High-power semiconductor laser constant-temperature welding device

A semiconductor and laser technology, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of inability to actually control the temperature of solder joints, complex parameter adjustment, and single structure, and achieve easy industrialized mass production and good control performance. , Accurate temperature control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

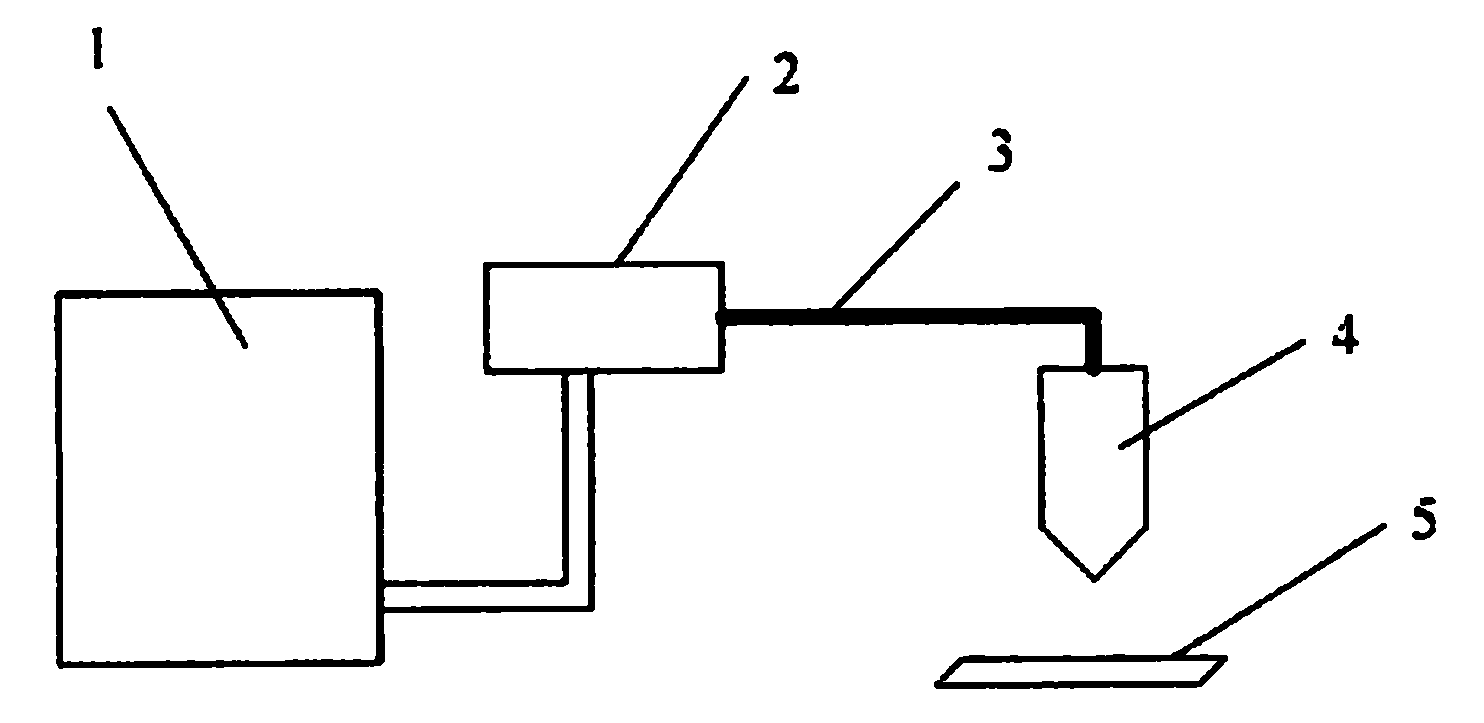

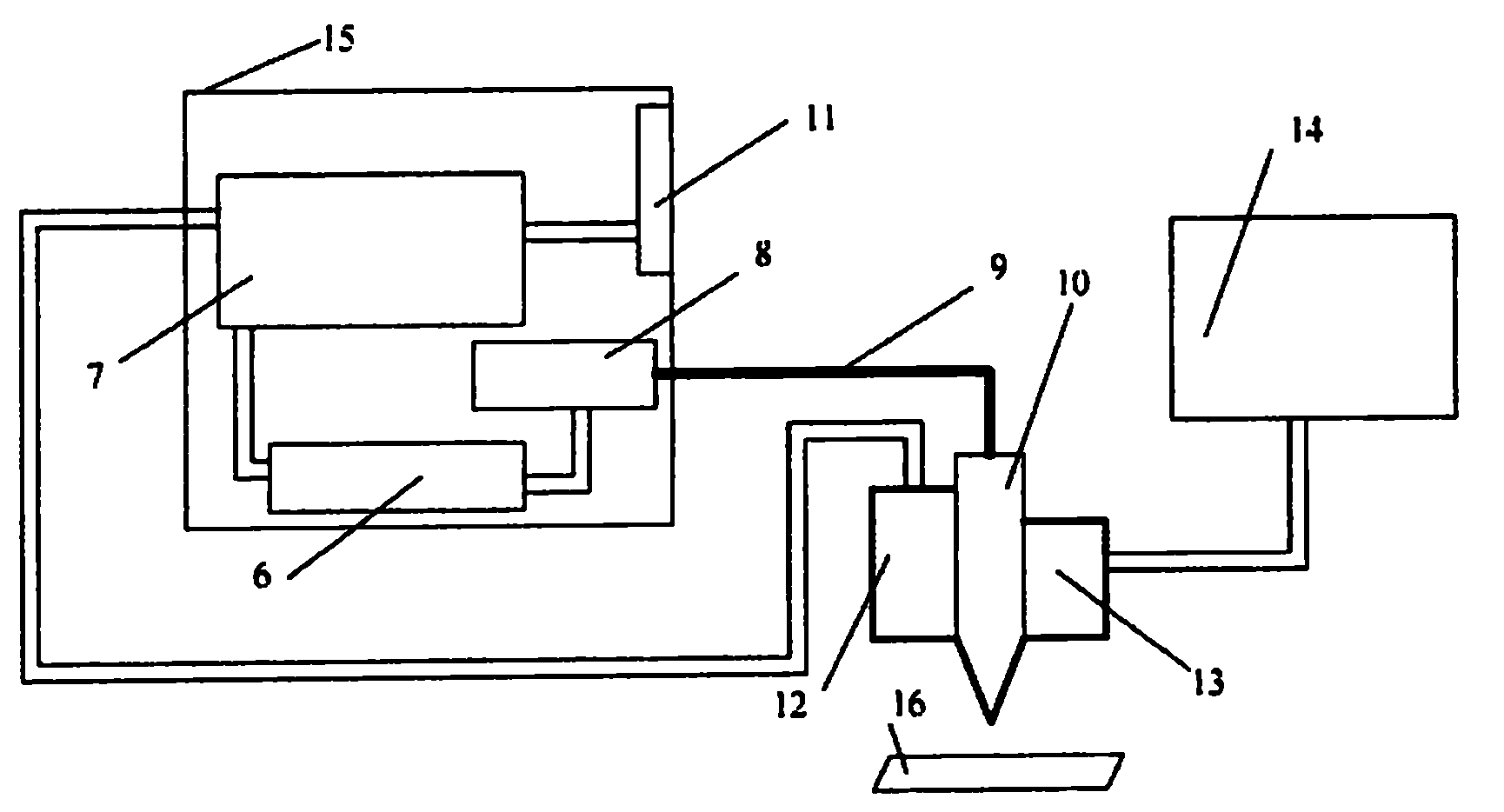

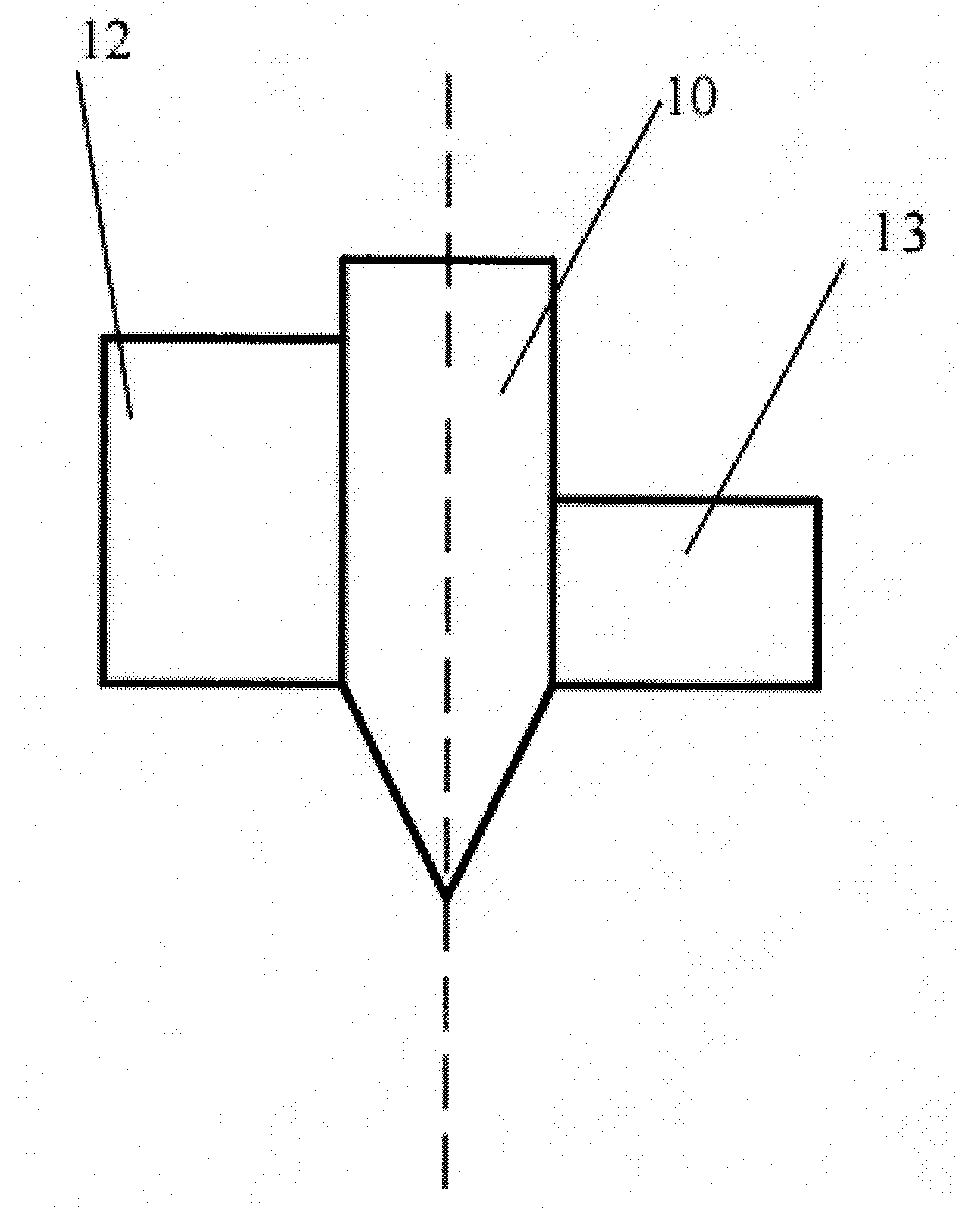

[0019] The specific implementation examples of the high-power semiconductor laser constant temperature welding device referred to in the present invention are combined Figure 2 to Figure 4 The description is as follows:

[0020] One end of the programmable logic controller 7 of the device controls the laser driving power supply 6 , one end receives the signal detected by the infrared high temperature detector 12 , and the other end communicates with the touch screen 11 . One end of the optical fiber 9 is connected to the semiconductor laser module 8 , and the other end is connected to the laser focusing head 10 . The output end of the laser driving power supply 6 is connected to the semiconductor laser module 8 , and the charge-coupled device 13 is connected to the display 14 . Such as figure 2 As shown, the laser drive power supply 6 , the programmable logic controller 7 , the semiconductor laser module 8 and the touch screen 11 are fixed on the bottom plate 15 . Wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com