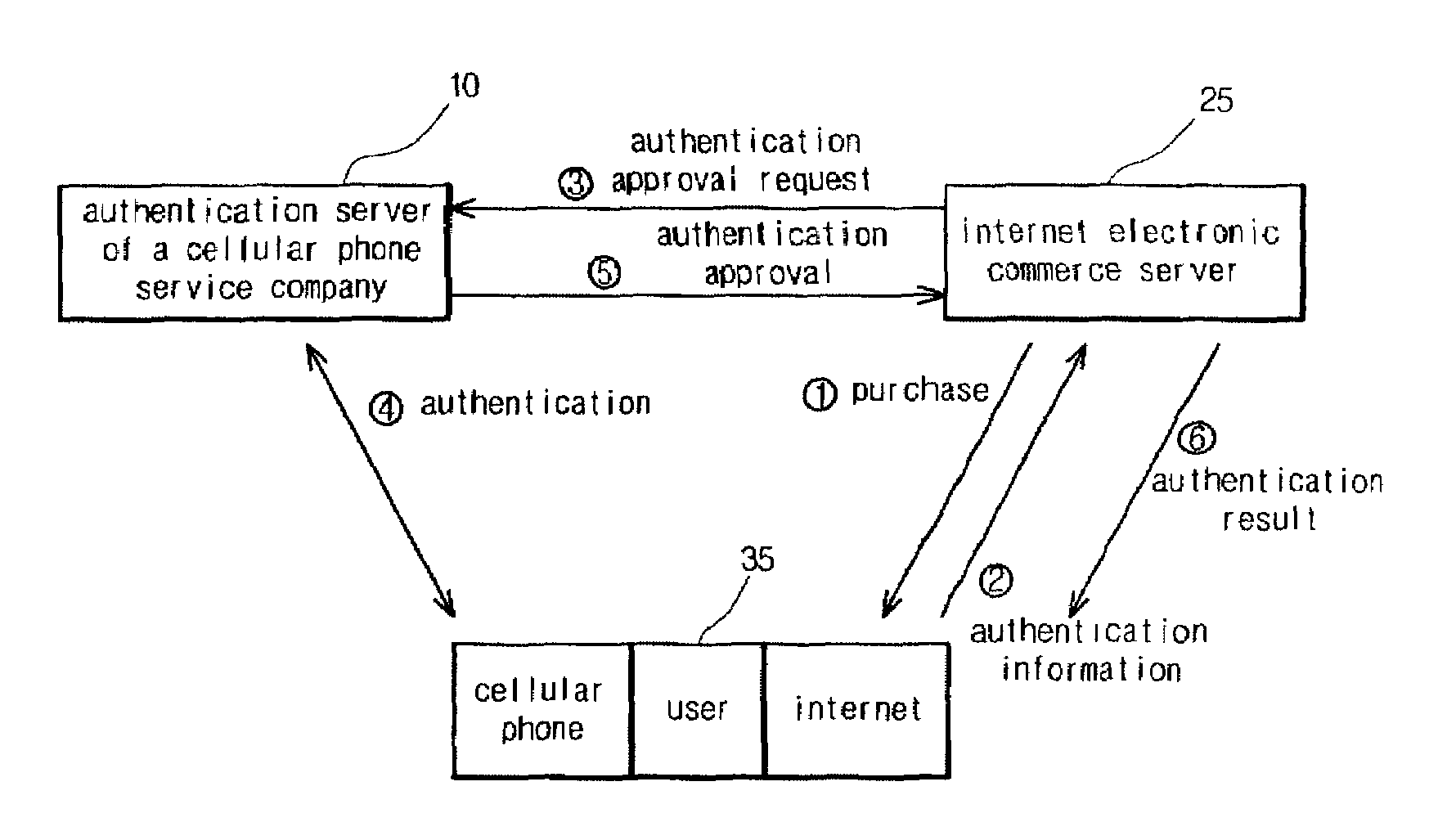

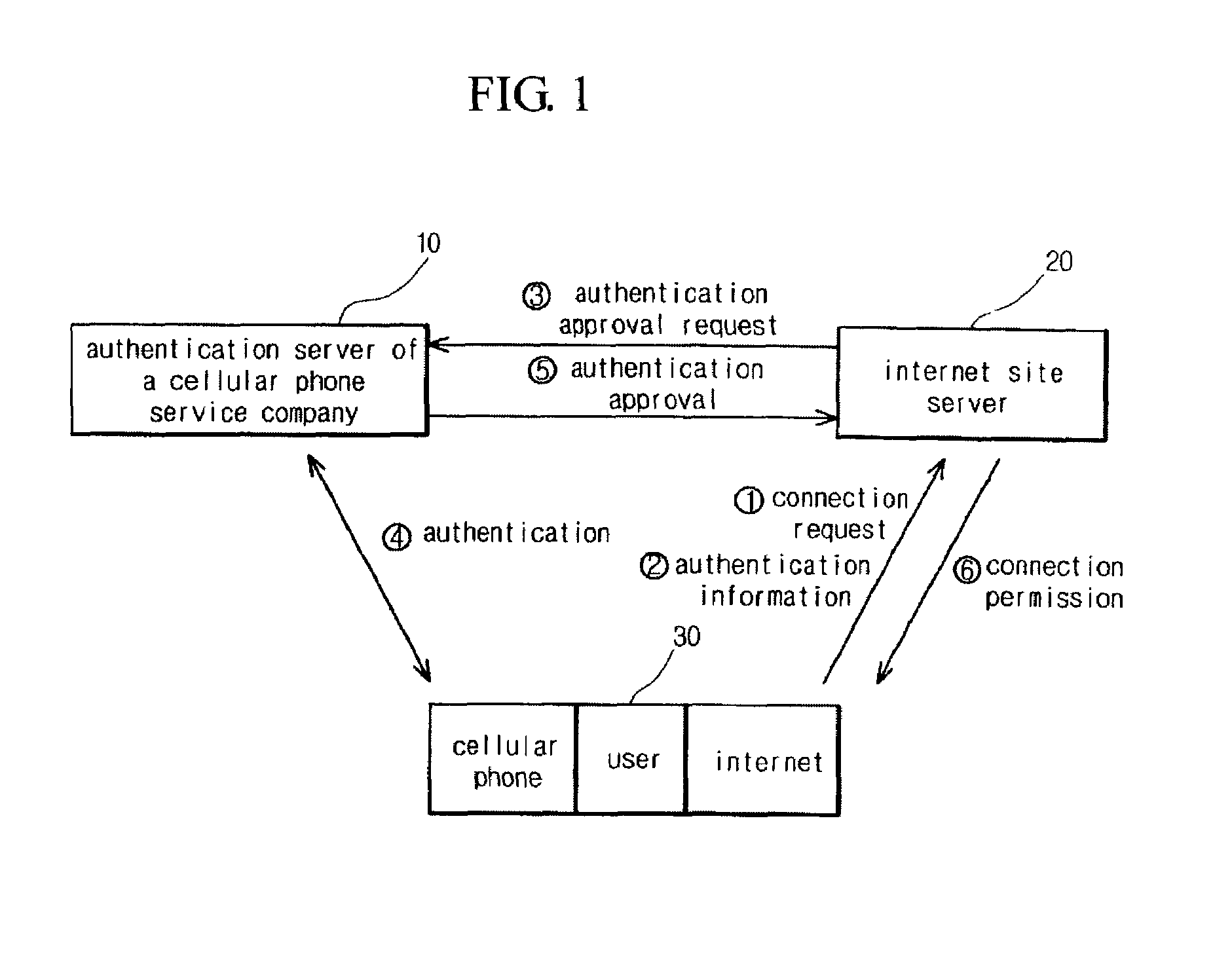

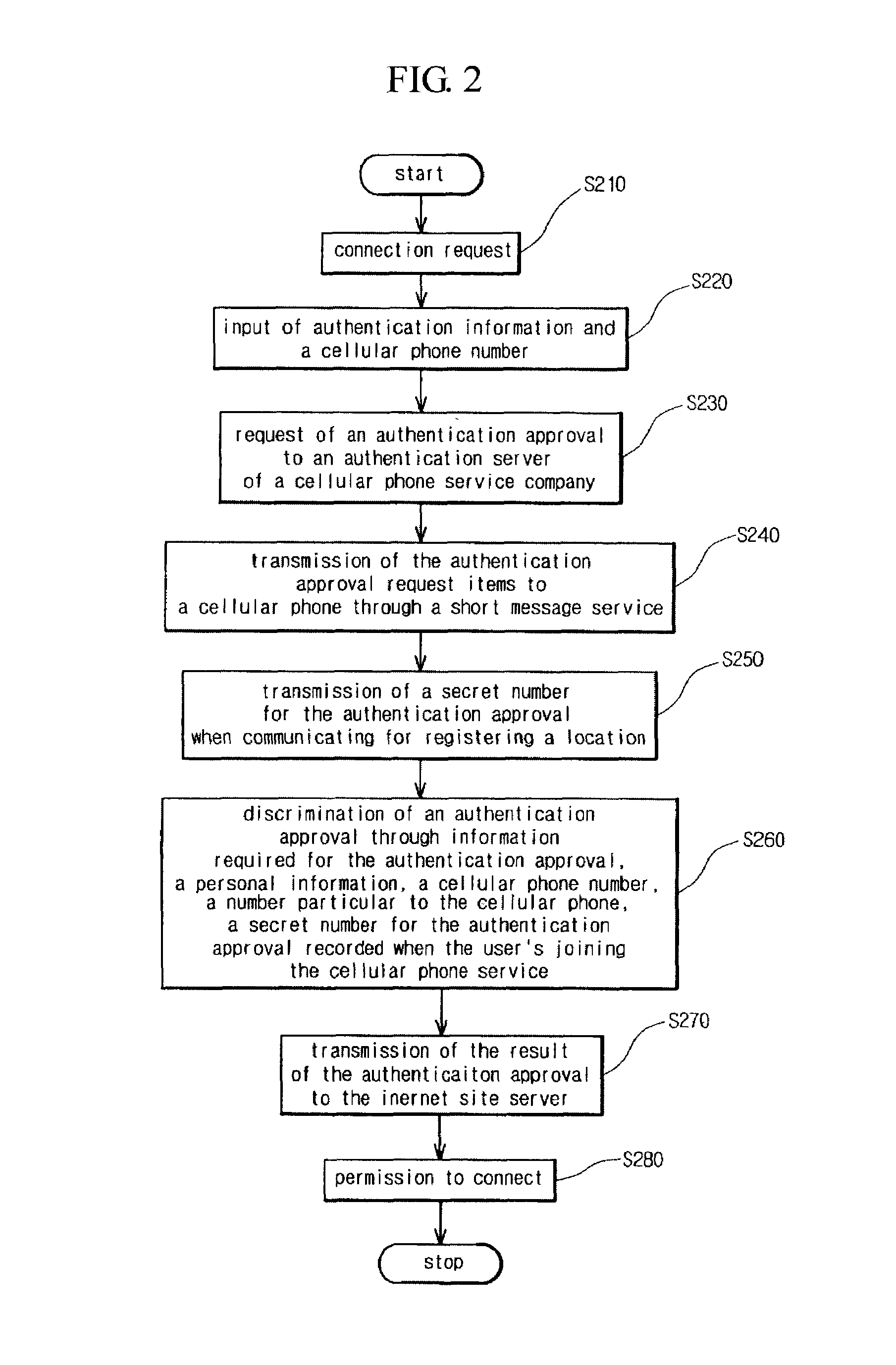

Authentication method using cellular phone in internet

InactiveUS7447784B2Prevent dangerSecure safetyDigital data processing detailsTelephonic communicationMobile telephonyAuthentication protocol

The present invention discloses an authentication method using a cellular phone in internet. According to the present invention, when connecting to internet or performing electronic commerce, the authentication is performed through the cellular phone in parallel with a personal information stored when user's joining the cellular phone service, a number particular to the cellular phone, a secret number in an authentication required for the connection or the settlement of accounts. Specifically, in authentication process for making up accounts, besides the line connected to internet, a separate cellular phone line is used and if the authentication data of the internet site server is identical to that of the cellular phone service company, the authentication process is completed, thereby eliminating the danger of hacking basically.

Owner:MICROINSPECTION

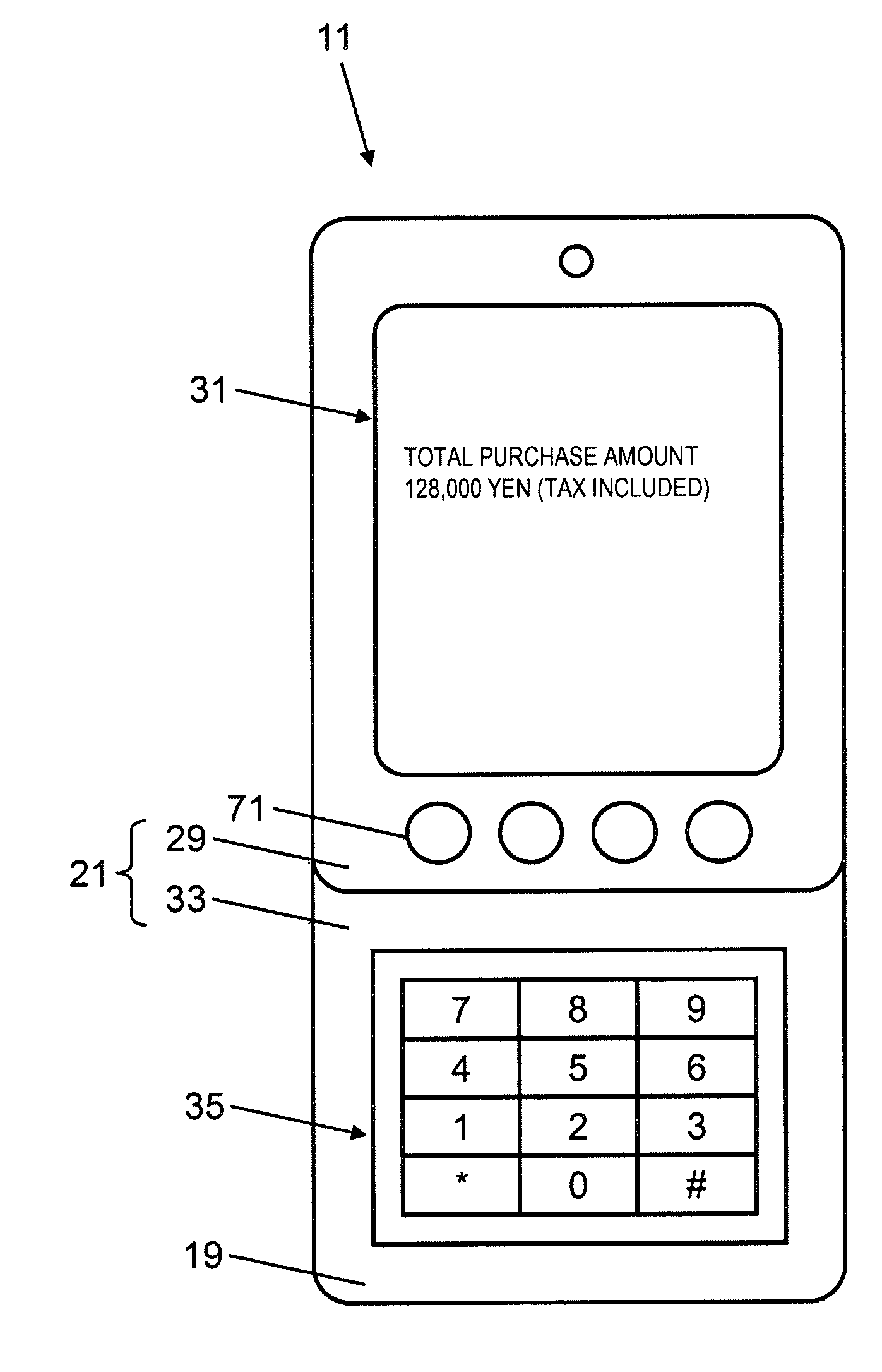

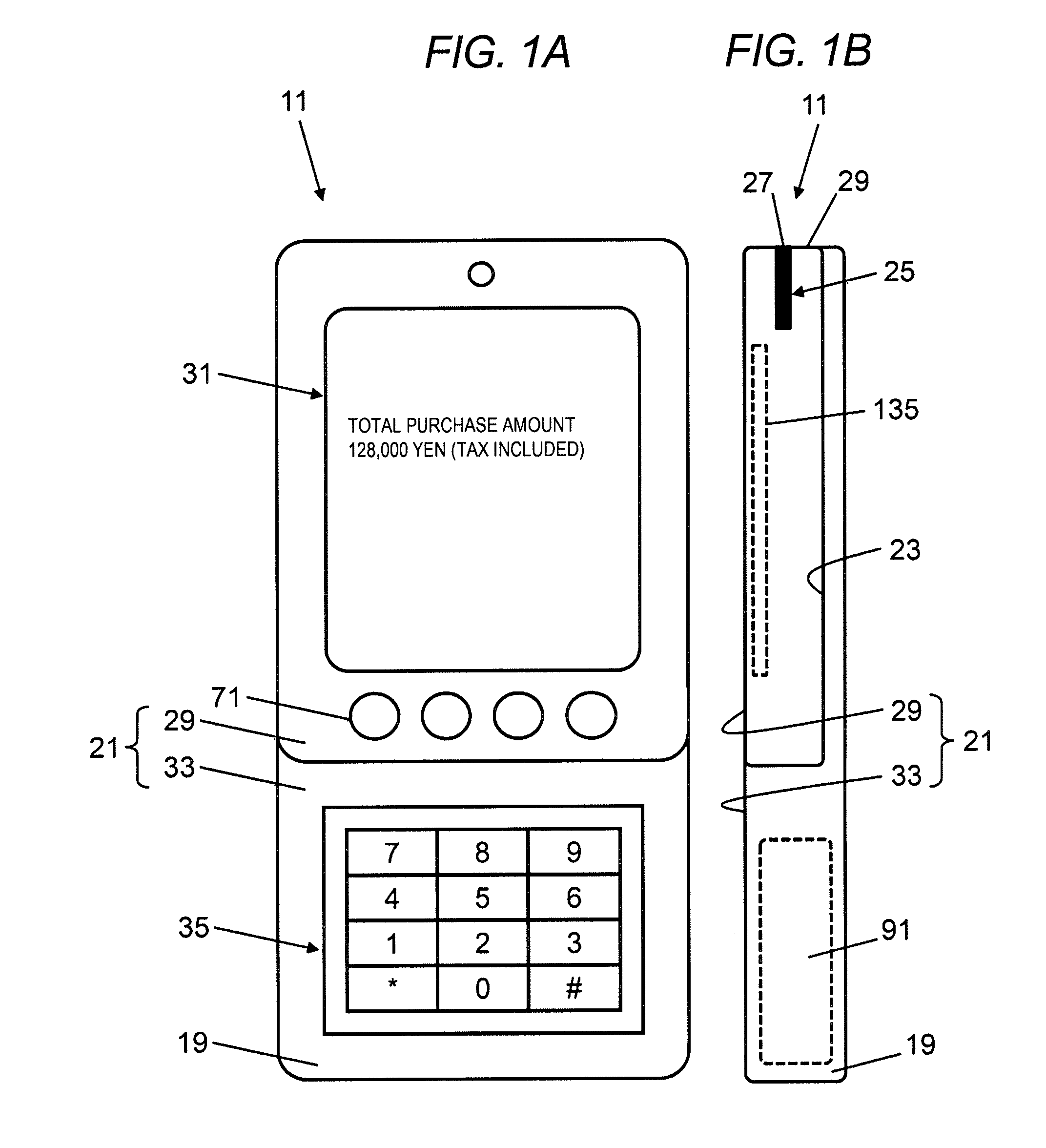

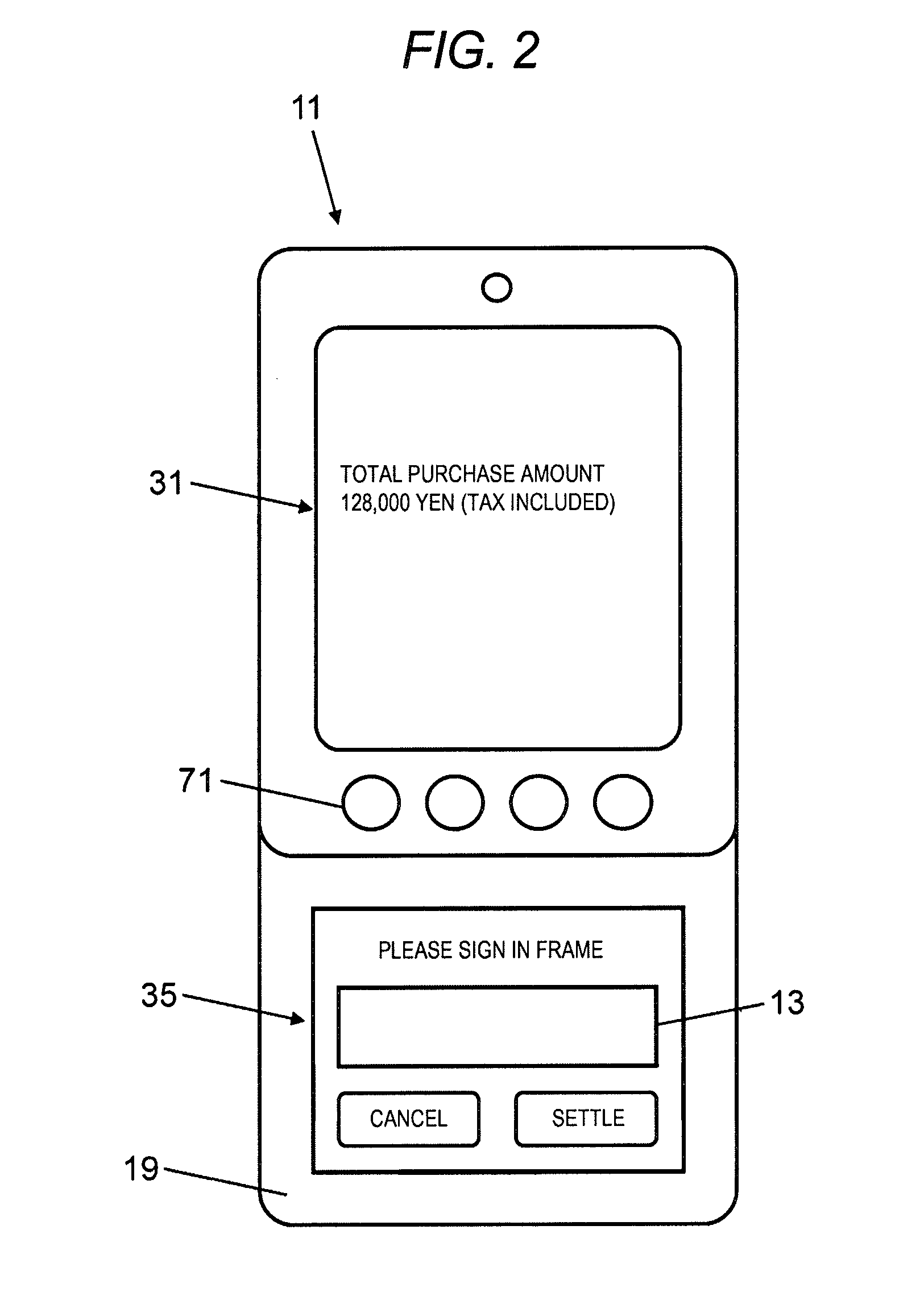

Information processing device and portable settlement terminal device

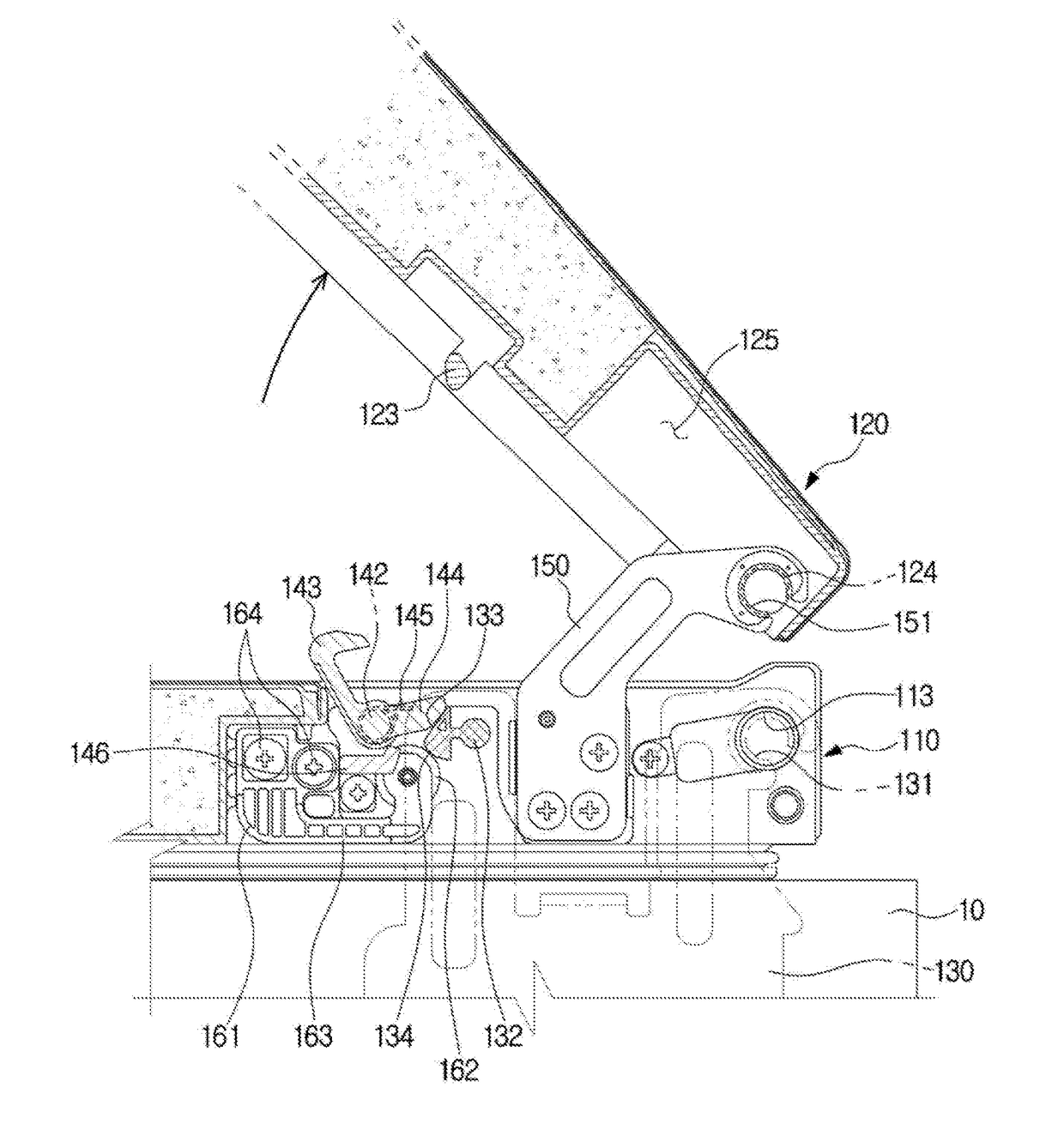

ActiveUS20150324615A1Secure safetyEasily holdAcutation objectsError detection/correctionSecure stateTerminal equipment

An information processing device includes a first information processing unit that is accommodated in a housing, and in which a first input display section is provided on an operational surface of the housing, and a tamper-resistant secure second information processing unit that is accommodated in front of the first information processing unit in the housing gripped by an operator, and in which a second input display section is provided in front of the first input display section on the operational surface. Further, in the information processing device, for example, a secure state display section that indicates a secure mode in authentication input, or indicates a non-secure mode in a case other than the authentication input is disposed on the operational surface. Even when a secure portion and a non-secure portion are present together, security of authentication information is secured, and an operator's mistake or an incorrect operation is suppressed.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

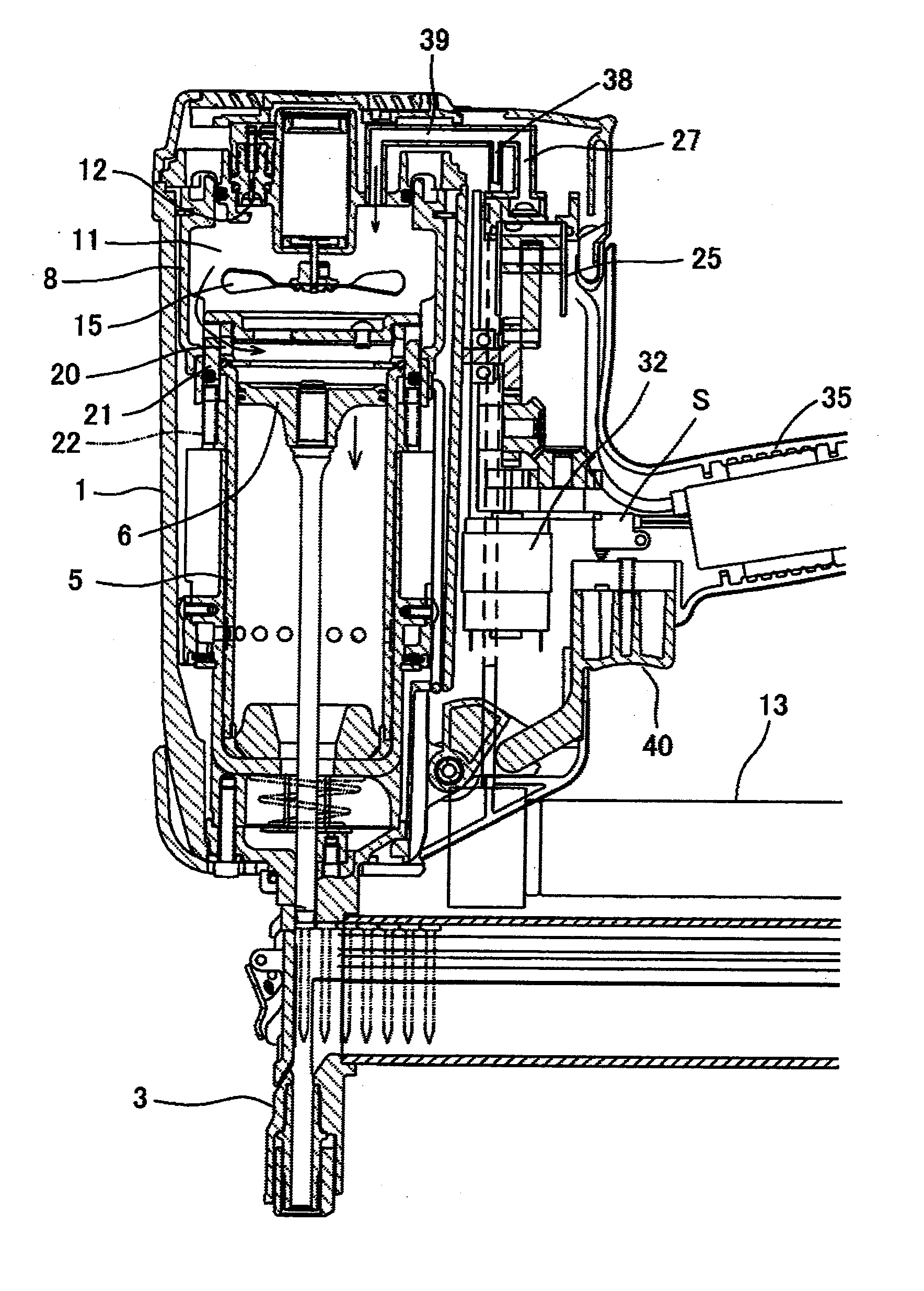

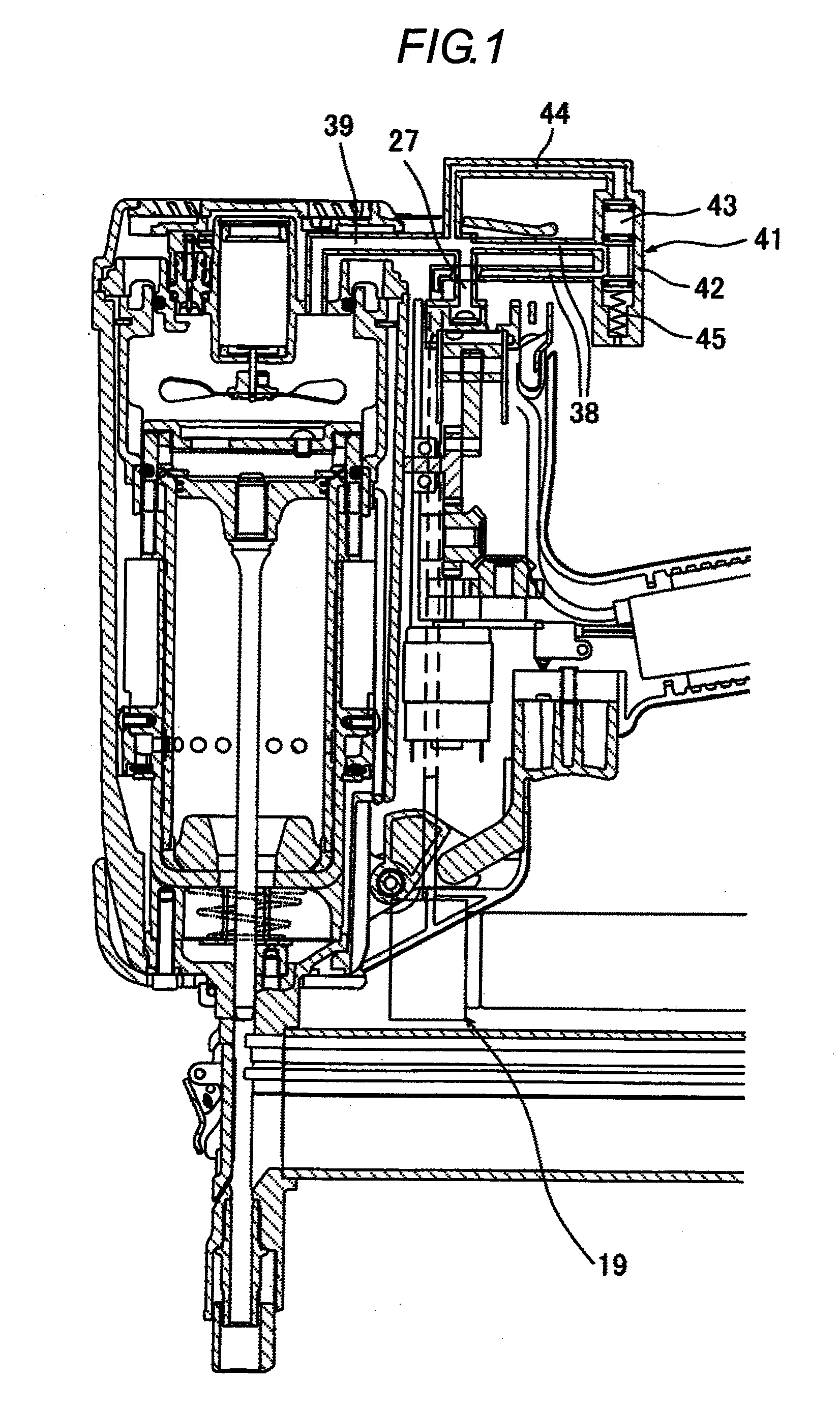

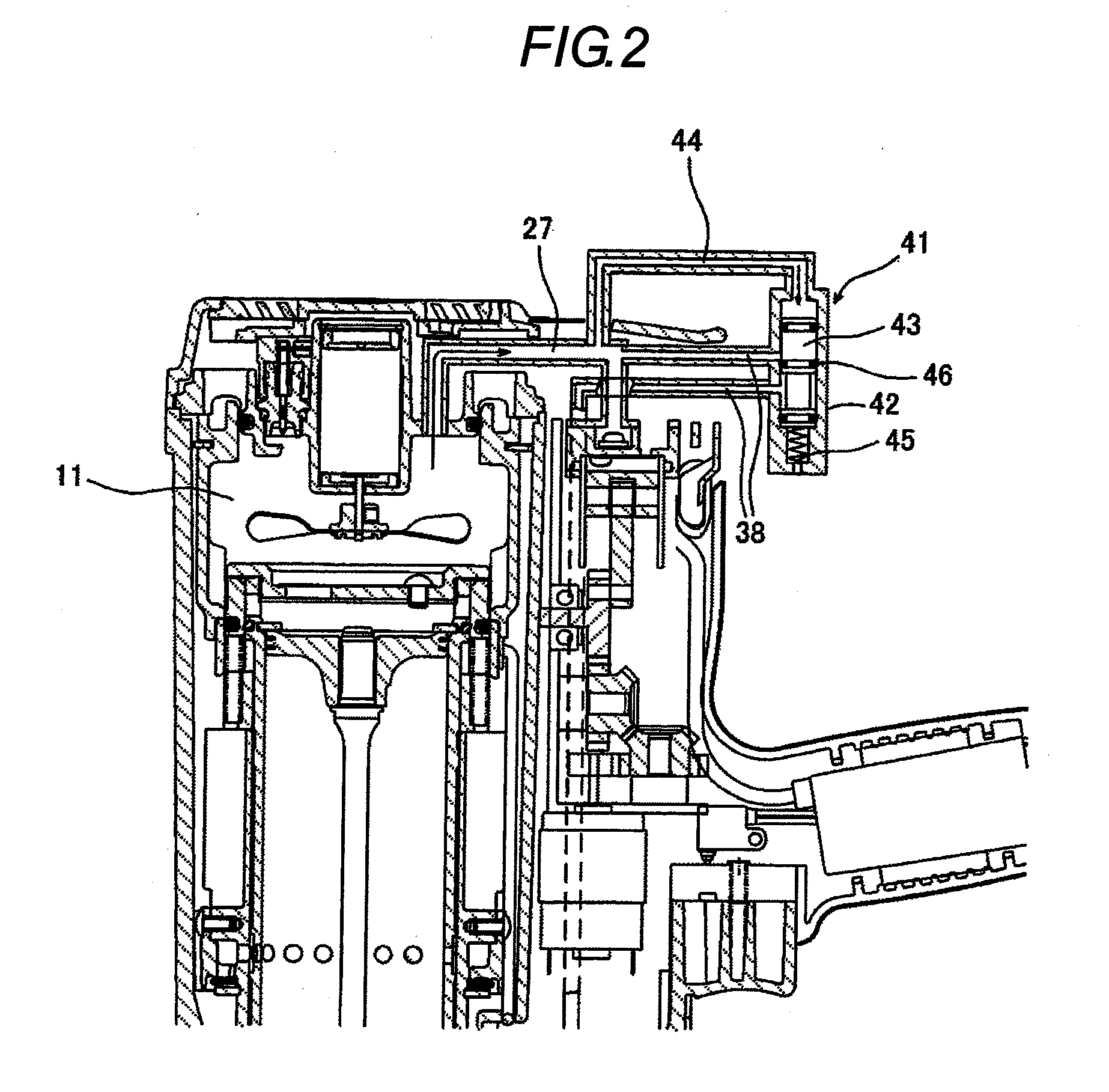

Gas internal combustion type nailing machine

InactiveUS20100108736A1Secure durabilitySecure safetyStapling toolsMachines/enginesCombustion chamberFuel supply

The present gas internal combustion type nailing machine is provided with: a striking cylinder for slidably accommodating a striking piston therein; a combustion chamber formed in an upper side and capable of being opened and closed; a compressor for supercharging compressed air into the combustion chamber; a fuel supply device for supplying a fuel gas into the combustion chamber; and a safety device for preventing the nailing machine from being driven for ignition when the supercharge pressure of the compressed air exceeds a set pressure value.

Owner:MAX CO LTD

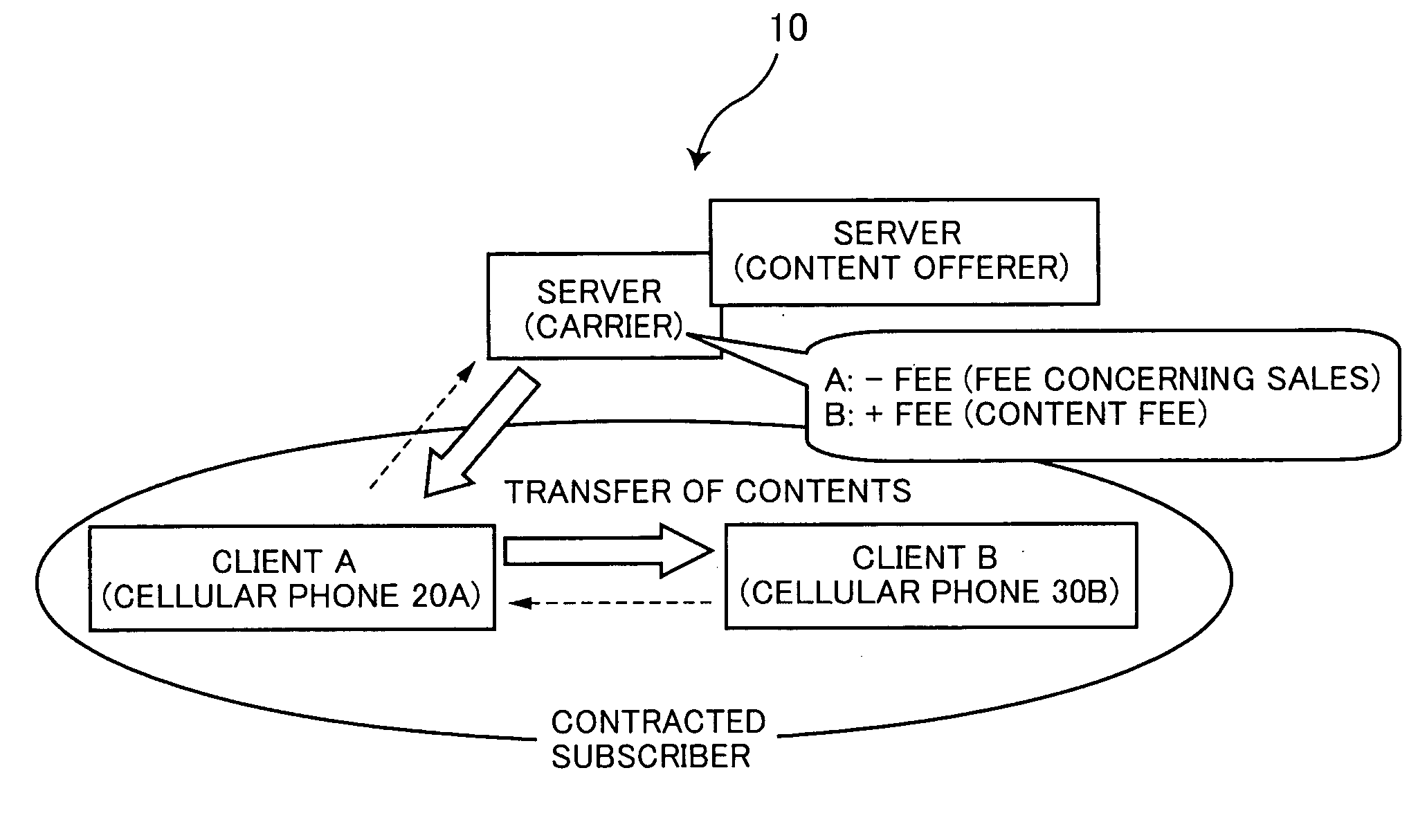

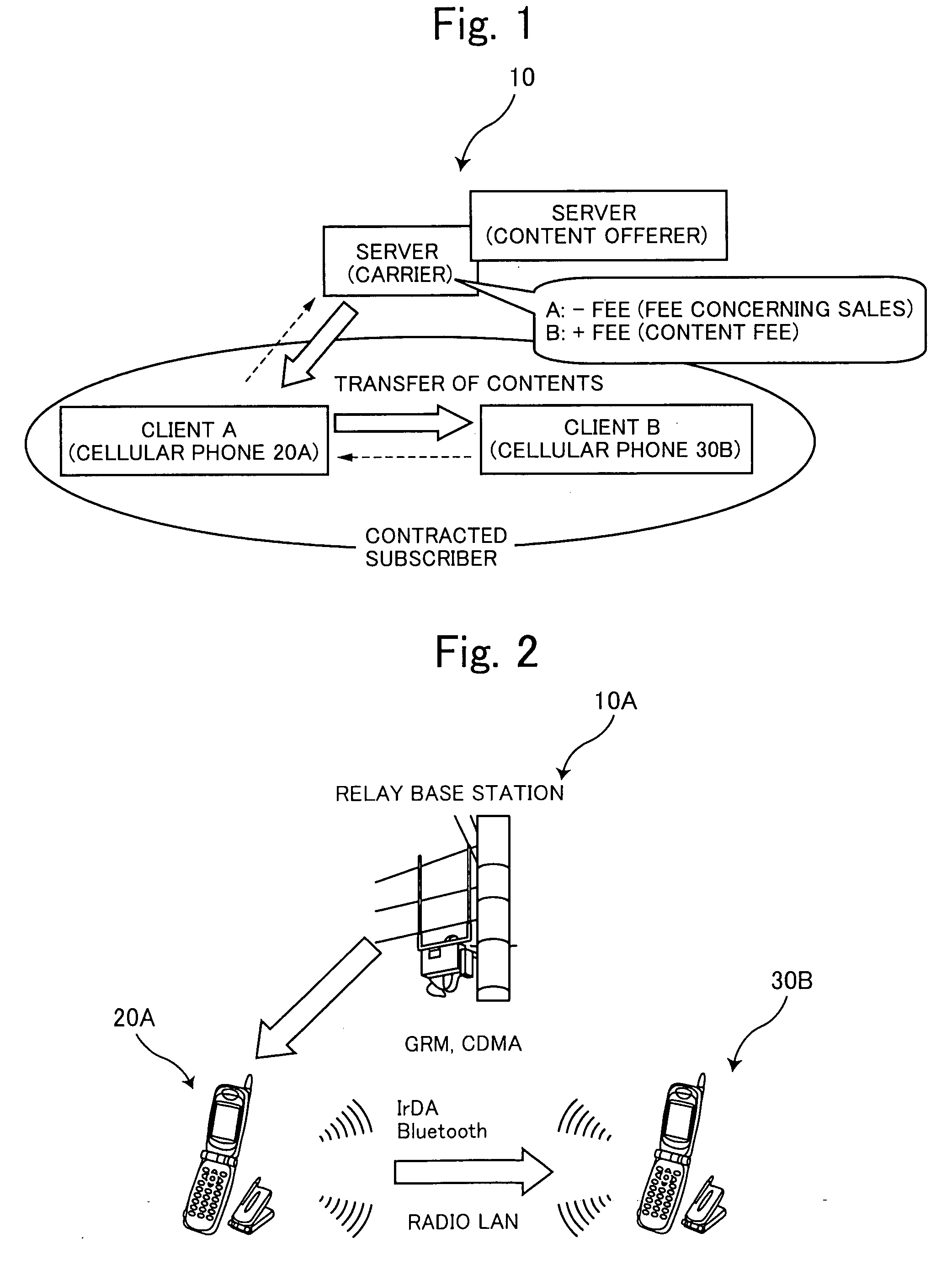

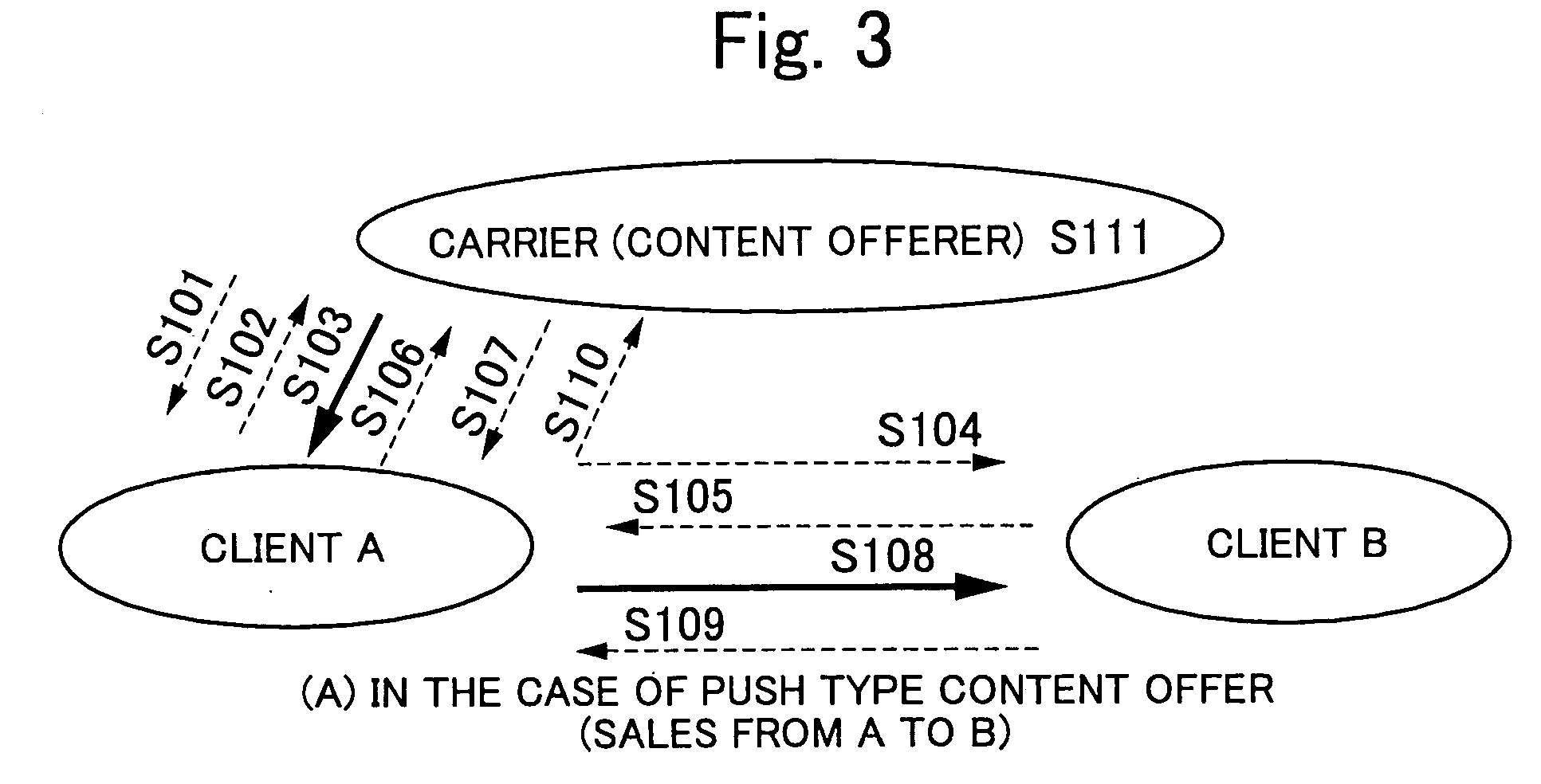

Sending method of pay contents, radio terminal and carrier

InactiveUS20050222858A1Secure safetyMetering/charging/biilling arrangementsAccounting/billing servicesRadiotelephoneInfrared communication

The present invention relates to a sending method of pay contents in a communication system which carry out communication through predetermined communication network (e.g., radiotelephone network or the like) using a predetermined first communication scheme (e.g., CDMA scheme or the like). The sending method includes radio terminals which carry out peer-to-peer communication using a predetermined second communication scheme (e.g., infrared communication, communication adhering to Bluetooth standards), and a carrier which carries out communication using the first communication scheme with each of the terminals. When pay contents possessed by a first radio terminal are transferred to a second radio terminal, first, permission of transfer of the pay contents to the second radio terminal is received from a carrier and then, the pay contents are transferred. After the pay contents are transferred to the second radio terminal, the carrier is informed of completion of transfer operation.

Owner:FUJITSU LTD

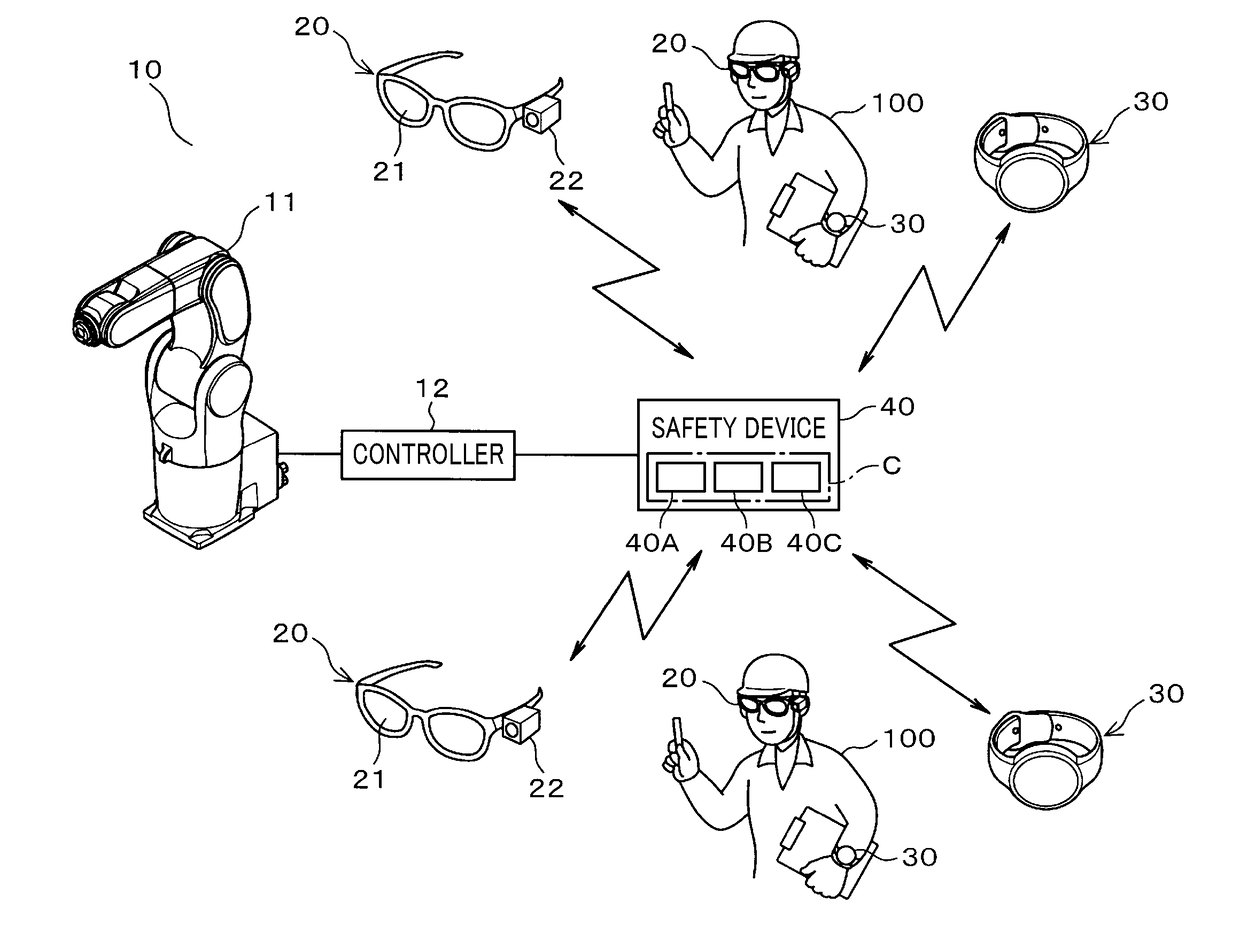

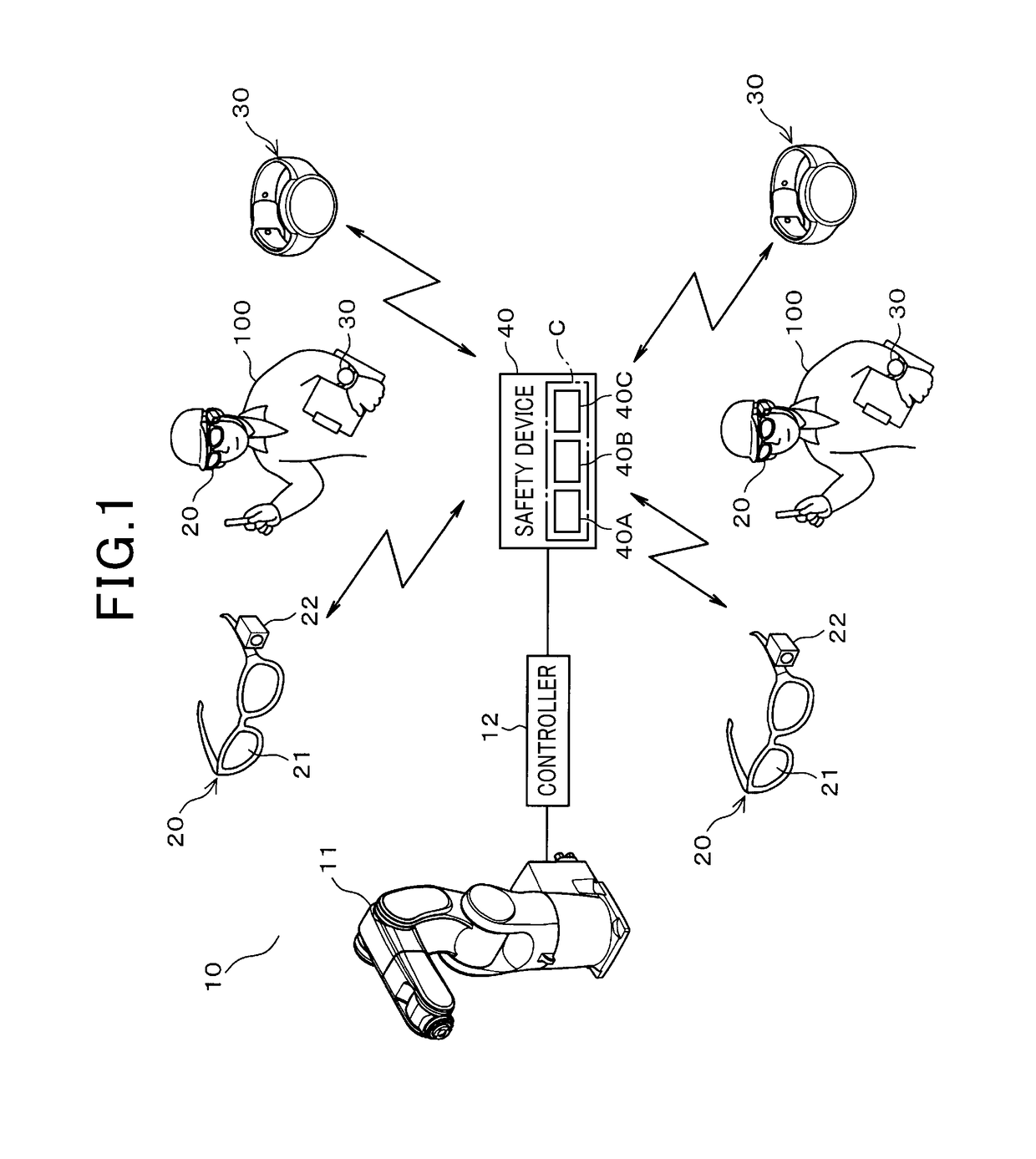

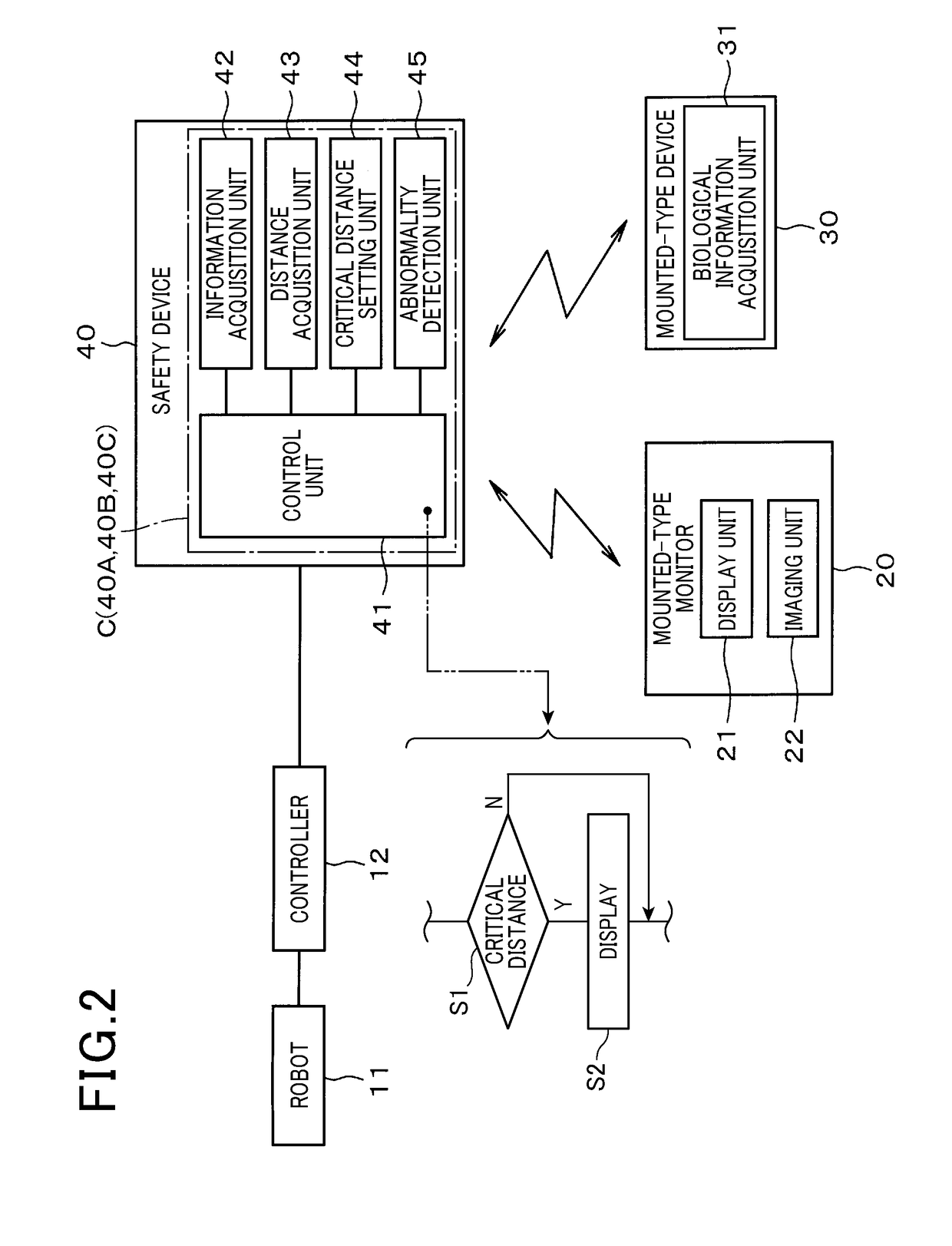

Safety system for industrial robots

ActiveUS20170197313A1Secure safetySafely workProgramme controlProgramme-controlled manipulatorEngineeringCritical distance

A system to secure people's safety in places such as a factory wherein people and industrial robot collaborate with each other in a state that a physical fence surrounding the preferred industrial robot's working region is excluded. The system is capable of acquiring respective distances between robot and a plurality of people. Furthermore, a critical distance of each person is set on the basis of at least one of personal information that each person individually has and environment information to be set depending on the robot's setting environment. A mounted-type monitor is respectively mounted on the plurality of people and is capable of displaying information within a view of each person, and a control unit is capable of controlling display content thereon. According to the display control, when a distance between robot and each person becomes less than a critical distance, the distance state is displayed on the mounted-type monitor.

Owner:DENSO WAVE INC

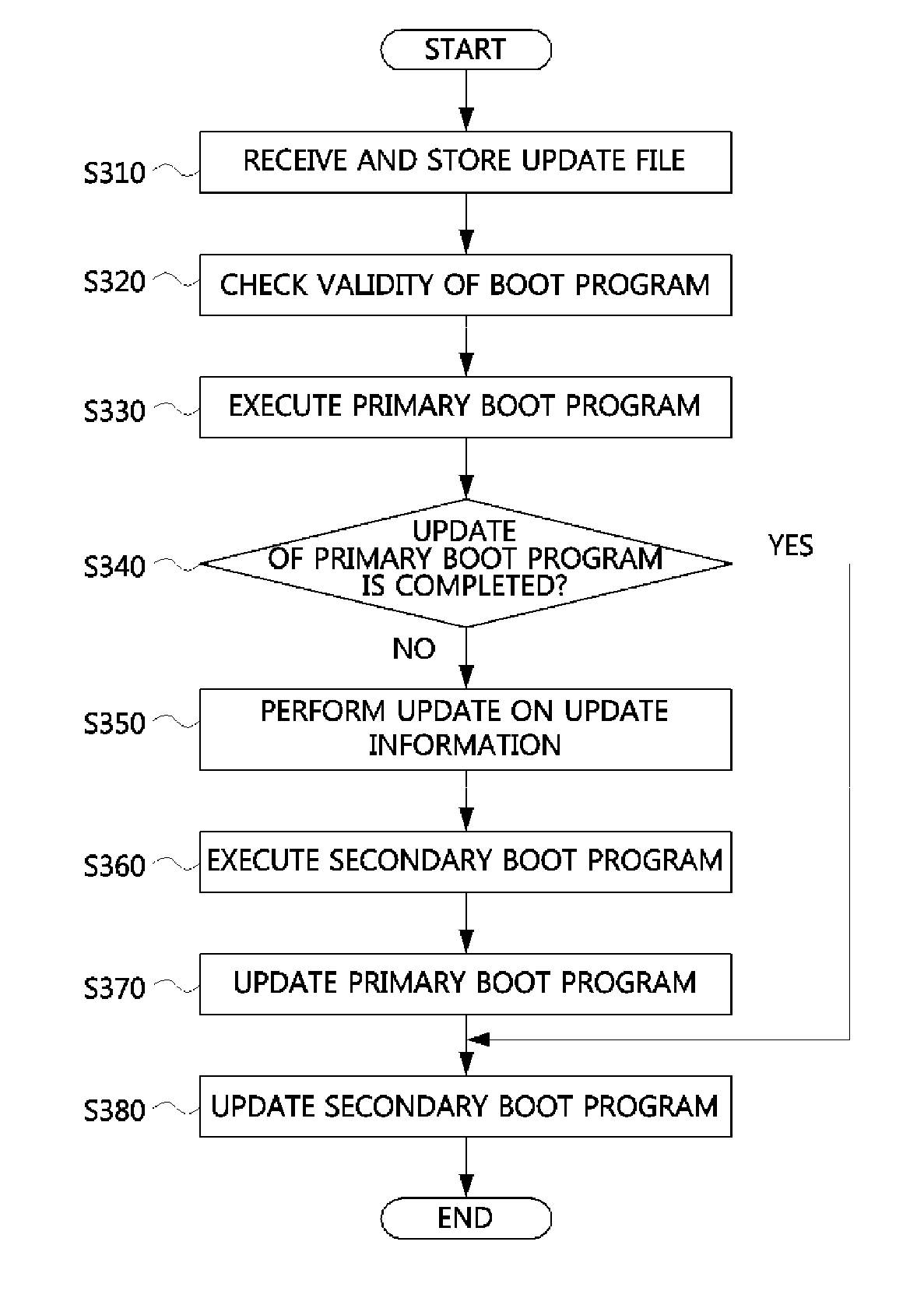

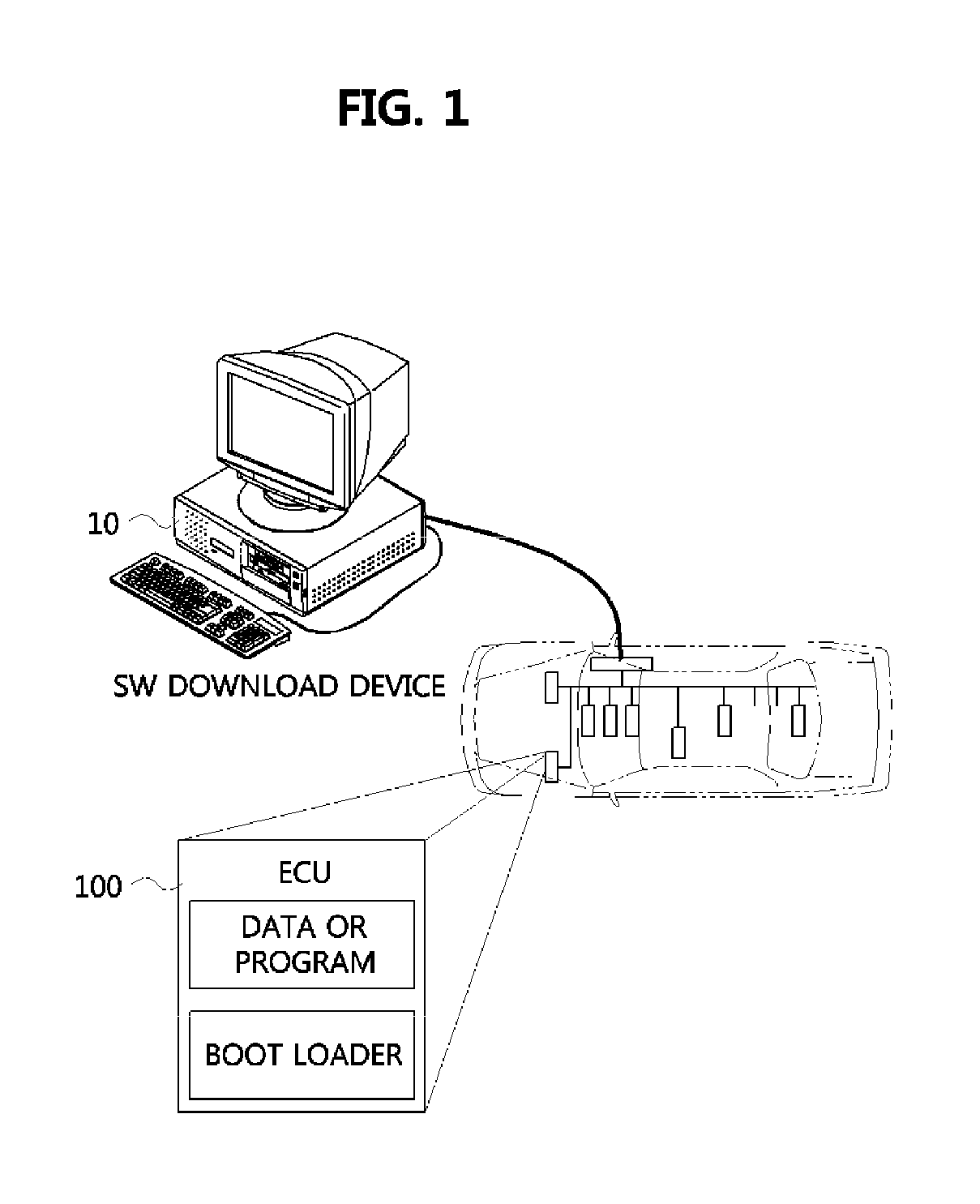

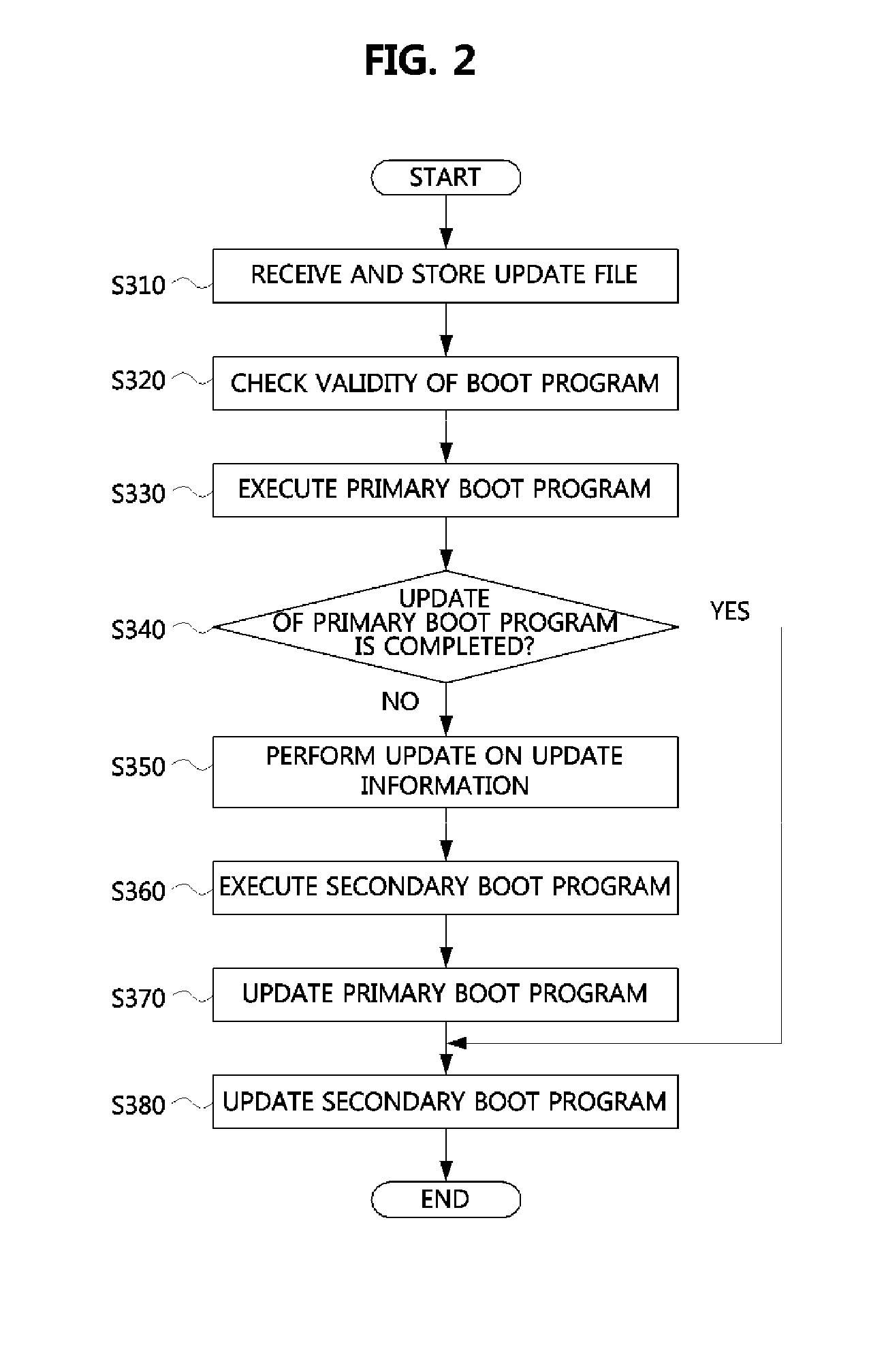

Method and apparatus for updating boot loader

Disclosed is an apparatus and method for updating a boot loader of an embedded system for a vehicle, the method including receiving and storing an update file, checking validities of a primary boot program and a secondary boot program based on update information according to the update file, and sequentially executing updates of the primary boot program and the secondary boot program. Since the secondary boot program, which is a backup boot program, maintains an executable state all the times, even if an error occurs during a boot program update, the update is executed again by use of the secondary boot program, thereby securing the safety of an embedded system for a vehicle.

Owner:ELECTRONICS & TELECOMM RES INST

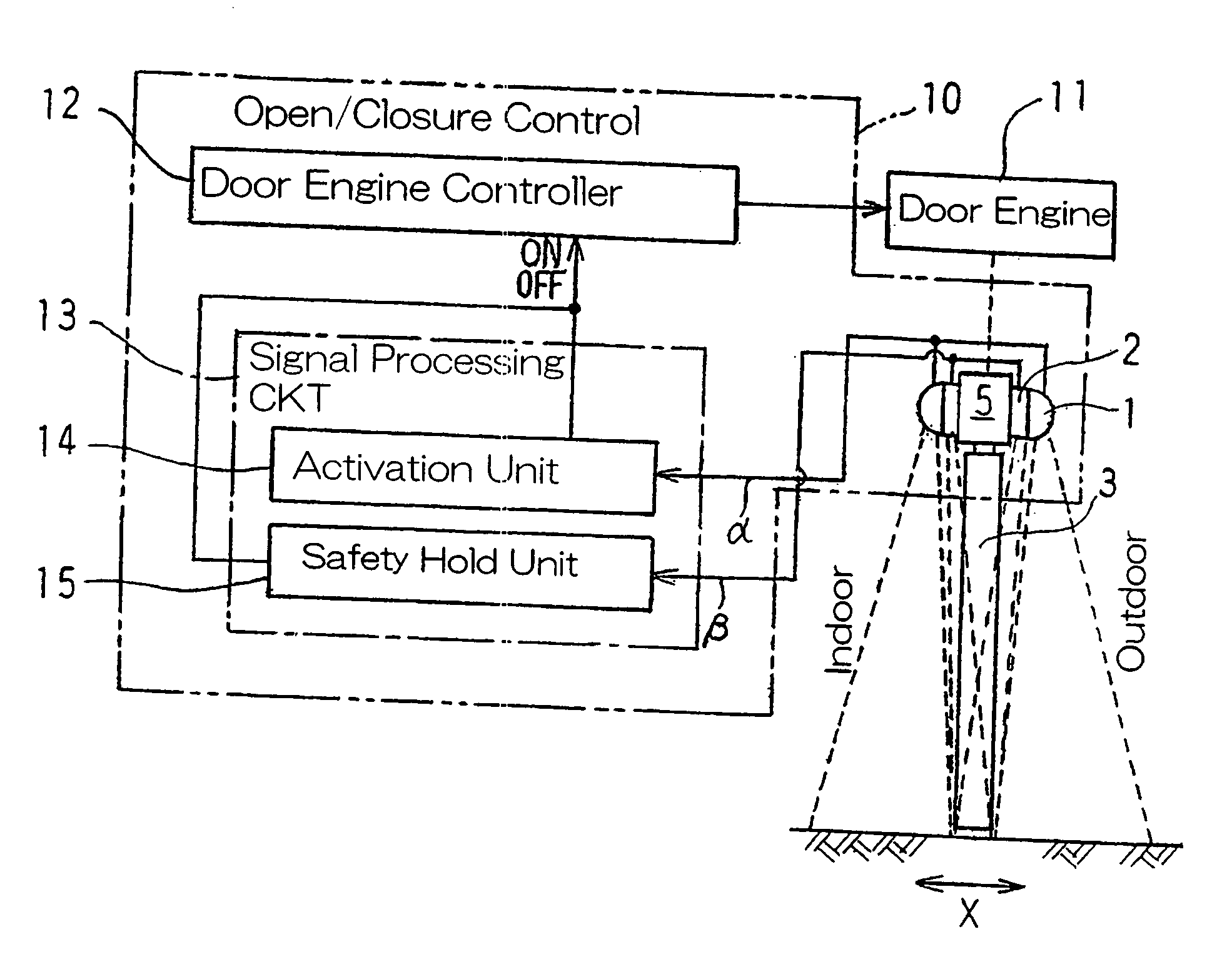

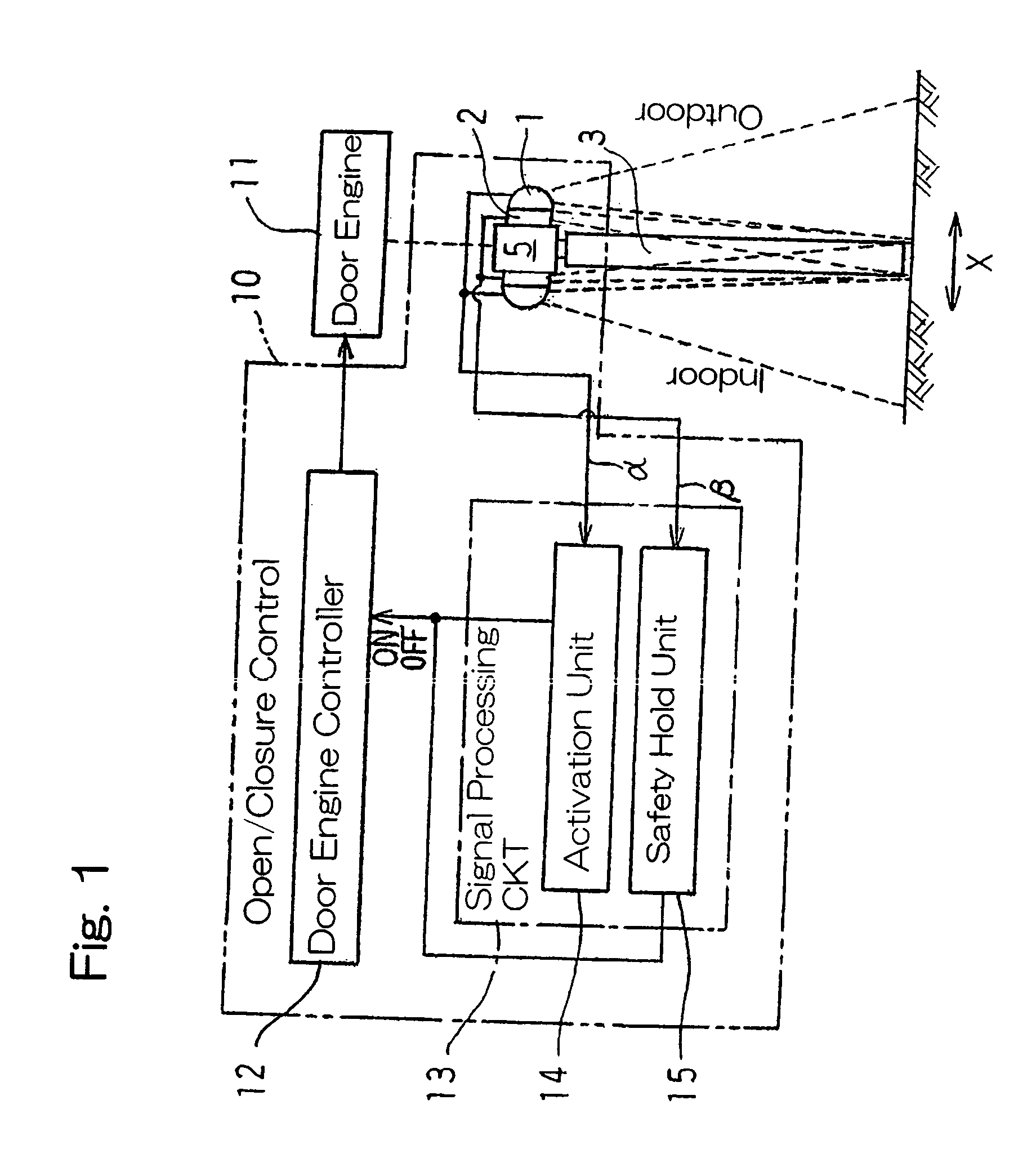

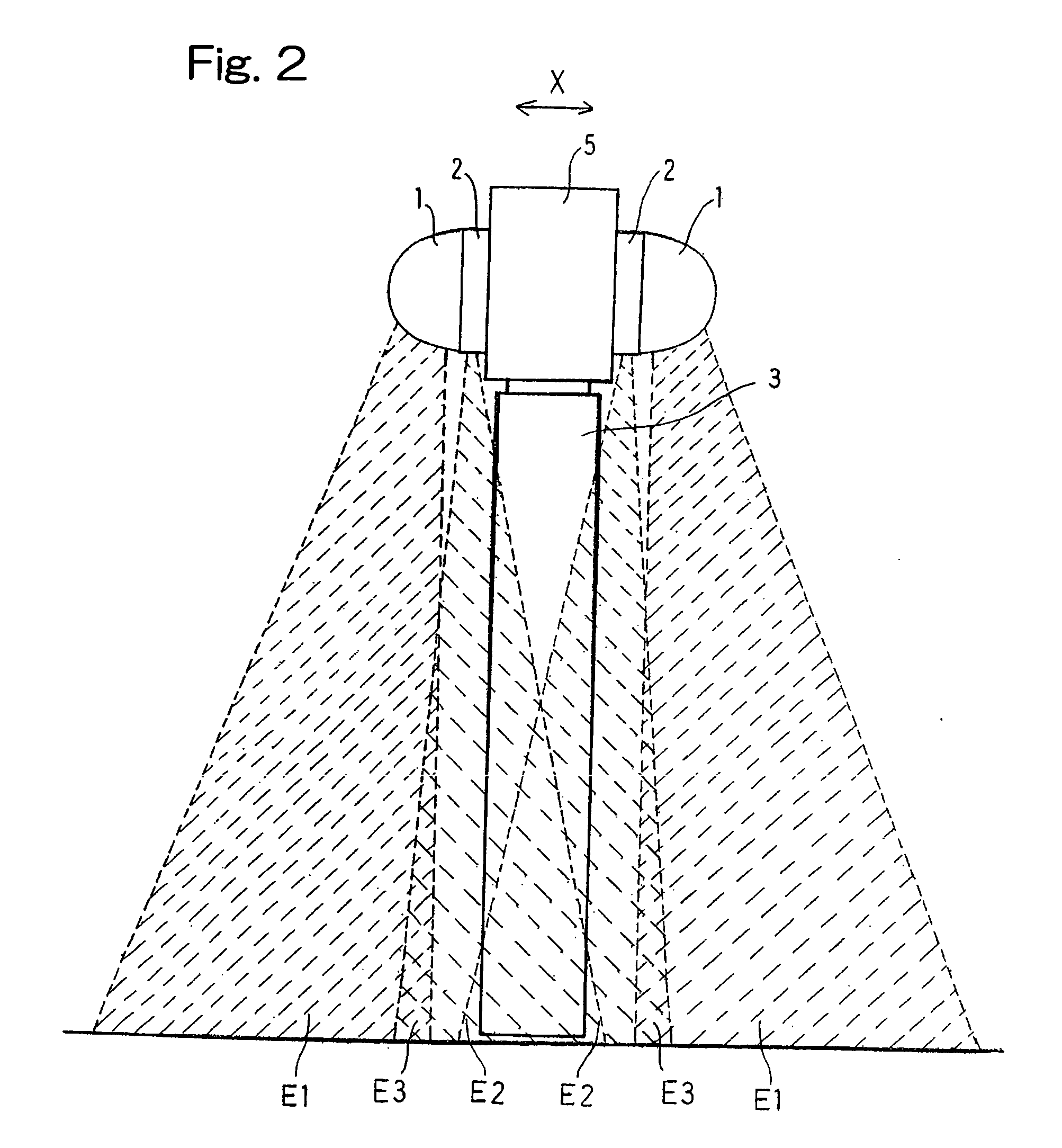

Sensor device for automatic door assembly

InactiveUS20060162254A1Cost reductionSecure safetyMotor/generator/converter stoppersElectric motor controlEngineeringMechanical engineering

To provide a compact sensor device for the automatic door assembly, which can be mounted and dismounted easily to a support member and be effective to secure the safety in the doorway vicinity, a activation sensor (1) for opening a door (3) and a safety sensor (2) for keeping the door (3) open are supported in a fashion overlapped one above the other in a direction conforming to the direction in which they are secured to a support member (5).

Owner:OPTEX CO LTD

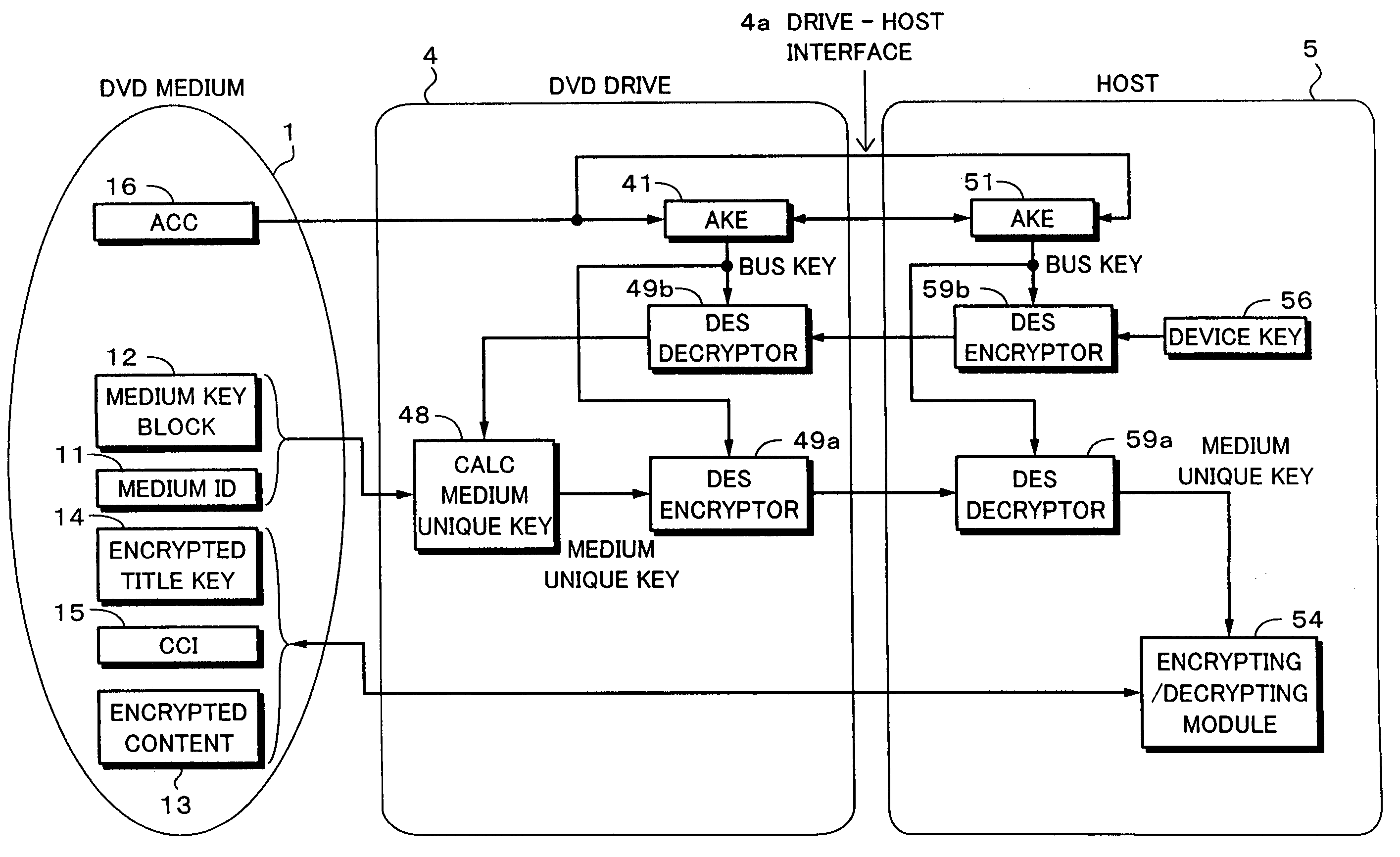

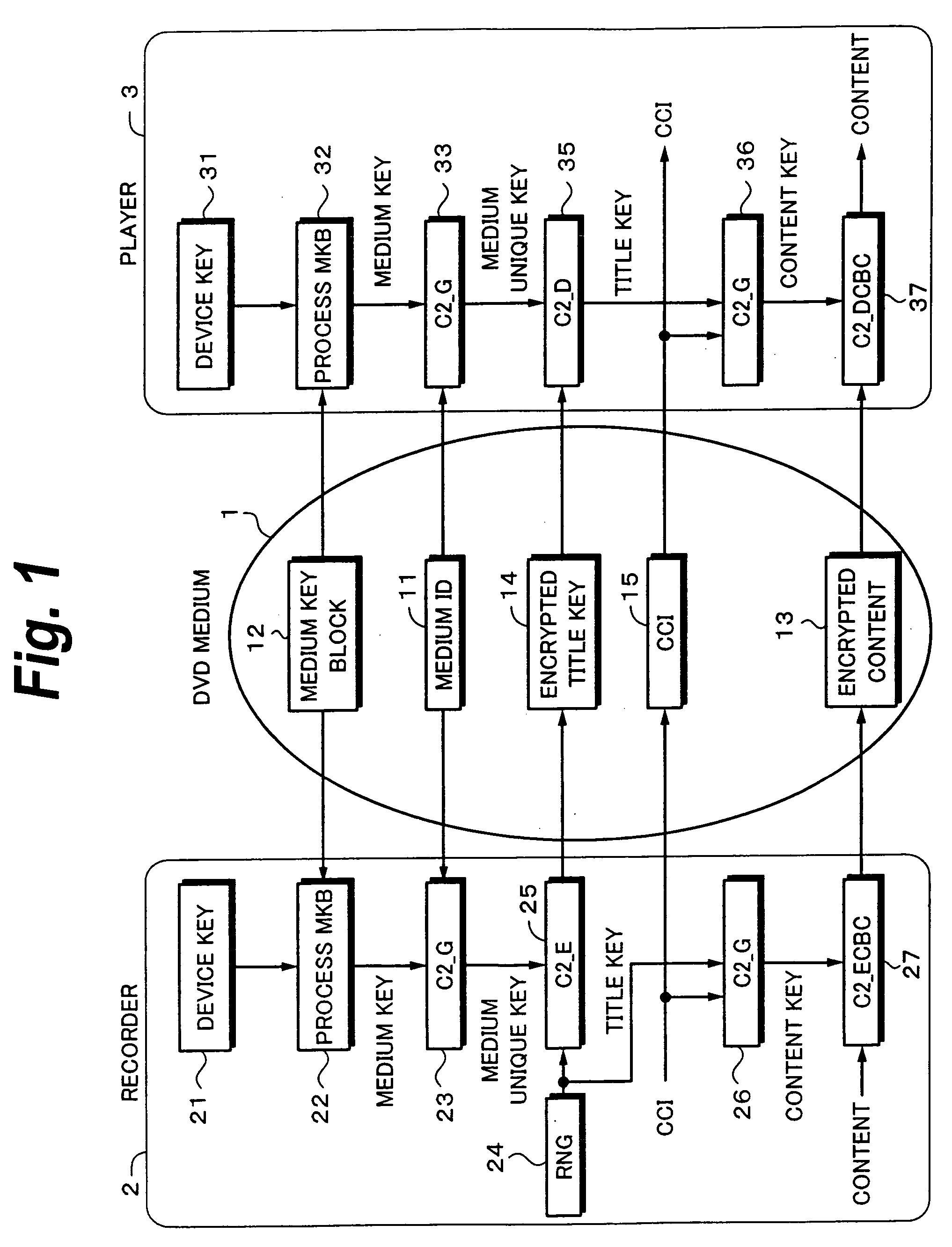

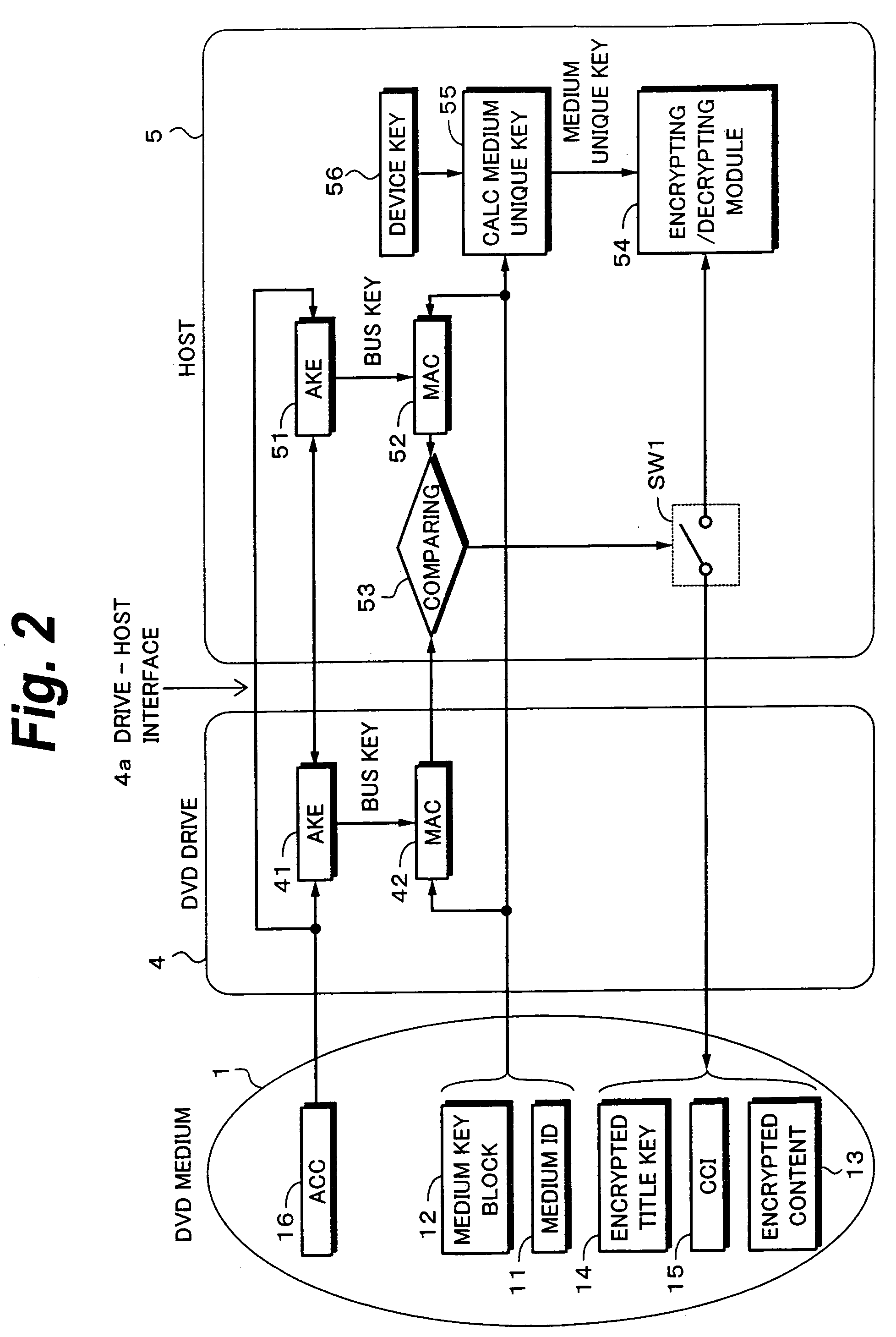

Recording/reproduction device, data processing device, and recording/reproduction system

InactiveUS20050081047A1Secure safetySafety of the copyright protection technology can be securedKey distribution for secure communicationUser identity/authority verificationData processingComputer hardware

A device key 46 is implemented on a drive 4 side. To securely transmit the device key 46 to a host 5, the device key 46 is encrypted with a bus key. The host 5 side decrypts the device key with the bus key. A medium unique key calculating block 55 calculates a medium unique key with an MKB 12, a medium ID, and the decrypted device key 46. When the calculated medium key is a predetermined value, the drive 4 is revoked and the process is stopped. The medium unique key is supplied to an encrypting / decrypting module 54. A content key is obtained with an encrypted title key 14 and a CCI 15. With the content key, an encrypted content is decrypted and a content that is recorded is encrypted.

Owner:SONY CORP

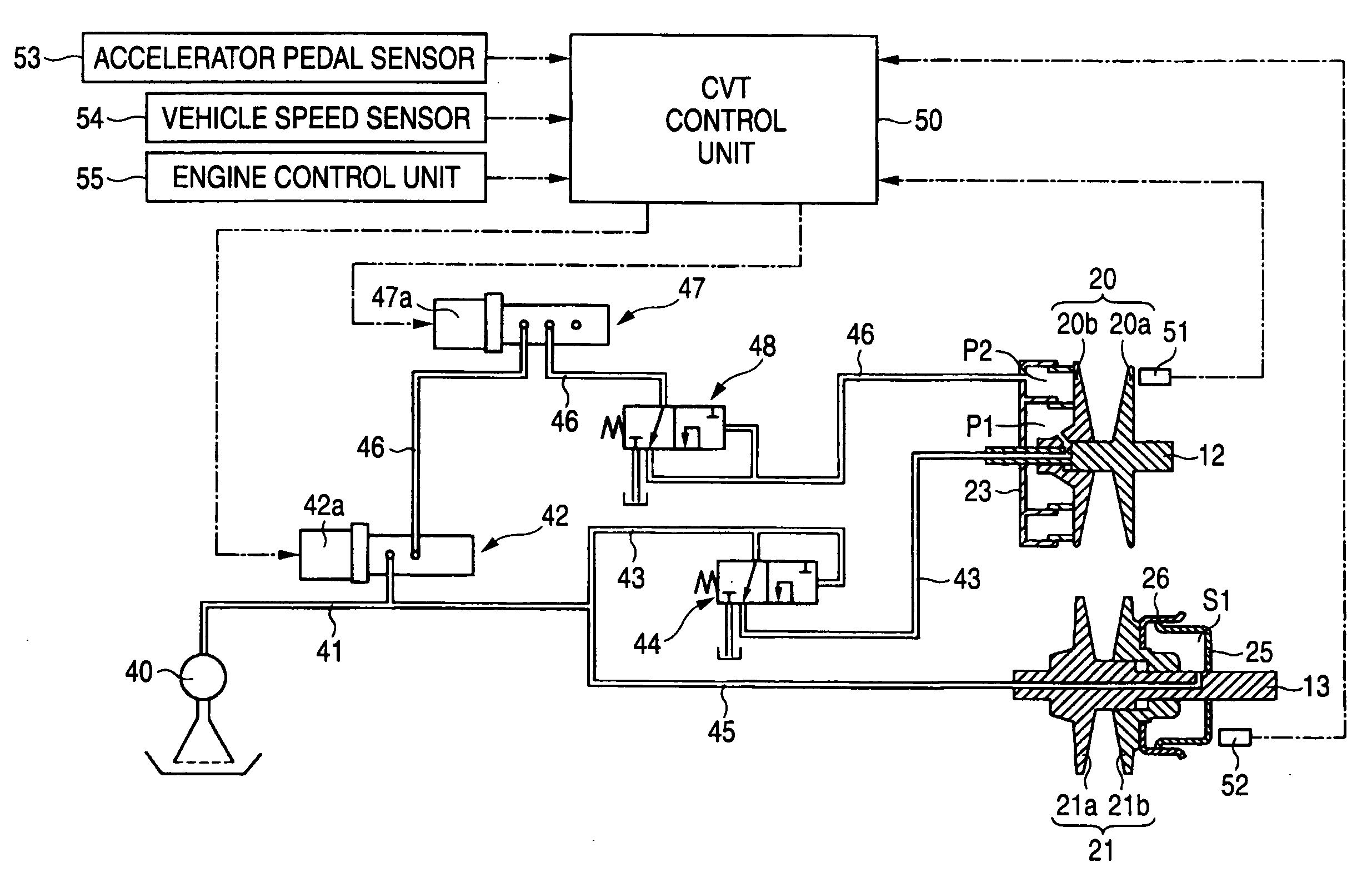

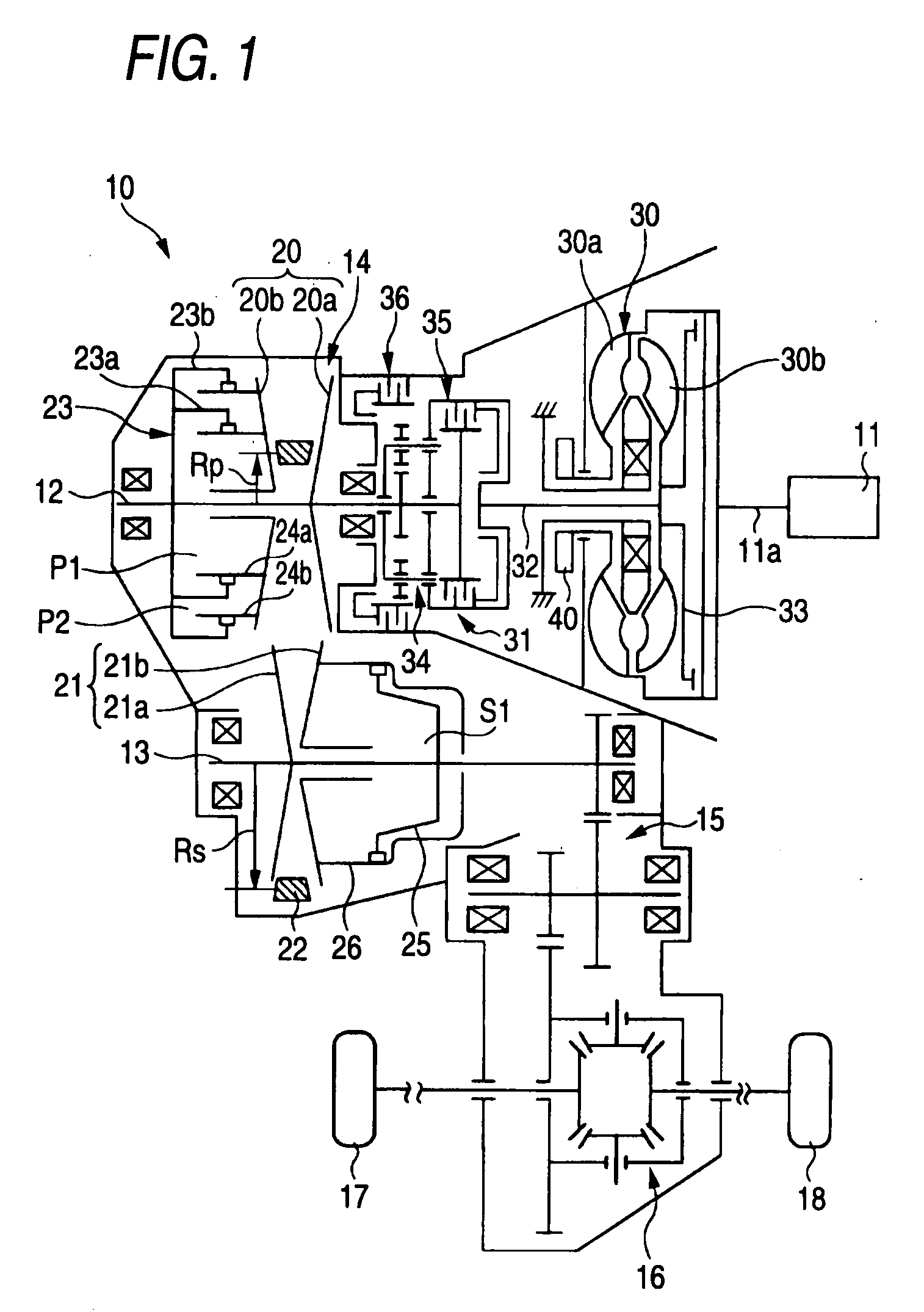

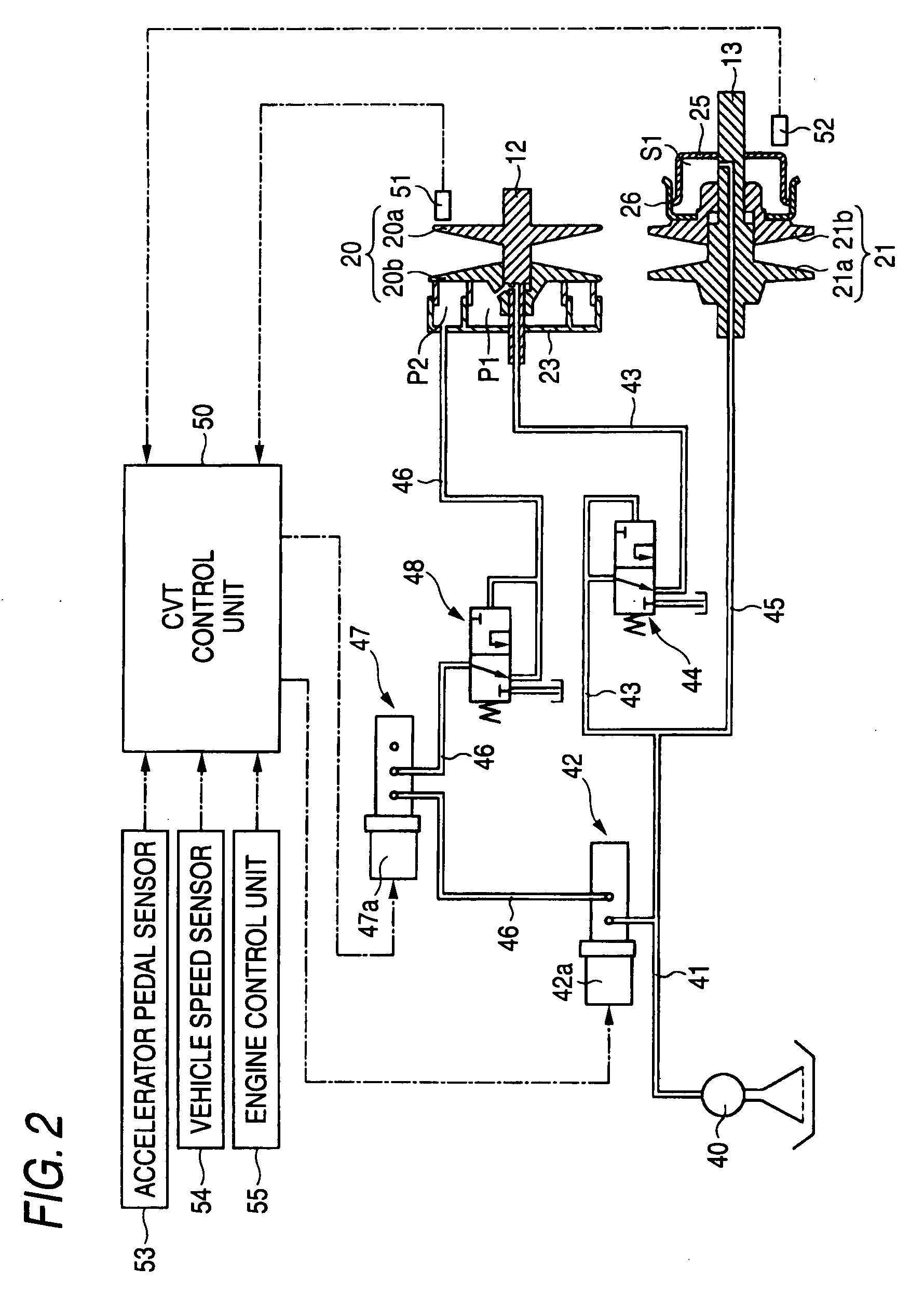

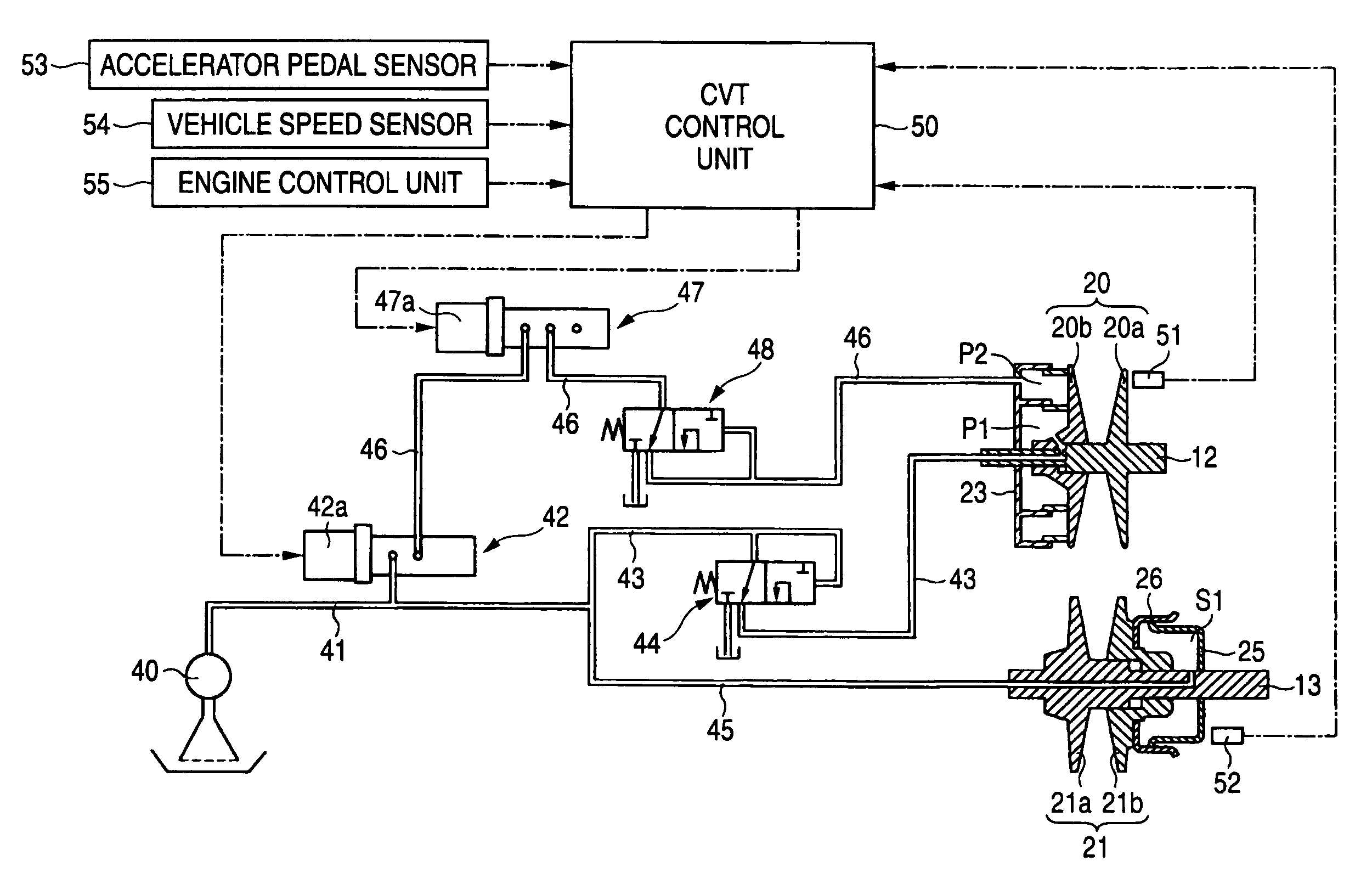

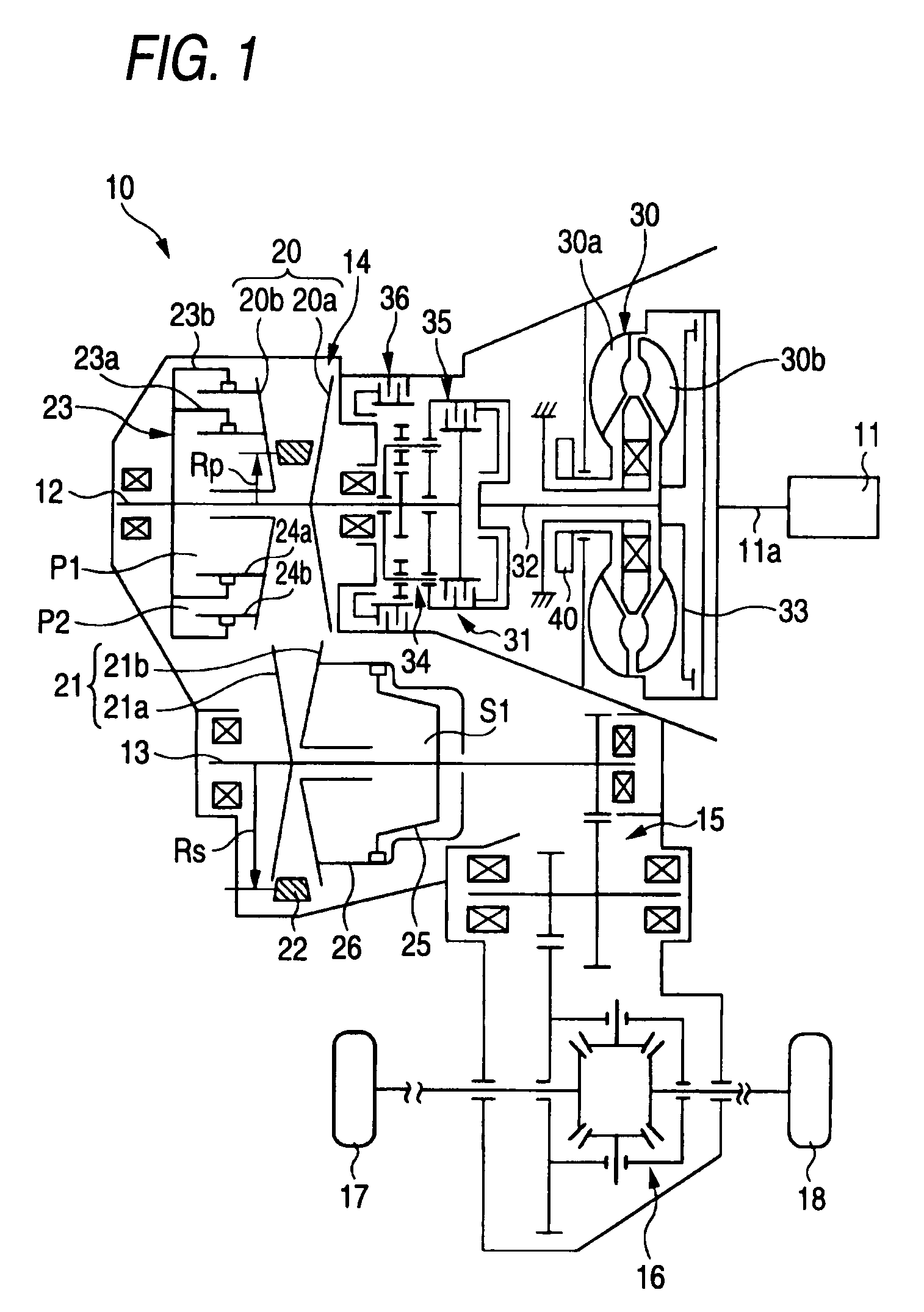

Control device for continuously variable transmission

Safety as well as the minimum driving performance is secured by preventing abrupt down-shifting if a line pressure valve or a primary pressure control valve fails. A line pressure path connected to an oil pump is connected with a line pressure control valve. A first primary pressure path branched from the line pressure path is connected with a hydraulic fluid chamber through a fail-safe valve, and a secondary pressure path branched from the line pressure path is connected to a hydraulic fluid chamber. The line pressure control valve is connected with a second primary pressure path in communication with a hydraulic fluid chamber, and this secondary primary pressure path is provided with a primary pressure control valve and a limiter valve. When the line pressure control valve and the primary pressure control valve fail and excess line pressure or primary pressure is output, the pressure in the hydraulic fluid chamber is reduced by the fail-safe valve, so that the pressure in the hydraulic fluid chamber is reduced by the limiter valve.

Owner:SUBARU CORP

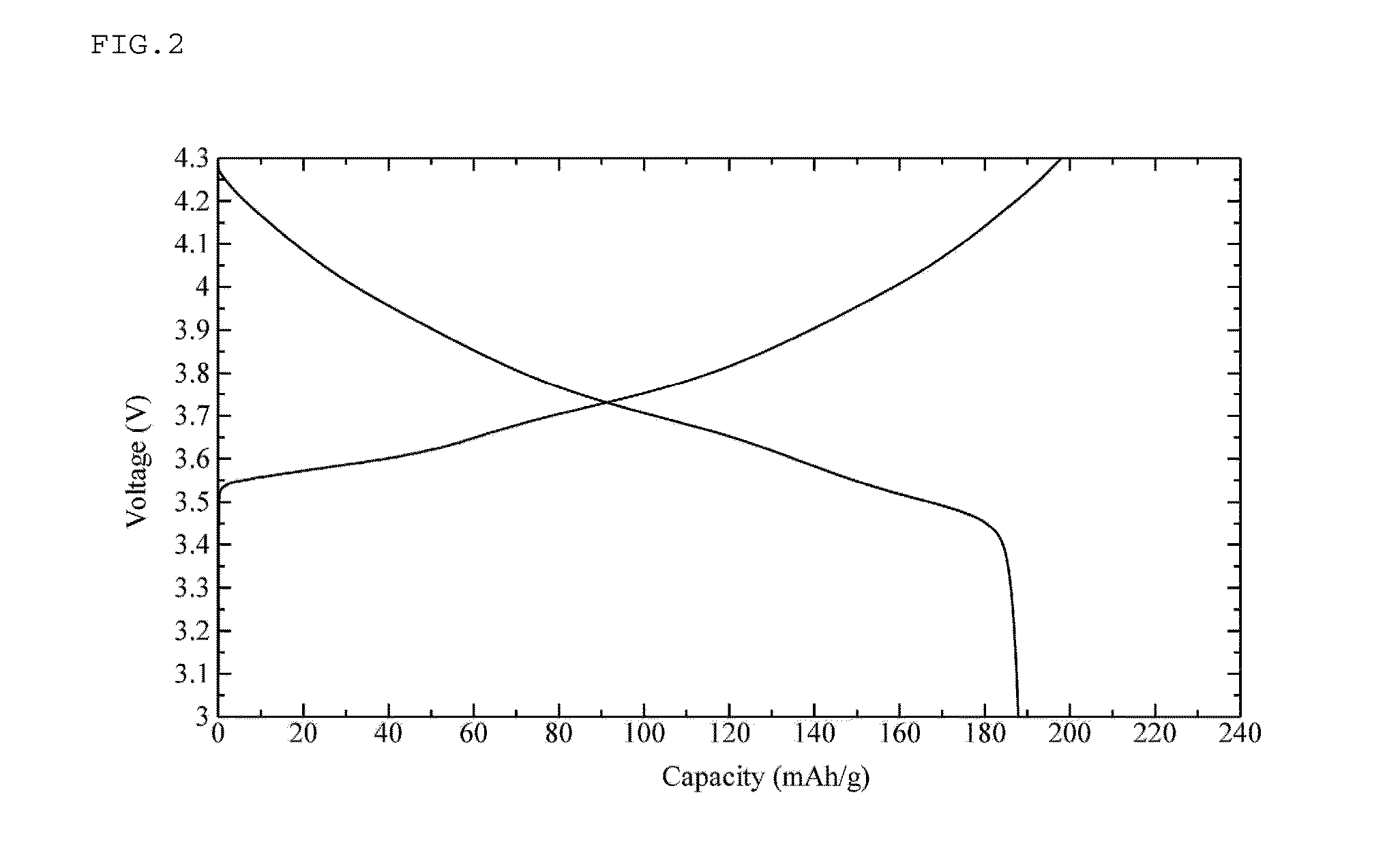

Positive electrode active substance for nonaqueous electrolyte secondary cell, method for producing same, and nonaqueous electrolyte secondary cell using positive electrode active substance

ActiveUS20150188136A1Large capacityReduce irreversible capacityPositive electrodesNon-aqueous electrolyte accumulator electrodesDischarge efficiencyOccupancy rate

A positive electrode active material is provided that has a high capacity, a low irreversible capacity, an excellent initial charge / discharge efficiency, and excellent rate characteristics. This positive electrode active material comprises a hexagonal lithium nickel complex oxide having a layer structure and represented by the general formula LixNi1-y-zCoyMzO2 (0.98≦x≦1.04, 0.25≦y≦0.40, 0≦z≦0.07, and M is at least one element selected from Al, Ti, Mn, Ga, Mg, and Nb), wherein a lithium occupancy rate in a lithium main layer as obtained by Rietveld analysis from the x-ray diffraction pattern is at least 98.7%, and a crystallite diameter as calculated from the peak for the (003) plane in x-ray diffraction is 50 to 300 nm.

Owner:SUMITOMO METAL MINING CO LTD

Enclosure for outdoor equipment

InactiveUS6904933B2Secure safetyPrevent dew condensationCasings/cabinets/drawers detailsCheck valvesElectronic circuitEngineering

An enclosure for outdoor equipment, which can prevent the enclosure from being damaged by a rise of air pressure inside the enclosure by exhausting air from the enclosure, and further can secure safety of the enclosure and can secure easiness for fixing an inside air pressure adjusting mechanism to the enclosure and also can prevent a dew condensation from occurring in the enclosure, is provided. The enclosure for outdoor equipment provides an inside air pressure adjusting mechanism. The inside air pressure adjusting mechanism provides a valve seat and a valve element which is seated on the valve seat in a state that the valve element can be opened and closed by placing a sealing component between them. The inside air pressure adjusting mechanism is inserted to a hole of the enclosure for outdoor equipment, in which an electronic circuit is disposed, and fixed so that the inside air pressure adjusting mechanism does not stick out largely from the front surface of the enclosure for outdoor equipment. With this, the atmosphere can be prevented from entering the enclosure and the air inside the enclosure is exhausted to the outside corresponding to a rise of the temperature inside the enclosure.

Owner:NEC CORP

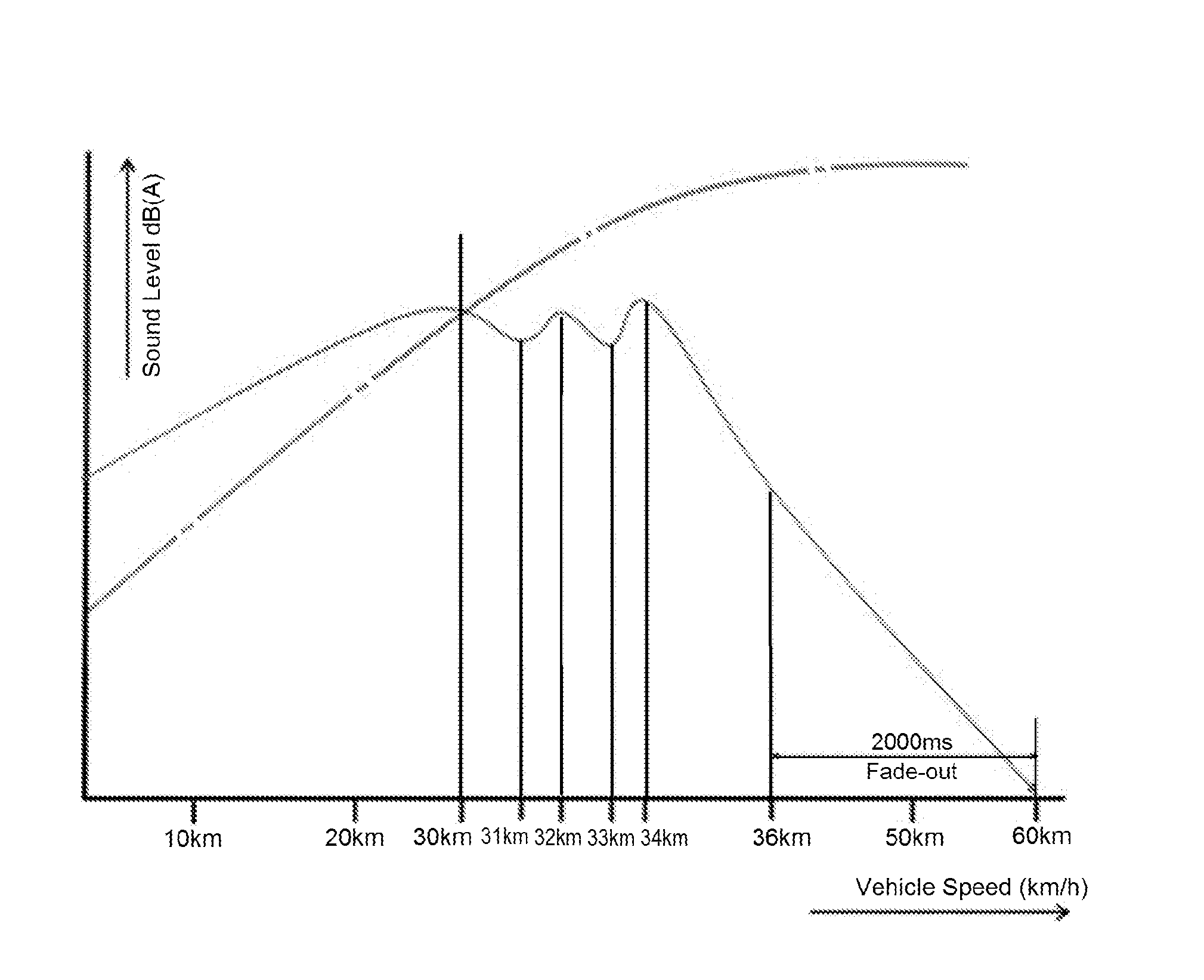

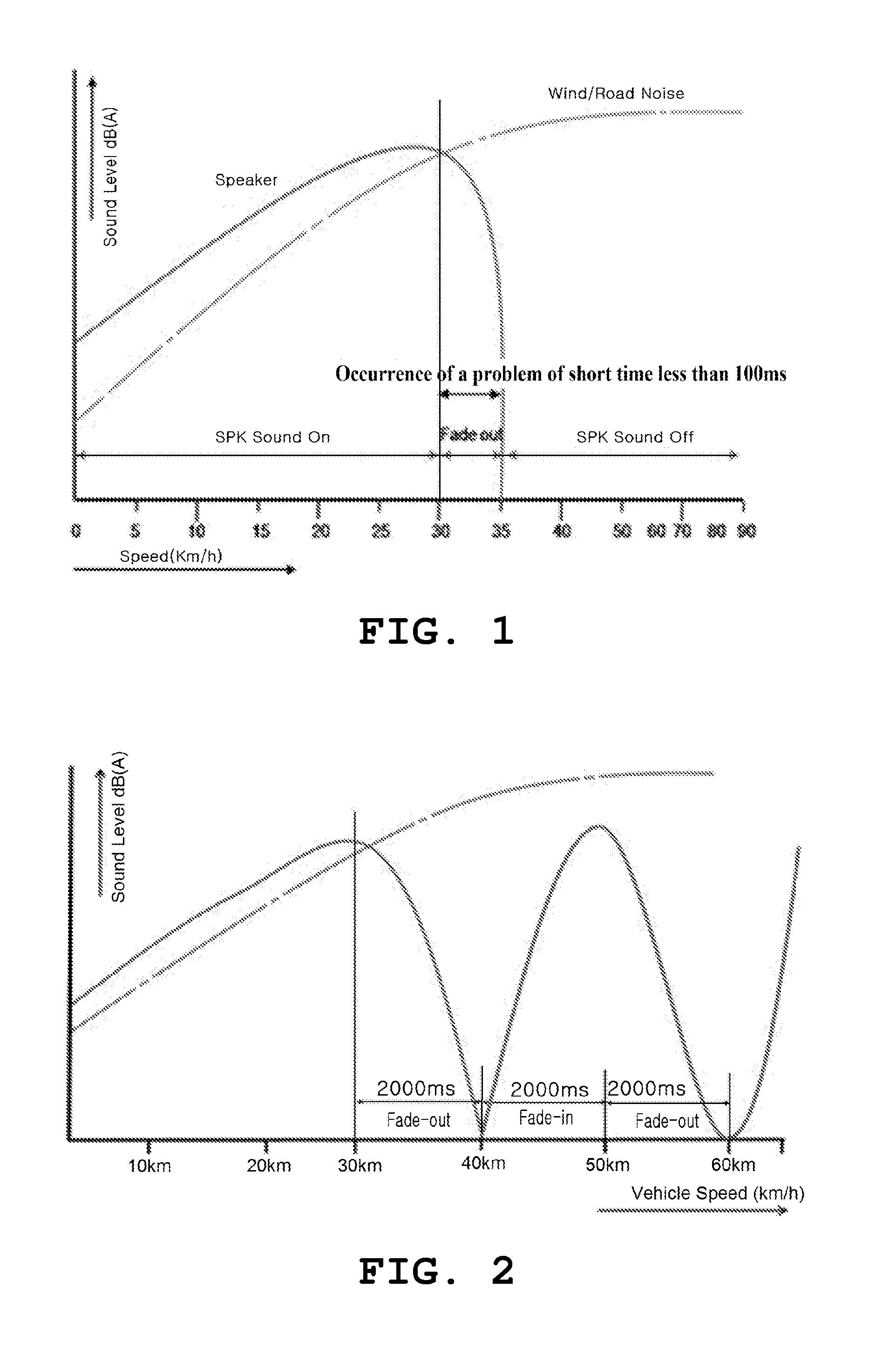

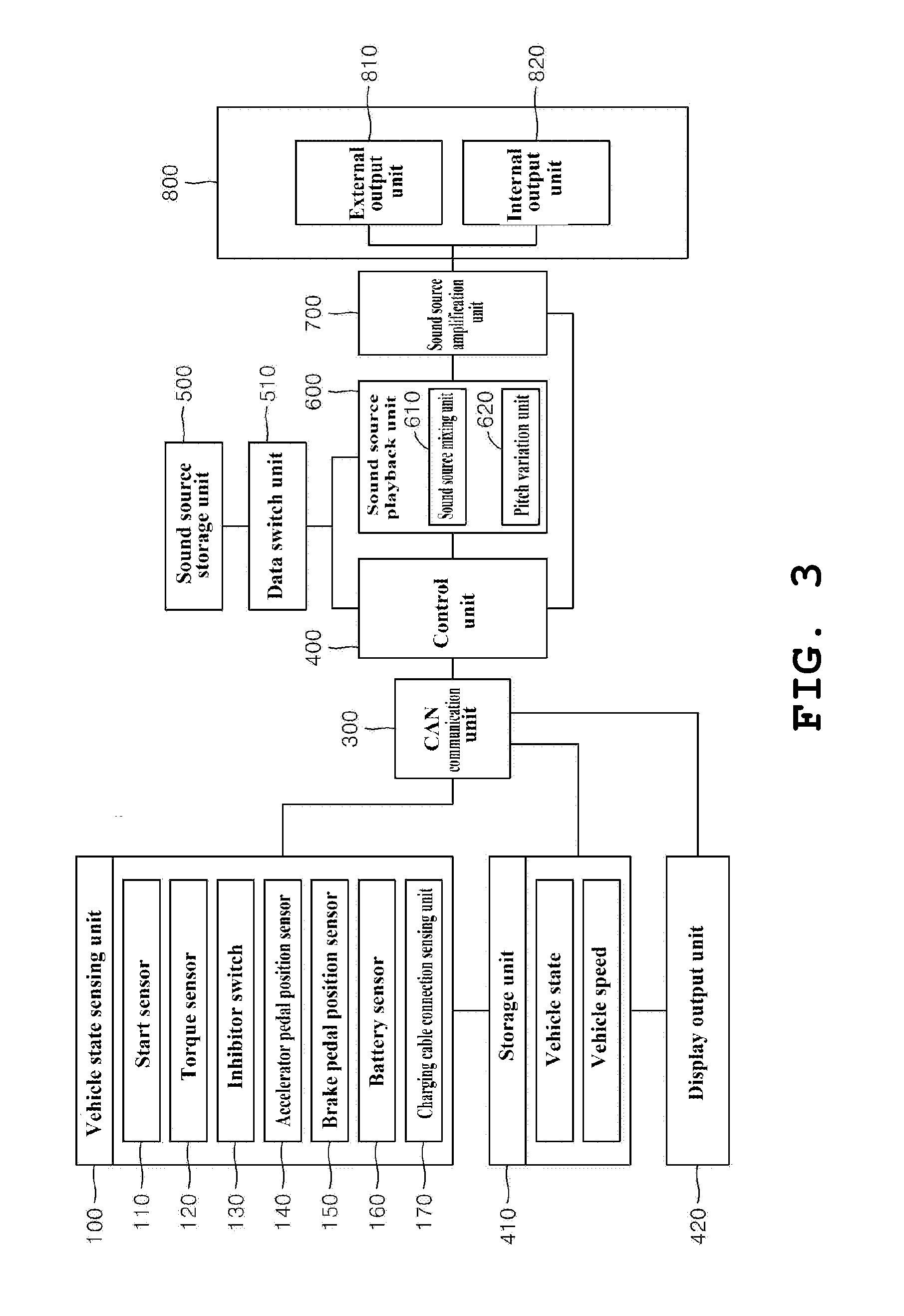

Sound generating system for environment friendly vehicle and a method for controlling the system

ActiveUS20170001559A1Secure safetyEnsure safetyAcoustic signal devicesSound producing devicesEngineeringControl unit

An environmentally-friendly vehicle sound generator apparatus. The apparatus includes a vehicle state sensing unit, a sound source storage unit, a sound source playback unit, a sound source amplification unit, a sound output unit, and a control unit. The control unit receives a sensing signal from the vehicle state sensing unit and controlling the operation of the sound source playback unit so as to play back the operating sound in different playback methods to control and change the operating sound according to the received sensing signal. The vehicle state sensing unit senses a vehicle speed, and if it is determined according to a vehicle speed signal that the vehicle speed reaches a preset speed range, the control unit fades out the output of the sound output unit at a preset ratio of the vehicle speed to a time elapsed after the vehicle speed reaches the preset speed range.

Owner:LS AUTOMOTIVE TECH CO LTD

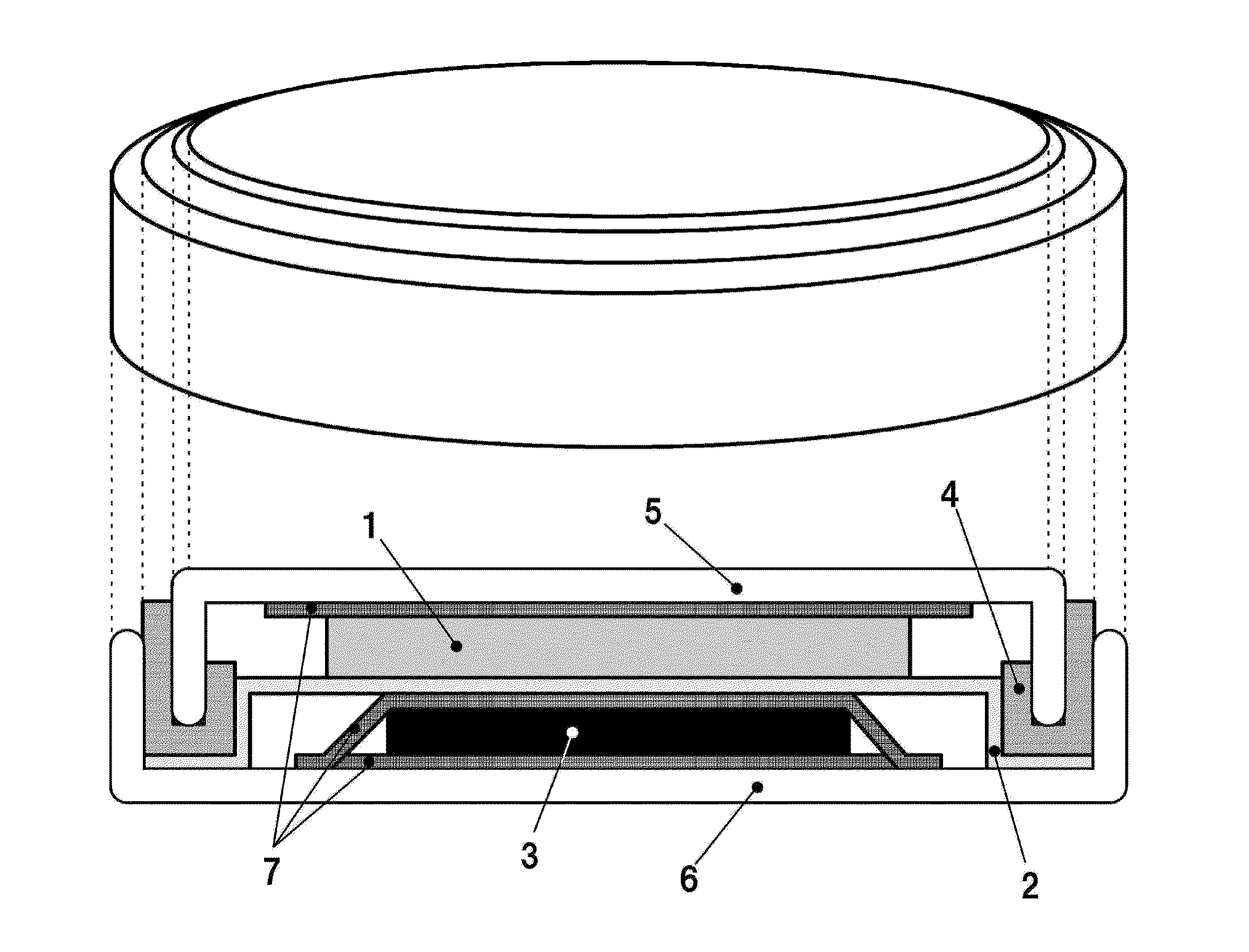

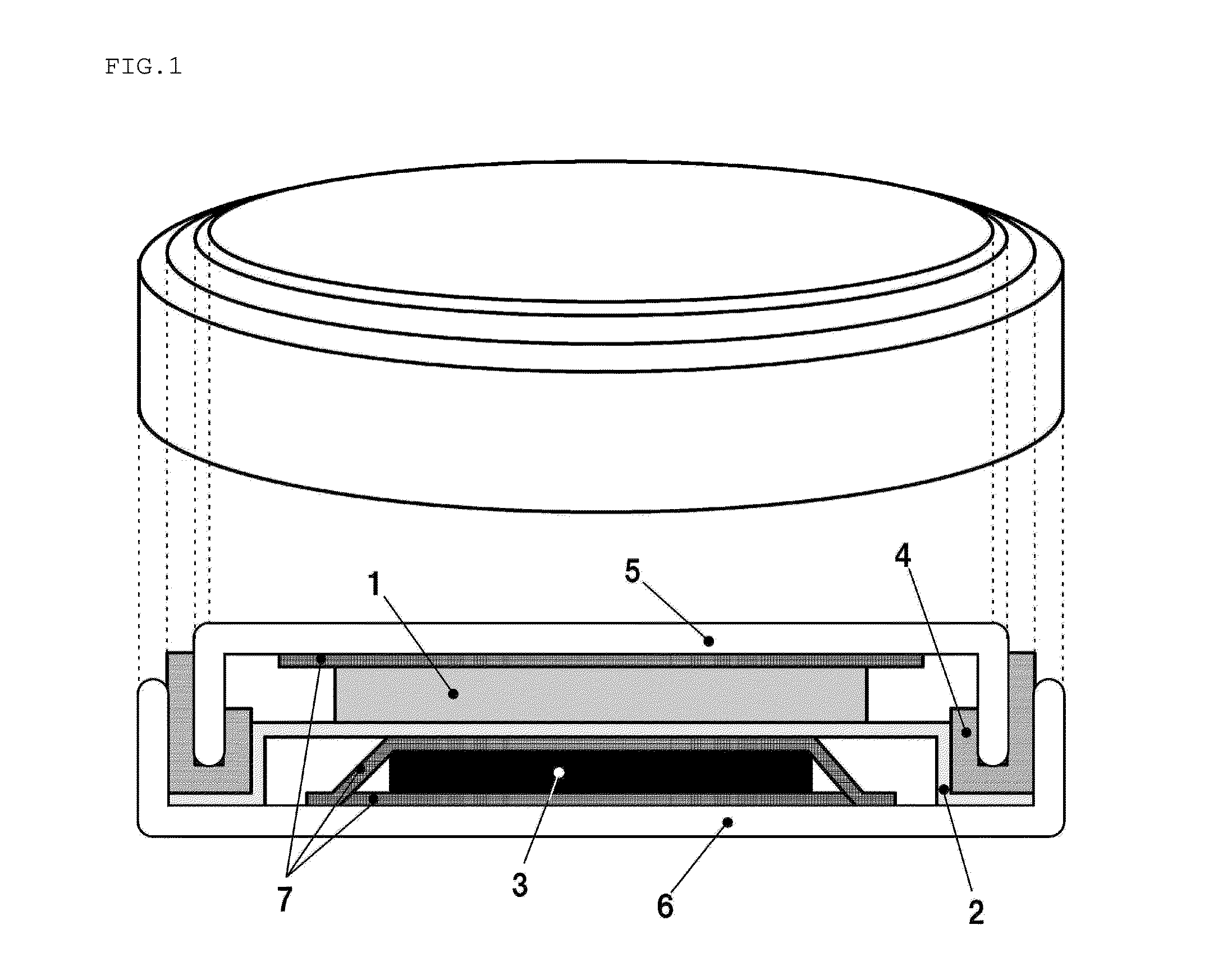

Secondary battery

InactiveUS20050208347A1Simple structureSecure designBatteries circuit arrangementsFinal product manufactureEngineeringElectrolyte

This invention concerns a secondary battery which ensures safety with a simple structure and promotes exaltation of the service life of battery. This secondary battery is formed by interposing a nonaqueous electrolyte between the positive pole and the negative pole and connecting a group of diodes between the positive pole terminal forming the positive pole and the negative pole terminal forming the negative pole in the direction in which the forward direction voltage is applied. Owing to this structure, the secondary battery is enabled to possess the function of protecting the battery from overcharging and overdischarging even when the voltage is abnormally lowered during the course of discharging.

Owner:NISSAN MOTOR CO LTD

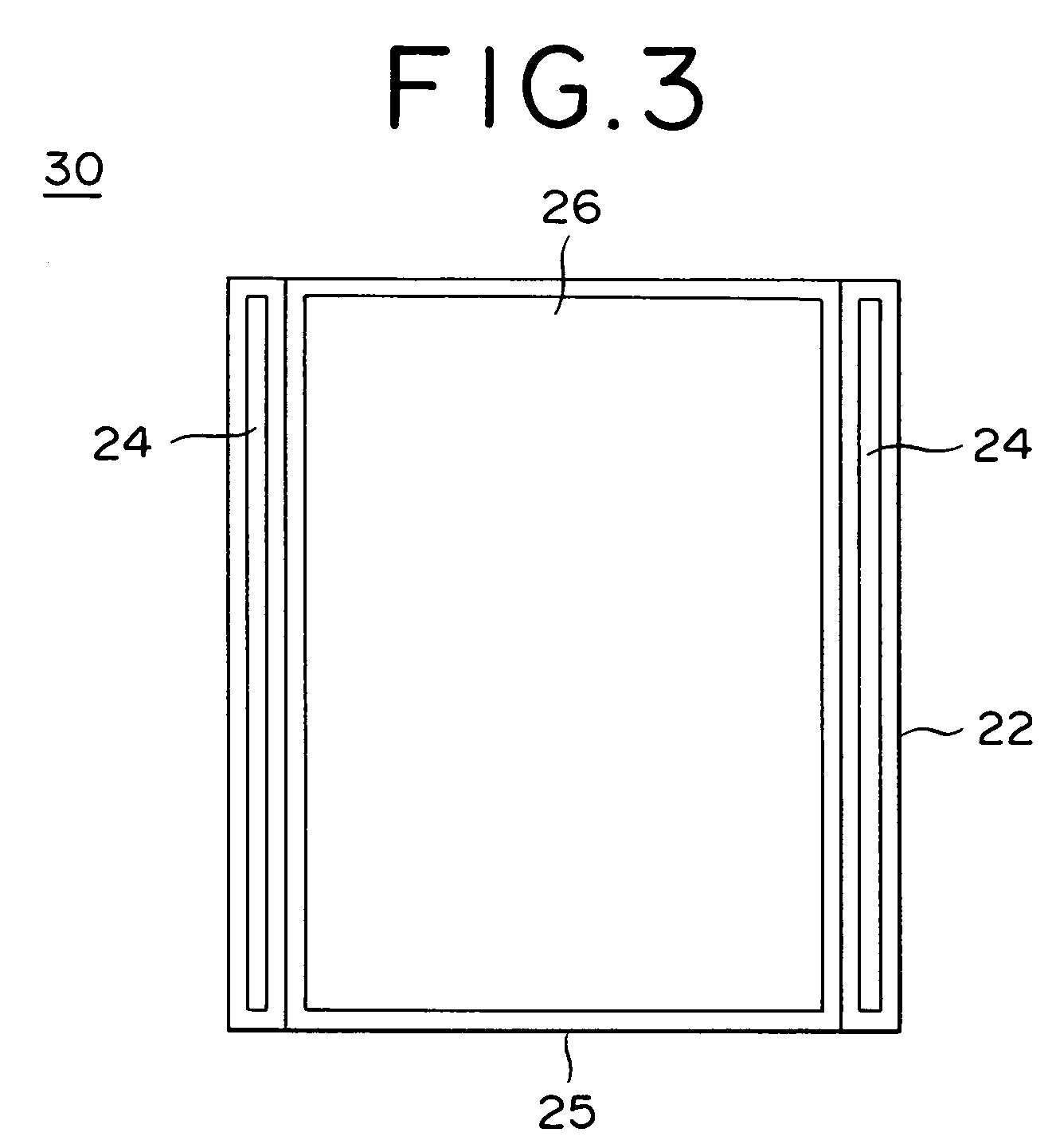

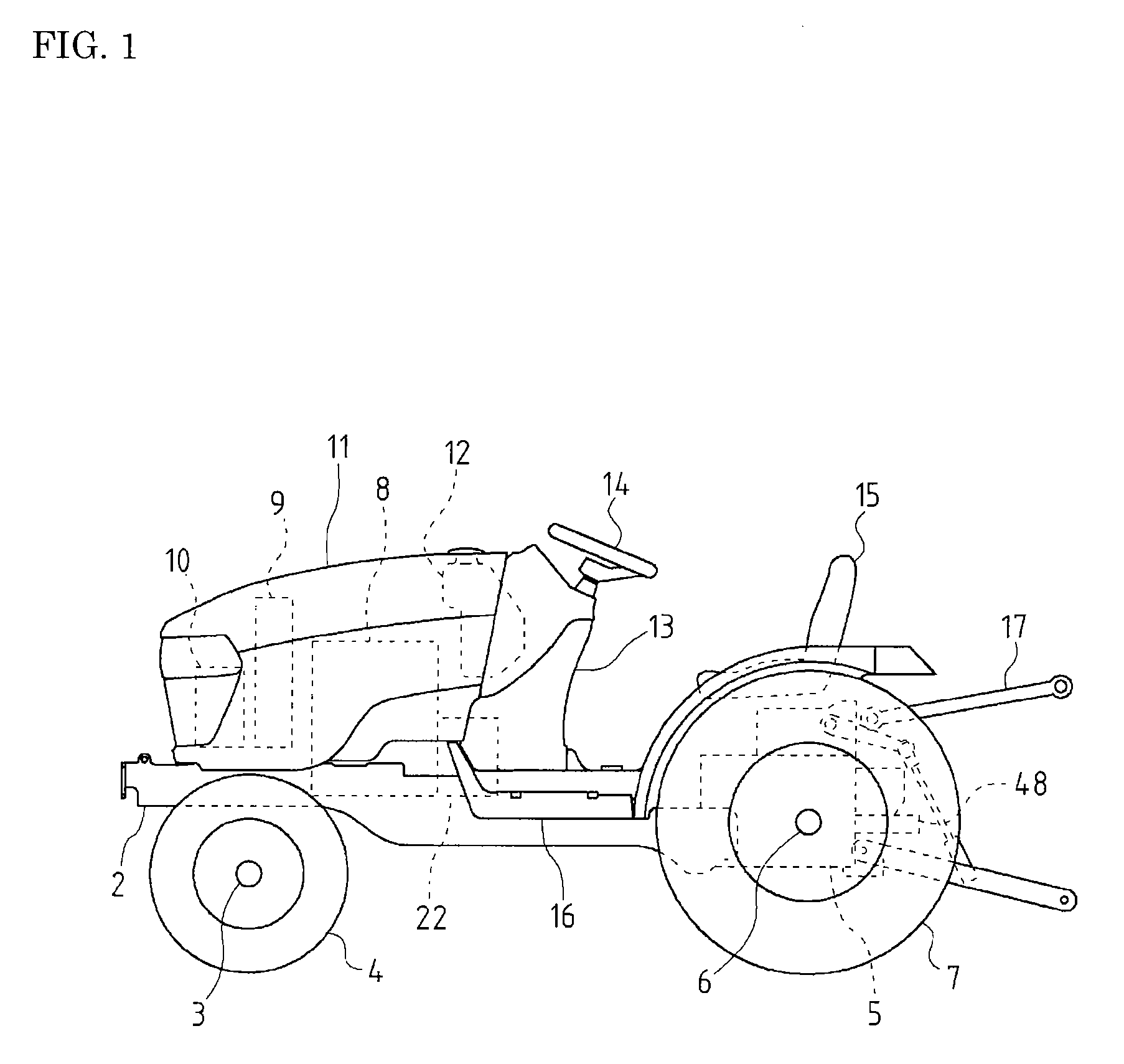

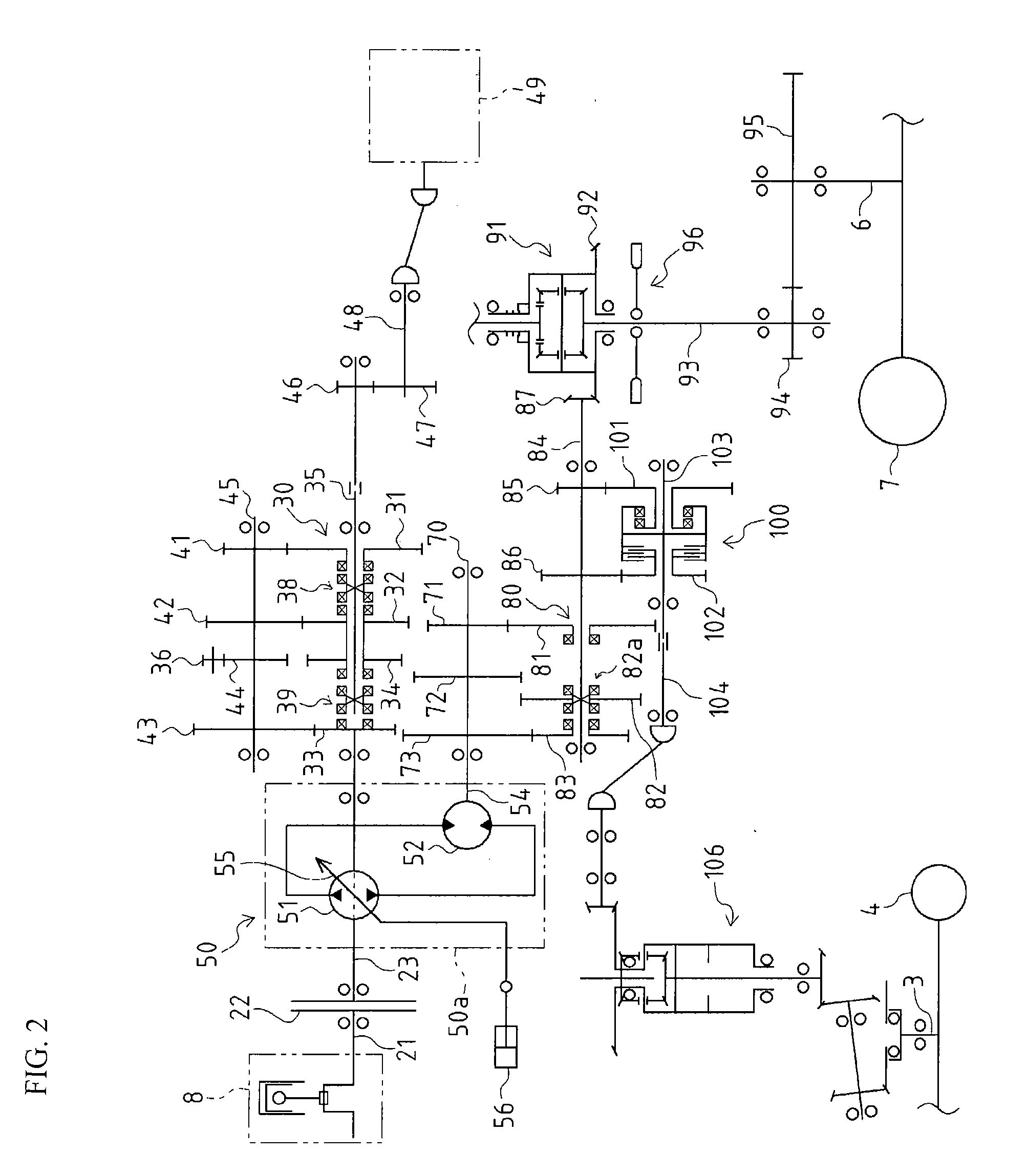

Working Vehicle with HST

ActiveUS20100043419A1Improve durabilitySecure safetyRotary clutchesGearing controlClutchHydraulic pump

A working vehicle with an HST in which over-rotation of a hydraulic pump in the HST or the pump input shaft thereof is prevented when a main clutch is disconnected during a run. When a main clutch connection / disconnection detection means (112) detects (S2) the disconnection state of the main clutch (22) during a run, a control means (110) judges (S3) whether a vehicle speed detected by a vehicle speed detection means (116) is at least a set speed or not, and if the vehicle speed is at least the set speed, the movable swash plate (55) of the hydraulic pump (51) in an HST (50) is controlled to sustain it at the current inclination angle (S4).

Owner:YANMAR POWER TECHNOLOGY CO LTD

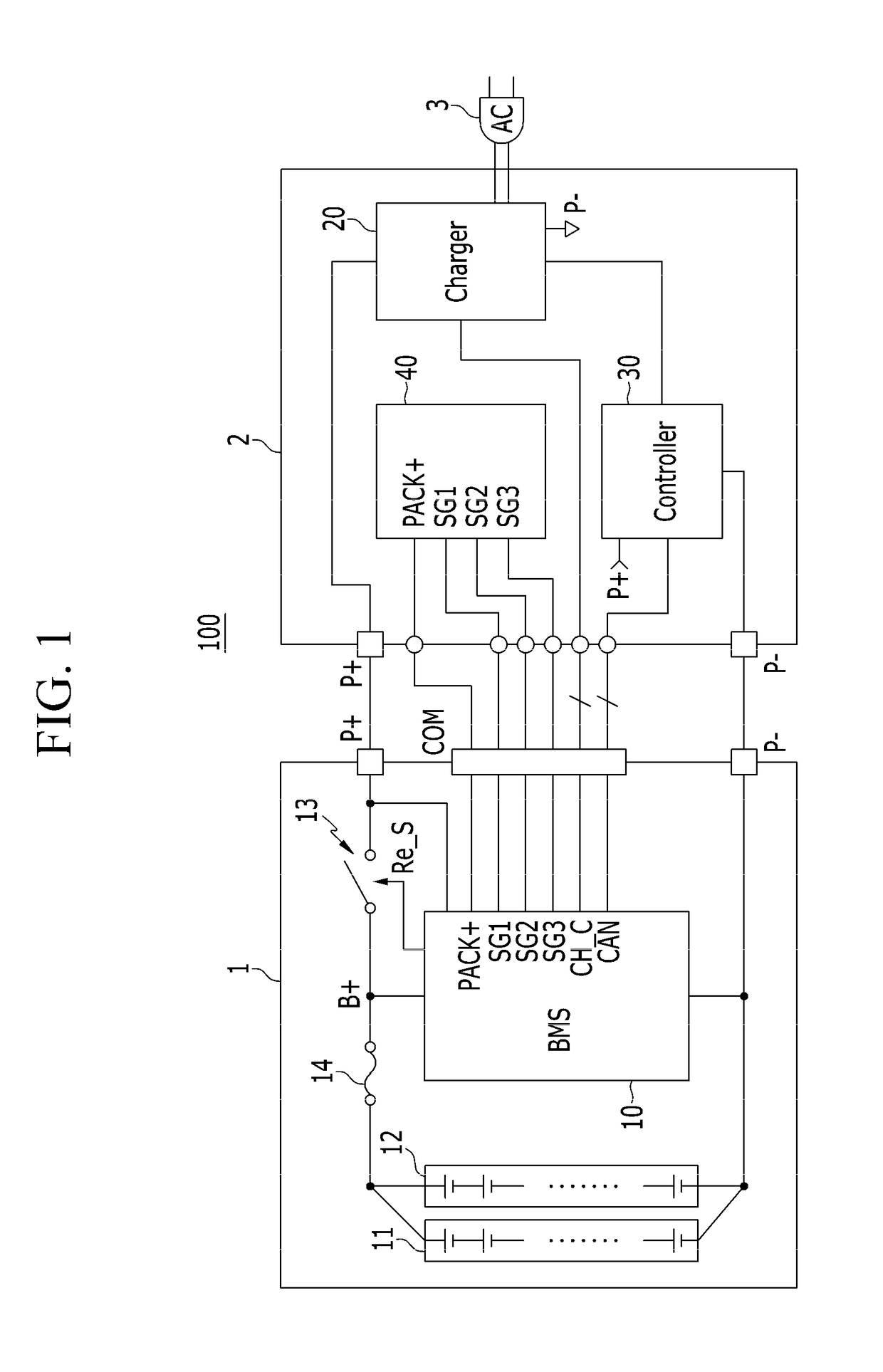

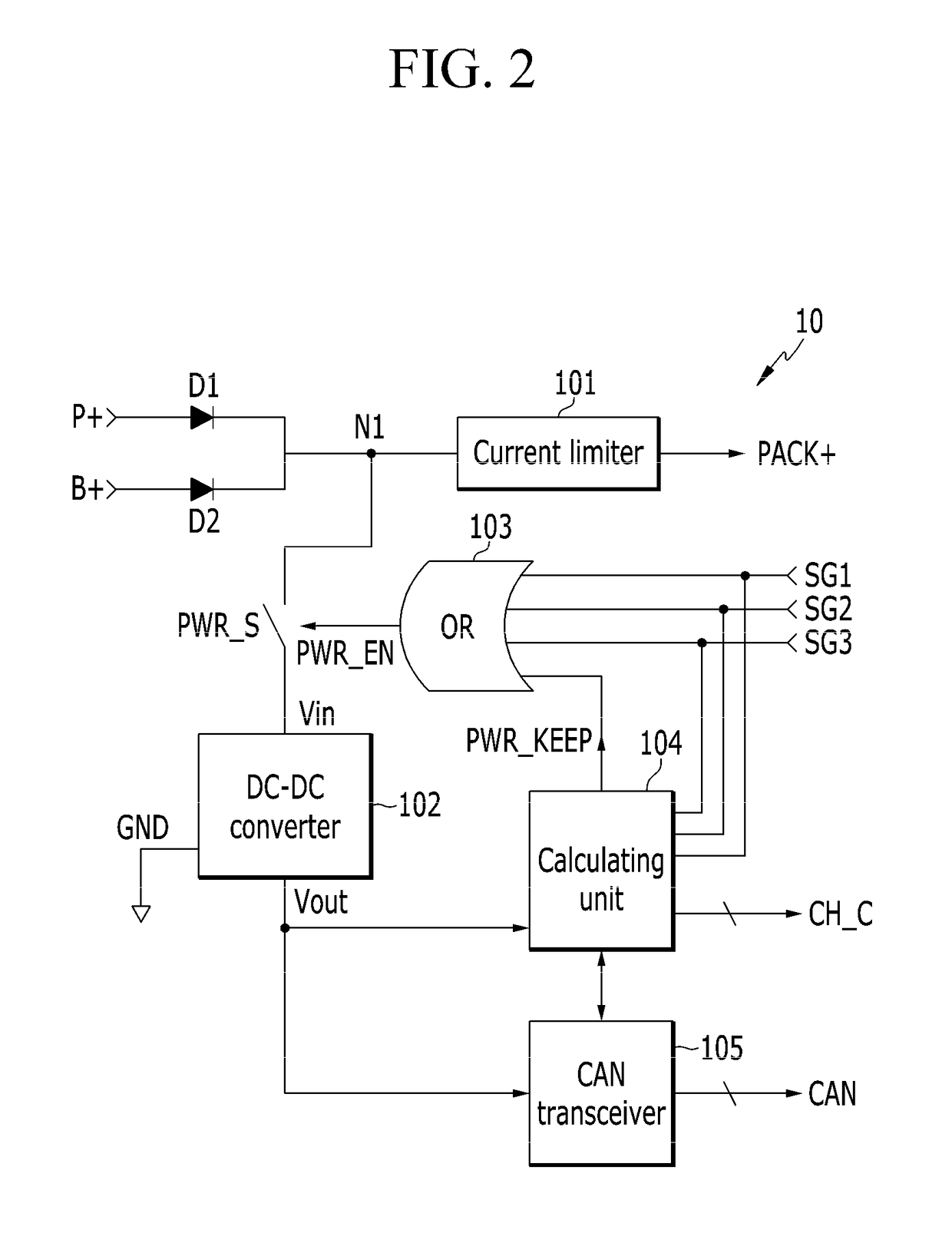

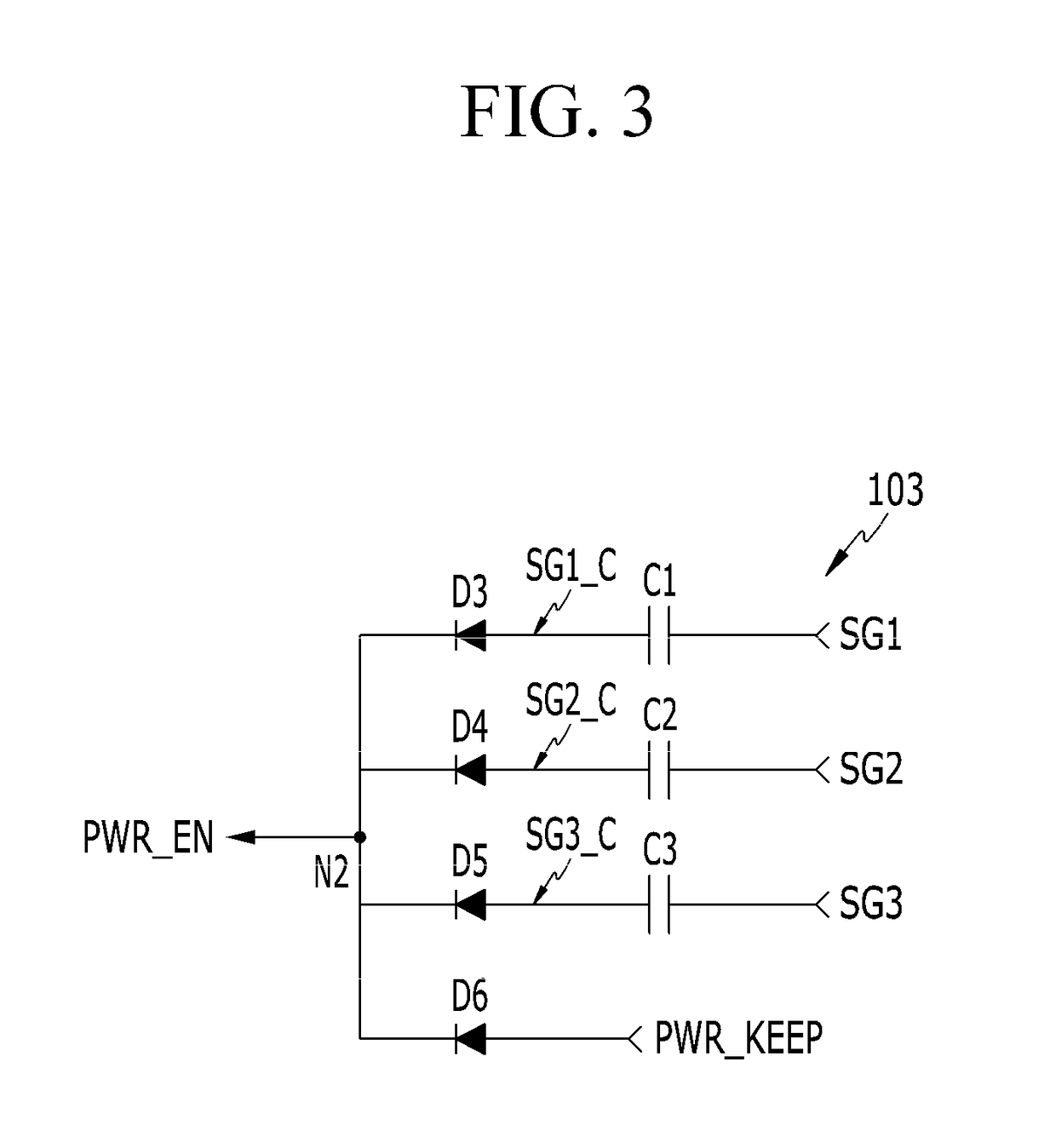

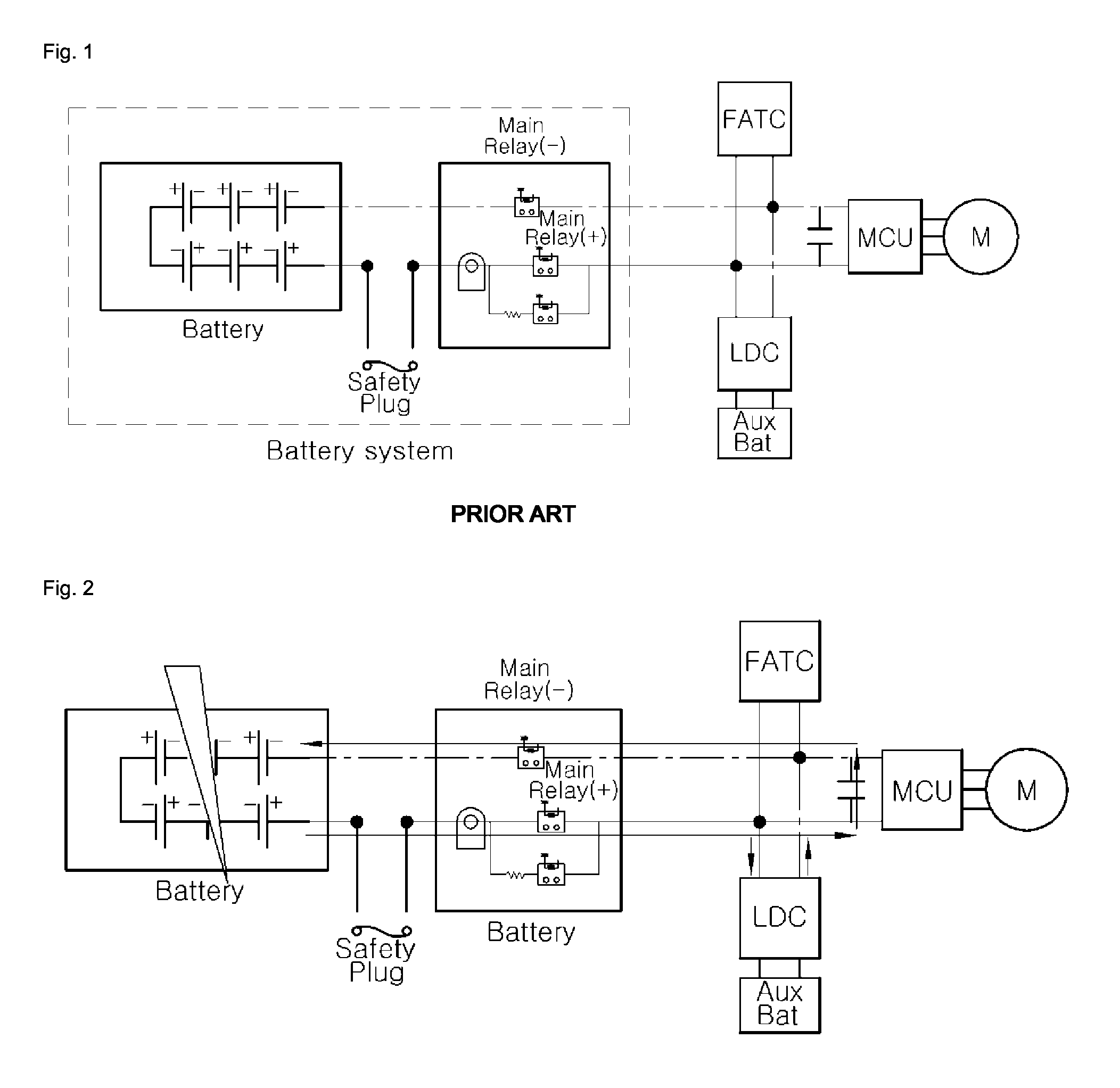

Battery pack, method for managing battery pack, and vehicle comprising battery pack

ActiveUS20190089168A1Secure safetyMaximize usabilityCircuit monitoring/indicationIndicating/monitoring circuitsEngineeringBattery management systems

Disclosed is a battery pack including: at least one battery module including a plurality of battery cell; and a battery management system (BMS) configured to determine an operation mode of a battery pack according to an enabled switch signal between at least two switch signals, which wake up the battery pack, and control the battery pack according to the determined operation mode.

Owner:SAMSUNG SDI CO LTD

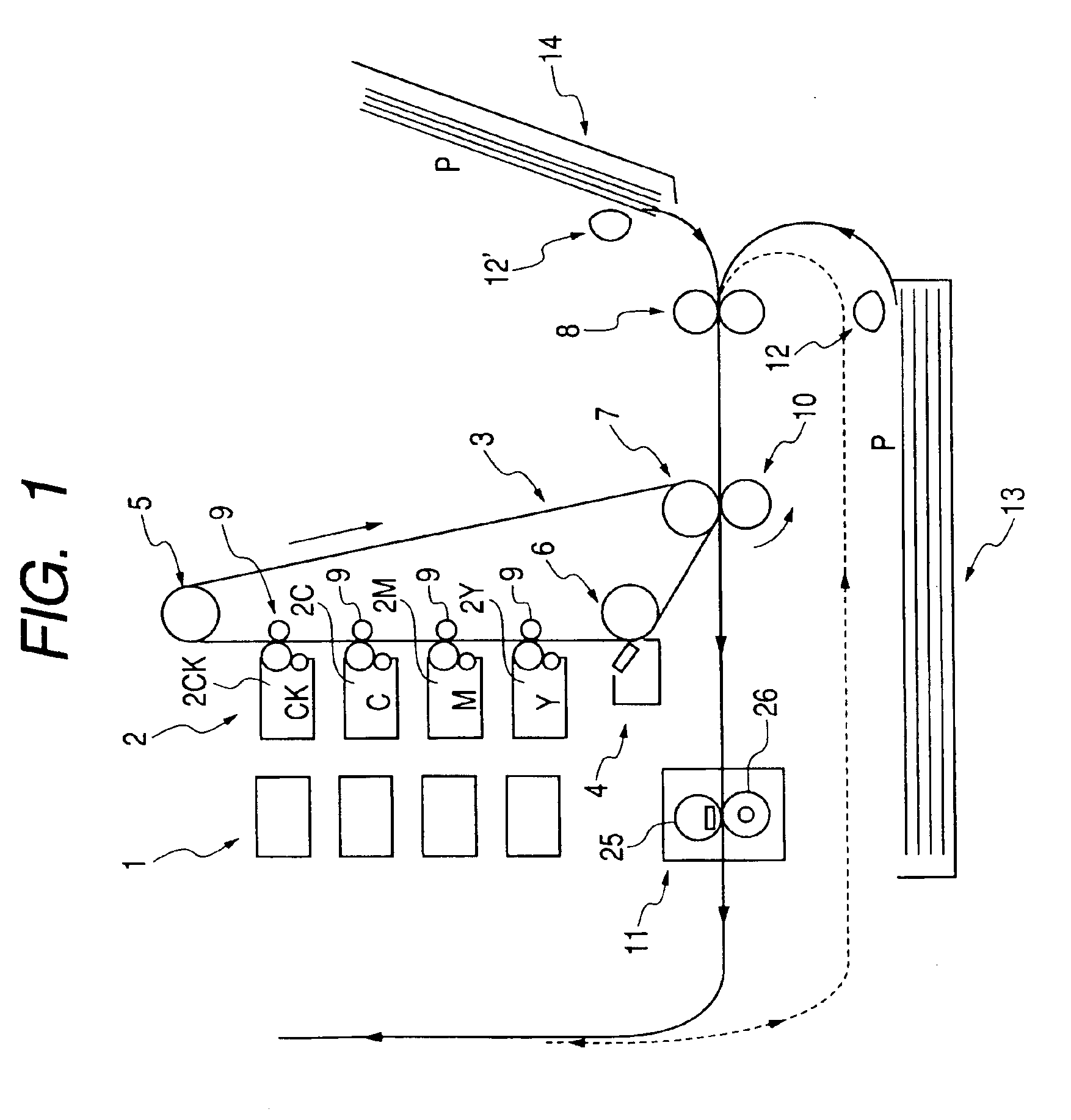

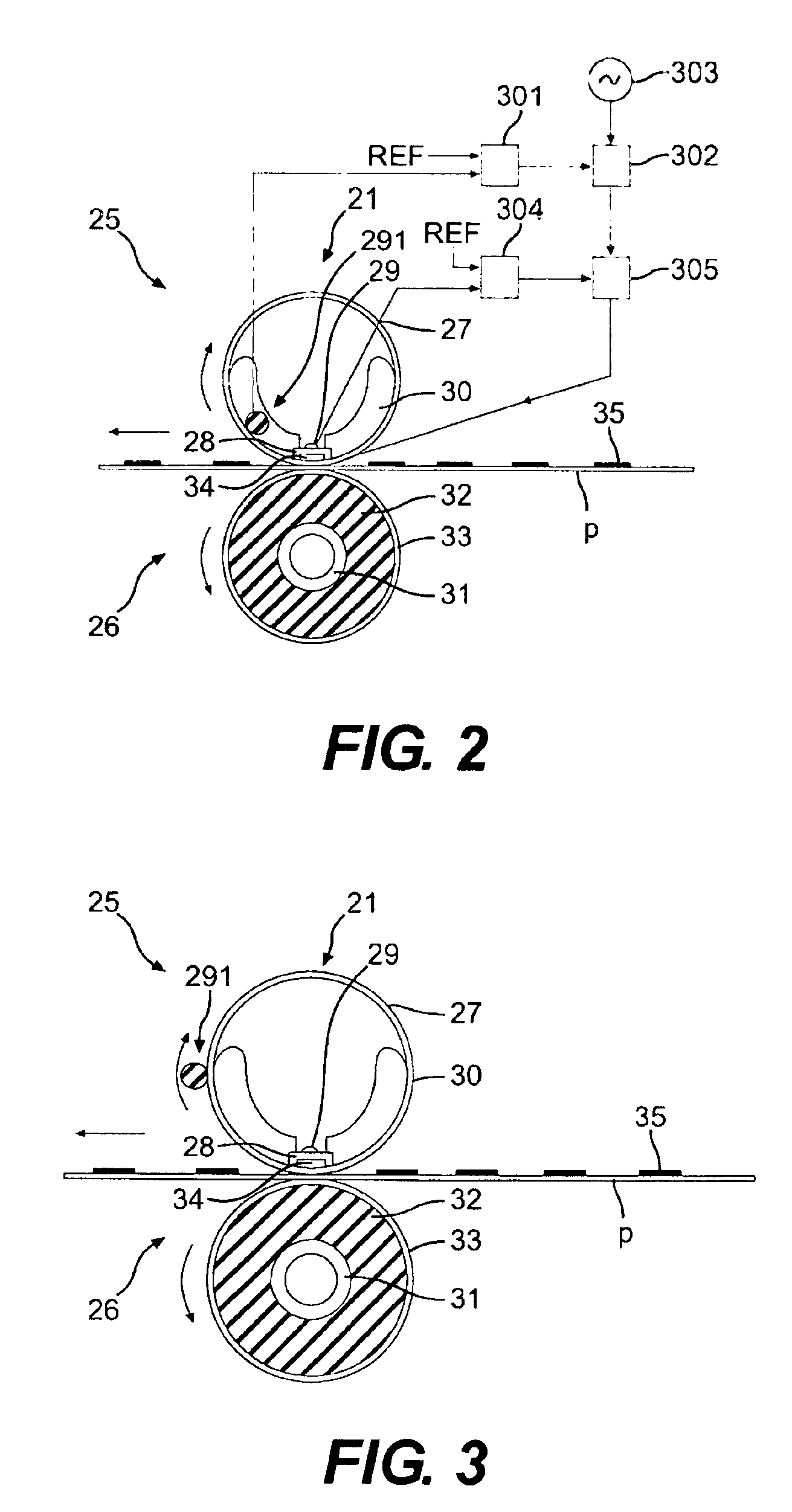

Fixing apparatus and image forming apparatus

ActiveUS6950616B2Secure safetyStably useOhmic-resistance heatingElectrographic process apparatusElectrical and Electronics engineeringTemperature control

Owner:CANON KK

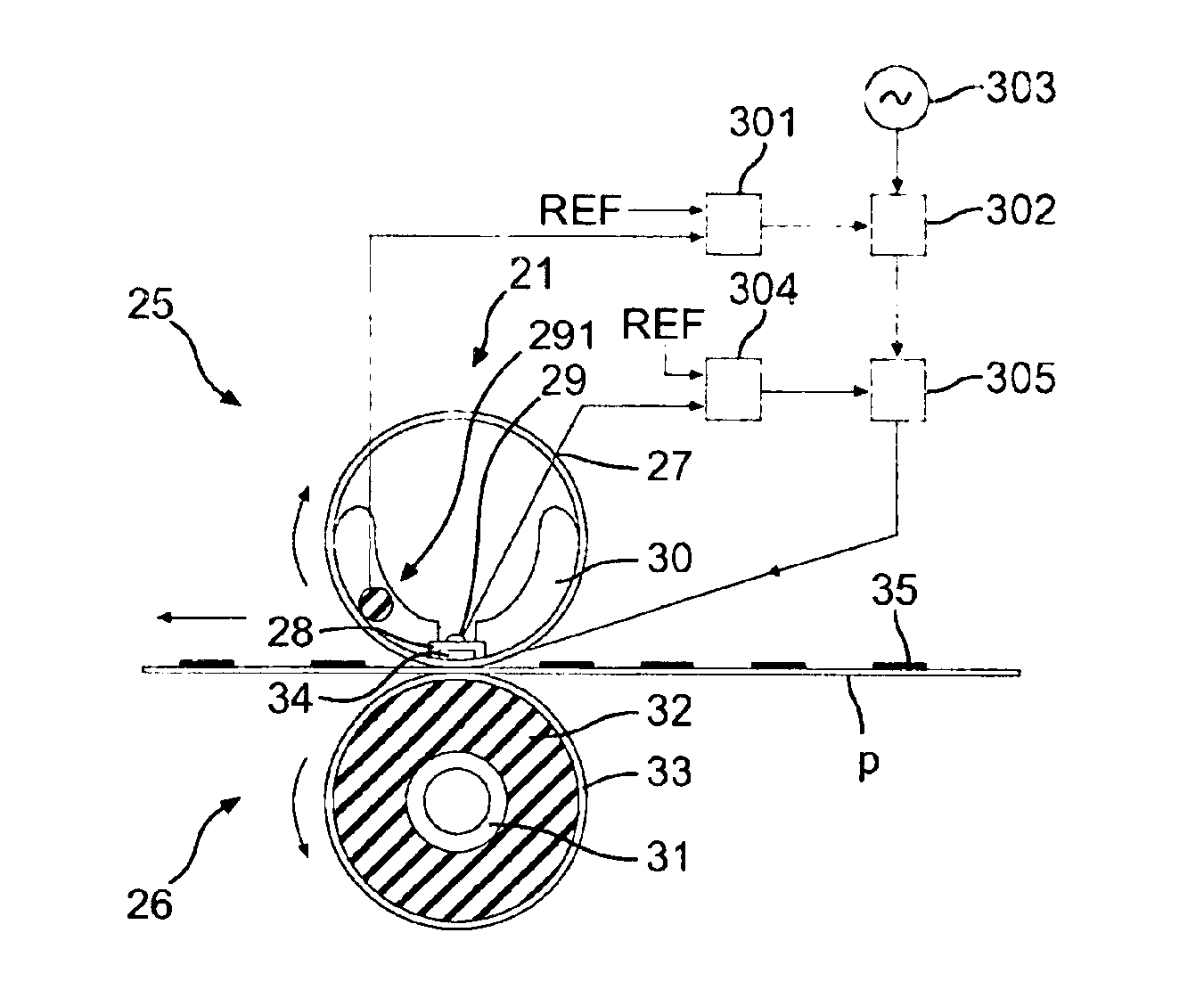

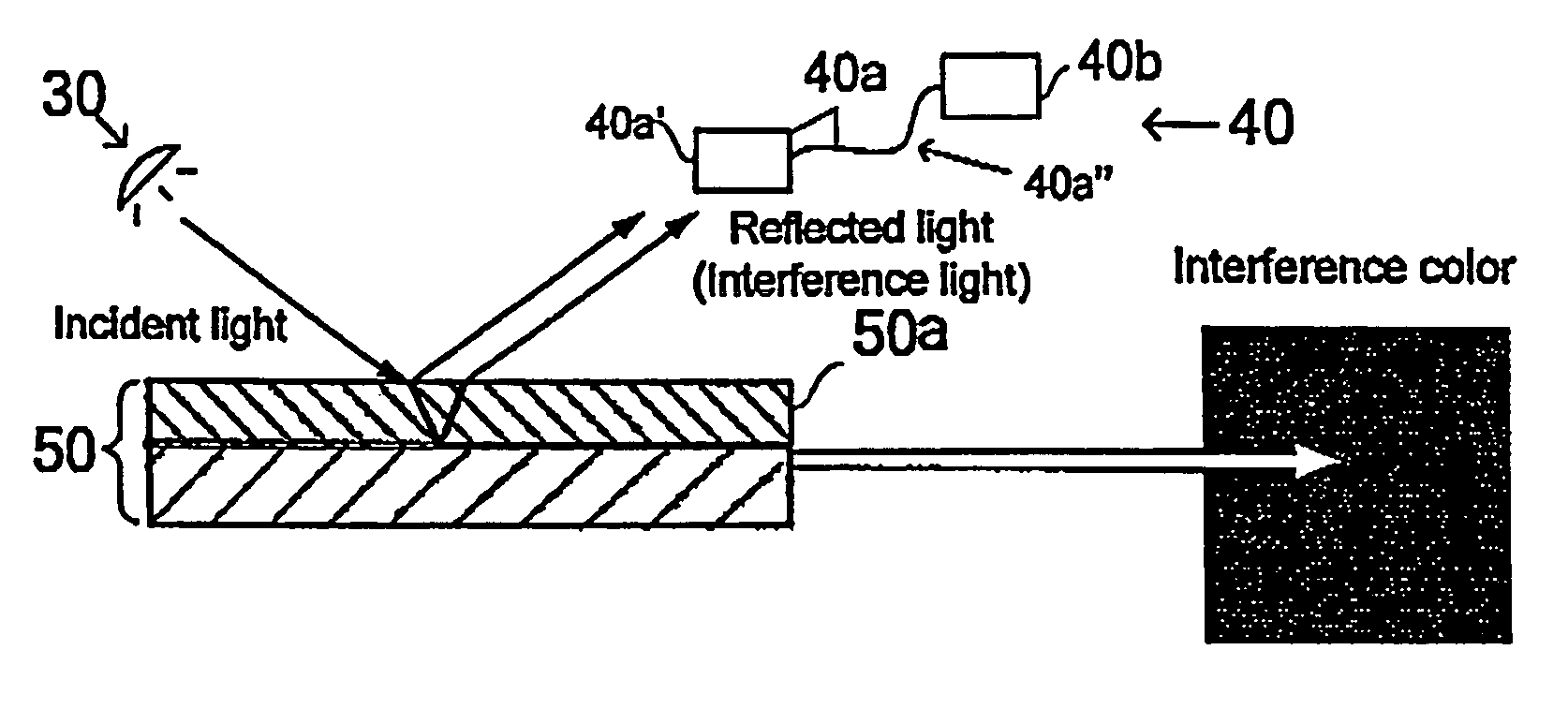

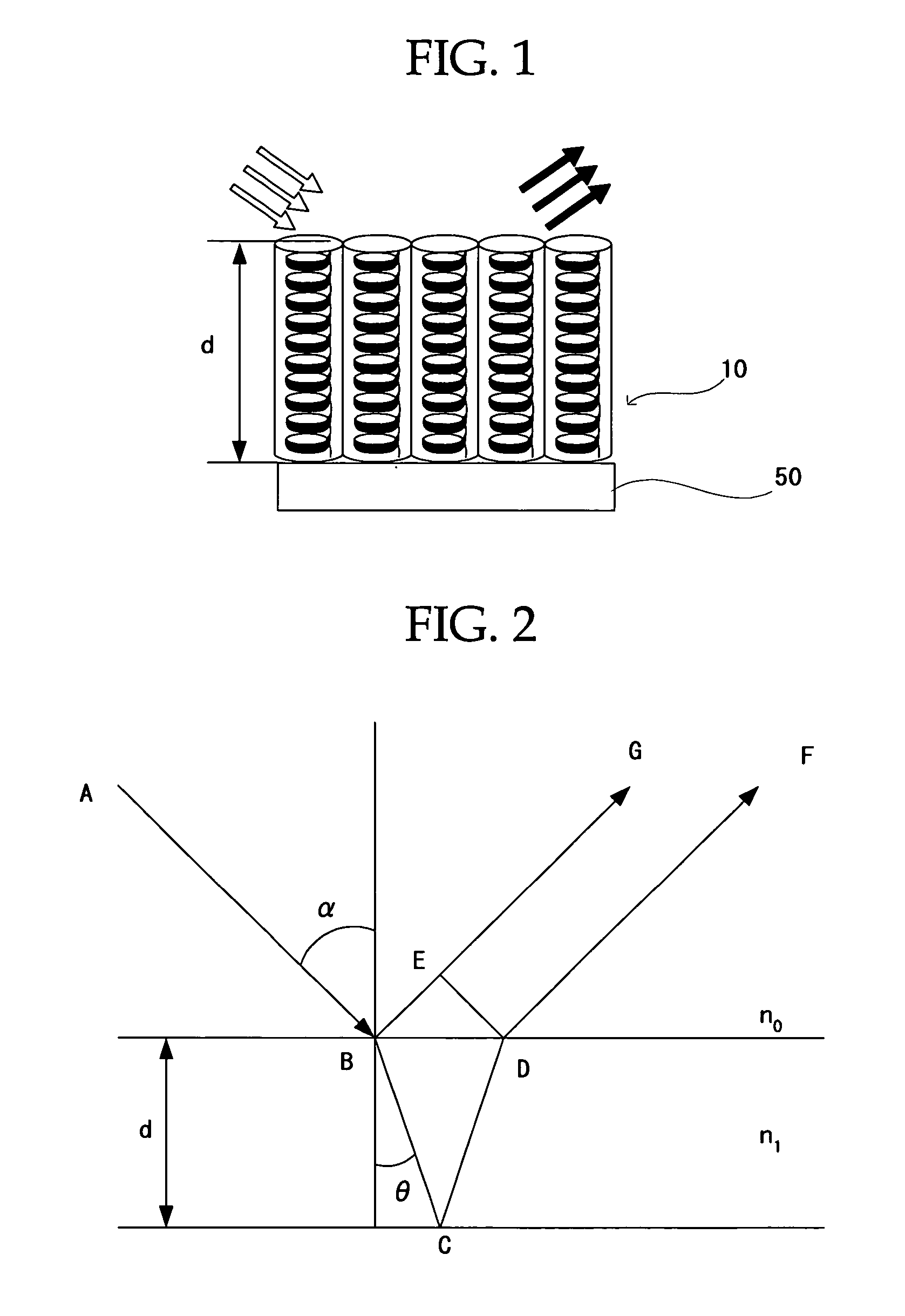

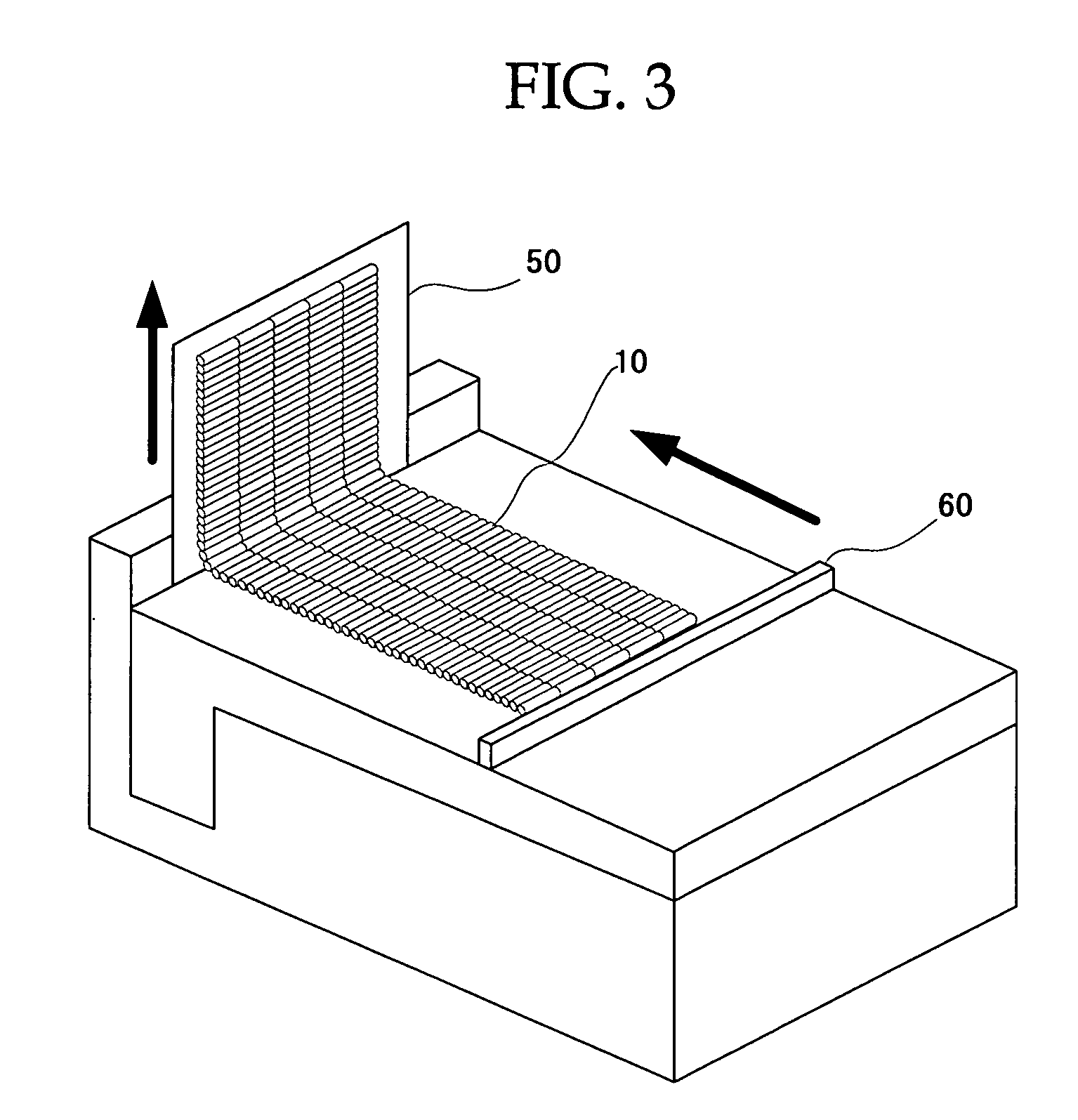

Optical switch and safety apparatus using the same

InactiveUS7076127B2Avoid hazardSecure safetyPhase-affecting property measurementsVoltage-current phase angleOptical switchToxic material

Provided are optical switches applicable to various safety apparatuses which can control an operation of a circuit by detecting a switching signal such as pathogens and toxic substances, and safety apparatuses using the optical switches. The optical switch comprises an optical irradiation unit to irradiate light; an optical interference unit which can interact with a switching signal, interferes with light irradiated from the optical irradiation unit and radiates it as interference light, and can vary the wavelength of the interference light after interaction with the switching signal; and a switching unit which is provided in the path of the interference light, detects a wavelength change of the interference light, and conducts one of activating and deactivating a circuit. The safety appatatus comprises the optical switch and a hazard evasive apparatus activating unit which activates a hazard evasive apparatus using the optical switch.

Owner:FUJIFILM CORP +1

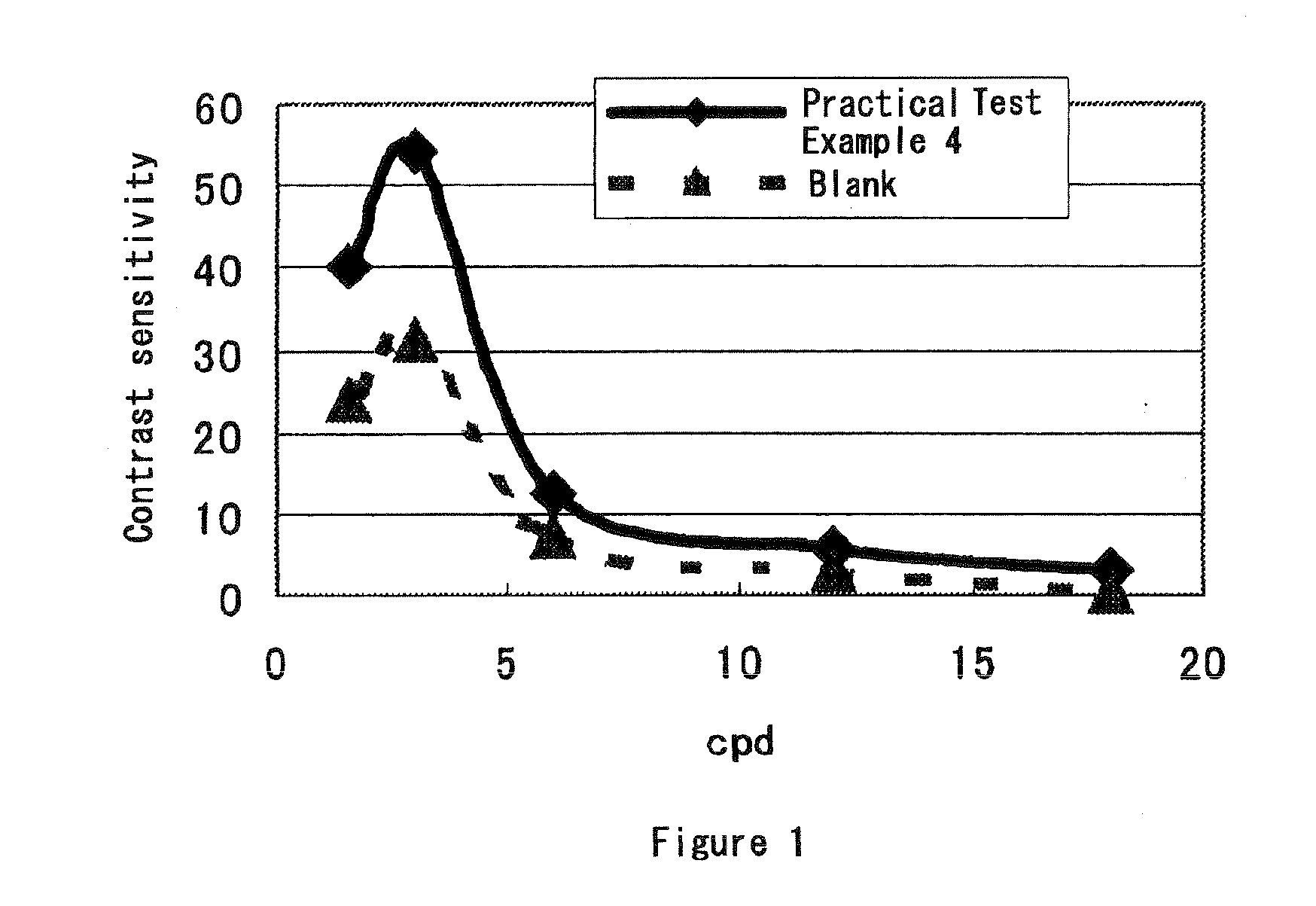

Ophthalmic composition

InactiveUS20130244978A1Relieve pressureImproving eye drynessBiocideHydroxy compound active ingredientsCellulosePolyethylene glycol

Owner:ROHTO PHARM CO LTD

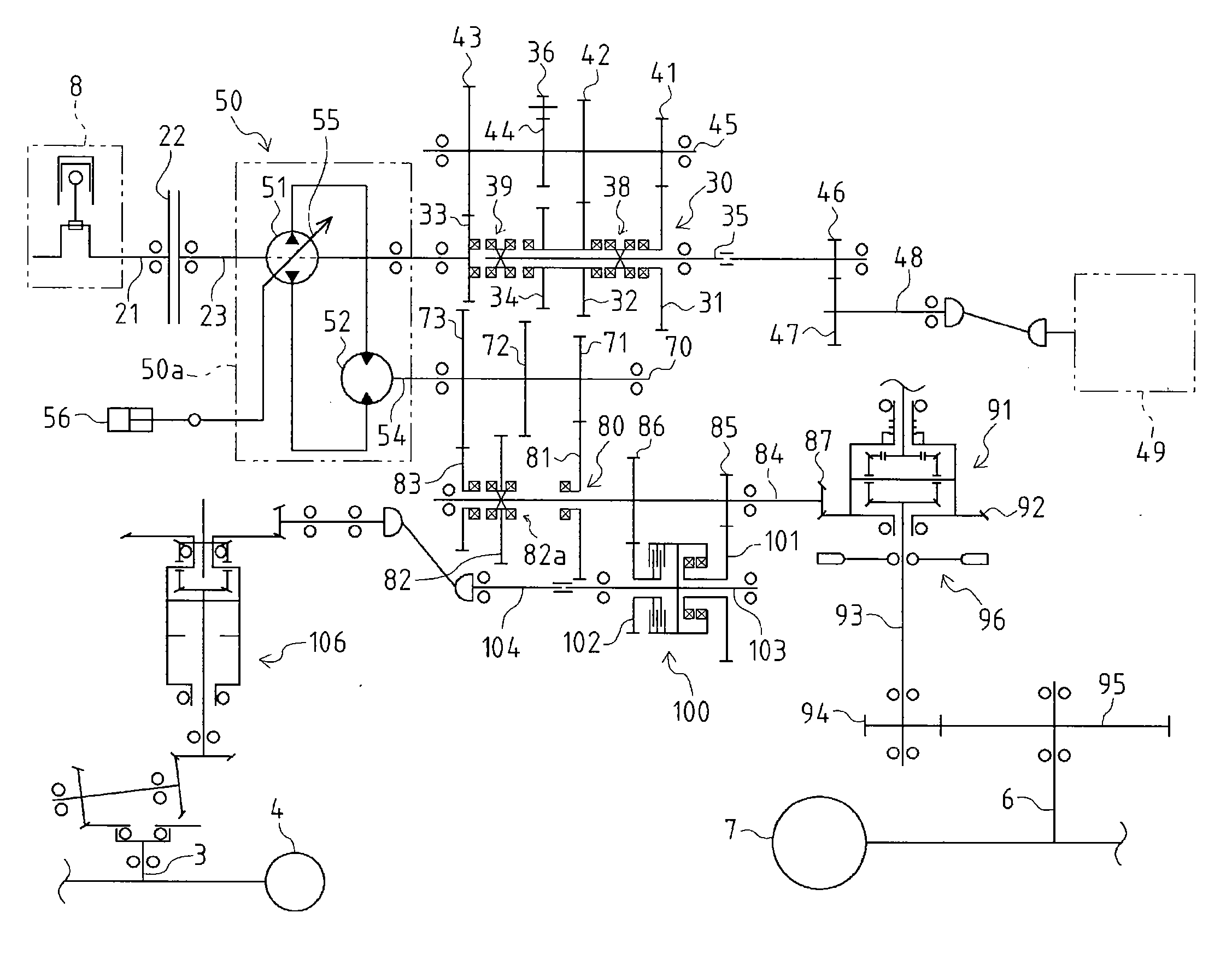

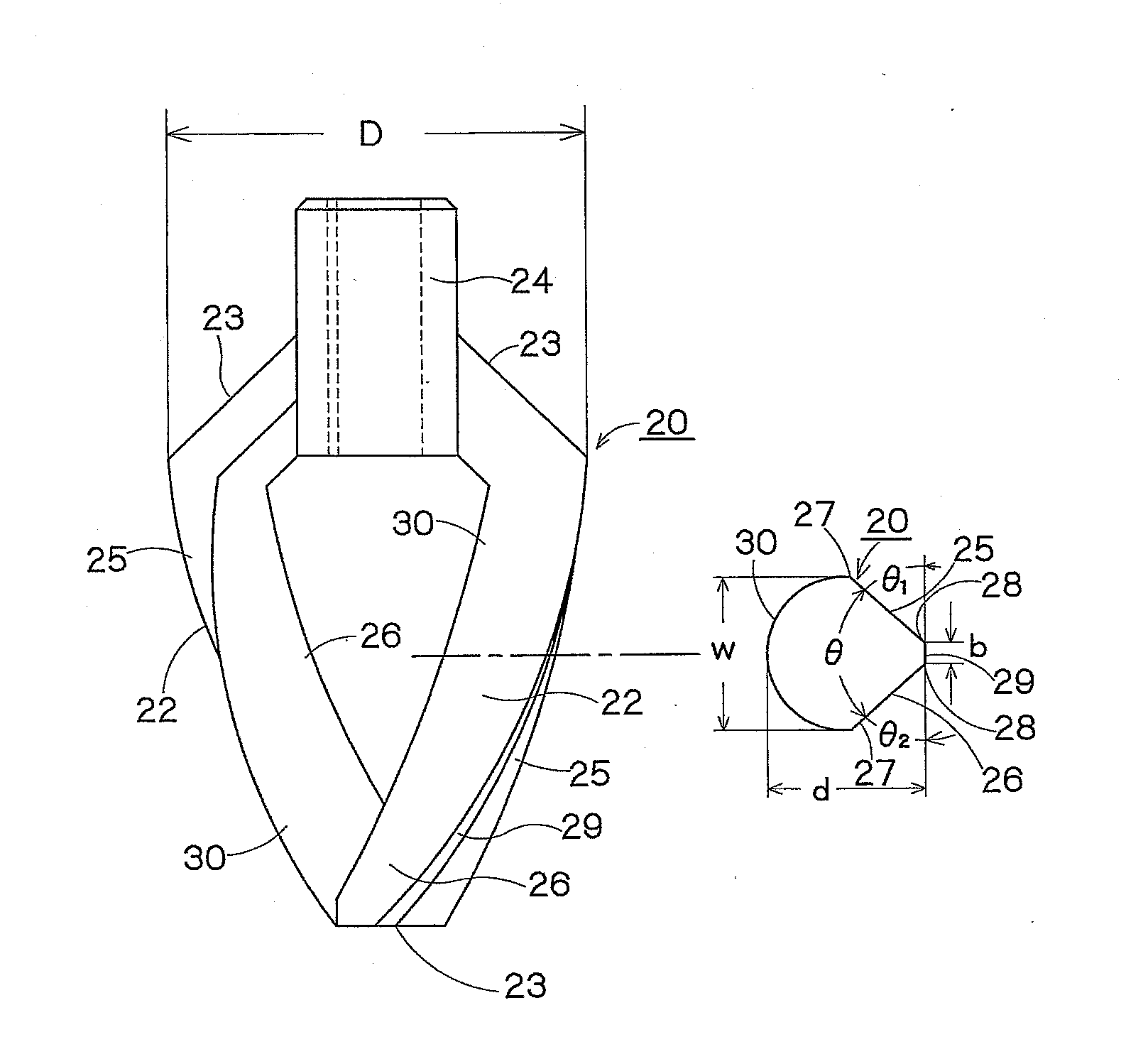

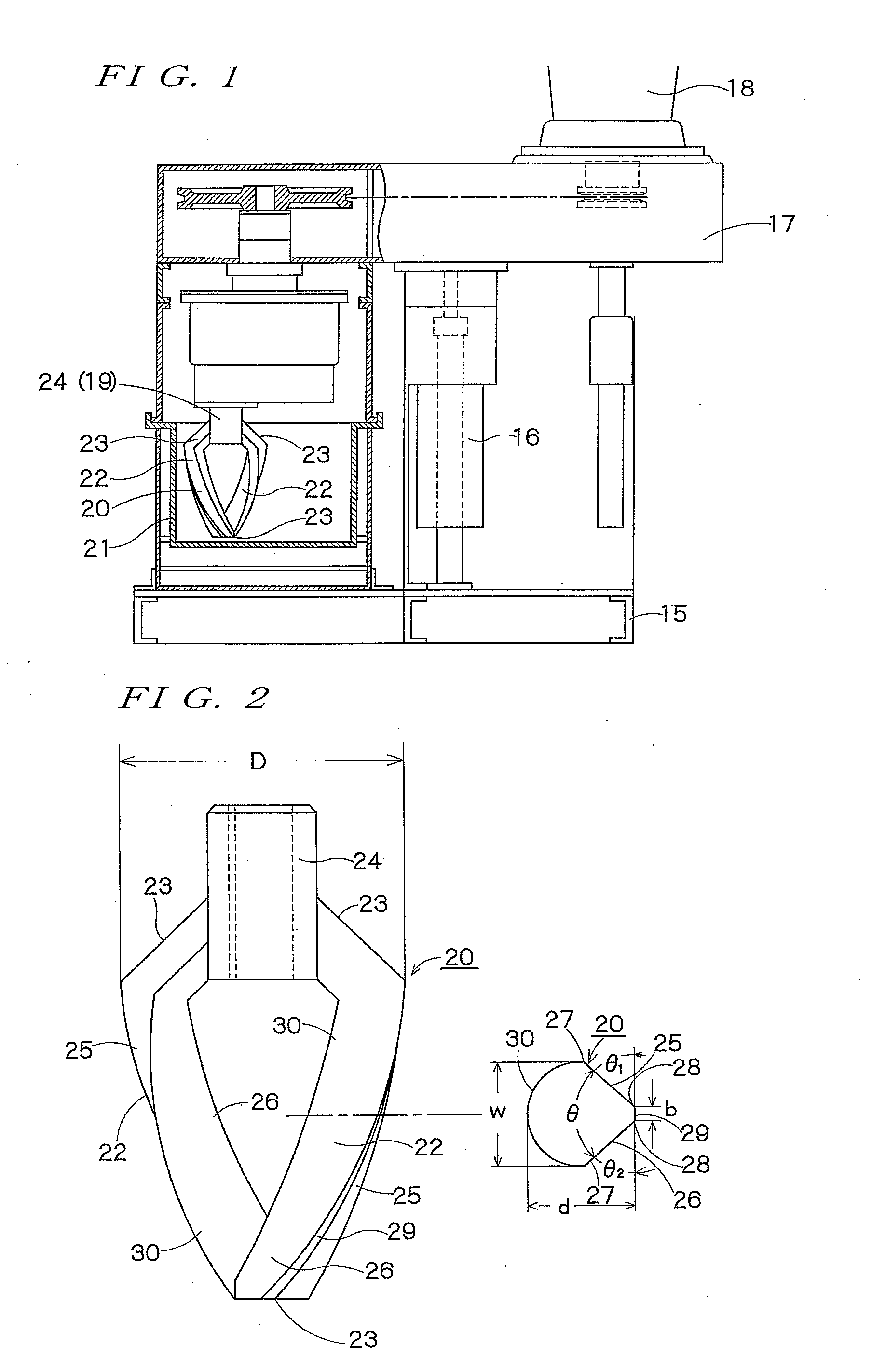

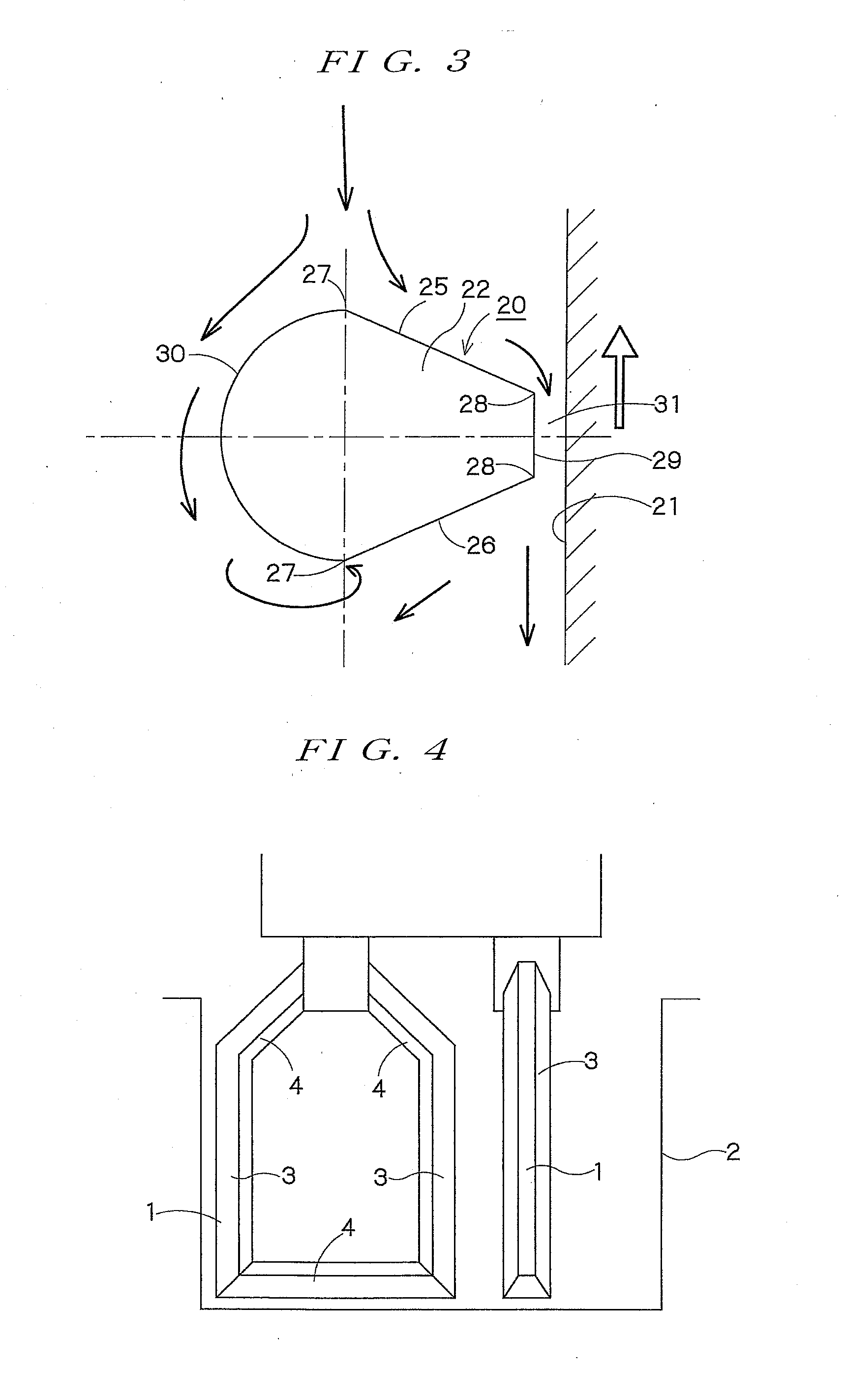

Planetary mixer

ActiveUS20150231579A1Improve flowSecure safetyRotary stirring mixersMixing methodsCeramicMechanical engineering

A planetary mixer which is used for production steps of various products in chemistry, medical treatment, electronics, ceramics, medicines, foods, feed and the like, and in which flame-shaped stirring blades are allowed to perform planetary motion in a tank, by which solid / liquid type treatment materials are subjected to stirring, blending, mixing / kneading, kneading or the like and it is intended to prevent adhesion of materials to a vertical side portion of the flame-shaped stirring blades.The vertical side portion 22 of the frame-shaped stirring blades 20 is constituted to have a cross-sectional configuration which has two slope faces 25, 26 slanting toward an inner wall of the tank, an edge face 29 connecting outward front ends 28 of the slope faces, and an arcuate inner face 30 connecting inward front ends 27 of the slope faces. The inward front ends are located far apart from the inner wall of the tank and the outward front ends are located near the inner wall of the tank, in which the distance between the inward front ends is broad and the distance between the outward front ends is narrow. Since the inner face 30 of the vertical side portion is formed into an arcuate configuration, the materials can flow without backwater, and adhesion and fixing thereof can be prevented.

Owner:INOUE SEISAKUSHO MFG

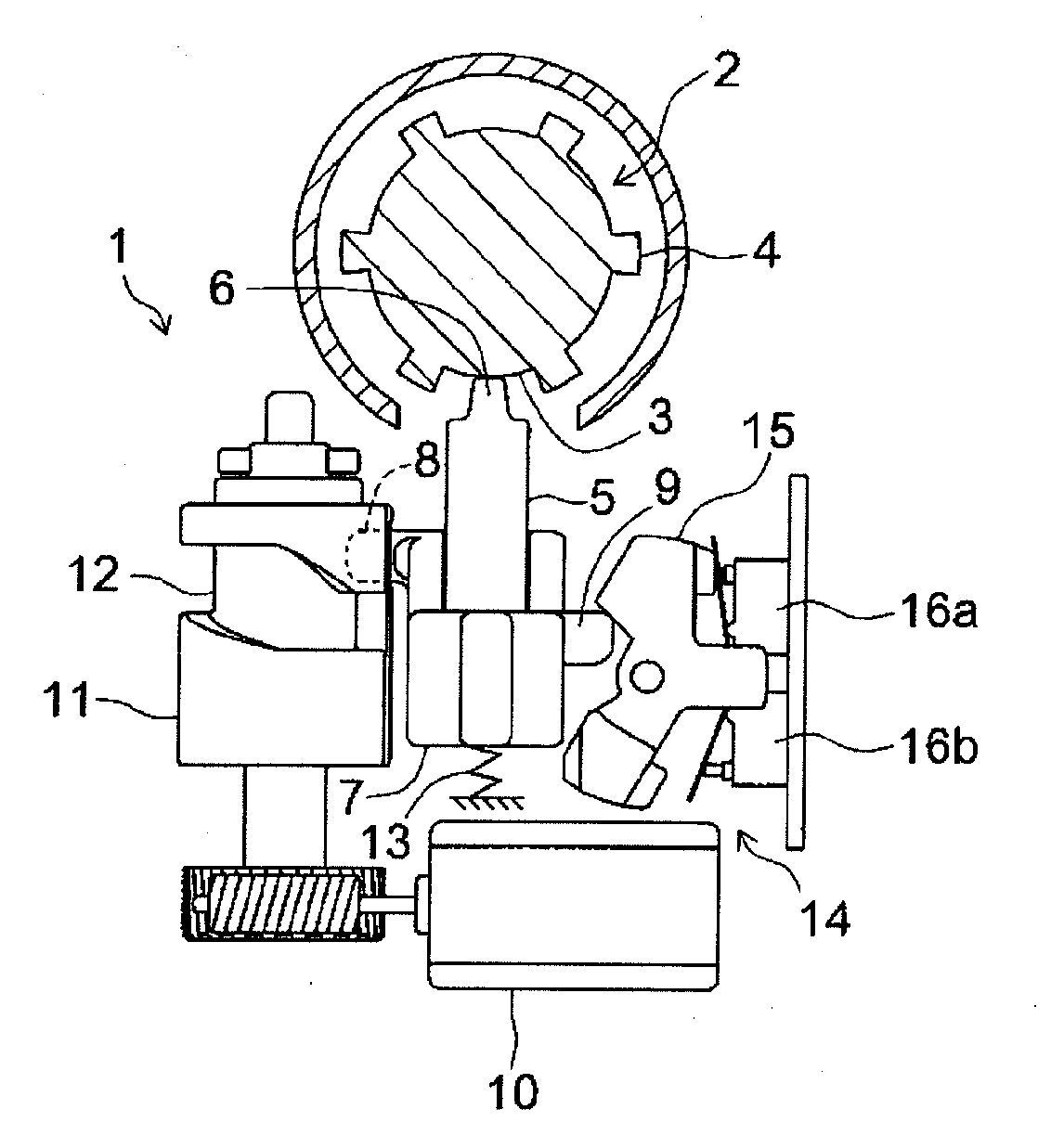

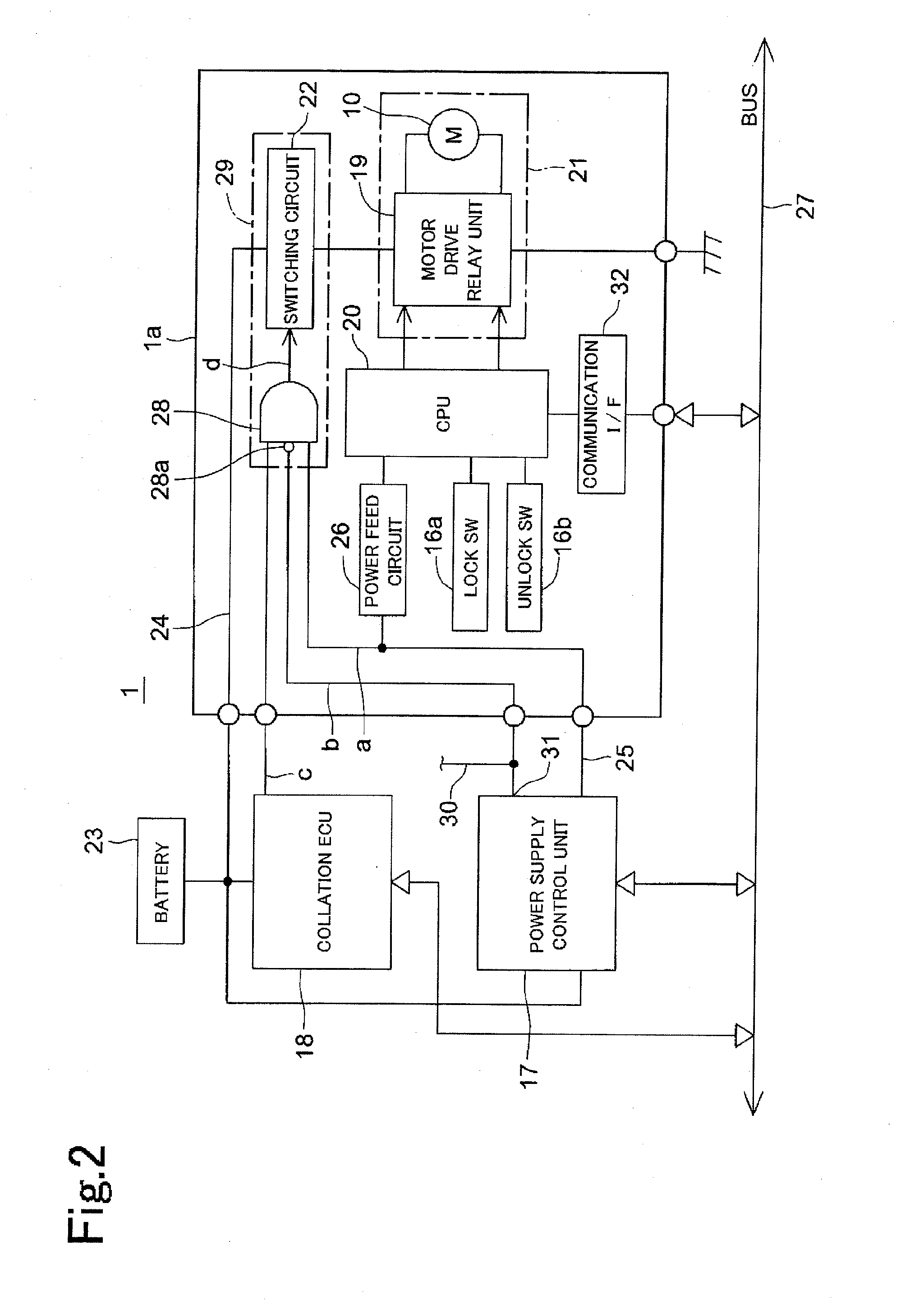

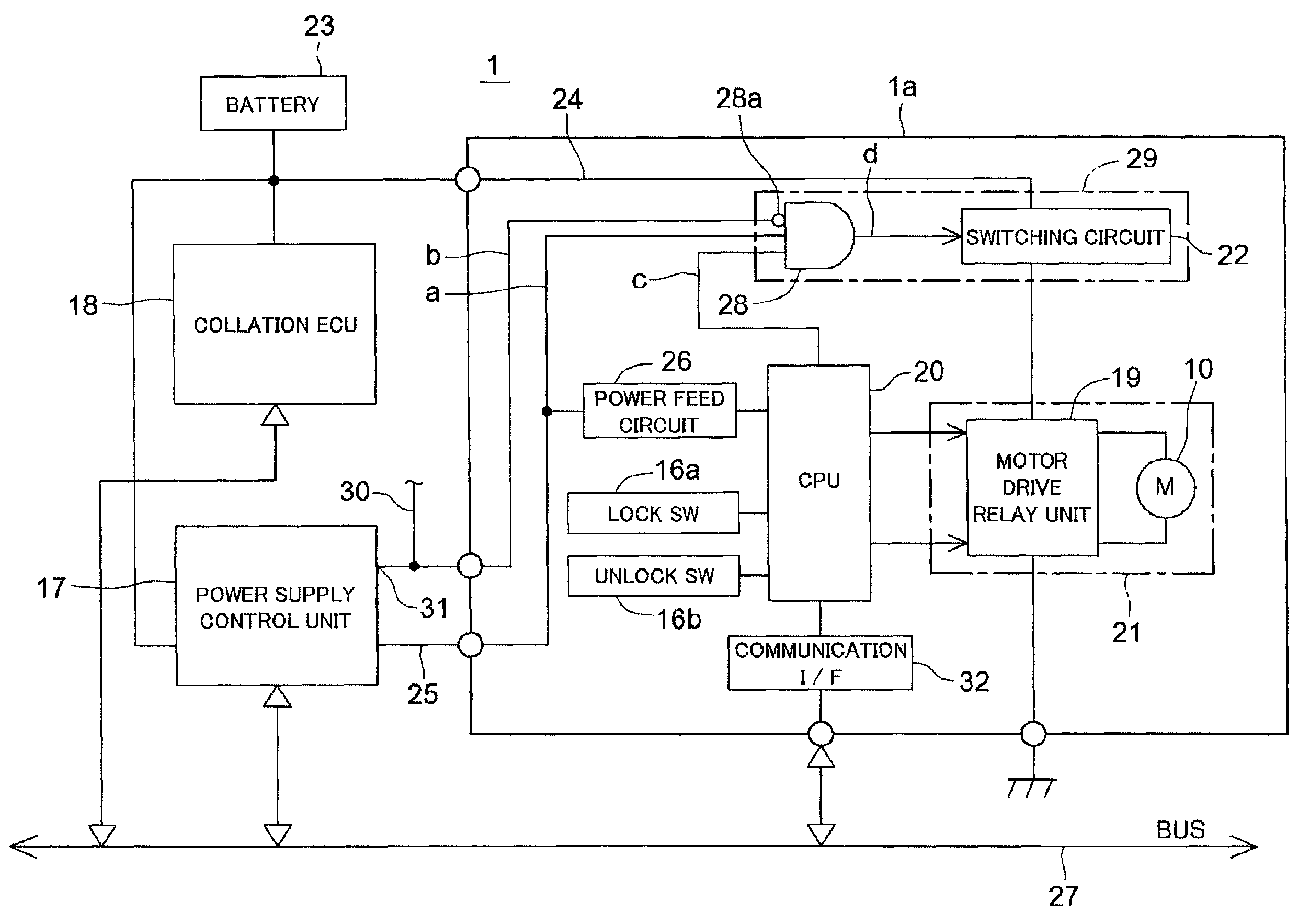

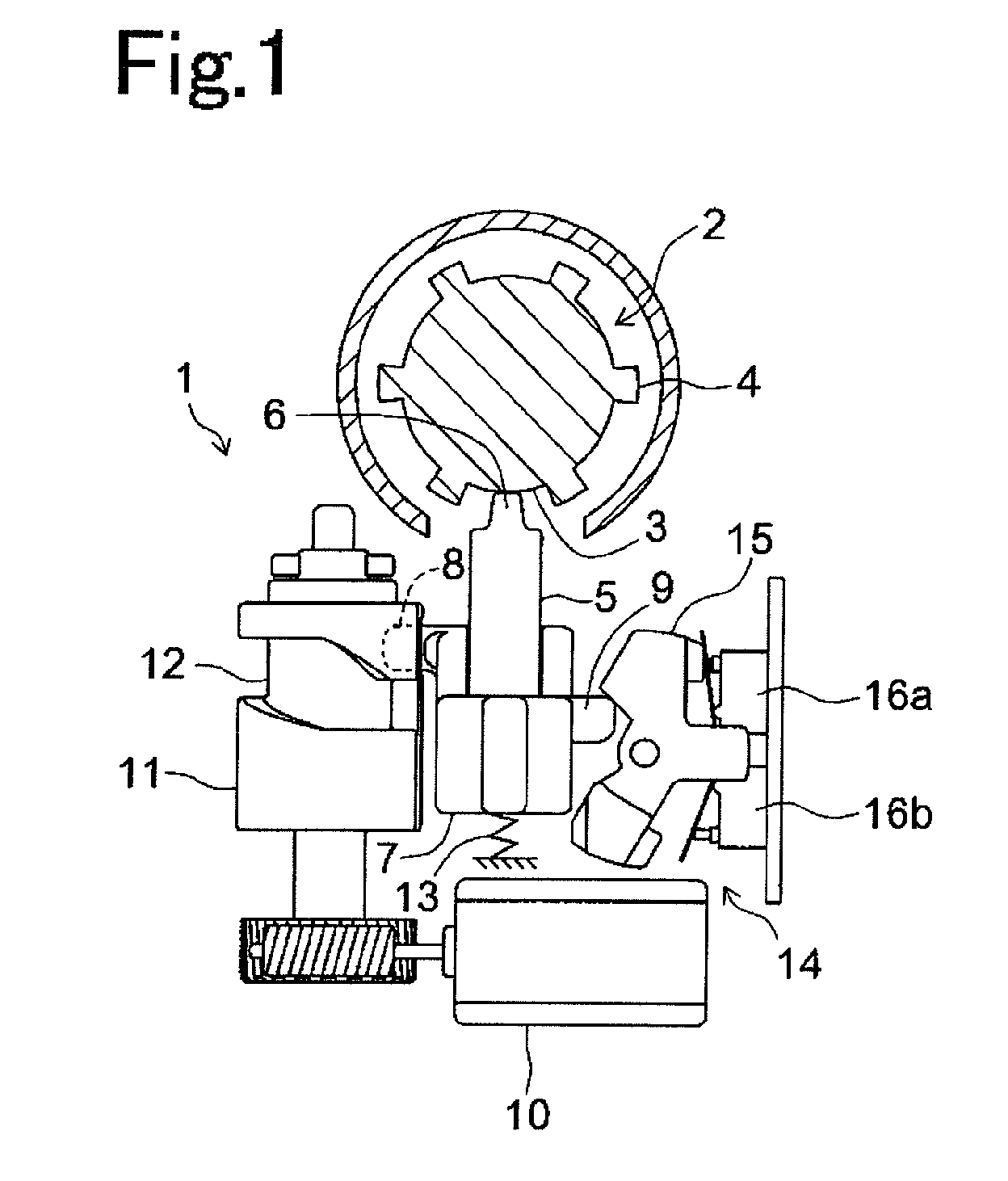

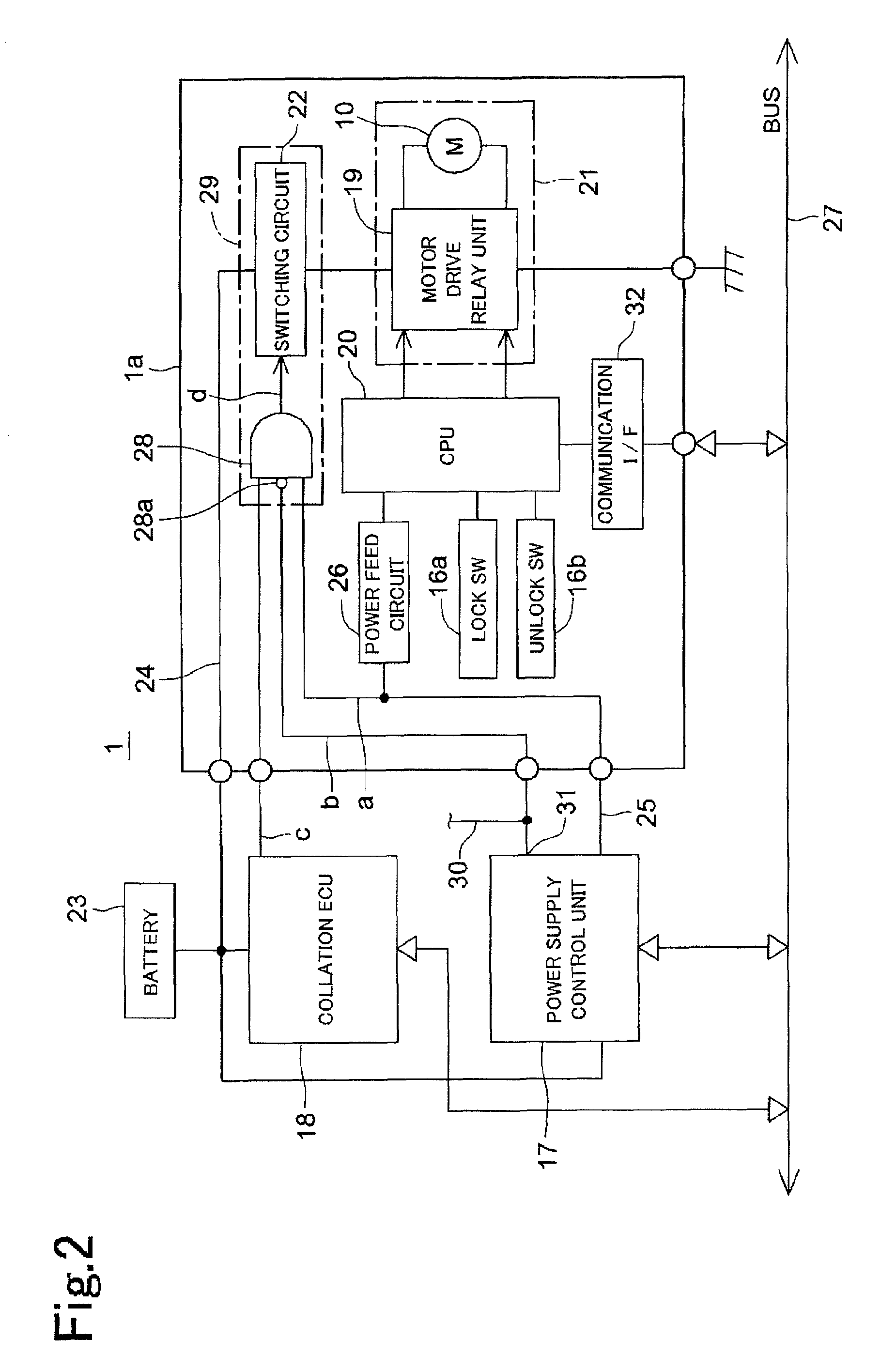

Motor-driven steering lock apparatus

InactiveUS20100018265A1Secure reliabilitySecure safetyAnti-theft devicesElectric switchesMotor driveElectrical battery

The invention provides a motor-driven steering lock apparatus which can improve a reliability of locking and unlocking operations, with a simple circuit structure. A power supply line from a battery and a driving means are connected by a switching means only at a time when a feed signal from a host first control means to a drive control means (CPU), a power supply-enabling signal from the host first control means and a power supply-enabling signal from a host second control means are input to the switching means.

Owner:U SHIN LTD

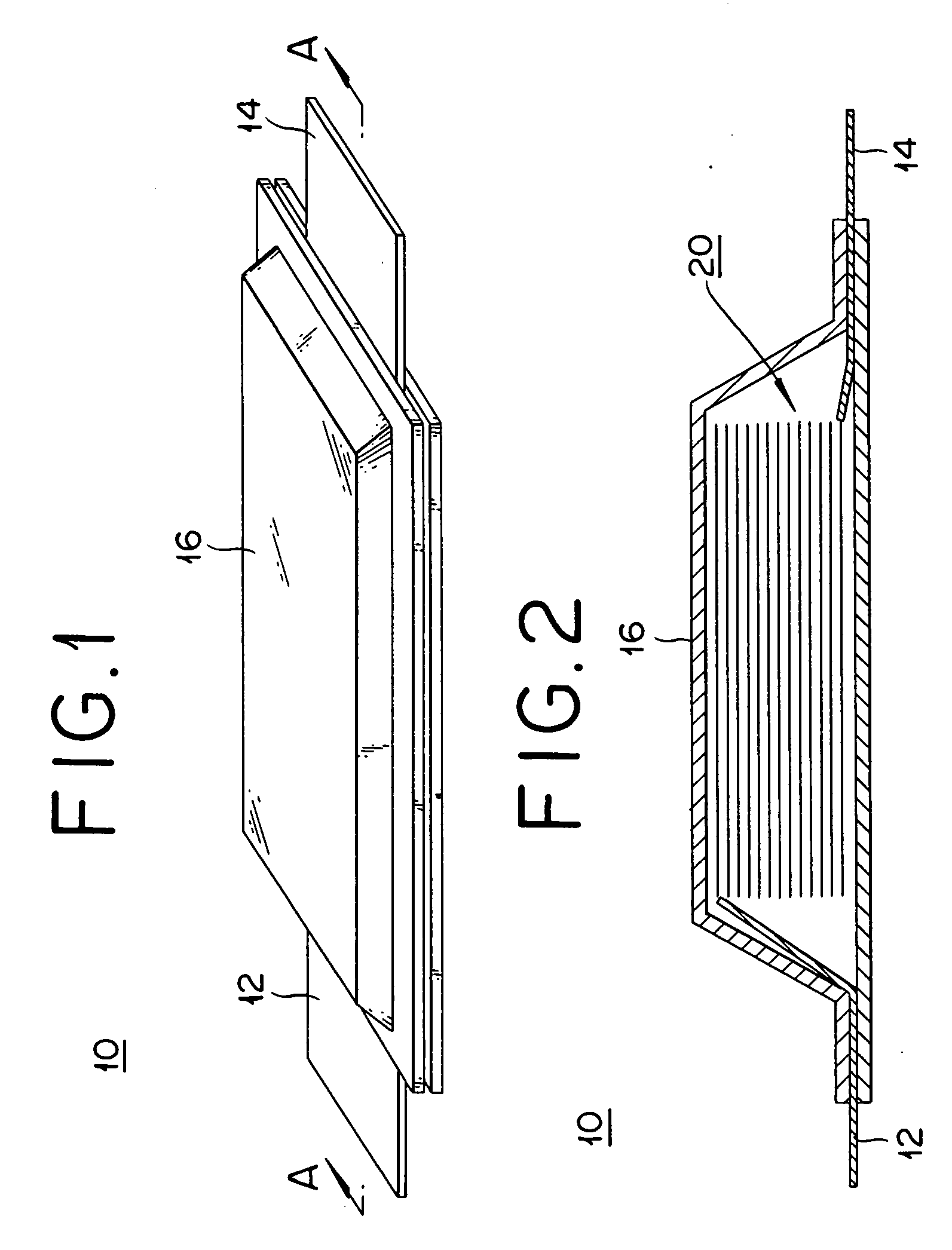

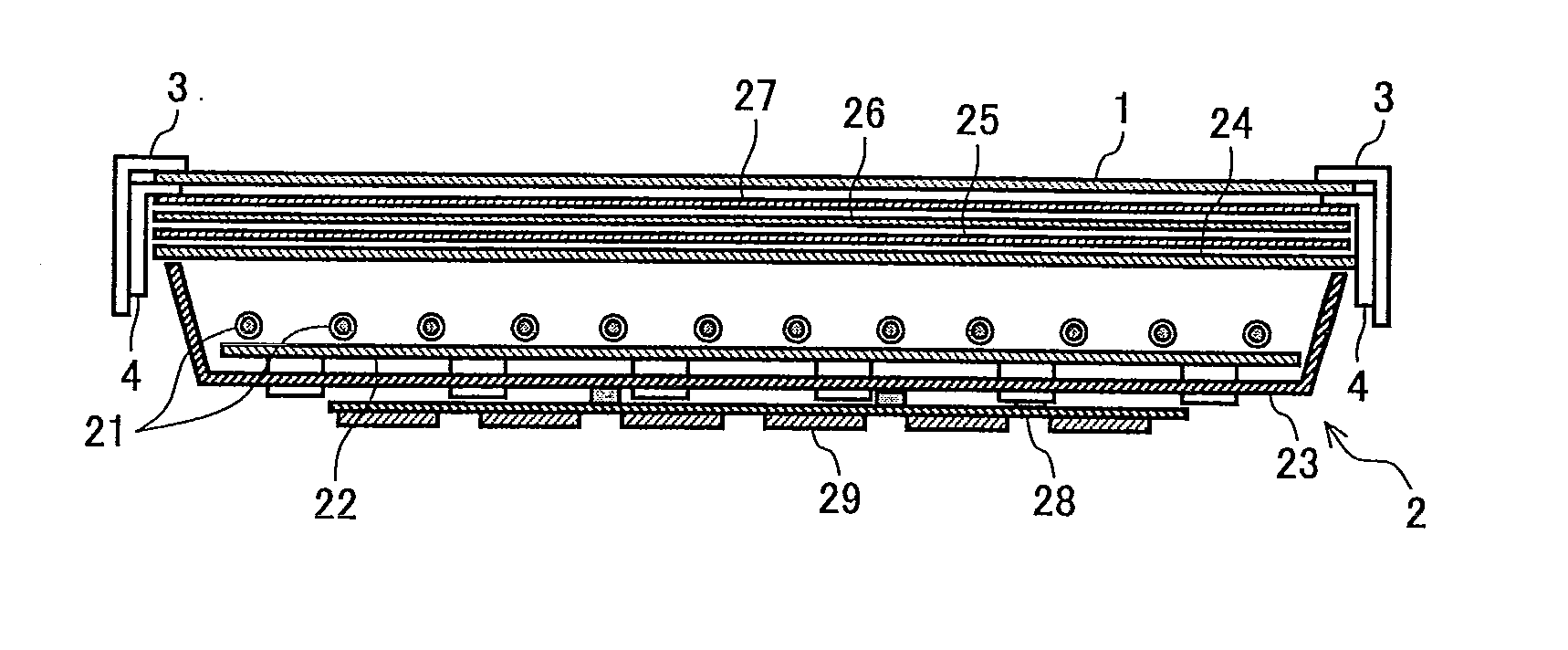

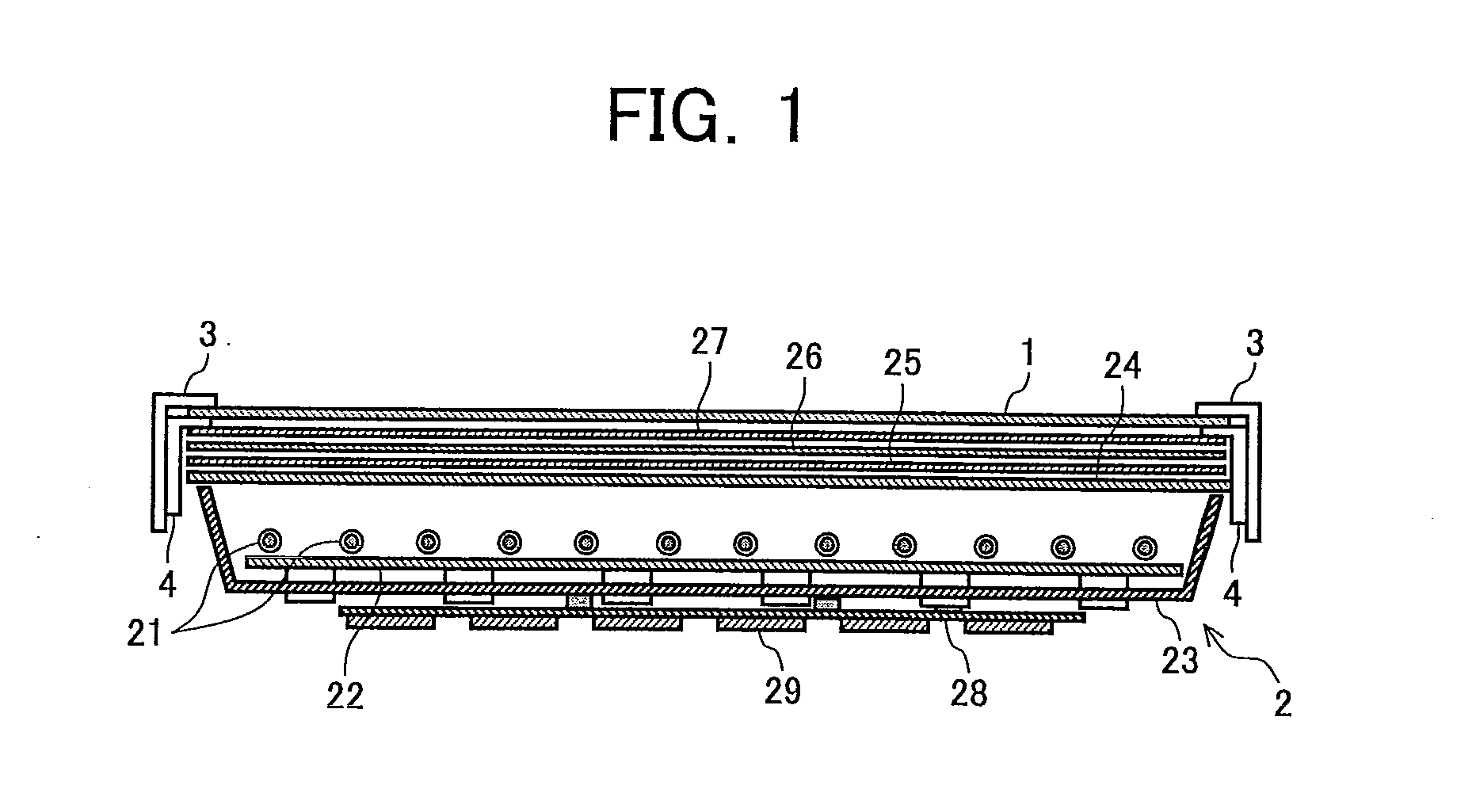

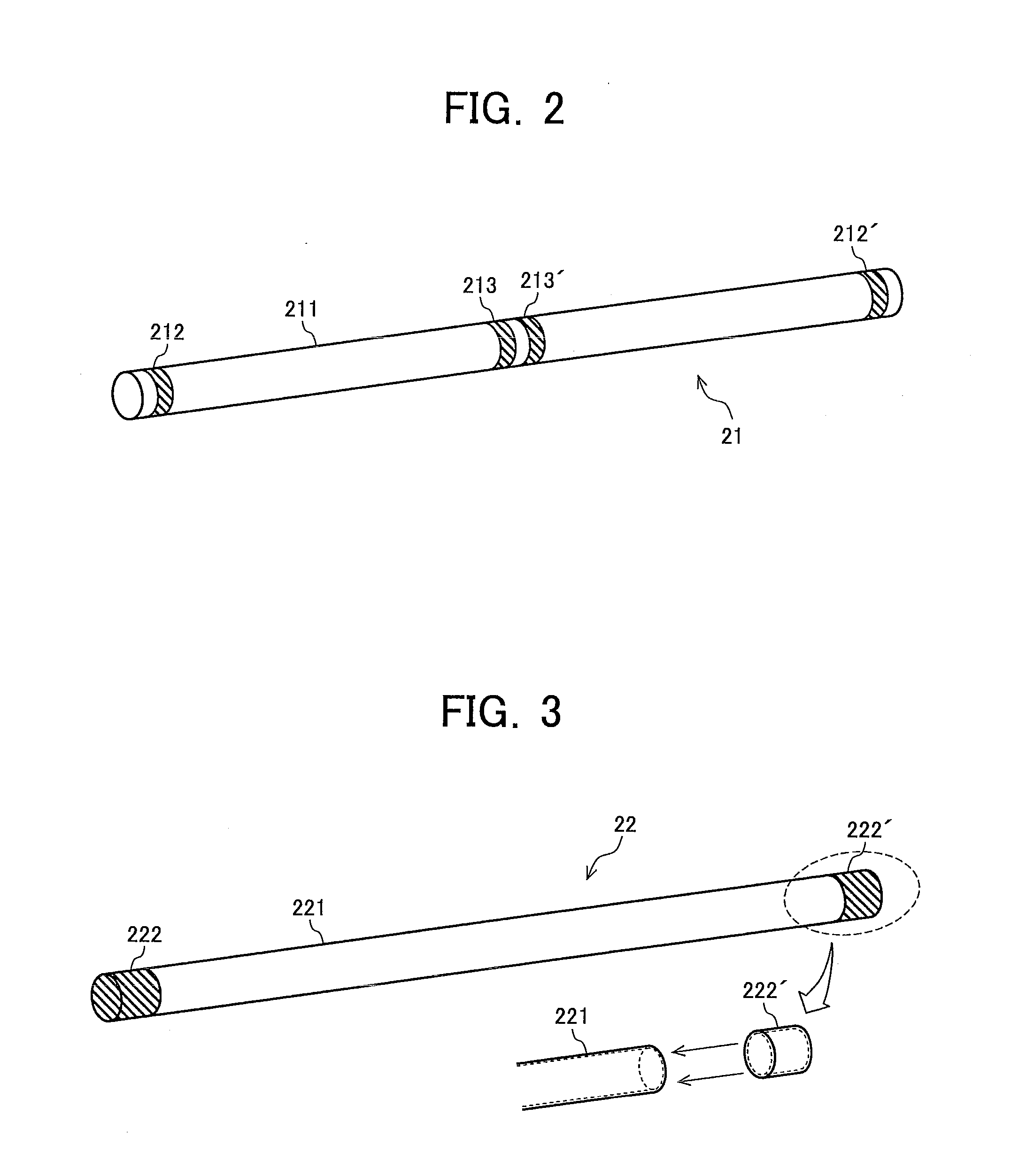

Backlight device and liquid crystal displaying device

InactiveUS20100053492A1Uniform distribution of luminance and chromaticitySecure safetyCoupling device connectionsIlluminated signsLiquid-crystal displayLiquid crystal

A frame is narrowed by a technically reasonable design, without technical limitation for frame narrowing which tends to be considered troublesome when bent-tube type fluorescent tubes having U-shaped bent portions are to be alternately arranged to face each other nor without the trouble of storing the bent-type fluorescent tubes in a chassis while being manufactured. A backlight device (2) is provided with a backlight chassis (23) wherein a plurality of fluorescent tubes (21) having electrodes are arranged and stored, and an inverter circuit board is arranged on the rear surface of the backlight chassis (23). Furthermore, the backlight device (2) is provided with a storing section (30), which is attached to the backlight chassis (23) by storing a conductive holding section for holding the electrodes. With the storing section (30) attached to the backlight chassis (23), the electrodes of the fluorescent tubes (21) are electrically connected to a light source lighting circuit board arranged on the rear surface of the backlight chassis (23).

Owner:SHARP KK

Alarm apparatus

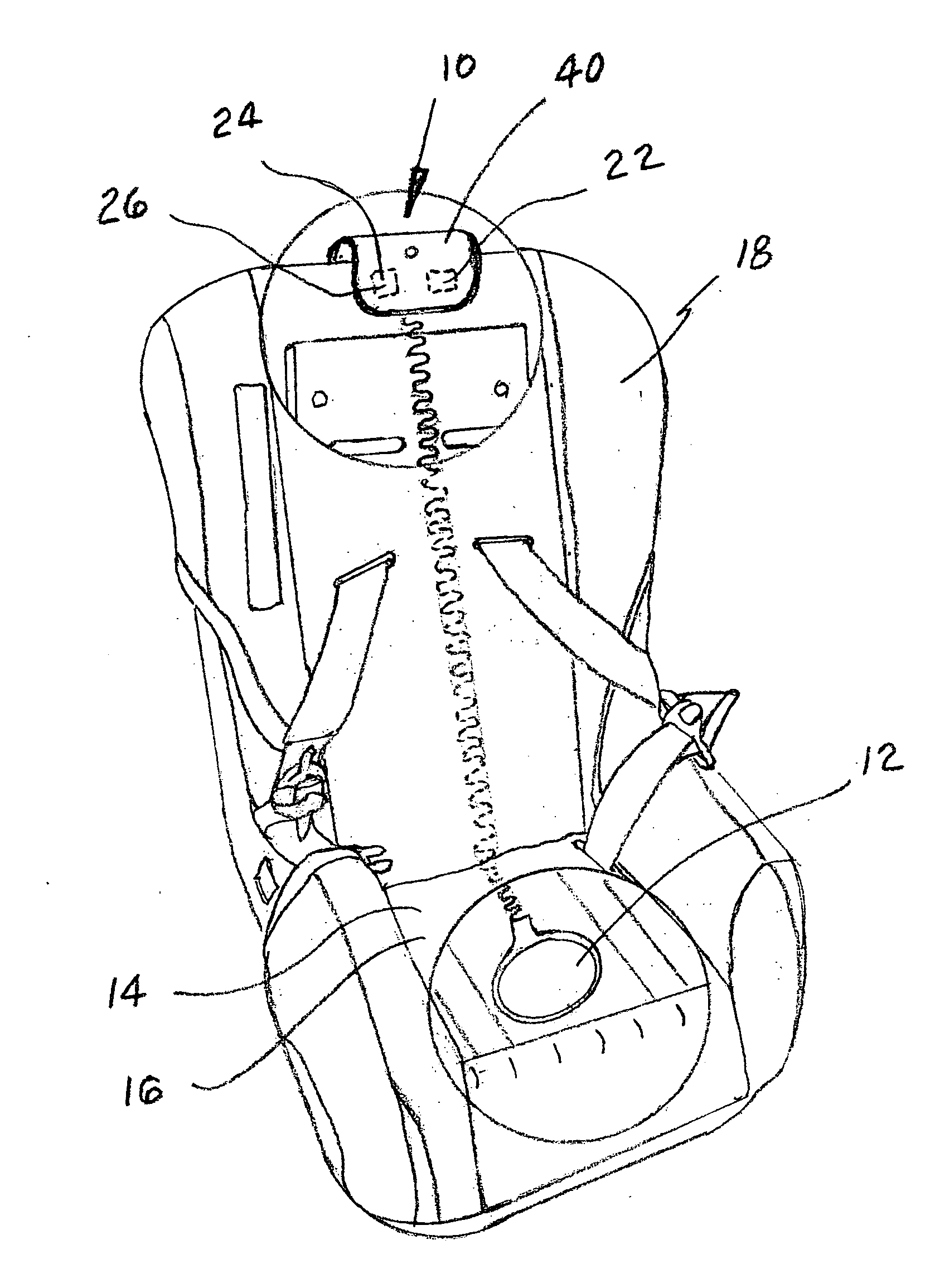

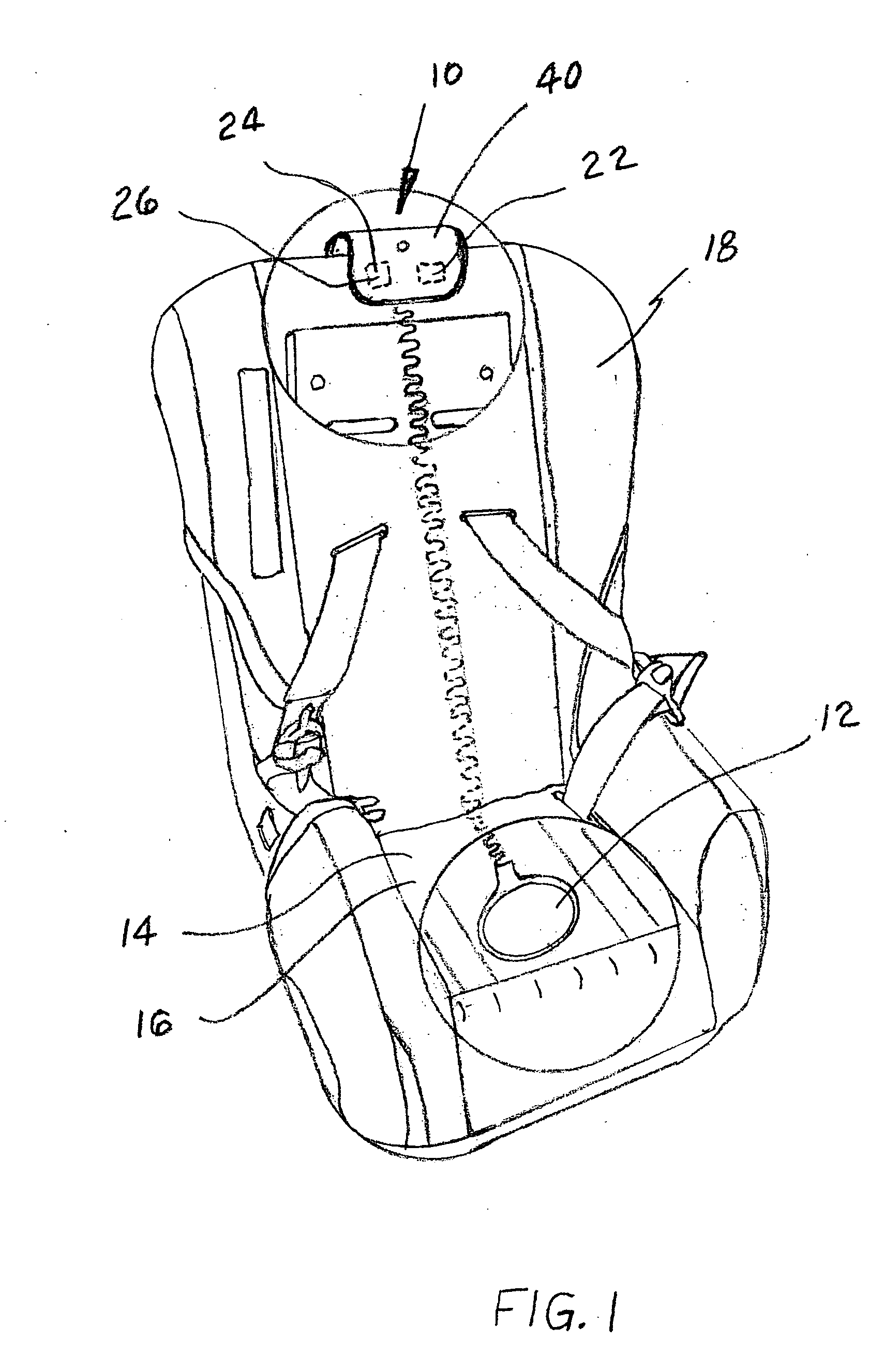

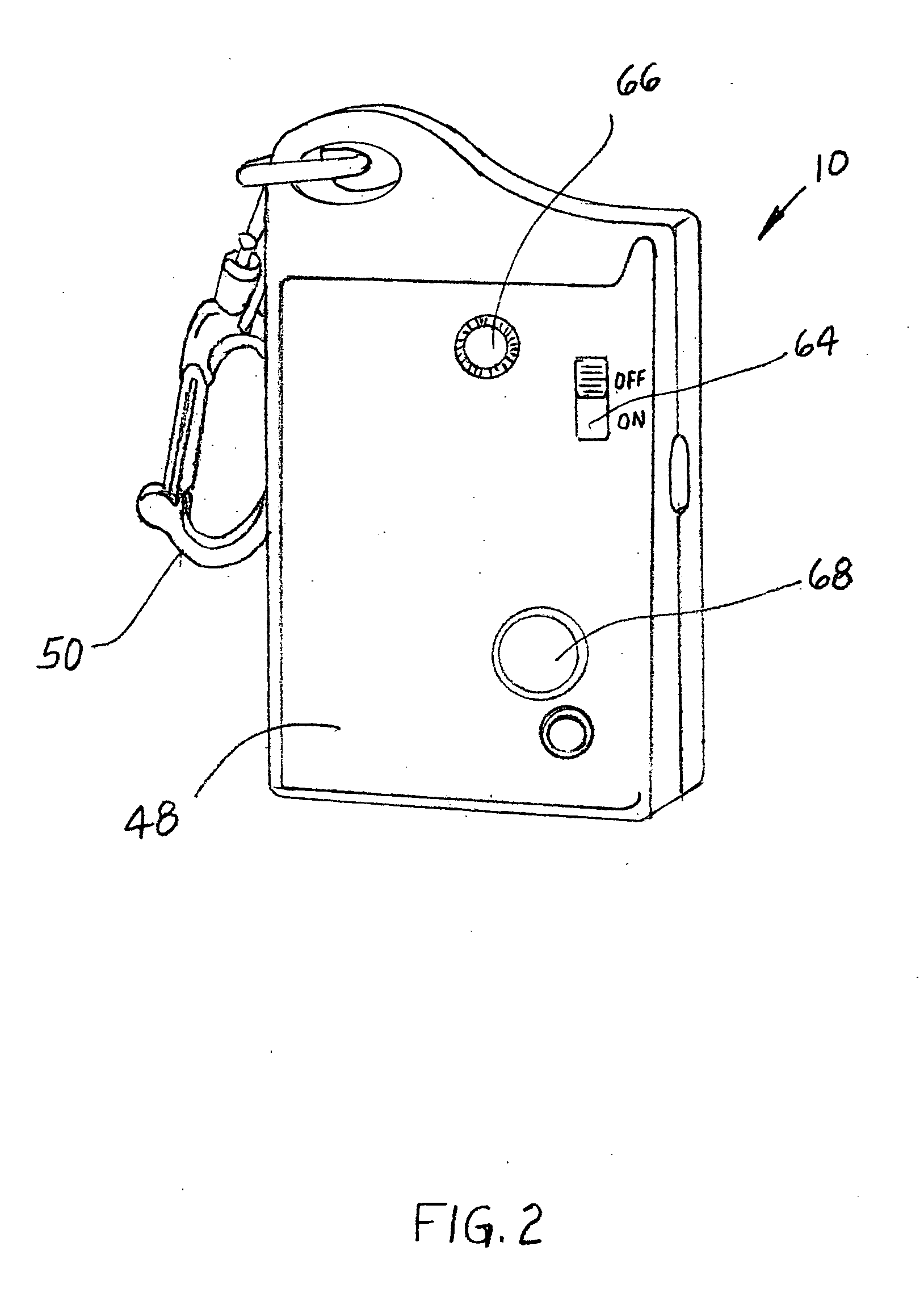

InactiveUS20080136633A1Secure safetySecuring the safety of childrenBurglar alarm by hand-portable articles removalChild seatsEngineeringElectrical and Electronics engineering

An alarm apparatus including a sensor pad for detecting a predetermined amount of pressure, a first transmitting means operably connected to such sensor pad for transmitting a first signal indicative of such sensor pad detecting an amount of pressure. A first power source supplies power to such sensor pad and first transmitting means. A receiving means receives such first signal when such receiving means is within a predetermined distance from such first transmitting means. A second transmitting means transmits a second signal indicative that the first signal is not being received by such receiving means. When such receiving means receives the second signal an alarm means will produce at least one of a predetermined sound, motion and visual display. A second power source is operably connected to the receiving means, the second transmitting means, and the alarm means for supplying power thereto.

Owner:MOSS WILLIE C

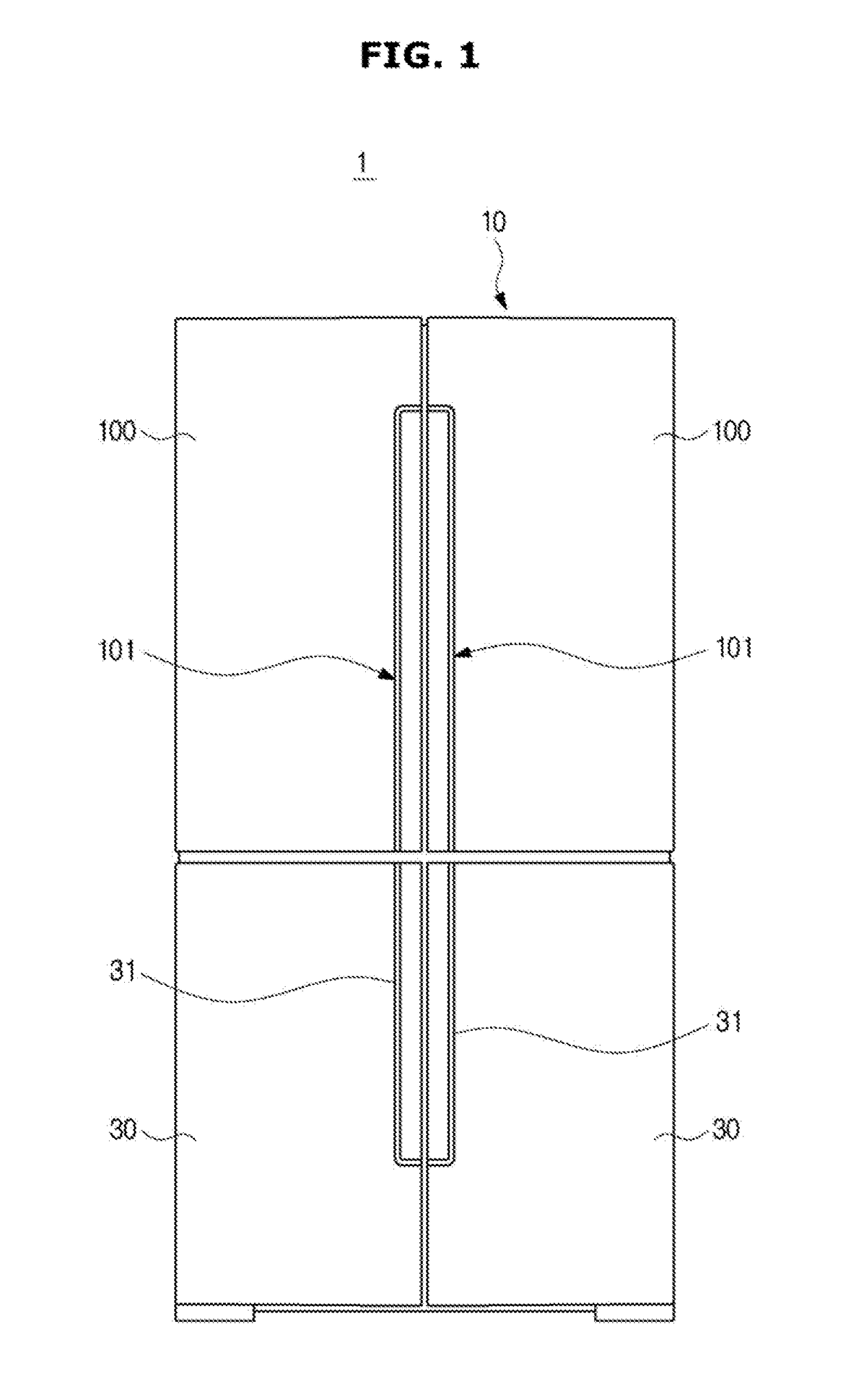

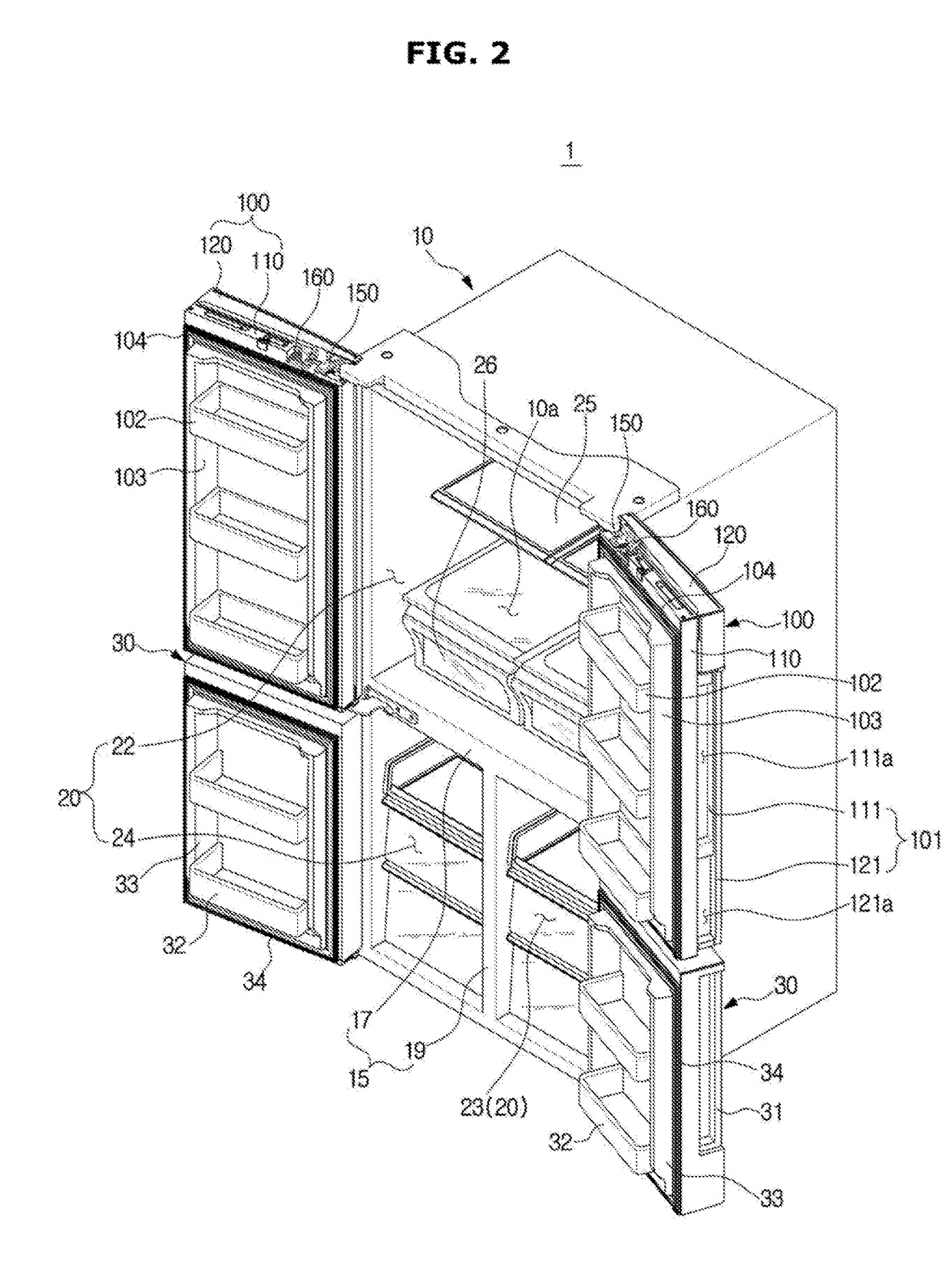

Refrigerator

ActiveUS20170356685A1Secure safetySimple configurationLighting and heating apparatusBuilding braking devicesRefrigerated temperatureElectrical and Electronics engineering

Owner:SAMSUNG ELECTRONICS CO LTD

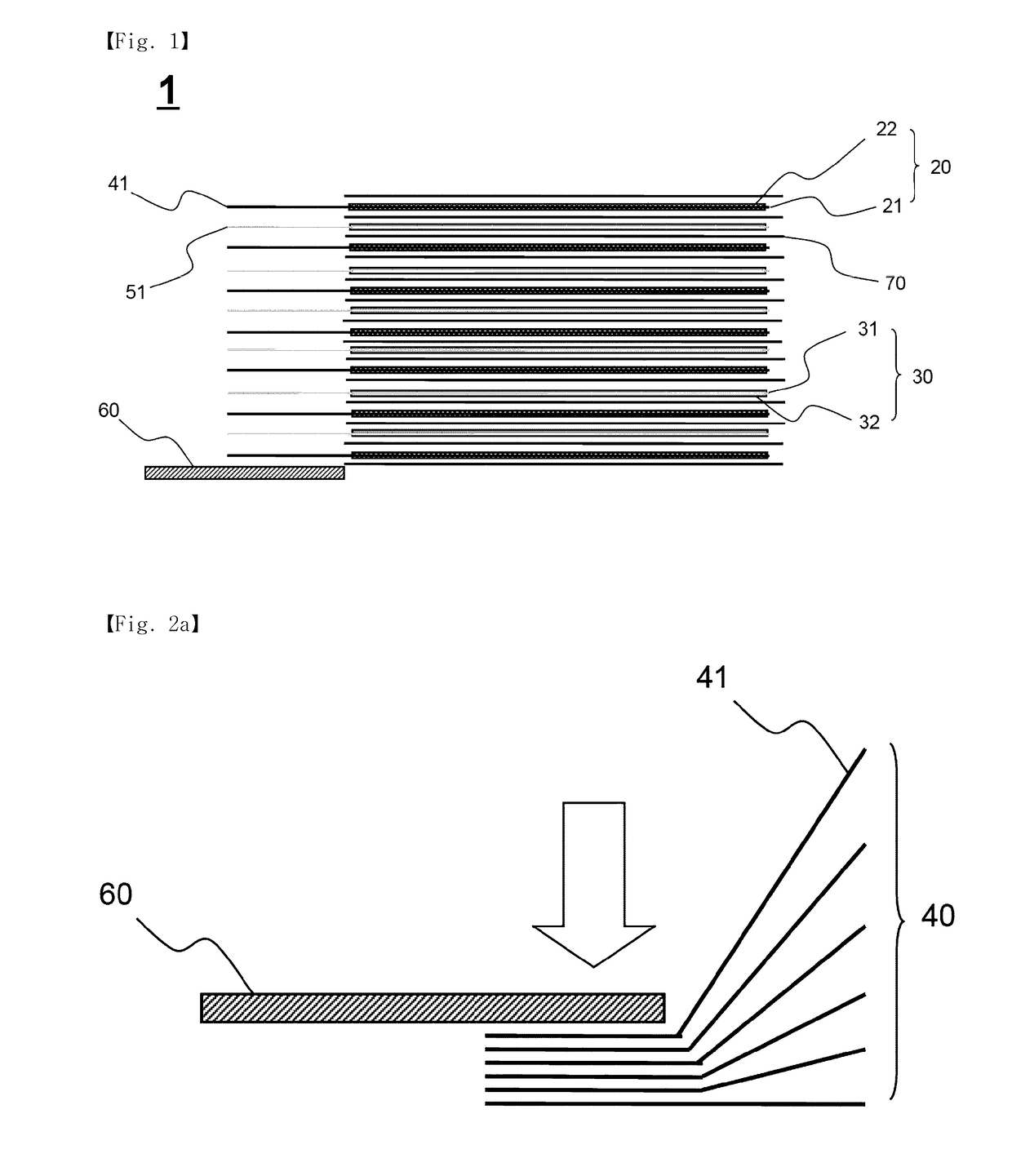

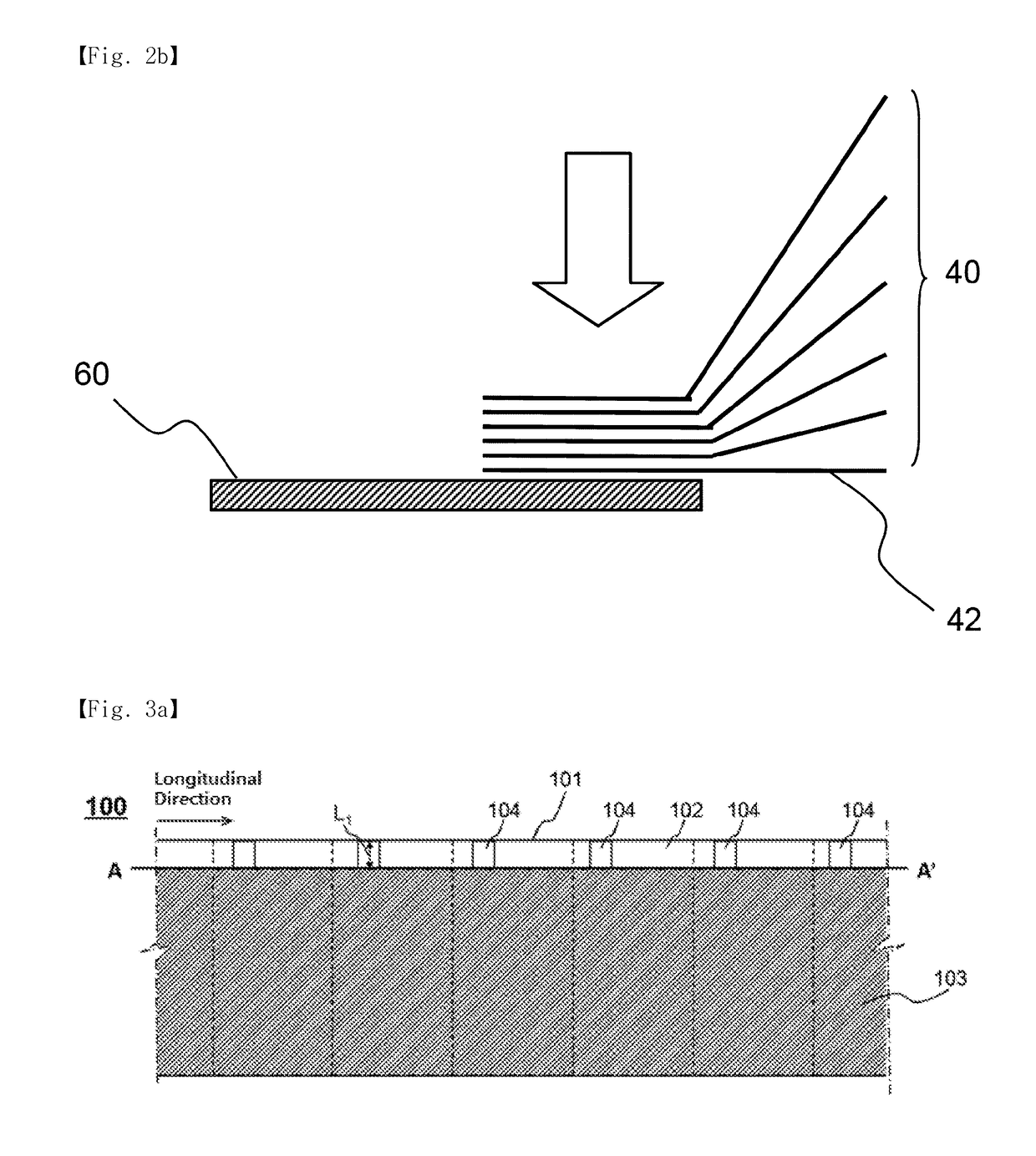

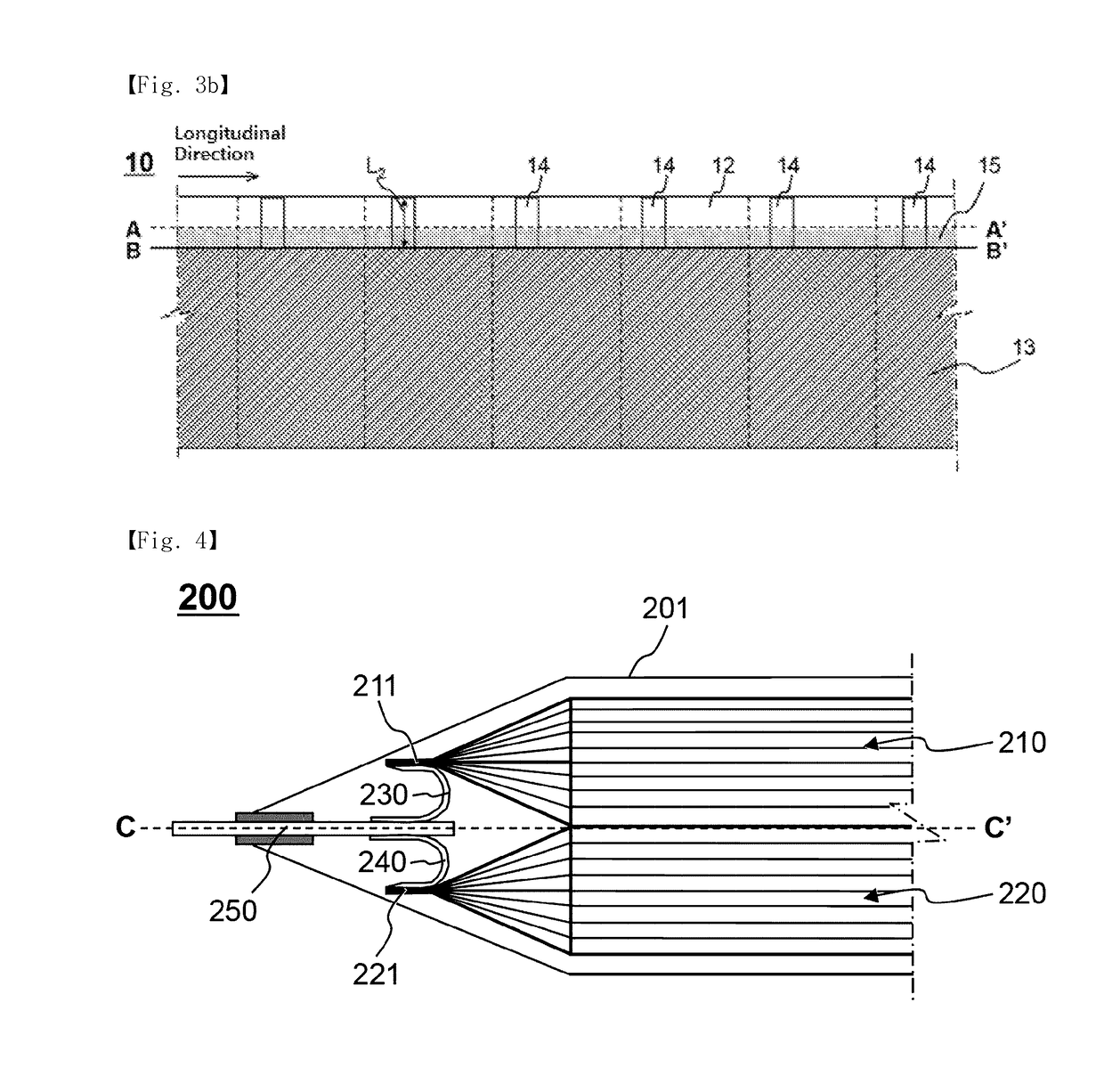

Battery cell having dual welding structures

ActiveUS20190013506A1Increase energy densitySecure safetyFinal product manufactureSmall-sized cells cases/jacketsElectrical and Electronics engineeringBattery cell

The present disclosure provides a battery cell including: two or more electrode groups having a structure in which electrodes including a positive electrode, a negative electrode, and a separator interposed between the positive electrode and the negative electrode are stacked, wherein each of the electrode groups includes an electrode tab junction on one side and is electrically connected to an electrode lead drawn to an outside of a battery case via a conductive connecting member, and has a structure including a first welding junction formed between one end of the conductive connecting member and the electrode tab junction and a second welding junction formed between the other end of the conductive connecting member and the electrode lead.

Owner:LG ENERGY SOLUTION LTD

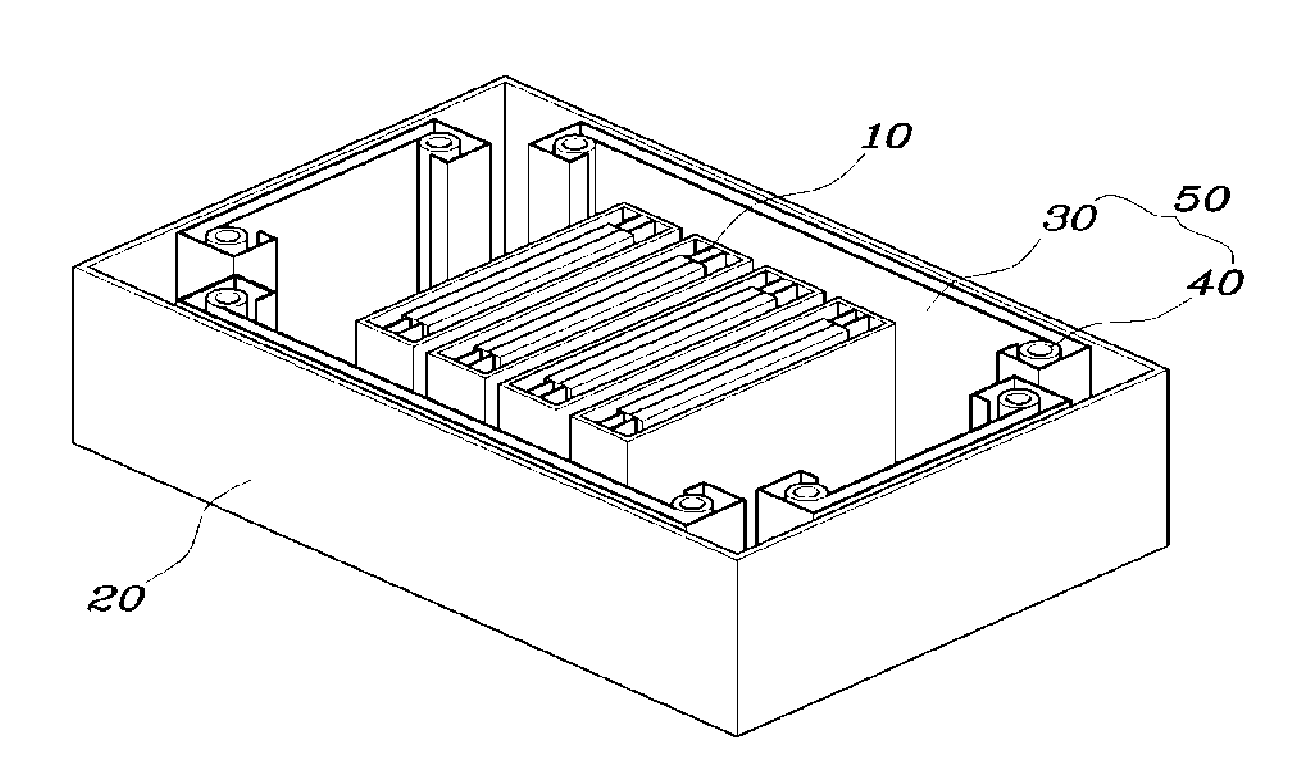

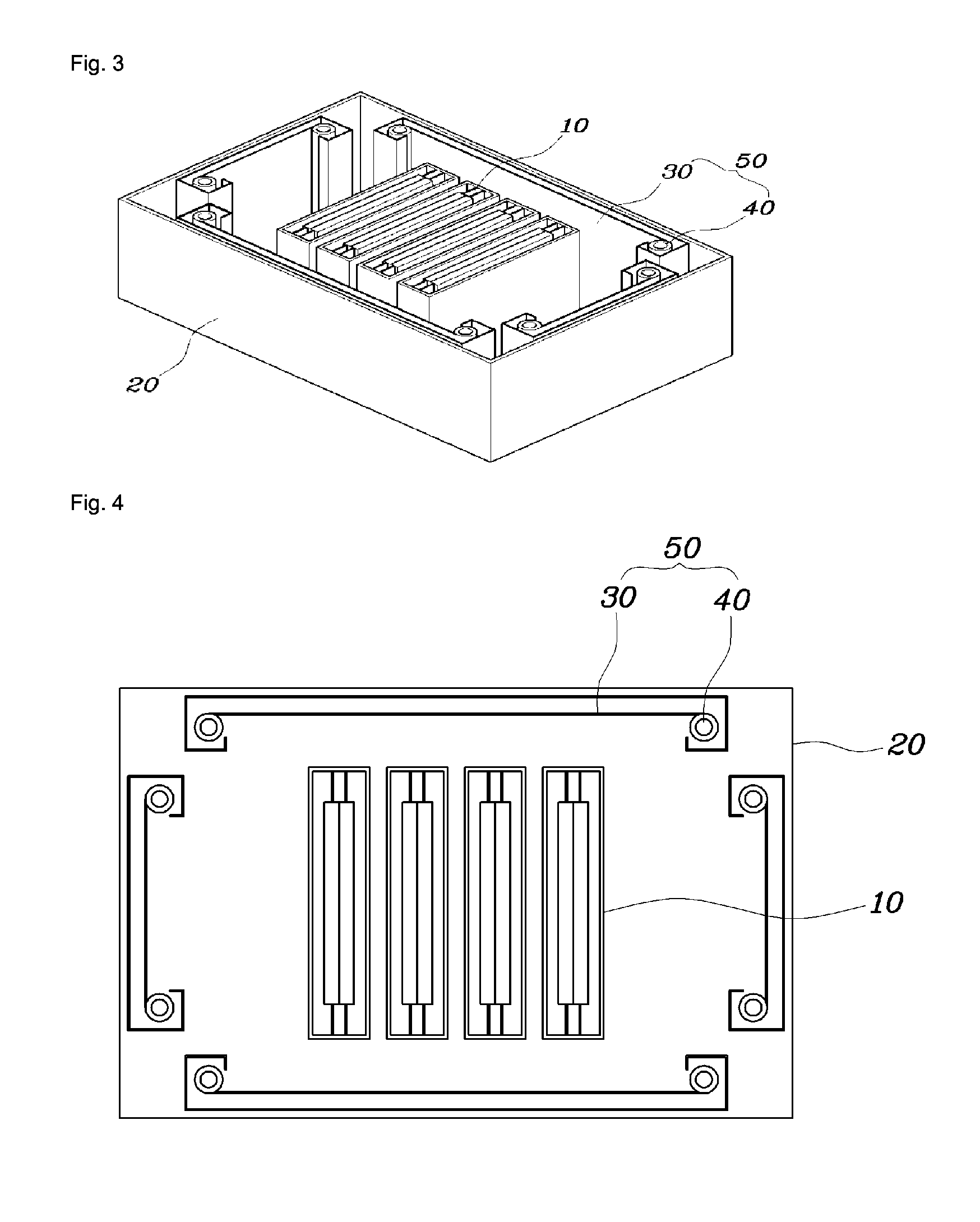

Apparatus for protecting battery pack

ActiveUS20130040189A1Secure safetyPrevent short-circuitingCell component detailsPropulsion by batteries/cellsElectricityEngineering

Provided is an technique for protecting a battery pack, in which an insulating film member and a support member are installed in a housing surrounding the battery pack, and the insulating film member is wound around and unwound from the support member fixedly installed in the housing. The technique prevents a short circuit from being caused by a conductive object penetrating into a high-capacity battery used in an HEV, PHEV or EV, so that it can prevent ignition and smoke from being generated by the battery as a result. The technique is configured to mount a battery of an HEV, PHEV or EV within a spatial margin and increase safety in the event of a collision. The technique can be applied to all vehicles using electricity in addition to the HEV, PHEV or EV.

Owner:HYUNDAI MOTOR CO LTD +1

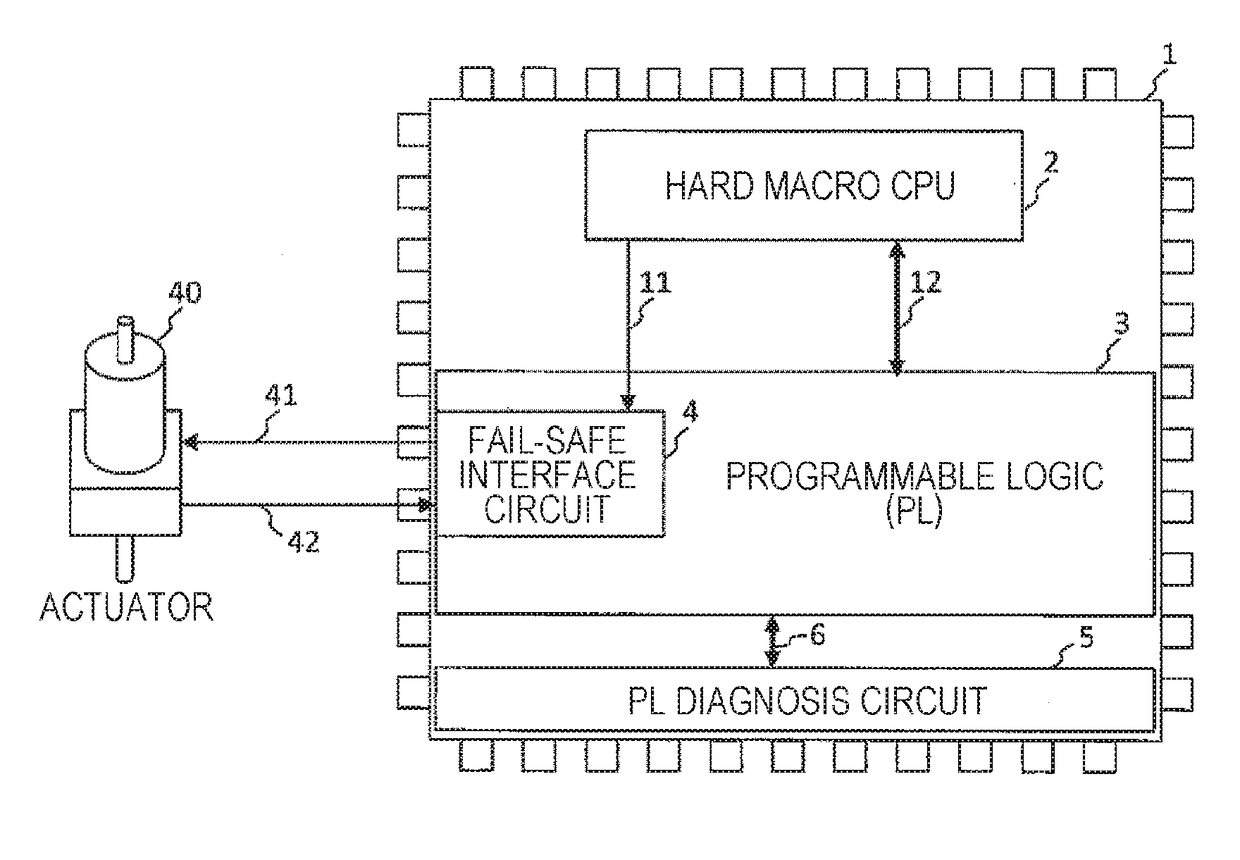

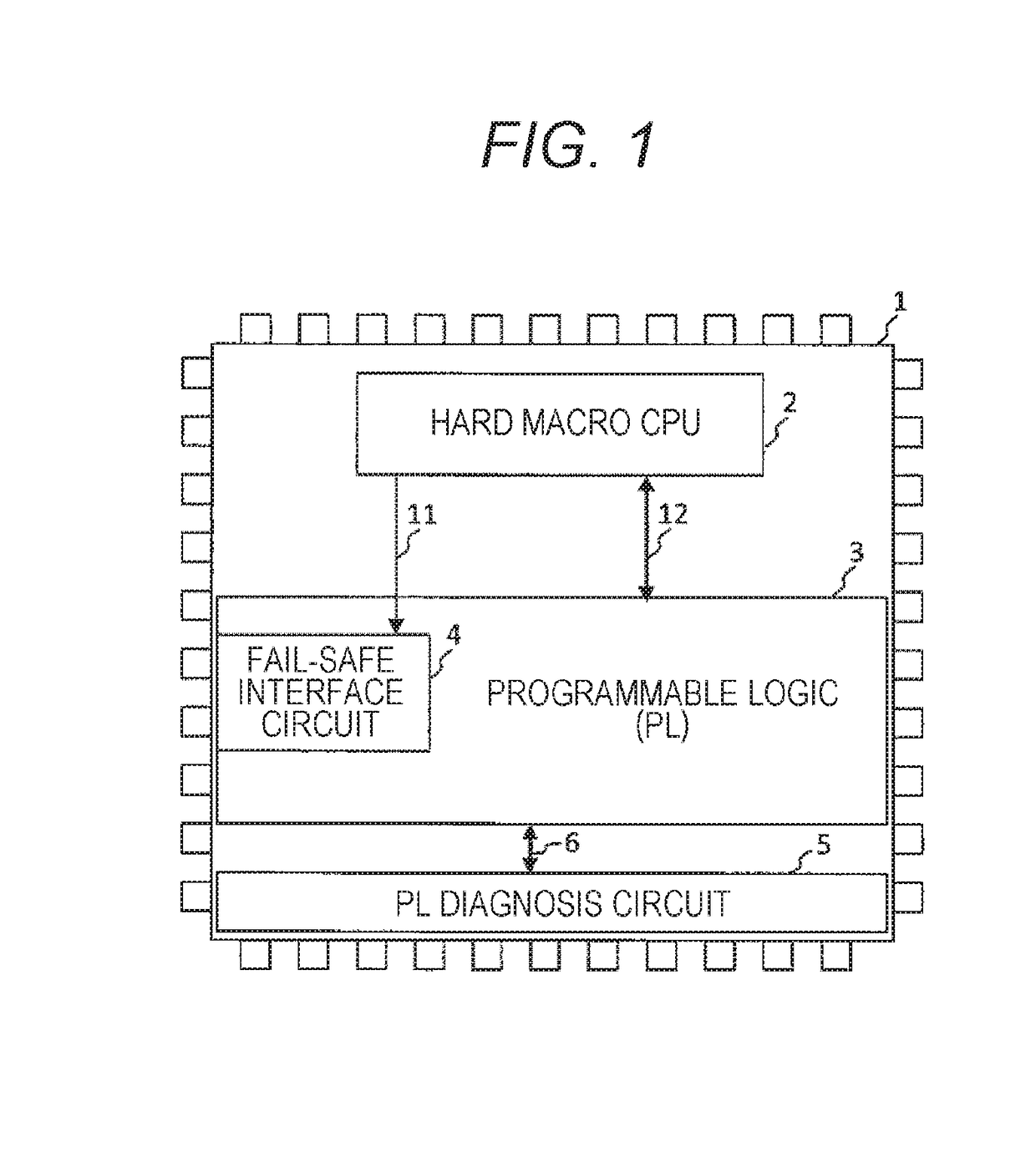

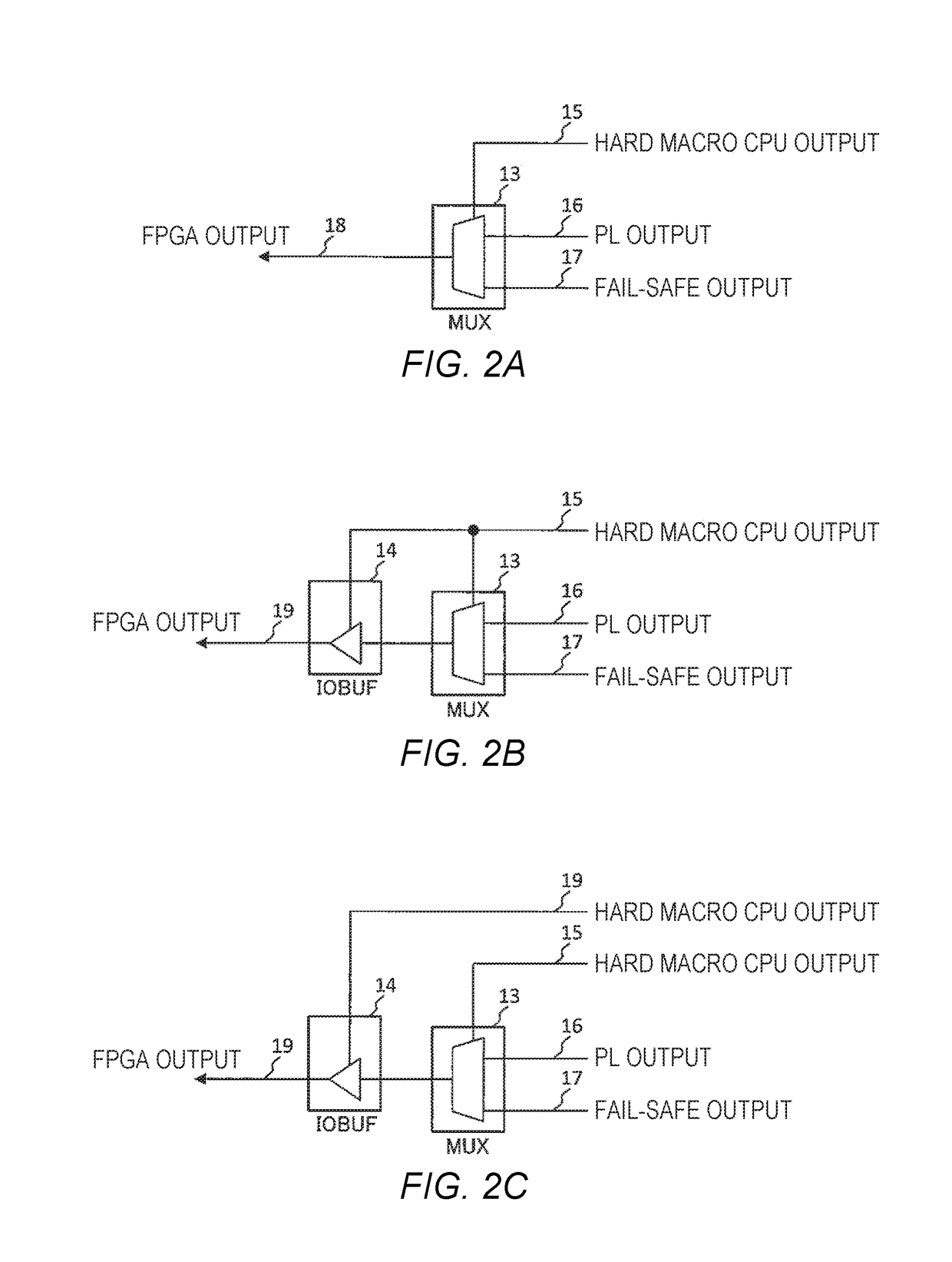

Field Programmable Gate Array

ActiveUS20180113757A1Secure safetyInappropriate valueVisible signalsElectrical testingProgrammable logic deviceInterface circuits

An object of the invention is to provide a field programmable gate array which is able to prevent an inappropriate value from being output to the outside of an FPGA even when an SRAM-based programmable logic portion is out of order and to secure safety of a system. The field programmable gate array of the invention includes a hard macro CPU in which a circuit structure is fixed, a programmable logic in which a circuit structure is changeable, a diagnosis circuit which diagnoses an abnormality of the programmable logic, and a fail-safe interface circuit which is able to control an external output from the programmable logic to a safe side, and the hard macro CPU outputs a fail-safe signal which is an output of a safe side to the fail-sate interface circuit when an error is detected by the diagnosis circuit.

Owner:HITACHI LTD

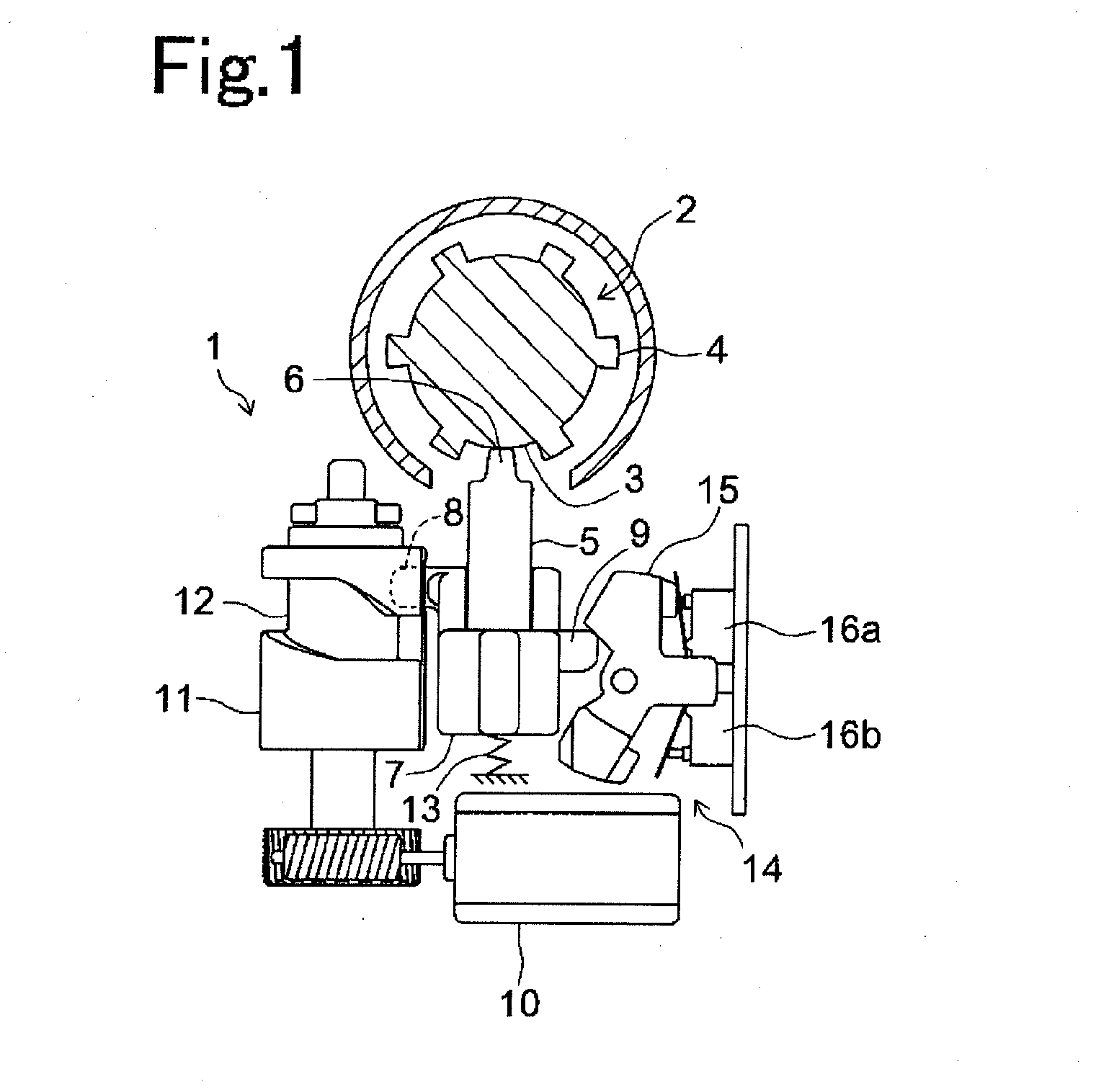

Motor-driven steering lock apparatus

InactiveUS7982334B2High locking reliabilitySimple circuit structureAnti-theft devicesElectric switchesMotor driveSimple circuit

The invention provides a motor-driven steering lock apparatus which can improve a reliability of locking and unlocking operations, with a simple circuit structure. A power supply line from a battery and a driving means are connected by a switching means only at a time when a feed signal from a host first control means to a drive control means (CPU), a power supply-enabling signal from the host first control means and a power supply-enabling signal from a host second control means are input to the switching means.

Owner:U SHIN LTD

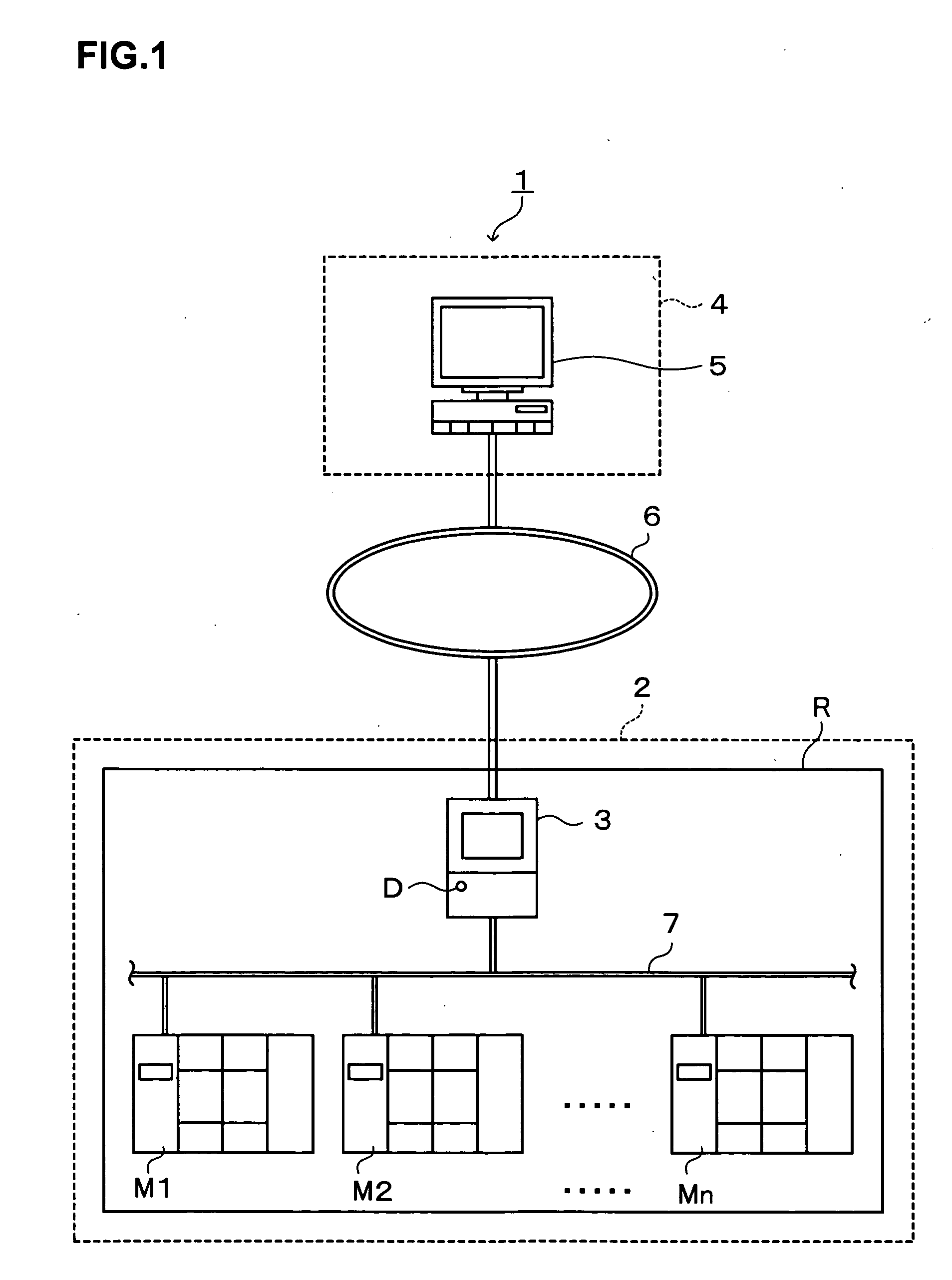

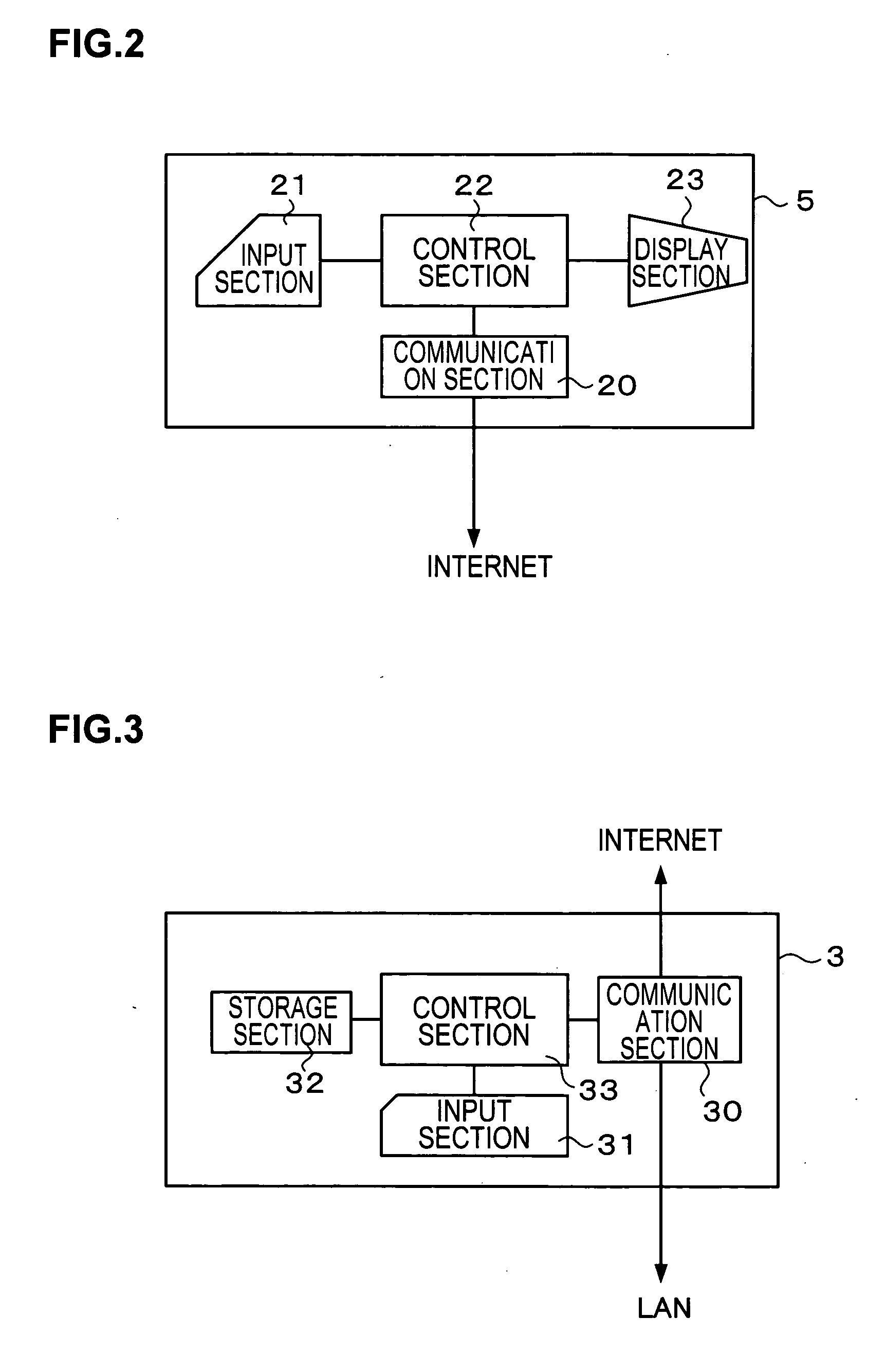

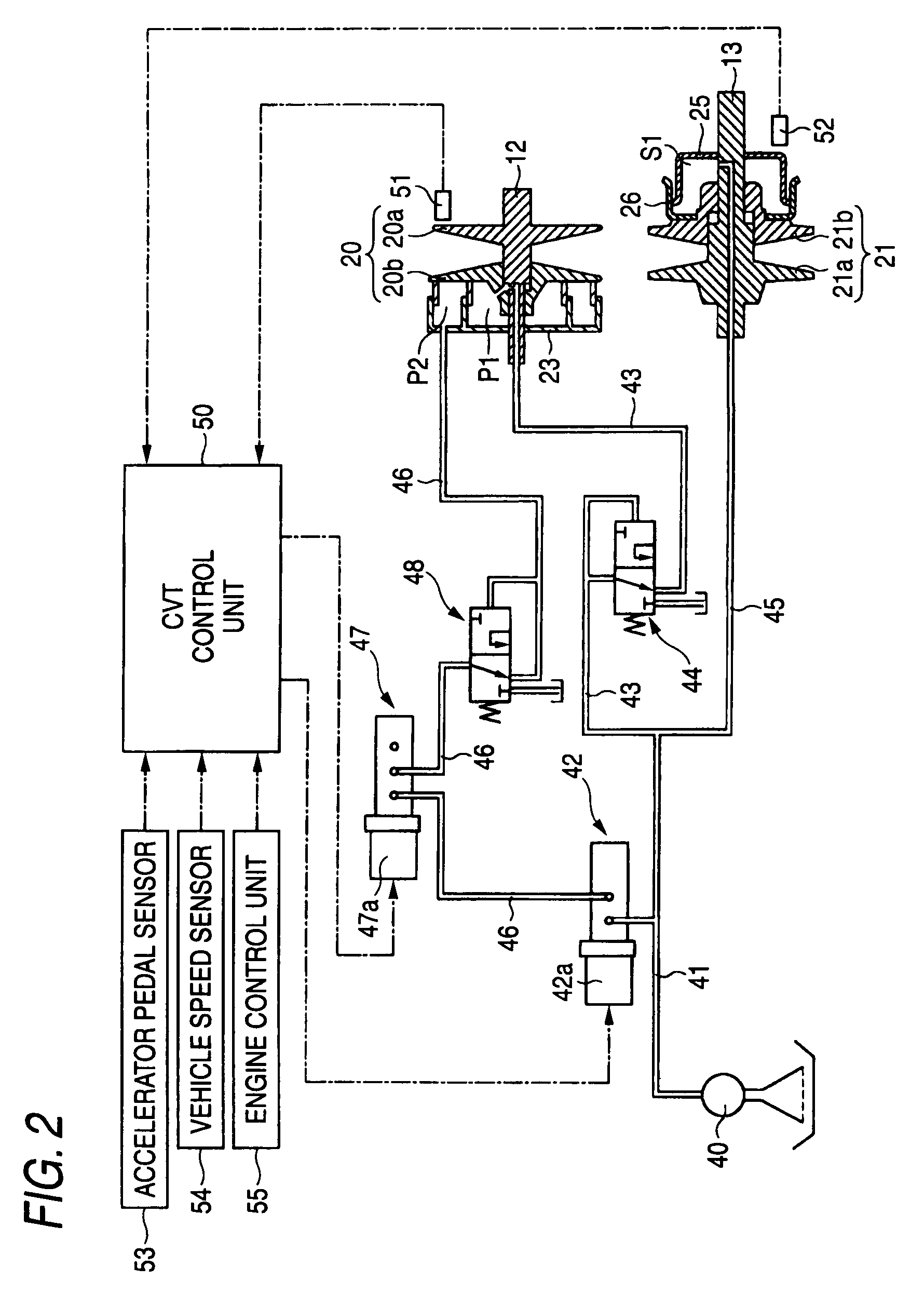

Maintenance system, substrate processing device, remote operation device, and communication method

ActiveUS20060073654A1Operational securitySecure safetyLiquid surface applicatorsSemiconductor/solid-state device manufacturingEngineeringCommunication control

An object of the present invention is to maintain a coating and developing system by remotely operating it more safely. The present invention is a maintenance system of a substrate processing apparatus, including a remote operation unit for operating the substrate processing apparatus from a remote place by transmitting a remote operation information to a side of the substrate processing apparatus through a communication network and providing the remote operation information to the substrate processing apparatus, and a communication control unit for receiving the remote operation information transmitted to the side of the substrate processing apparatus and providing the remote operation information to the substrate processing apparatus. The communication control unit provides the remote operation information to the substrate processing apparatus only when there is an allow setting for the remote operation by a worker in the side of the substrate processing apparatus.

Owner:TOKYO ELECTRON LTD

Control device for continuously variable transmission

Safety as well as the minimum driving performance is secured by preventing abrupt down-shifting if a line pressure valve or a primary pressure control valve fails. A line pressure path connected to an oil pump is connected with a line pressure control valve. A first primary pressure path branched from the line pressure path is connected with a hydraulic fluid chamber through a fail-safe valve, and a secondary pressure path branched from the line pressure path is connected to a hydraulic fluid chamber. The line pressure control valve is connected with a second primary pressure path in communication with a hydraulic fluid chamber, and this secondary primary pressure path is provided with a primary pressure control valve and a limiter valve. When the line pressure control valve and the primary pressure control valve fail and excess line pressure or primary pressure is output, the pressure in the hydraulic fluid chamber is reduced by the fail-safe valve, so that the pressure in the hydraulic fluid chamber is reduced by the limiter valve.

Owner:SUBARU CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com