Prepolycondensating reactor device

A reactor and pre-condensation technology, applied in chemical/physical/physical chemical fixed reactors, chemical instruments and methods, chemical/physical/physical chemical processes, etc., can solve the problem of maintaining a constant material temperature and increasing production costs , Long process flow and other issues, to achieve the effect of ensuring sufficient reaction and evaporation, saving production costs, and simplifying the equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

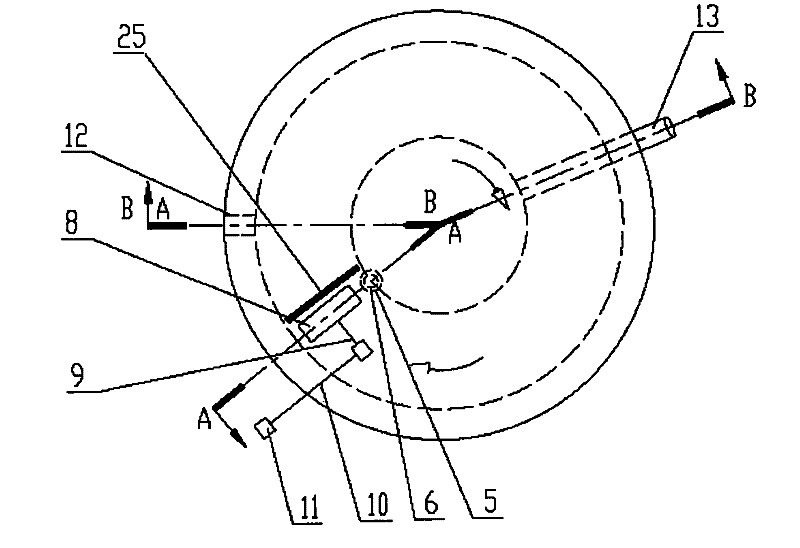

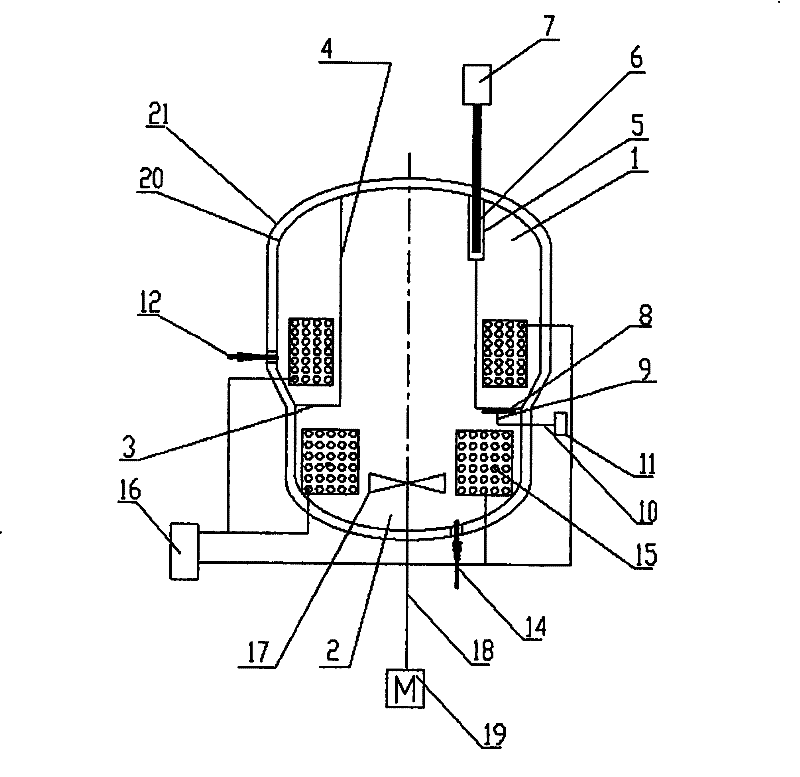

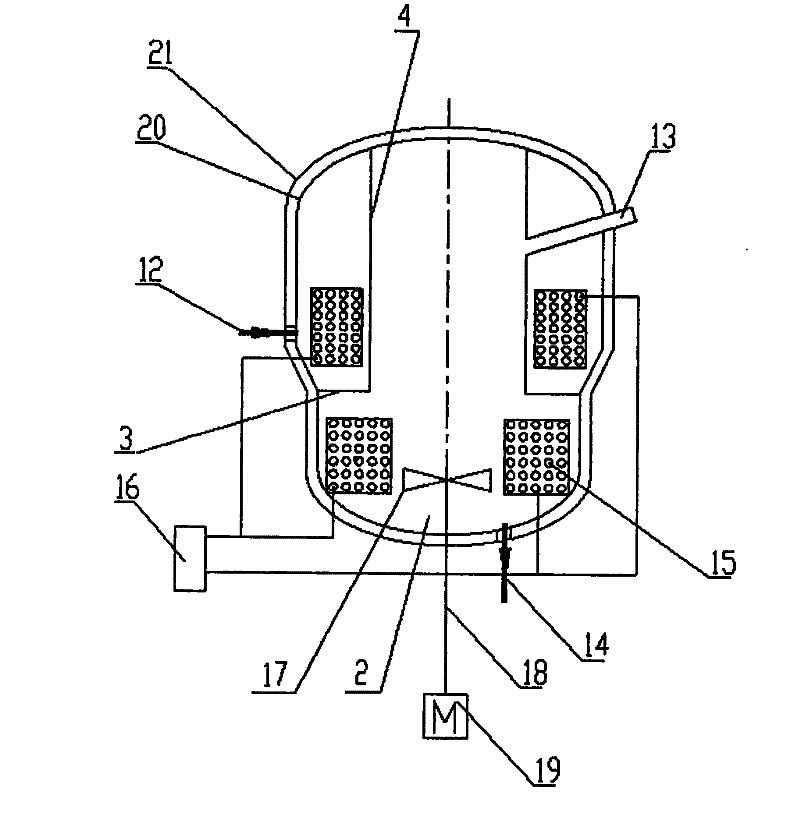

[0024] see Figure 1 to Figure 3 , the present invention provides a pre-condensation reactor device, which includes a closed shell 20, the closed shell is divided into an upper chamber 1 and a lower chamber 2 by a partition 3, and the middle part of the partition extends upwards into Isolation cylinder 4.

[0025] The upper part of the isolation cylinder 4 is provided with a pilot valve 7, the pilot valve is a regulating valve, and the regulating valve includes a vertical slit arranged on the isolation cylinder, and a valve plug 6 that can be inserted into the slit to move up and down , the two sides of the slit are provided with slit side walls 5 that cooperate with the valve plug, the lower part of the valve plug is a polished rod that can form a sealing pair with the slit, and the upper part is a screw rod that extends to the sealing Outside the shell, there is a nut threadedly fitted with it, and the nut is fixedly connected with the shell.

[0026] The isolation cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com