Low-temperature negative-pressure wastewater zero-discharge system

A low-temperature negative pressure, zero-emission technology, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of high-quality heat energy consumption and high energy consumption, reduce abrasion and improve heat transfer Effect, effect of extending heat usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

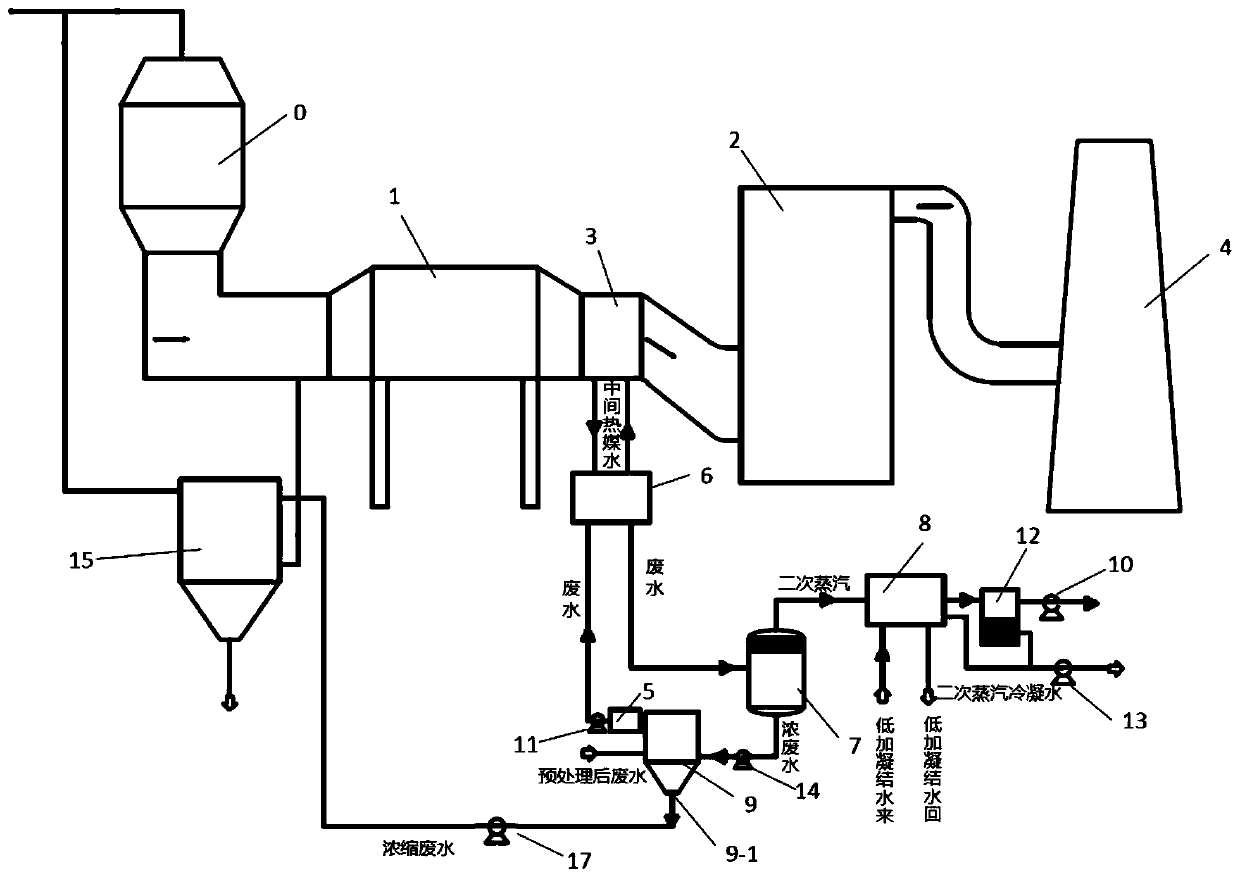

[0074] This embodiment provides a low-temperature negative pressure wastewater zero discharge system, such as figure 1 As shown, it includes a dust removal unit 1 and a desulfurization unit 2 connected together, and also includes an economizer 3 and a wastewater concentration system. The economizer 3 is arranged between the dust removal unit 1 and the desulfurization unit 2, or is arranged along the direction of flue gas flow. Before dust removal unit 1; dust removal unit 1 is an electric dust collector, desulfurization unit 2 is a desulfurization tower, and economizer 3 is a low-temperature economizer. The setting of economizer 3 can improve the dust removal capacity of dust removal unit 1.

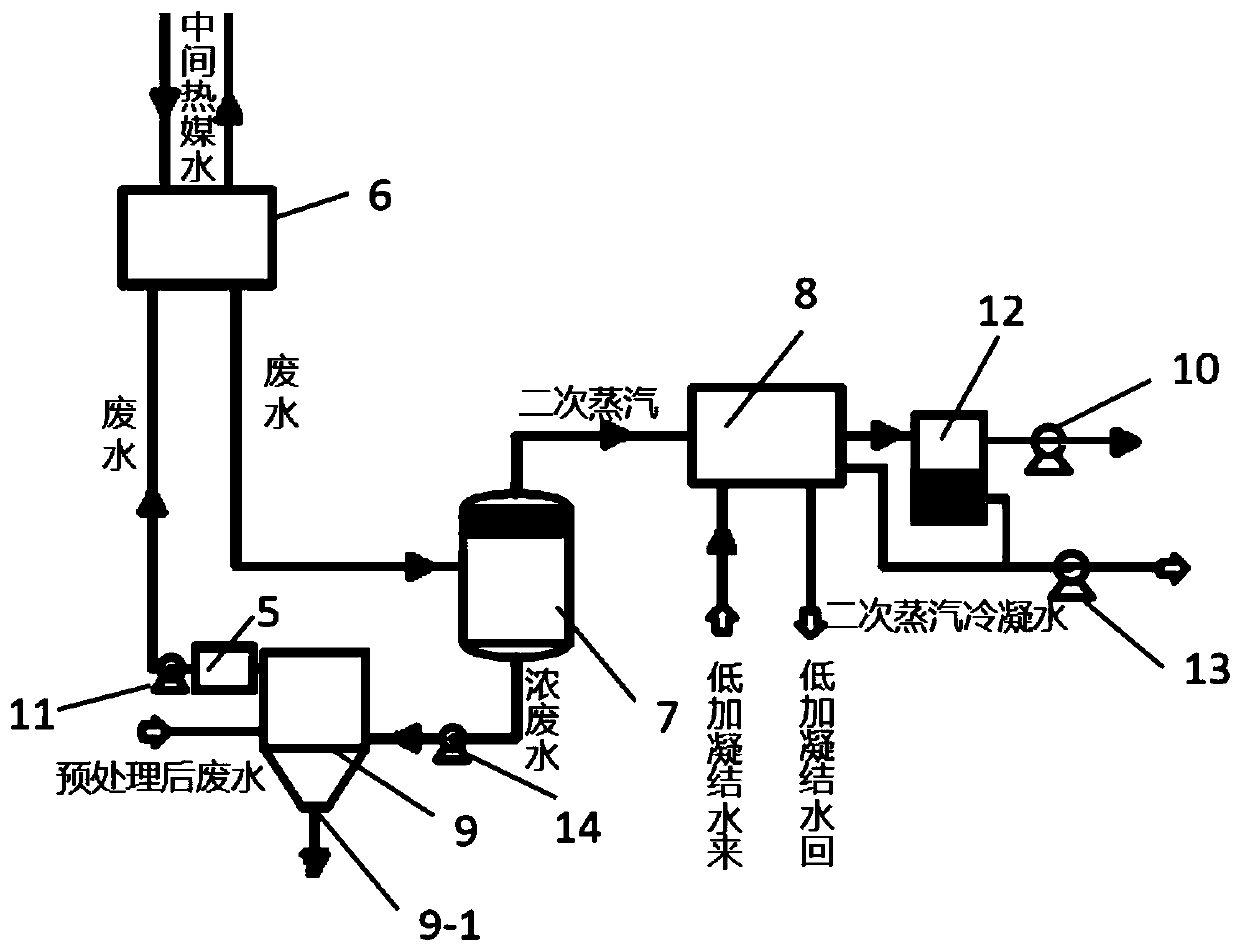

[0075] Such as figure 2 As shown, the waste water concentration system includes: a first heat exchanger 6, which communicates with the economizer 3, so that the waste water and the first heat exchange medium from the economizer 3 exchange heat in the first heat exchanger 6; the first T...

Embodiment 2

[0101] Such as figure 1 As shown, this embodiment provides a zero-discharge system for low-temperature negative-pressure wastewater, which includes a connected dust removal unit 1, a desulfurization unit 2, and a chimney 4, and also includes an economizer 3 and a wastewater concentration system. The economizer 3 is installed in the dust removal Between unit 1 and desulfurization unit 2; dedusting unit 1 is an electric precipitator, desulfurization unit 2 is a desulfurization tower, and economizer 3 is a low-temperature economizer; figure 2 As shown, the waste water concentration system includes: a first heat exchanger 6, which communicates with the economizer 3, so that the waste water and the first heat exchange medium from the economizer 3 exchange heat in the first heat exchanger 6;

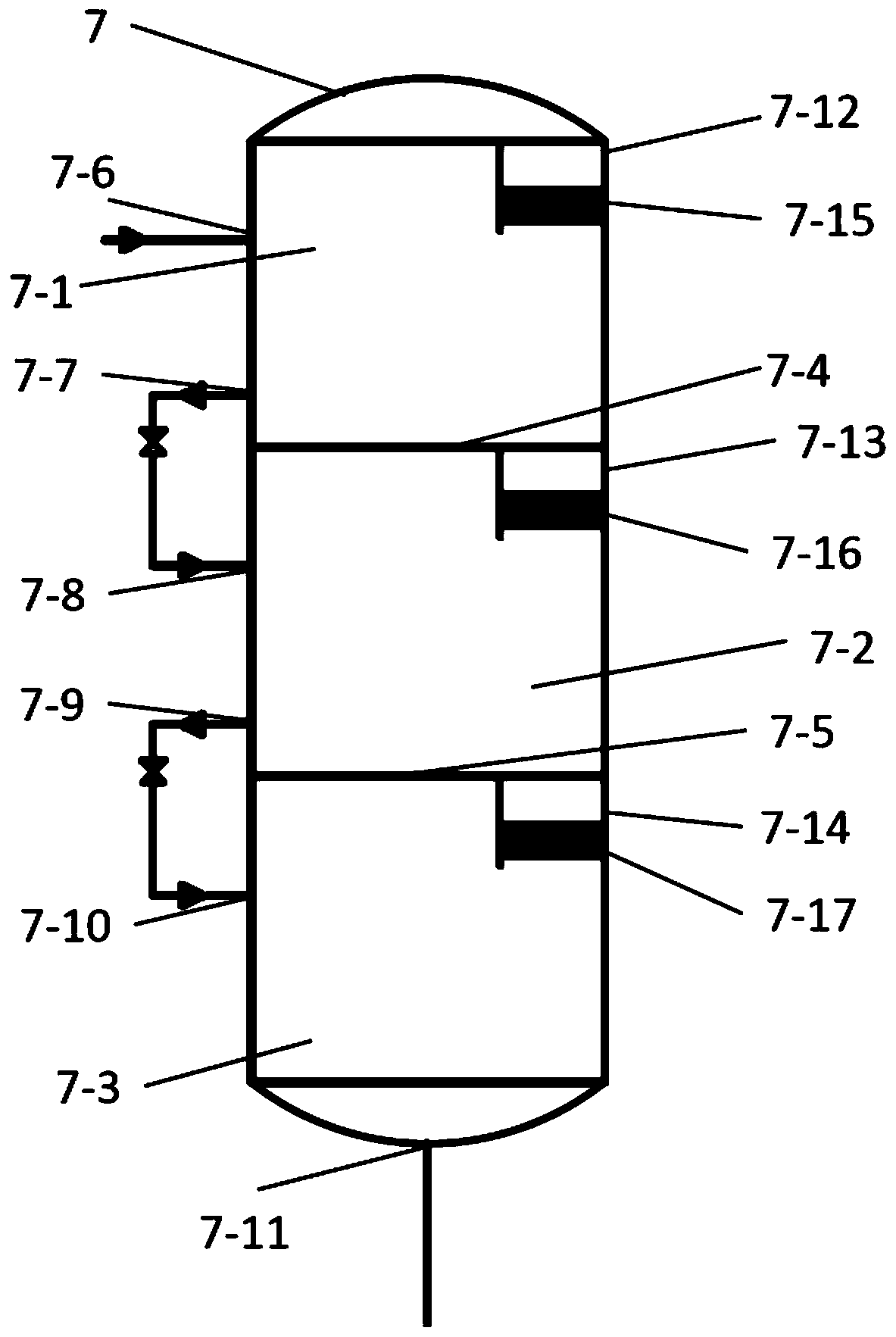

[0102] Flash tank 7, such as Figure 4 As shown, a first partition 7-4 and a second partition 7-5 are arranged inside, along the direction from the liquid inlet 7-6 of the flash tank 7 to th...

Embodiment 3

[0123] This embodiment provides a zero-discharge system for low-temperature negative-pressure wastewater, which is the same as Embodiment 2, the only difference is that the heat exchange component 8 in this embodiment is composed of a shell-and-tube heat exchanger, such as Figure 9 As shown, its specific structure is as follows:

[0124] The heat exchange assembly 8 includes a shell and a number of heat exchange tubes 8-10 arranged in it to form a shell side and a tube side respectively. The heating system is connected so that the second heat exchange medium in the low heating system enters the tube side to exchange heat with the steam in the shell side; the heat exchange assembly 8 is provided with a first baffle plate 8-11 and a second baffle plate 8-12 , along the direction of the outflow end and inflow end of the heat exchange tube 8-10, the first baffle plate 8-11 and the second baffle plate 8-12 are sequentially arranged in the heat exchange assembly 8 and divide the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com