Oil water fuel composite exhaust gas powered two-stroke engine

A kind of engine and composite technology, which is applied in the direction of combustion engine, internal combustion piston engine, engine components, etc., and can solve the problem of high power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

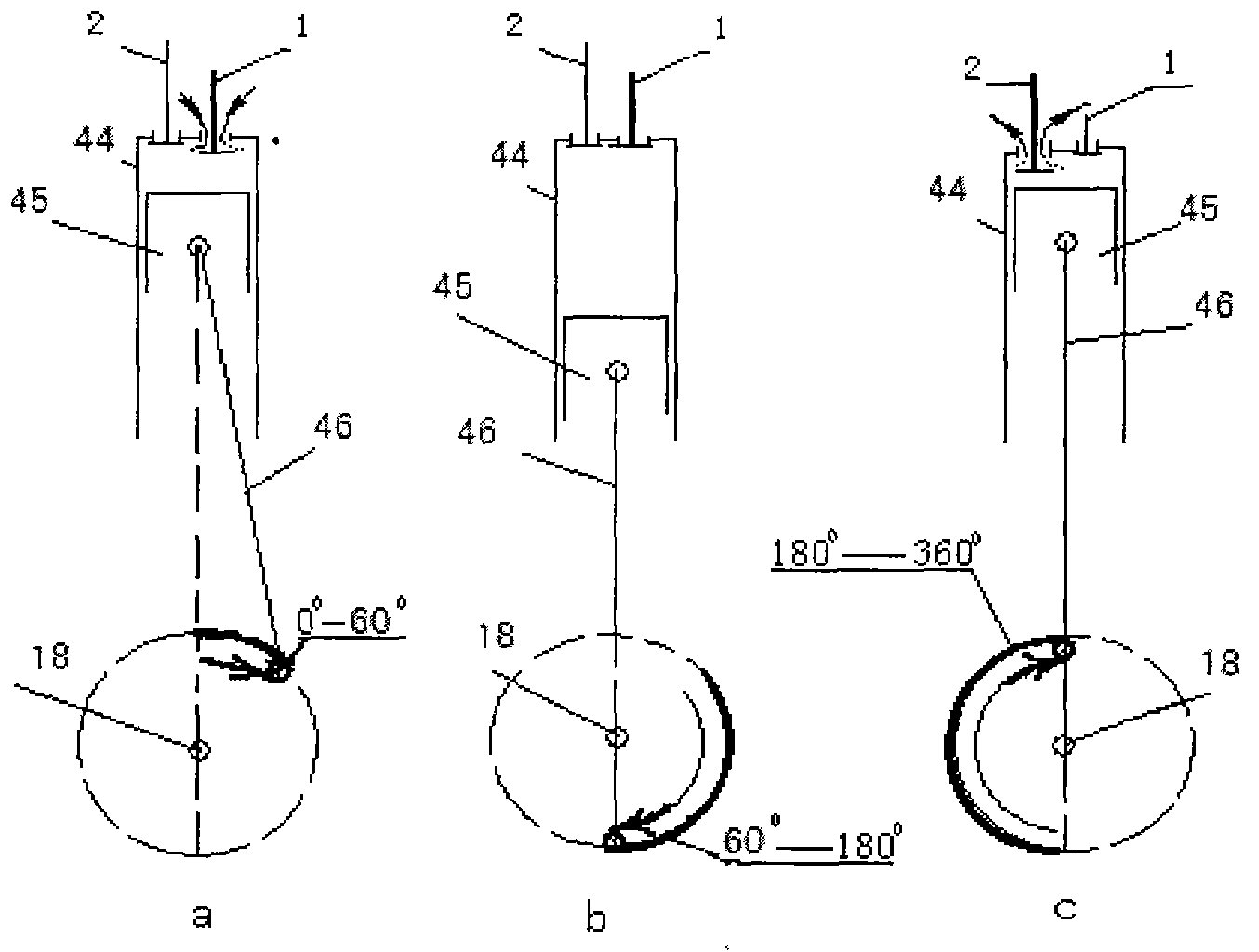

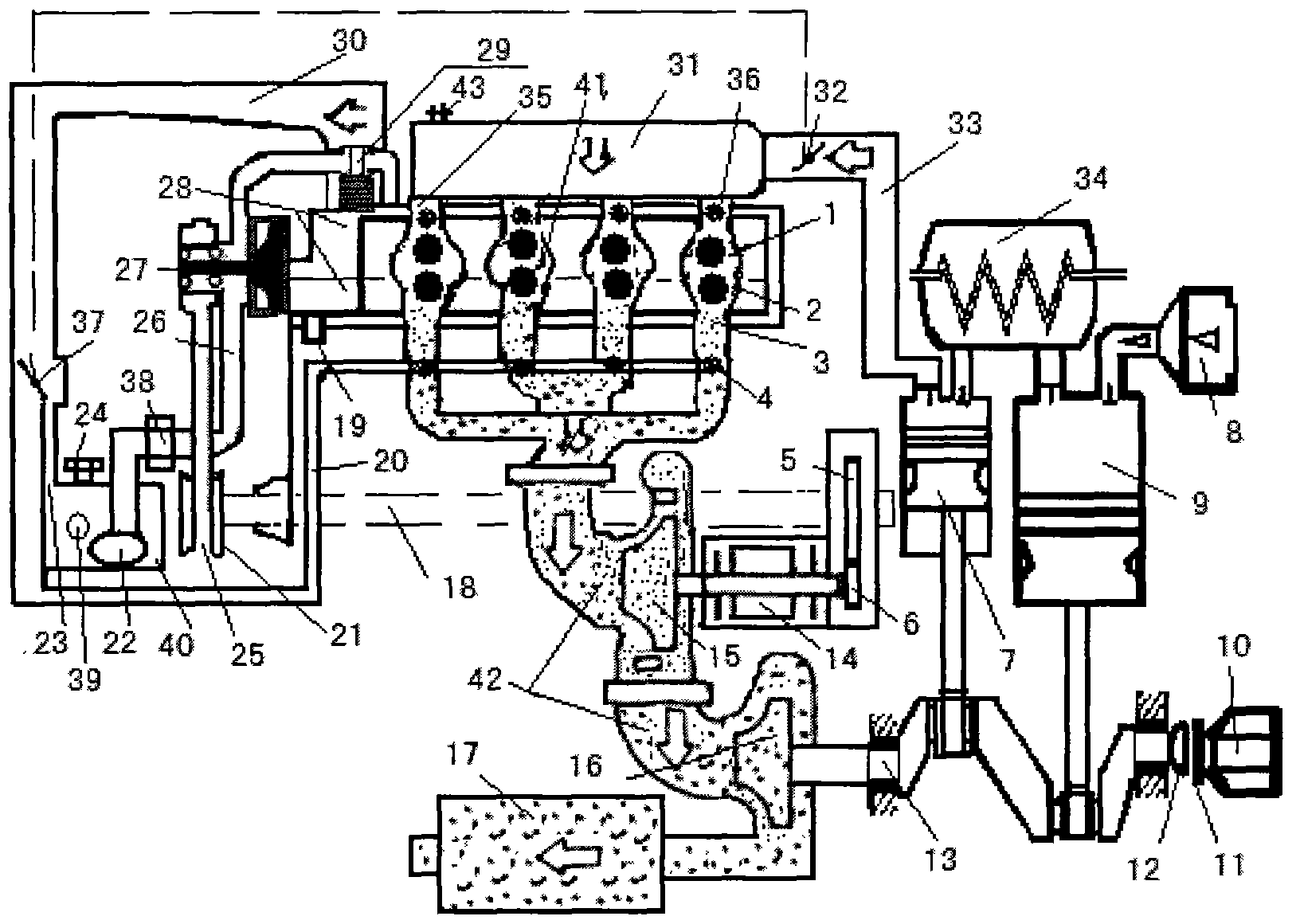

[0025] exist figure 2 In the oil-water fuel exhaust gas-powered two-stroke engine described in, because the piston four-stroke engine is designed as an oil-water fuel compound exhaust gas-powered two-stroke engine, the ignition system of the original piston four-stroke engine EFI fuel system. Crankshaft I (18) position sensor serrated disc signal rotor and camshaft position sensor serrated disc signal rotor number of teeth is doubled according to the prototype crankshaft I (18) position sensor and camshaft position sensor The number of teeth of the serrated disc signal rotor, so the ignition times and fuel injection times of the electronic fuel injection fuel system of the oil-water fuel composite exhaust gas power type two-stroke engine ignition system are higher than those of the piston type four-stroke engine ignition system and the fuel injection system. , The number of fuel injections is also doubled, and the ignition time is designed so that the top dead center of a cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com