Device for treating wastewater by using low-grade flue gas

A flue gas treatment, low-grade technology, applied in the direction of gaseous effluent wastewater treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of adverse effects on unit efficiency, high-quality heat energy consumption, high investment cost, etc., and achieve good social and economic benefits impact, low operating costs, and low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

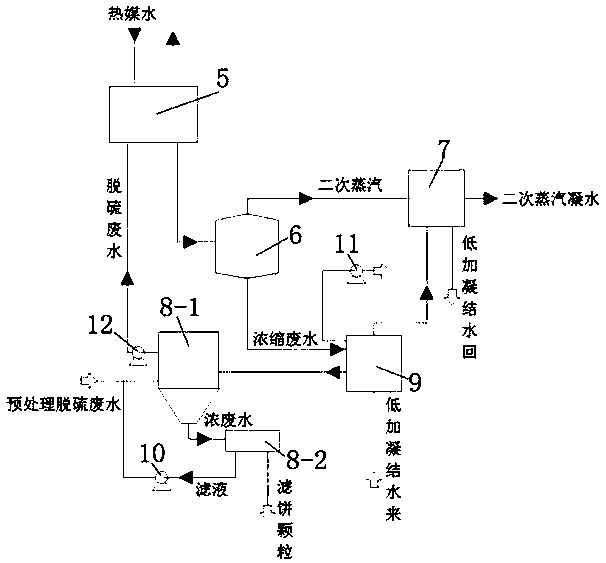

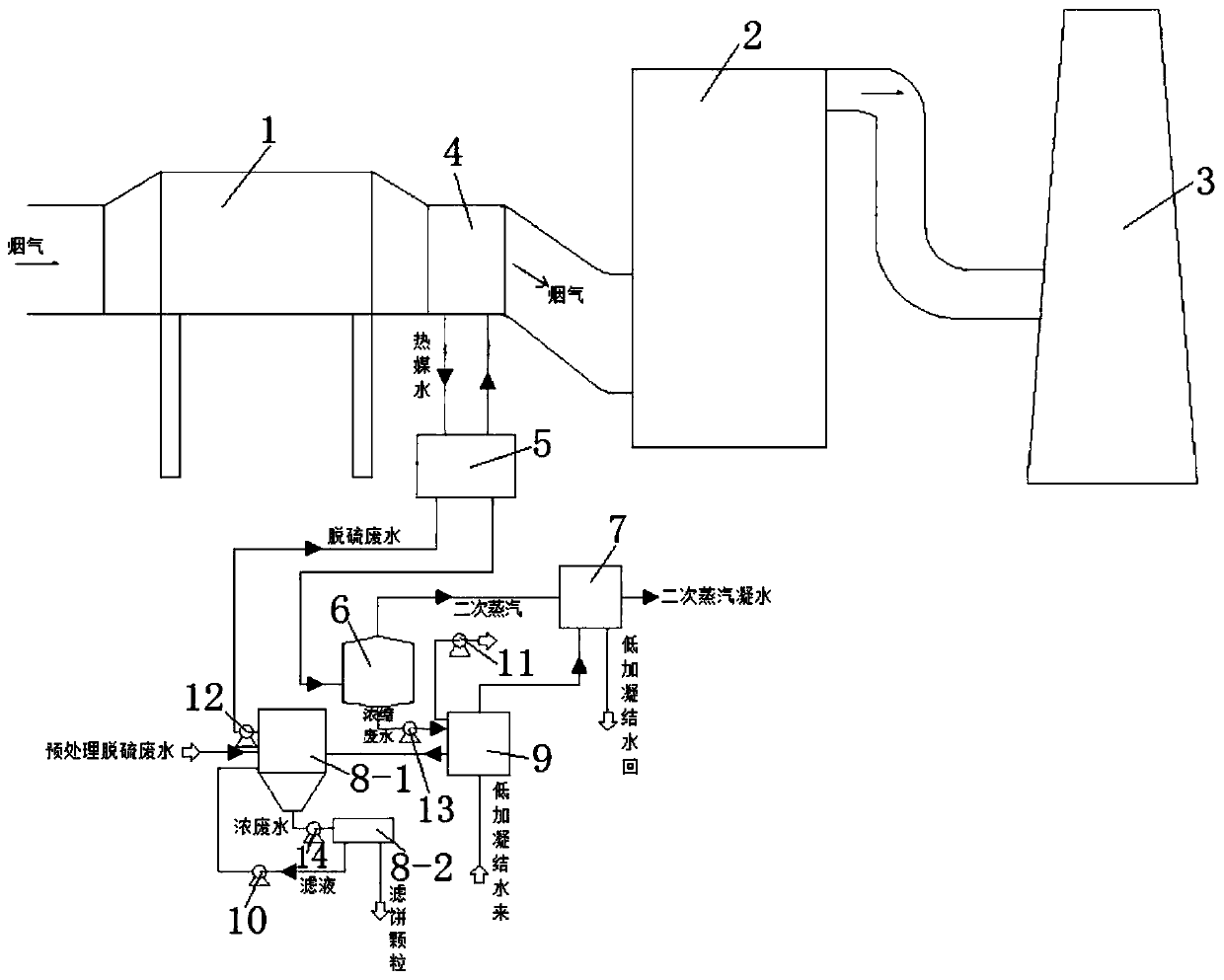

[0034] This embodiment provides a device for treating waste water using low-grade flue gas, such as figure 1 and 2 As shown, it includes a dedusting unit 1 and a desulfurization unit 2 connected in communication, and also includes an economizer 4, which is arranged between the dedusting unit 1 and the desulfurization unit 2 or along the flow direction of the flue gas, and is arranged upstream of the dedusting unit 1. In the embodiment, the dedusting unit 1 is an electric dust collector, the economizer 4 is a low-temperature economizer, and the desulfurization unit 2 is a desulfurization tower, which also includes,

[0035] The first heat exchanger 5 communicates with the economizer 4 to exchange heat between the desulfurization waste water and the first heat exchange medium from the economizer in the first heat exchanger 5, specifically, the first heat exchange medium is Intermediate heat medium water obtained after heat exchange of high-temperature flue gas;

[0036] The fl...

Embodiment 2

[0042] This embodiment provides a device for treating waste water using low-grade flue gas, such as figure 1 and 2 As shown, on the basis of the above-mentioned embodiment 1, in order to improve the heat utilization efficiency and the desulfurization wastewater treatment effect, a second heat exchanger 9 is also included, which is arranged between the flash tank 6 and the precipitation unit 8-1. The inlet end of the heat exchanger 9 is connected to the outlet of the concentrated waste water, and the outlet end is connected to the straight line section, so that the concentrated waste water can exchange heat with the second heat exchange medium in the second heat exchanger 9. Specifically, the second heat exchange medium is from the outside The low addition of condensate;

[0043] Such as figure 1 As shown, it also includes a third heat exchanger 7, communicated with the secondary steam outlet on the upper part of the shell, and the third heat exchanger 7 is also communicated ...

Embodiment 3

[0045] This embodiment provides a device for treating waste water using low-grade flue gas. On the basis of the above-mentioned embodiment 1 or 2, it also includes a first pump 11, which communicates with the flash tank 6 and is used to make the flash tank 6 It is in a negative pressure state and controls its internal vacuum; that is, in order to ensure that the heated wastewater can be flashed and concentrated, the low temperature phase change concentration system needs to be equipped with a vacuum pump (that is, the first pump 11), the vacuum pump and the wastewater flash tank and condensation After the condenser is connected in series, the secondary steam is first cooled in the condenser to form secondary steam condensate, and a phase change occurs during the cooling process to generate negative pressure, which can maintain the negative pressure state of the system by itself, but the system starts and maintains vacuum Stability requires a vacuum pump to be installed. The vac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com