Crystal form transformation energy-saving device, alumina roasting system and production method thereof

A technology of crystal transformation and energy-saving devices, which is applied in chemical instruments and methods, inorganic chemistry, chemical industry, etc., can solve the problems of rising exhaust gas discharge temperature, unfavorable roaster production capacity, and large gas consumption, so as to reduce fuel consumption. The effect of unit consumption, lower temperature and lower concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

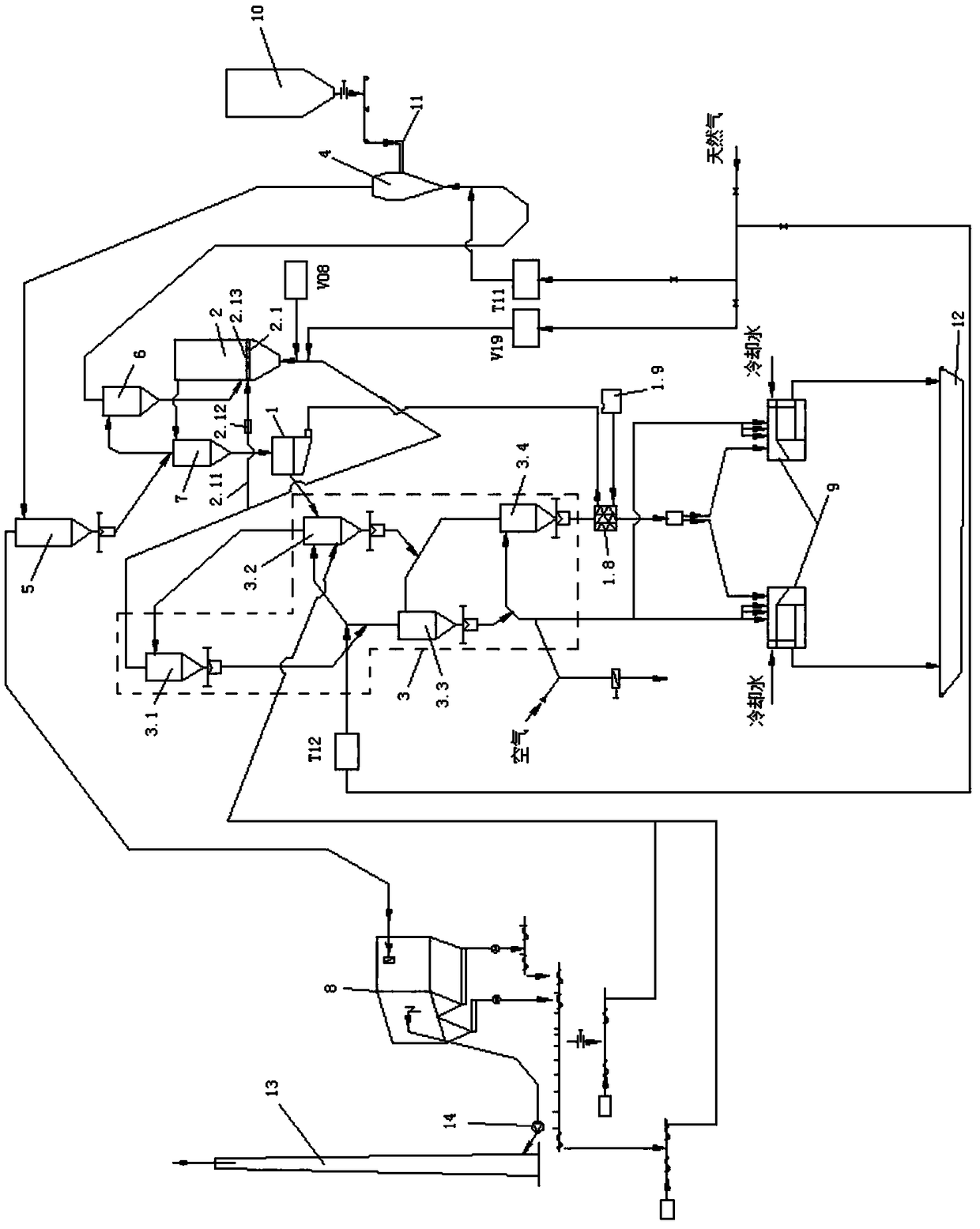

[0061] A kind of alumina roasting system, see figure 1, including crystal conversion energy-saving device 1, main roaster 2, cyclone separation device 3, Venturi dryer 4, first cyclone preheater 5, second cyclone preheater 6, auxiliary roaster 7, electric dust collector 8 , fluidized bed cooler 9, aluminum hydroxide storage bin 10, product bin 12 and chimney 13, specifically as follows:

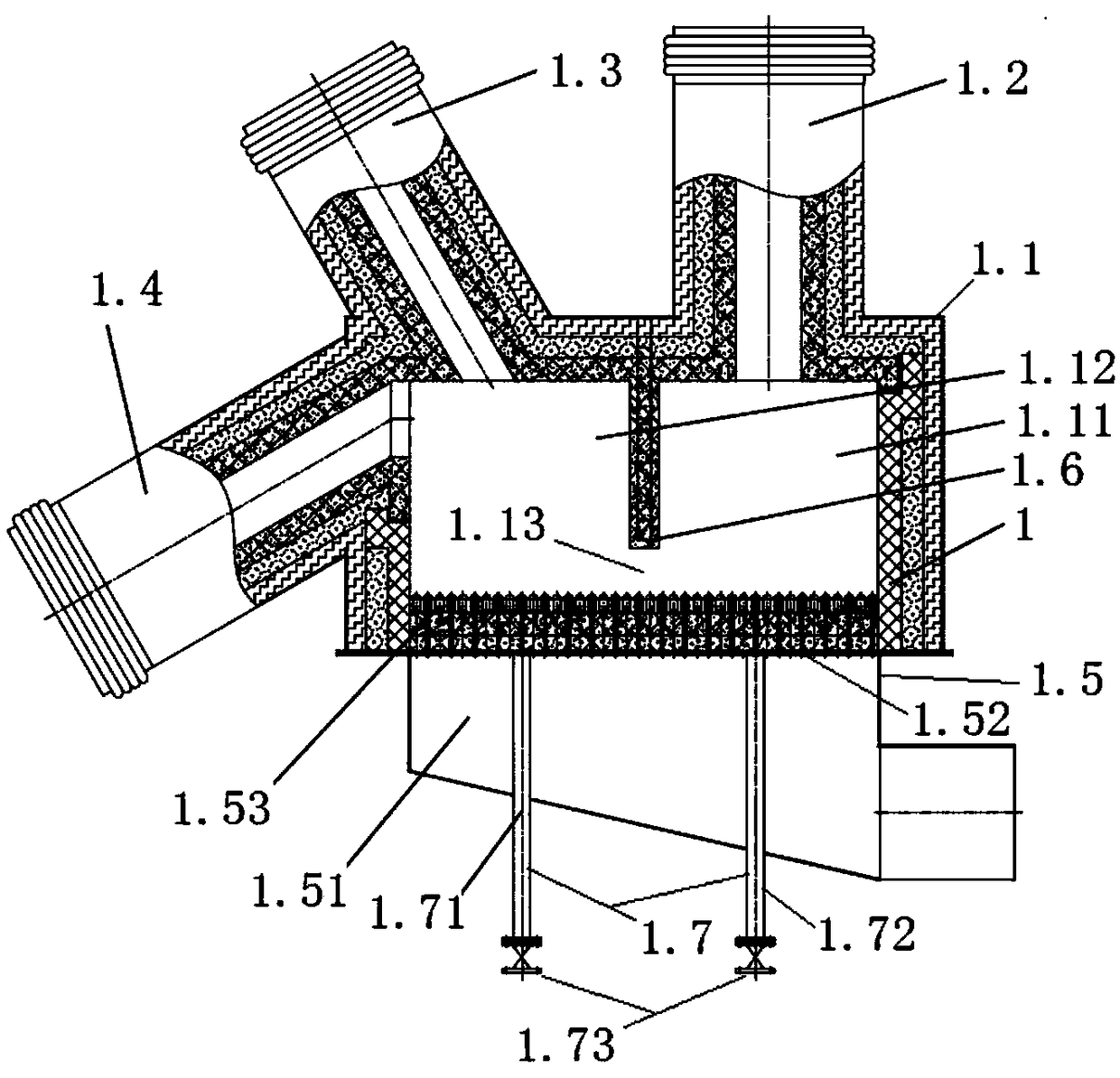

[0062] The structure of the crystal form conversion energy-saving device 1 is detailed in figure 2 , including the main box 1.1, the discharge pipe 1.2, the pressure balance pipe 1.3, the return pipe 1.4, the air distribution mechanism 1.5 and the discharge pipe group 1.7, the details are as follows:

[0063] The inner cavity of the main box 1.1 is divided into a loose bed 1.11 and a conveying bed 1.12 arranged side by side by a partition 1.6, and the lower end of the partition 1.6 and the bottom of the inner cavity of the main box 1.1 form a channel 1.13 for materials to pass through , pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com