System for concentrating wastewater by heating via low-temperature flue gas

A technology for wastewater concentration and low-temperature flue gas, which is applied in heating water/sewage treatment, gaseous discharge wastewater treatment, lighting and heating equipment, etc. Improve condensation effect and solve the effect of consuming high-quality heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

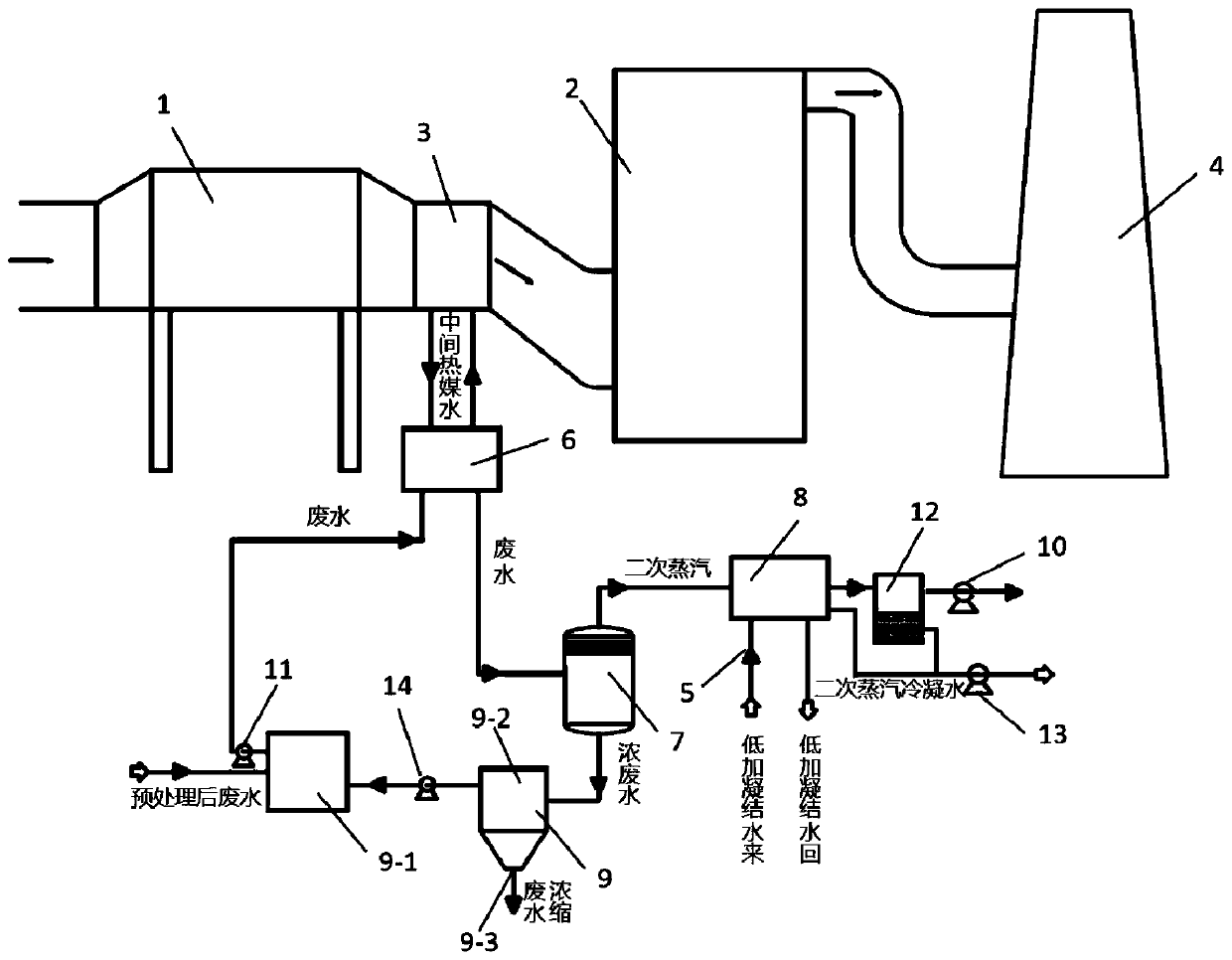

[0067] This embodiment provides a low-temperature flue gas heating wastewater concentration system, such as figure 1 As shown, it includes a dust removal unit 1 and a desulfurization unit 2 connected together, and also includes an economizer 3 and a wastewater concentration system. The economizer 3 is arranged between the dust removal unit 1 and the desulfurization unit 2, or is arranged along the direction of flue gas flow. Before dust removal unit 1; dust removal unit 1 is an electric dust collector, desulfurization unit 2 is a desulfurization tower, and economizer 3 is a low-temperature economizer. The setting of economizer 3 can improve the dust removal capacity of dust removal unit 1.

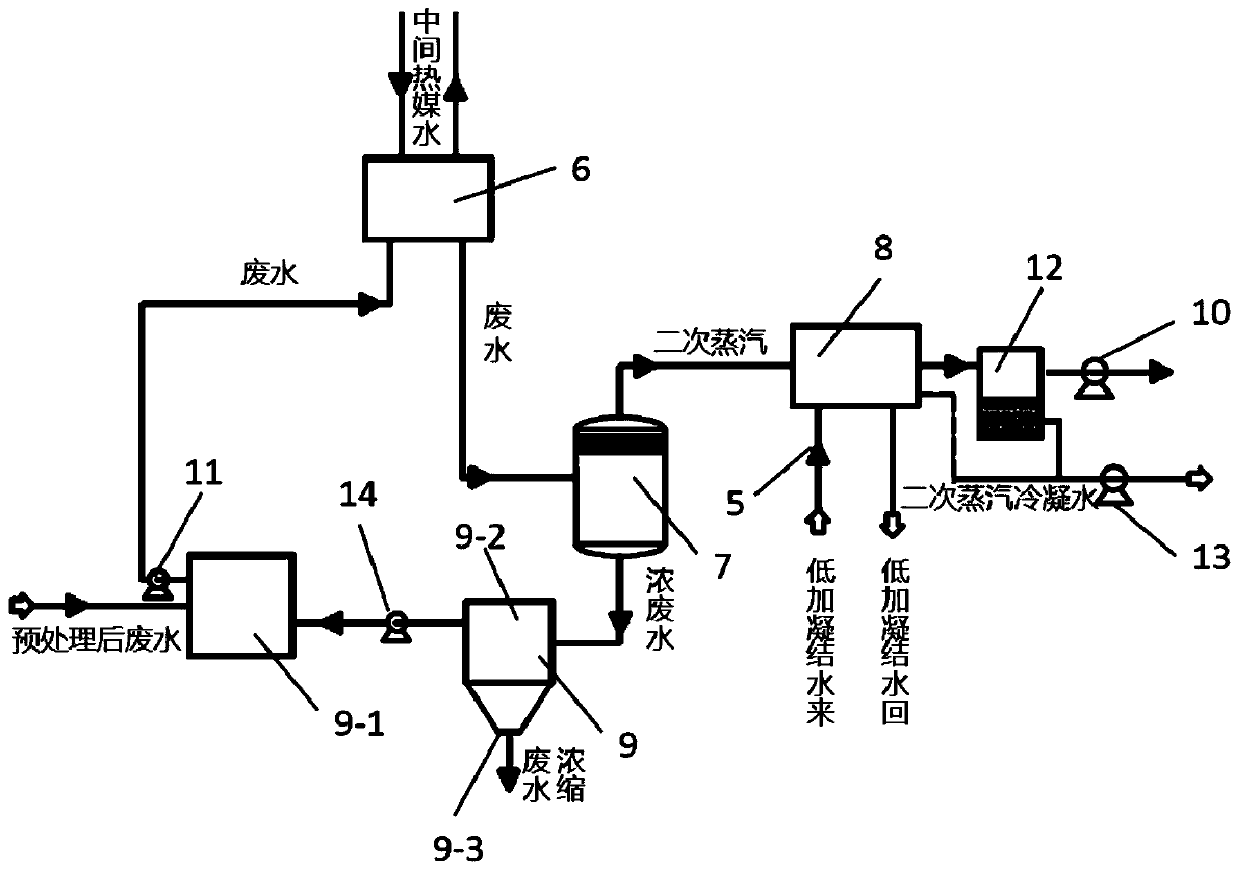

[0068] Such as figure 2 As shown, the waste water concentration system includes: a first heat exchanger 6, which communicates with the economizer 3, so that the waste water and the first heat exchange medium from the economizer 3 exchange heat in the first heat exchanger 6; the first The...

Embodiment 2

[0094] Such as figure 1 As shown, this embodiment provides a low-temperature flue gas heating wastewater concentration system, which includes a connected dust removal unit 1, a desulfurization unit 2, and a chimney 4, and also includes an economizer 3 and a wastewater concentration system. The economizer 3 is arranged on the dust removal unit Between unit 1 and desulfurization unit 2; dedusting unit 1 is an electric precipitator, desulfurization unit 2 is a desulfurization tower, and economizer 3 is a low-low temperature economizer; the wastewater concentration system includes:

[0095] The first heat exchanger 6 communicates with the economizer 3, so that the waste water and the first heat exchange medium from the economizer 3 exchange heat in the first heat exchanger 6;

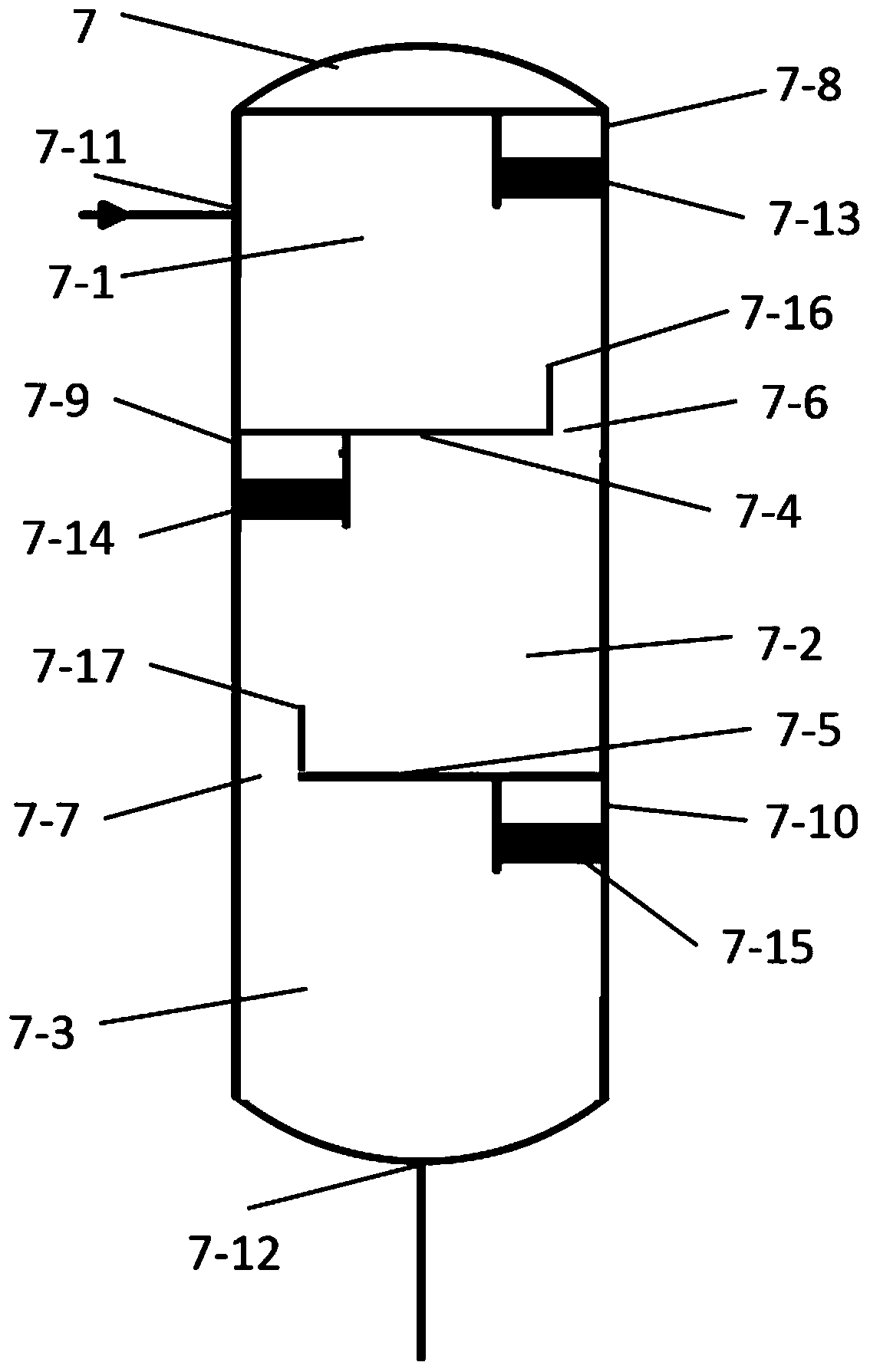

[0096] Flash tank 7, such as Figure 9 As shown, a first partition 7-4 and a second partition 7-5 are arranged inside, along the direction from the liquid inlet 7-11 to the liquid outlet 7-12 of the flash ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com