Regeneration system for achieving deep utilization of sensible heat of raw flue gas

A regeneration system and original flue gas technology, applied in preheating, gas treatment, steam generation, etc., can solve the problems of waste of energy and water resources, inability to make deep use of a large amount of latent heat of raw flue gas, and large investment costs, so as to reduce operation cost, quality improvement, water saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

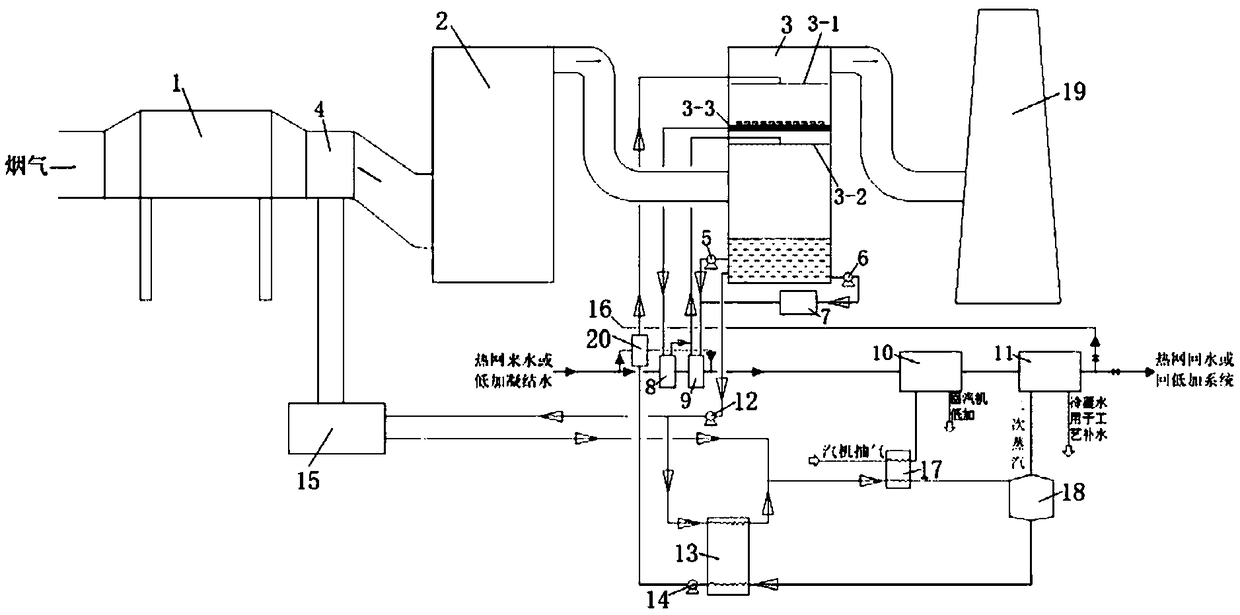

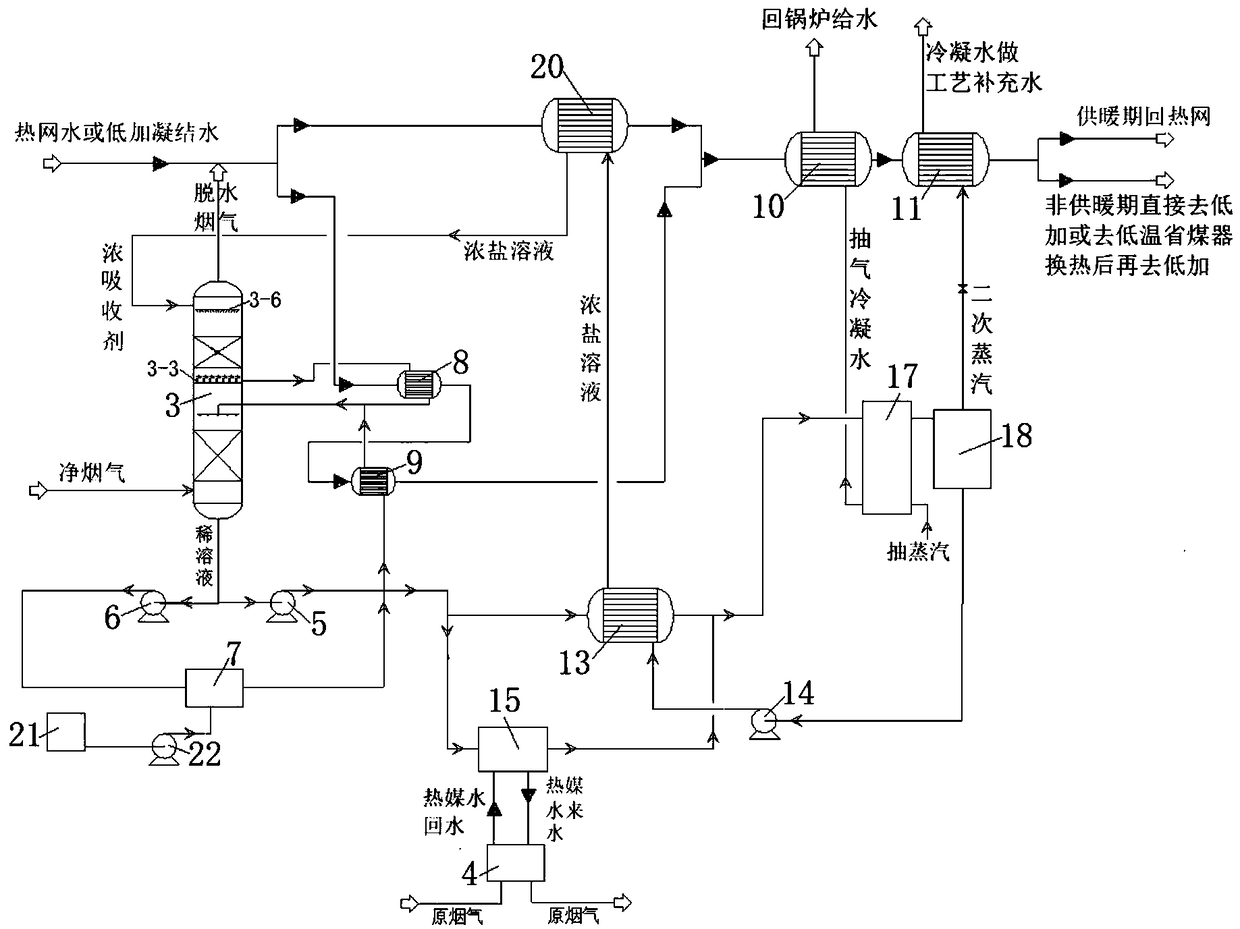

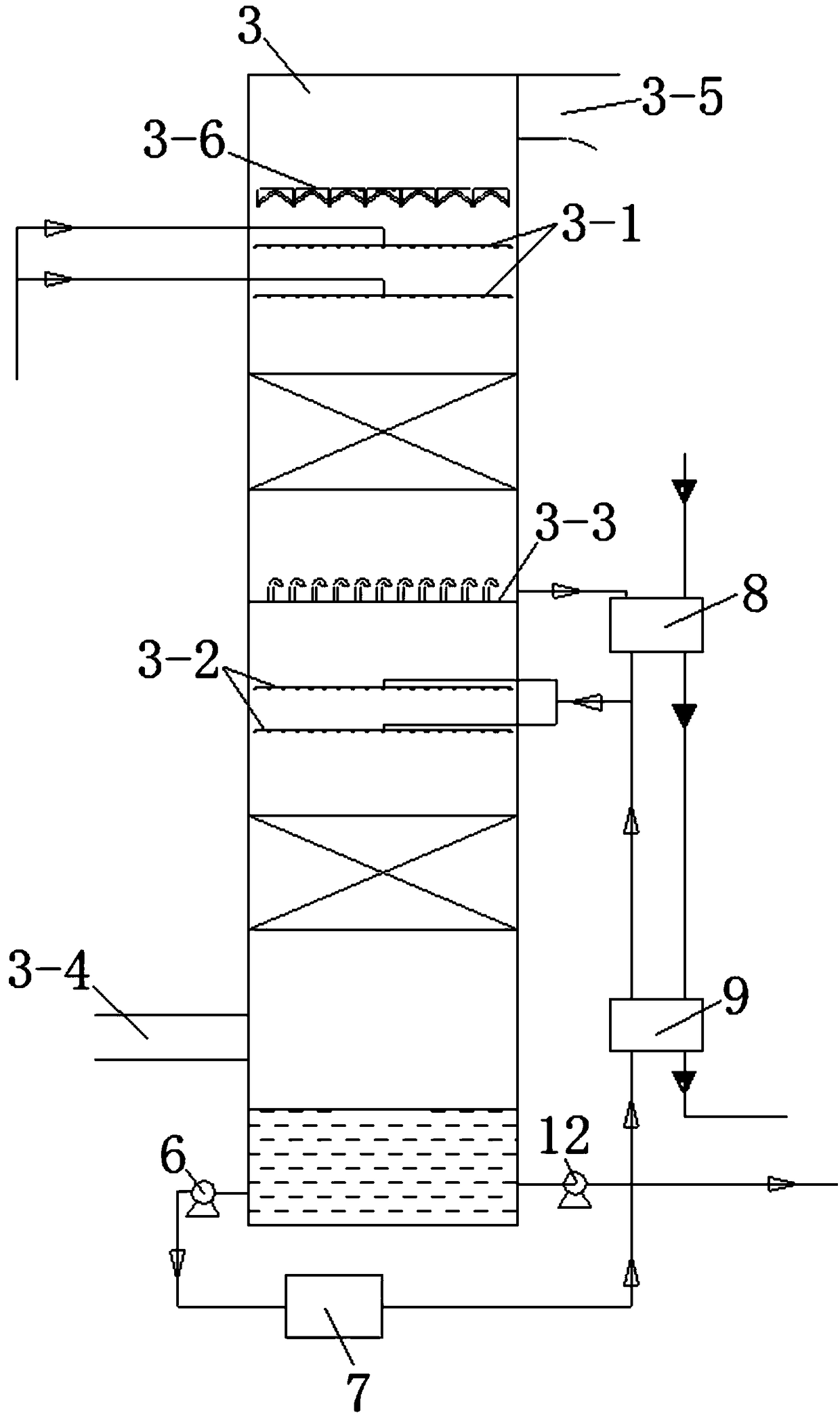

[0047] This embodiment provides a regeneration system for deep utilization of raw flue gas sensible heat, such as figure 1 with 2 As shown, it includes a dedusting device 1, a desulfurization device 2 and an absorption device 3 connected in sequence. For example, the dedusting device 1 can be an electric precipitator, the desulfurization device 2 can be a desulfurization tower, and the absorption device 3 can be an absorption tower. More specifically, it can be It is a spray tower or a packed tower, the lower part of the absorption device 3 is provided with a flue gas inlet 3-4, and the upper part is provided with a flue gas outlet 3-5, and also includes a liquid storage unit 3-3, for example, the liquid storage unit 3-3 can be a liquid disk, such as image 3 As shown, the liquid receiving plate has a disk suitable for the inner cavity of the desulfurization tower, and a through hole is set on the disk. Along the axial direction of the desulfurization tower, the through hole ...

Embodiment 2

[0060] This embodiment provides a raw flue gas sensible heat deep utilization regeneration system. On the basis of the above-mentioned embodiment 1, in order to improve the heat exchange effect and fully recover the sensible heat in the raw flue gas and the latent heat of the clean flue gas water vapor, And the waste liquid is fully regenerated, and the second heat exchanger 9 is also included. The lower part of the absorption device 3, the second heat exchanger 9 and the second spray unit 3-2 are connected in sequence to send the dilute solution to the into the second spray unit 3-2; meanwhile, in order to filter and modulate the concentrated solution as the absorption liquid in the absorption device, it also includes a solution filtration and conditioning system 7, the bottom of the absorption device 3, the solution filtration and conditioning system 7, The second heat exchanger 9 and the second spray unit 3-2 are connected in sequence, so that the dilute solution is sent to ...

Embodiment 3

[0062]This embodiment provides a raw flue gas sensible heat deep utilization regeneration system, on the basis of the above-mentioned embodiment 1 or 2, it also includes a third heat exchanger 10 and a fourth heat exchanger 11, the first heat exchanger 8 , the second heat exchanger 9, the third heat exchanger 10 and the fourth heat exchanger 11 are connected in sequence, so that the incoming water from the heating network or the condensed water at low temperature can pass through the first heat exchanger 8 and the second heat exchanger 9 in sequence , the third heat exchanger 10 and the fourth heat exchanger 11, and exchange heat with the substances entering the corresponding heat exchanger;

[0063] As a variable embodiment, according to the primary steam condensed water temperature and the secondary steam temperature, the positions of the third heat exchanger 10 and the fourth heat exchanger 11 can be interchanged, specifically, the first heat exchanger 8 and the second heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com