Wastewater concentration and waste heat recycling device and method

A waste water concentration and waste water heater technology, which is applied in separation methods, feed water heaters, chemical instruments and methods, etc., can solve the problems of large heat loss, high energy consumption, and a large amount of high-quality steam, and achieve low operating costs and high energy efficiency. The effect of low consumption and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

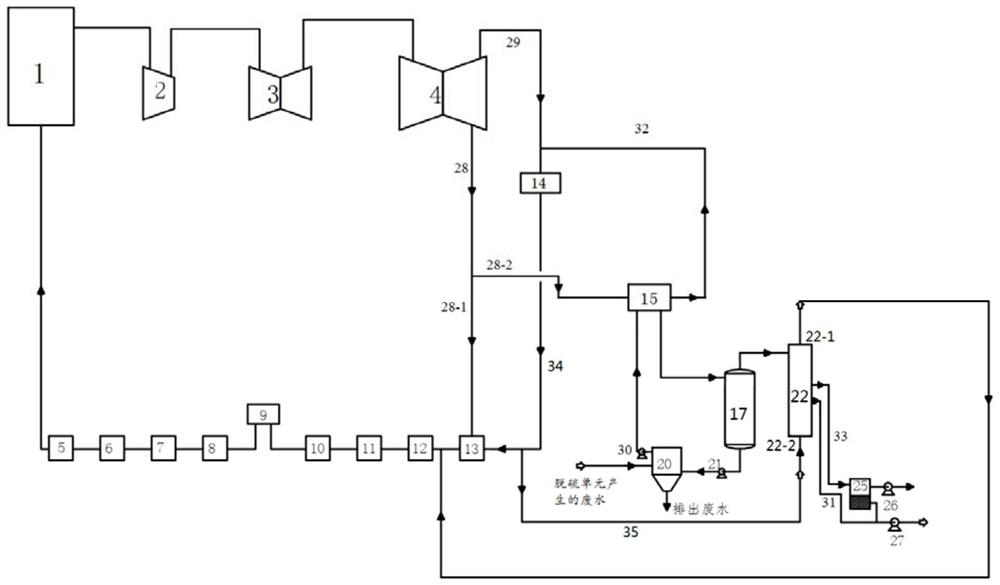

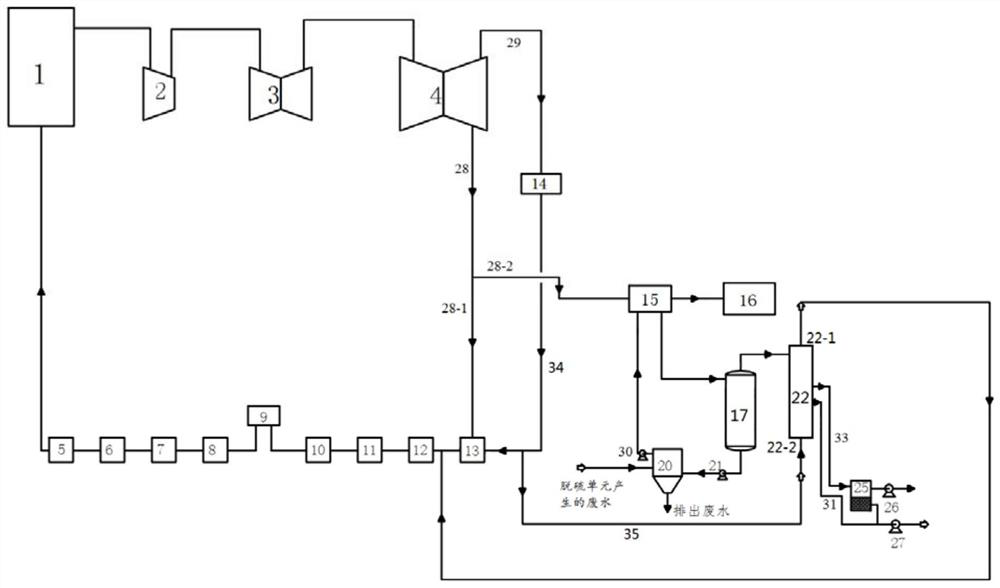

[0048] This embodiment provides a waste heat recovery device for waste water concentration, such as figure 1 As shown, including connected desulfurization unit, waste water concentration system and low-load condensate system;

[0049] The waste water concentrating system comprises a waste water heater 15, a flash tank 17, a first waste water transfer pump 21 and a waste water tank 20 connected in sequence, and the waste water tank 20 communicates with the waste water heater 15 through the second waste water transfer pump 30; in the waste water tank 20 A supernatant liquid outlet and a concentrated waste water outlet are provided, and at least one flash chamber is arranged in the flash tank 17. During normal operation of the device, the height of the waste water in the flash chamber is 5-50 cm, and the height is adjusted according to the waste water circulation amount; In the present embodiment, one flash chamber is arranged in the flash tank 17, the middle part of the flash ch...

Embodiment 2

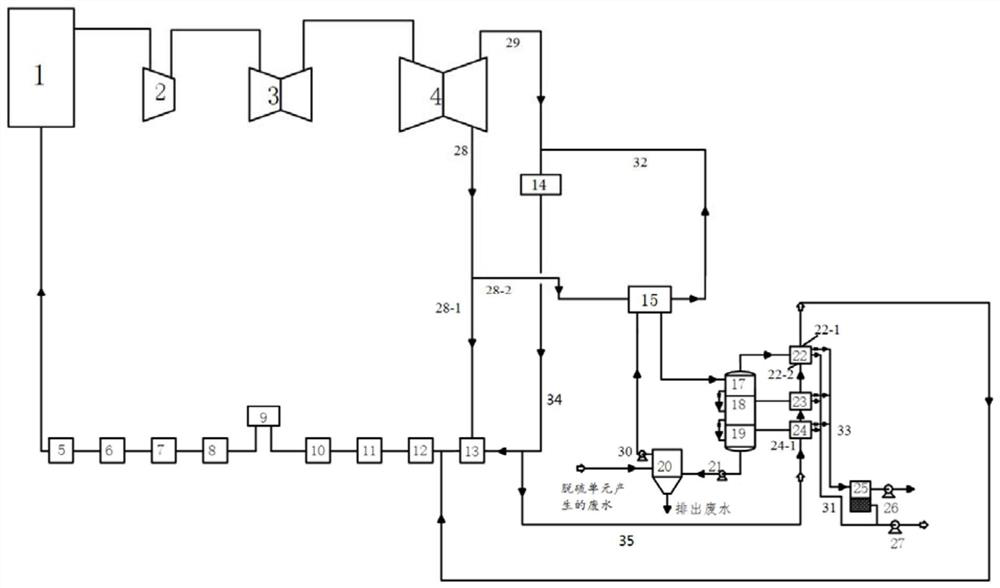

[0068] This embodiment provides a waste heat recovery method for waste water concentration, using image 3 provided means, comprising the following steps,

[0069] The generator set discharges the first heat exchange medium and the third heat exchange medium, the third heat exchange medium enters the condenser 14 through the second pipe 29, the steam condenses into water, and the first heat exchange medium enters through the first pipe 28 respectively In the first low heating heater 13 and the waste water heater 15;

[0070] The temperature of part of the steam from the generating set entering the waste water heater 15 is 97-99° C., which is used to heat the waste water from the waste water pool 20. The temperature of the waste water entering the waste water heater 20 is 33-37° C. After the waste water is heated, When the temperature reaches 65-95℃, it enters the flash tank for flash evaporation to obtain secondary steam, and the secondary steam enters the condenser, and the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com