Straight-shaft piston engine and drive method thereof

A technology of piston engine and driving method, which is applied in the direction of reciprocating piston engine, variable displacement engine, machine/engine, etc., and can solve the problems of long cycle, short piston stroke, laborious and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

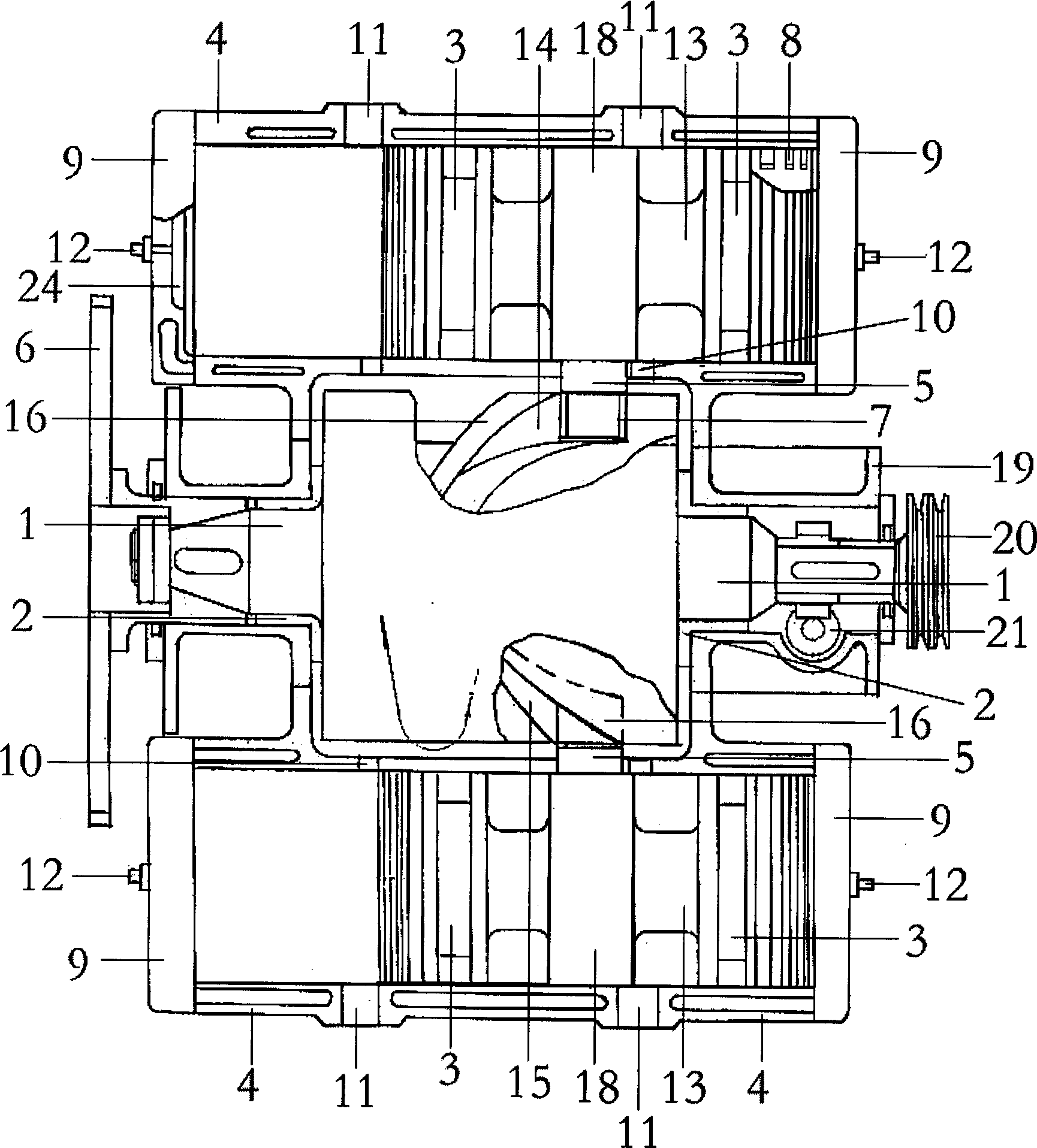

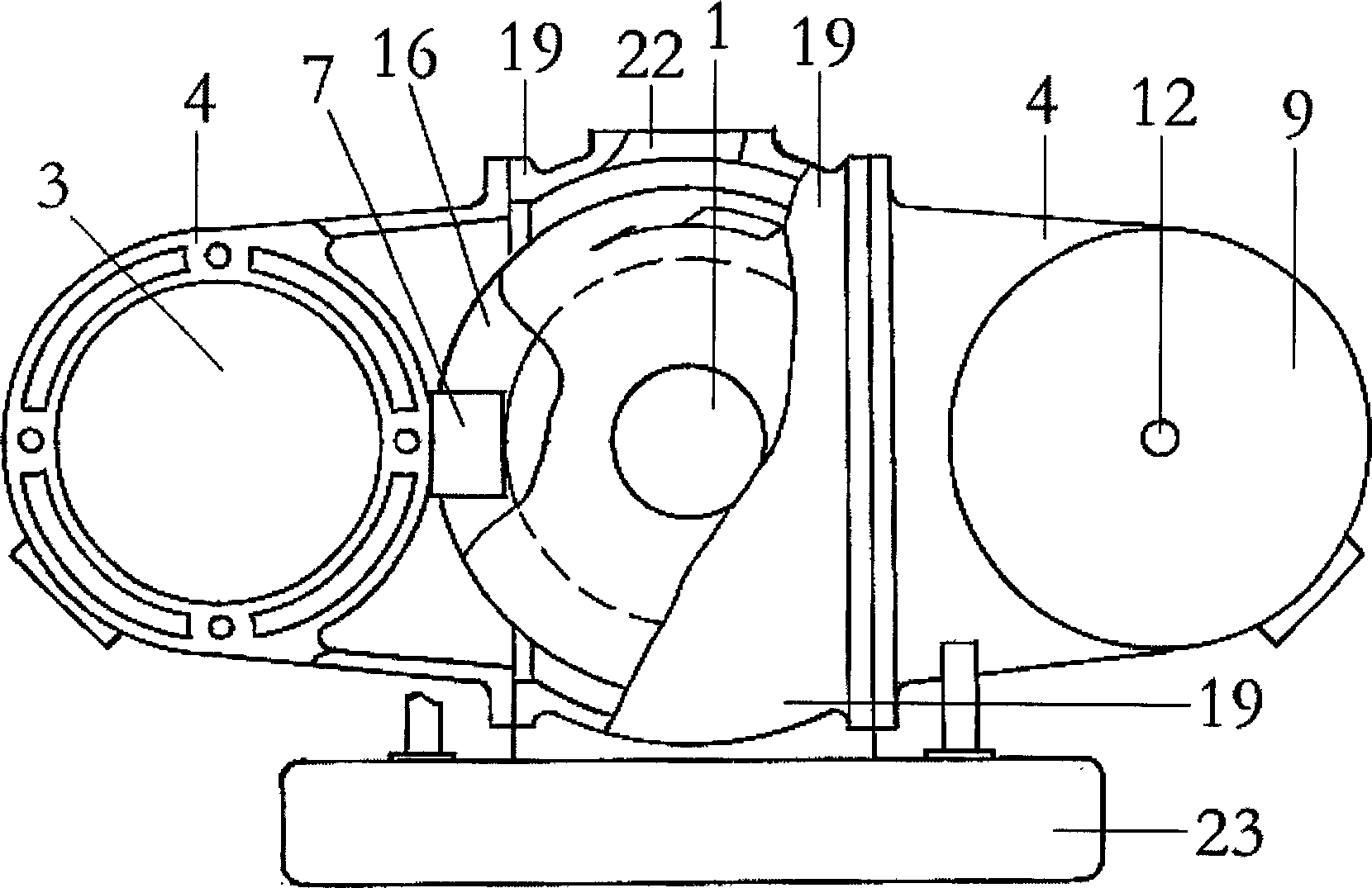

[0076] Composed of a body (19) and two cylinders (4), the body (19) is hollow, the center of the body (19) is relatively parallel to the main shaft (1) along the body (19), and the two ends of the body (19) The support bearings (2) are fixedly arranged on each part, and the two ends of the main shaft (1) pass through the support bearings (2).

[0077] One end of the body (19) is provided with a flywheel (6), and the flywheel (6) is fixedly connected with one end of the main shaft (1), and the flywheel (6) is connected with the clutch to output driving force.

[0078] The other end of the body (19) is provided with a sheave (20), and the sheave (20) is fixedly connected with the other end of the main shaft (1), and is connected with the fan by a belt.

[0079] One side of the body (19) is provided with a fuel tank (23), and the other side of the body (19) is provided with a total air intake (22) along the body (19), and the total air intake (22) is connected to the cylinder blo...

Embodiment 2

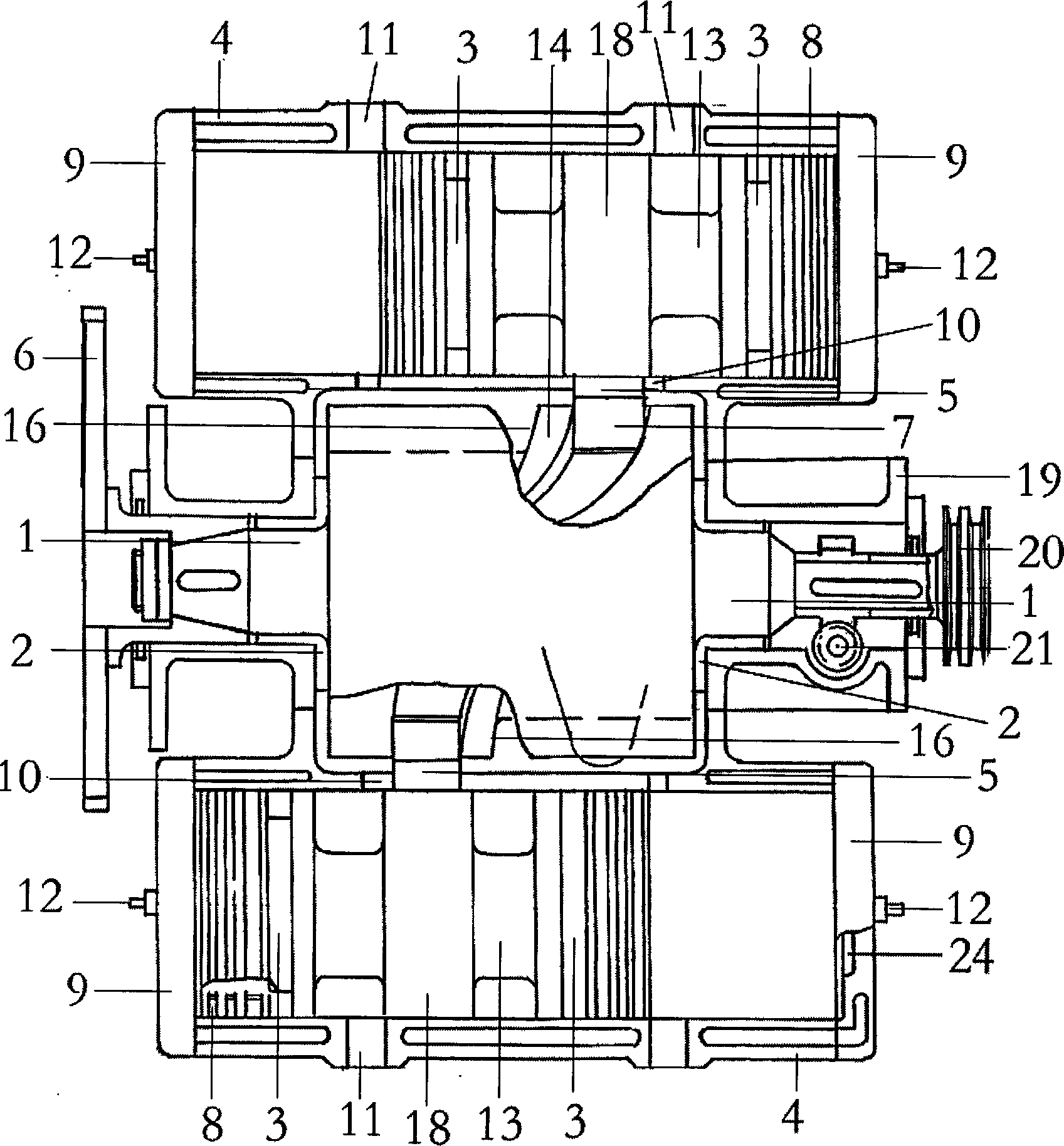

[0086] Composed of a body (19) and three cylinders (4), the body (19) is hollow, the central part of the body (19) is relatively parallel to the main shaft (1) along the body (19), and the two ends of the body (19) The support bearings (2) are fixedly installed on each part, and the two ends of the main shaft (1) pass through the support bearings (2), such as Figure 5 shown.

Embodiment 3

[0088] Composed of a body (19) and four cylinders (4), the body (19) is hollow, the center of the body (19) is relatively parallel to the main shaft (1) along the body (19), and the two ends of the body (19) The support bearings (2) are fixedly installed on each part, and the two ends of the main shaft (1) pass through the support bearings (2), such as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com