Copper-plated steel wire hot air circulation drying system

A technology of hot air circulation and drying system, which is applied in drying, drying machines, drying solid materials, etc., can solve the problems of unguaranteed drying quality and increased energy consumption, and achieve highly stable drying quality, high heat utilization rate, The simple effect of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

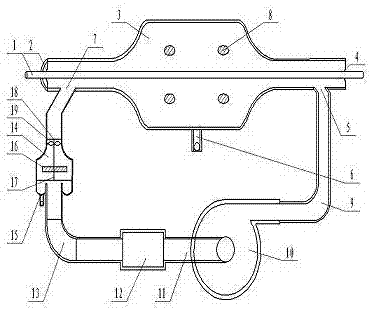

[0016] The embodiments of the present invention are one of many preferred solutions. In order to make the purposes, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings. Obviously, The described embodiment is a part of the embodiments of the present invention, but not all of the embodiments do not limit the copper-coated steel wire hot air circulation drying system. Tangential spiral air inlet 5, cyclone air drying cylinder 3, inclined three-way air outlet 7, return air bend 13, return air duct 11, and air inlet of automatic temperature-controlled hot air blower 10 are sequentially formed in series.

[0017] The cyclone air drying cylinder 3 has three sections of small-diameter pipes with a wire inlet at the front, a steam trap 6 at the lower part of the large-diameter pipe in the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com