Ratchet type rotor engine

A rotary engine, ratchet-type technology, applied in the direction of intermeshing engine, combustion engine, machine/engine, etc., can solve the problems of not being widely used and popularized, high quality requirements of parts and materials, and high requirements of machining accuracy, and it is easy to achieve. Application popularization and promotion, low processing difficulty, small friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

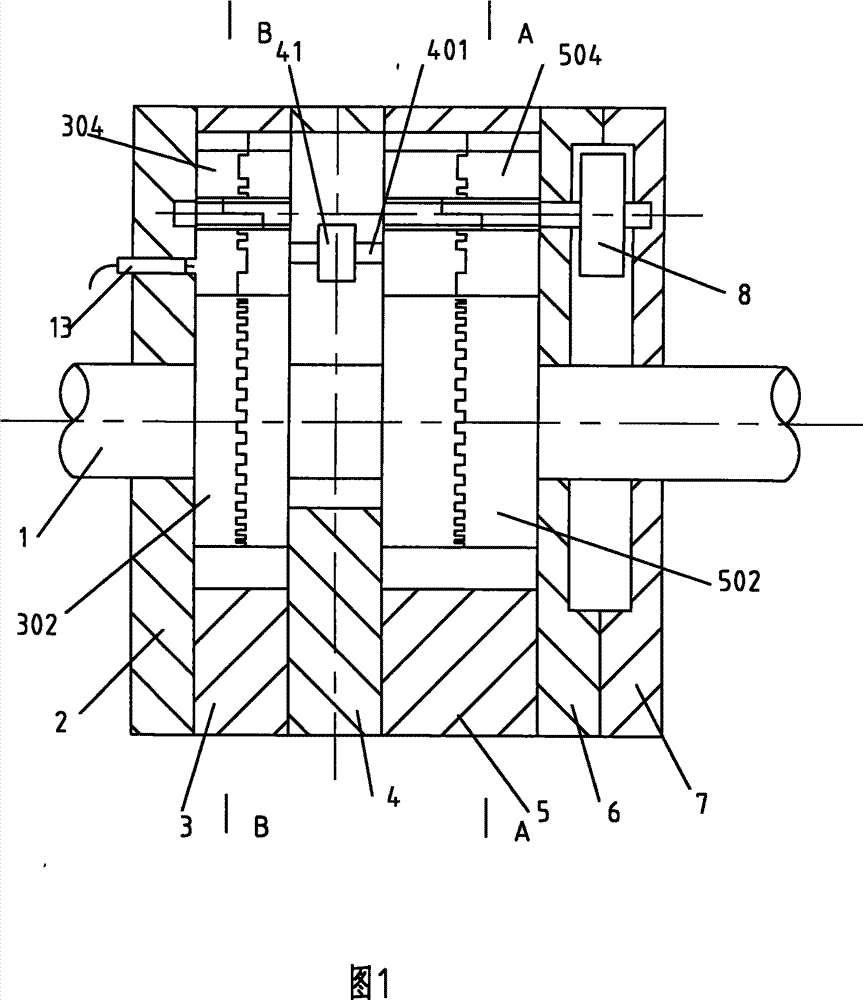

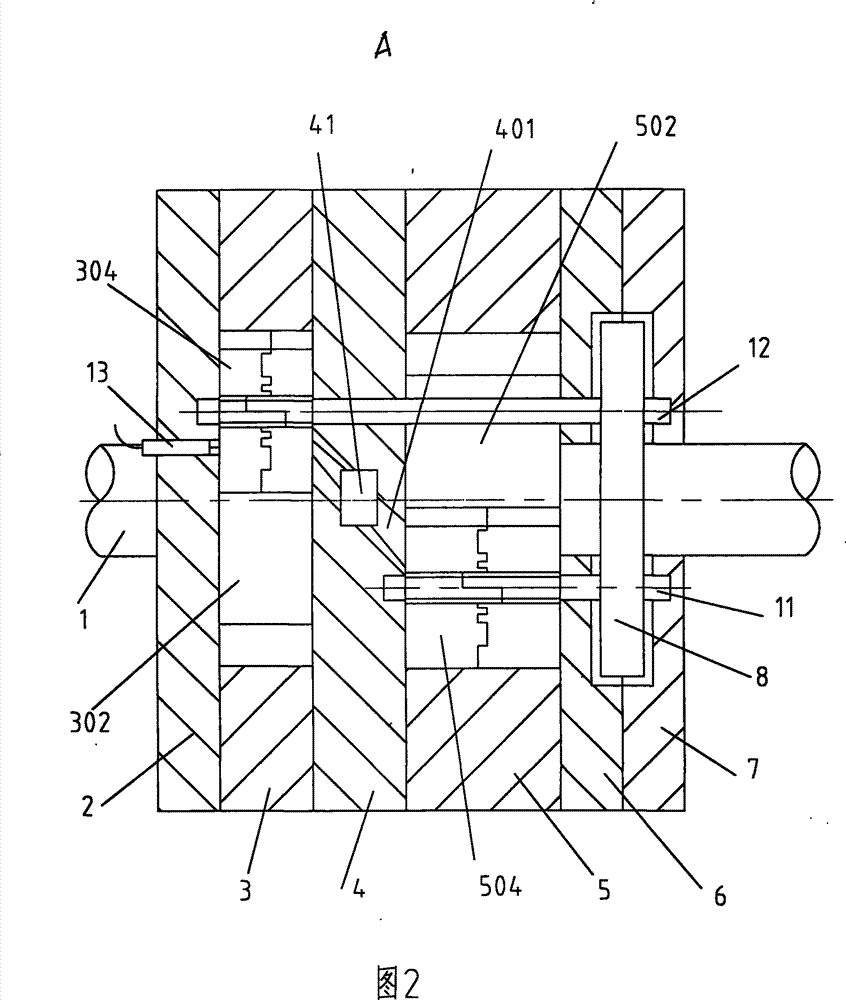

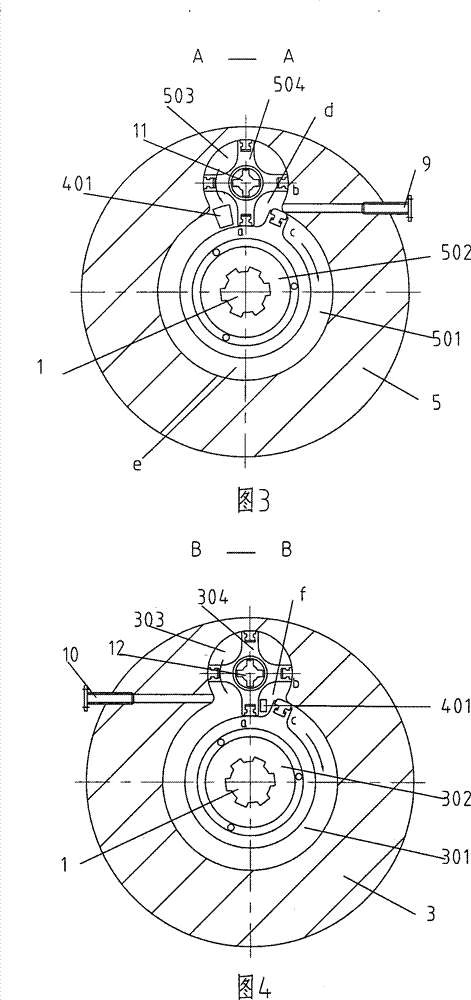

[0049] A single ratchet rotary engine such as figure 1 , 2As shown, it includes: the engine cylinder block is composed of a group of unit cylinder blocks, and each group of unit cylinder blocks is composed of a main shaft 1 and a front end cover 2 that is sealed and assembled together with each other, a power exhaust cylinder block 3, and a middle gas distribution plate 4 , the air intake compression cylinder 5, the control panel 6 and the rear end cover 7, the air intake compression cylinder 5 is provided with a circular air intake compression cylinder 501 and a ratchet intake compression ratchet rotor 502 for dynamic cooperation, The periphery of the circular intake compression cylinder 501 is connected with a circular compression auxiliary cylinder 503, and the intake compression gear ratchet 504 is arranged in the circular compression auxiliary cylinder 503. Air compression cylinder 501; a circular power exhaust cylinder 301 is arranged in the power exhaust cylinder body ...

Embodiment 2

[0078] Rotary engine with 4 ratchet sets, such as Figure 8 , 9 Shown: its structure is basically the same as that of Embodiment 1, the difference is that: the circular air intake compression cylinder 501 and the intake compression ratchet rotor 502 of 4 ratchets are dynamically matched, and the periphery of the circular intake compression cylinder 501 It is connected to four circular compression secondary cylinders 503, and an intake compression gear ratchet 504 is arranged in the circular compression secondary cylinder 503, and the circular compression secondary cylinder 503 is connected to the circular intake compression cylinder 501 through the intake compression gear ratchet 504; A circular power exhaust cylinder 301 is arranged in the power exhaust cylinder body 3, and the circular power exhaust cylinder 301 cooperates with the power exhaust ratchet rotor 302 of 4 ratchets, and the periphery of the circular power exhaust cylinder 301 is connected. 4 circular auxiliary c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com